An Ecosystem of Partners

Oct 1, 2018

Schindler executive talks about what differentiates its digital connection platform.

Riding the Internet of Things (IoT) wave like all OEMs striving to stay current, Schindler released its digital connection platform Schindler Ahead in 2017 (ELEVATOR WORLD, June 2017). Since that time, the platform has expanded well beyond its pilot markets. Its capability is now built into all new Schindler elevators and escalators, and new apps continue to be developed as the industry approaches what Jeremy Rainwater (JR), Schindler senior vice president in charge of Service, Repair and Modernization in the U.S., describes as a “seismic shift in the way we provide service to our customers.” Rainwater took the time to talk to EW about what the company believes sets its technology apart, how it was developed, what it offers and how it continues to evolve.

EW: Tell me about the evolution of Schindler Ahead.

JR: Schindler has a long history of developing technology to advance the vertical-transportation industry, from destination dispatch to regenerative drives. Remote monitoring is no exception. The digital age, combined with rising standards for customer service, has only increased the speed with which we must innovate and communicate with our customers. When we first began developing remote-monitoring technology decades ago, the necessary capabilities didn’t exist yet.

Our latest advancement, Schindler Ahead, is the result of decades of R&D, building on generations of customer feedback and cutting-edge technological partnerships, transforming the way the industry thinks about maintenance. Every customer, every building, every piece of equipment is distinctive. Traditional service and maintenance programs simply won’t provide the level of service, performance or transparency our customers demand today. With the advent of IoT, we’ve combined our own service model and field service team with an ecosystem of partners, including General Electric (GE) with its Predix software, to make Schindler Ahead a reality.

EW: What are its core components?

JR: By connecting a customer’s equipment to our network wirelessly via Schindler Ahead, we’re able to deliver a comprehensive suite of solutions, which includes 24/7 remote monitoring, from our Technical Operations Center in Ohio; customer support professionals who connect customers with service technicians and follow issues from start to finish; real-time notifications of equipment status changes and pre-arrival troubleshooting and analytics; and DigitalAlarm – a solution to the imminent obsolescence of analog phone lines for Americans with Disabilities Act-compliant emergency phones. We also provide equipment visibility with our customer portal, ActionBoard, through both desktop and mobile platforms.

We’ve tiered our Schindler Ahead offerings to allow customers to tailor the product to their specific needs. Each tier offers the ability to futureproof facilities for technological advancements and We’ve tiered our Schindler Ahead offerings to allow customers to tailor the product to their specific needs. Each tier offers the ability to futureproof facilities for technological advancements and

EW: What do you believe distinguishes it from other OEMs’ predictive- maintenance offerings?

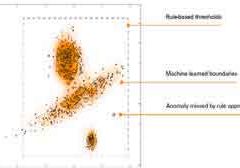

JR: Our partnership with GE and the utilization of Predix is a differentiator for us. GE has proven success using its industrial IoT technology to revolutionize maintenance of aircraft engines and locomotives. We’re harnessing that power with proprietary algorithms to detect patterns faster and more accurately.

Beyond the technology itself, we believe the critical distinguishing factor for predictive maintenance is how you marry human skill with technological capabilities. Our Technical Operations Center is the heart of Schindler Ahead, the place where our team of engineers and ESPs are constantly working to improve system sensitivity to better detect equipment anomalies and translate all that data into insights for a personalized customer experience. Having real-time visibility of every connected unit in our service portfolio and tools that enable faster, data-driven decisions give us an edge in reducing unplanned shutdowns and efficiently deploying resources. By coupling predictive analytics with a human touch and arming our technicians with the tools and information they need to do their jobs effectively, our customers will greatly benefit from this technology.

“Schindler Ahead is the result of decades of R&D, building on generations of customer feedback and cutting-edge technological partnerships, transforming the way the industry thinks about maintenance.”

EW: Who are its main customers?

JR: We see benefits for a wide variety of stakeholders, but the clearest beneficiaries of Schindler Ahead are building owners and building/facility managers. By building on and transforming the traditional service delivery and maintenance model, we’re able to provide them with increased efficiency and equipment uptime; cost control and transparency; and convenient applications for advertising, building communication, enhancing security and more. The benefits of the Schindler Ahead-connected portfolio will flow down to their tenants and the riding public, as well.

EW: Where are the customers located? Is there any part of the world where customers are more eager to embrace the technology? Any parts that seem more averse?

JR: We now have customers in nearly all 50 states. There has been tremendous excitement about the technology among our U.S. customers, which has driven our development to even faster speeds than we initially thought possible. It is important to note that, since April, Schindler Ahead has expanded beyond its pilot markets (Switzerland, Germany, the U.S., China and Australia). The technology is now available globally, and all new elevators and escalators are being shipped with Schindler Ahead capability. In terms of varying levels of adoption, we don’t see markets with higher demand than others.

EW: What do customers say they find most useful about Schindler Ahead?

JR: So far, we’ve seen two key customer camps emerge. There are those who highly value the technology’s performance benefits, real-time transparency and insights, and those who most value its cost-saving potential.

With ActionBoard, customers have access to all the information and benefits of Schindler Dashboard, with added features like HealthCheck, which gives customers a real-time view of their equipment’s operating status, customized notifications and a “campus view” feature to see their entire portfolio of equipment at a glance. The goal here is to provide customers with more intuitive access to information and transparency than ever before.

We also offer several ways to control operating costs through features like DigitalAlarm. When you consider the cost of unplanned outages and the ability of Schindler Ahead to circumvent that, there is a clear return on investment and potential financial benefit.

EW: Tell me about the Schindler Ahead apps and how they have evolved. What are the latest ones to be added? Have any faded away?

JR: In the same way that traditional service models are going extinct to make way for greater efficiency, the IoT has enabled us to transform the way we communicate and share insights with our customers. Schindler Ahead creates that ecosystem for providing insight in real time. It is starting to yield some exciting apps, including ActionBoard Mobile. Many of the apps that have been developed to date are for internal use for our engineers and technicians. There are also apps on the horizon designed to connect building managers and riders to equipment and products that will be introduced in the coming months, so we are just at the beginning of what we believe will be a seismic shift in the way we provide service to our customers.

EW: What are the main benefits of Schindler Ahead for equipment owners, property managers and passengers?

JR: Schindler Ahead is a powerful tool that provides radical levels of transparency, communication, customization and cost control. For both customers and passengers, the technology directly correlates to peace of mind via increased uptime, reducing the frequency of breakdowns and reducing return-to-service time if issues occur. For building managers, Schindler Ahead offers the convenience of real-time insights into the equipment’s health status and performance data, leveraging predictive analytics to circumvent future issues and optimize reliability and performance.

Get more of Elevator World. Sign up for our free e-newsletter.