An Extrasensory Experience

Jun 13, 2022

In this Project Spotlight, Schindler unit bridges gap between the city and the port in Mahón.

by Olga Quintanilla Marful

The Port of Mahón will always exude an authentic colonial flavor that great travelers appreciate. The port is considered one of the largest natural ports in the world, through which Phoenicians, Greeks and Romans have sailed. Its extraordinary geostrategic position in the western-most Mediterranean was exploited by English domination for three periods in the 18th century and, in between, a brief French occupation. Nestled on the east coast of the island of Menorca, Spain, the Port of Mahón is a meeting point for national and international cruise passengers, as well as numerous cargo ships that dock to unload essential raw materials to supply the island.

At 6 km in length, the port brings together different attractions. On the south bank is the City of Mahón and the town of Villa Carlos, with its respective promenades and areas of leisure and restoration.

On its northern shore, there is a power plant and a military zone, as well as a multitude of summer houses of celebrities and residents of the island. Following its perimeter to the north is the Military Fortress of La Mola, built under the reign of Isabel II, already in disuse but constituting a great tourist attraction.

Inside this magnanimous port, you can see four islets: the Lazareto de Mahón, which serves as a summer residence for officials of the Ministry of Health and where symposiums and scientific congresses are hosted; the King’s Island, in honor of King Alfonso III, conqueror of Menorca in 1287; the island of Pinto, a disused military islet; and, finally, the smallest, the island of La Cuarentena, an old sanitary enclosure that passed into military hands for a short time, but is also in disuse.

With work done by multinational OEM Schindler that was inaugurated in May 2021, this landscape steeped in history is combined with the natural surroundings enjoyed by travelers who admire the beauty of the port from 25 m above ground level.

Creative Design

For several years, various options were studied and designed, always with the aim of improving accessibility and bridging the gap between the city and the port. At first, Schindler proposed the construction of several escalators and mobile ramps that connected both points, but the idea was discarded due to the high visual impact it would entail. Finally, the City Council of Mahón, together with the port authority, approved the construction of an elevator capable of mimicking the city and the landscape to successfully save the existing 25-m gap between the city and the port.

After this decision, Schindler studied different alternatives that could respond to this need and, finally, it was decided to opt for the installation of one of Schindler’s largest range of products, the Schindler 5500 elevator.

This equipment offers capacity for 16 people and integrates perfectly with the landscape, thanks to the double panoramic boarding and the integral glazing throughout its route. The journey of tourists and residents through this engineering work becomes an extrasensory experience to admire the entire Menorcan coast and its bay. The Schindler 5500 lift is environmentally friendly, and the location offers great performance in terms of energy efficiency with a very low impact on carbon dioxide emissions.

Various Complications

COVID-19 had some impacts on the project, but Schindler was still able to complete it in the originally discussed timeframe.

At first, the client’s forecast was to begin assembly of the elevator during the first quarter of 2020. However, several components came from external suppliers, especially electronic chips, so there were some delays in shipments, and, therefore, the manufacturing process in Schindler’s factories.

The State of Alarm declaration in Spain during the month of March added to the consequent suspension of all non-essential activity, paralyzing the project completely. The elevator was manufactured and the materials ready, but it was not possible to move forward with the assembly nor was there any forecast of when activity would resume, so many issues had to be replanned to comply with the timing.

Thanks to experience and teamwork, the team managed to overcome the challenges. The main barrier was to lift the existing slope of 25 m and move from the upper to the lower area of the work. This required great effort, since, at that time, there was no elevator.

It should be noted that all the components necessary for the assembly of the equipment involved a weight close to 10 mT with a volume occupancy of 30 m3, or the equivalent of 25 pallets. The availability of an industrial warehouse, owned by the client, near the site of the equipment allowed the company to store the materials without causing major problems.

Weather conditions at the end of summer 2020 also did not favor the construction process. On specific occasions, strong gusts of wind were recorded, which posed a safety risk. To avoid problems, necessary measures were taken to ensure the safety of all involved in the construction.

Being an outdoor elevator, the early autumn rains forced extreme care during the transport and installation of the different components. This meant that, at the beginning, the execution had to be replanned and the construction reconsidered, adapting to the place and its specific conditions.

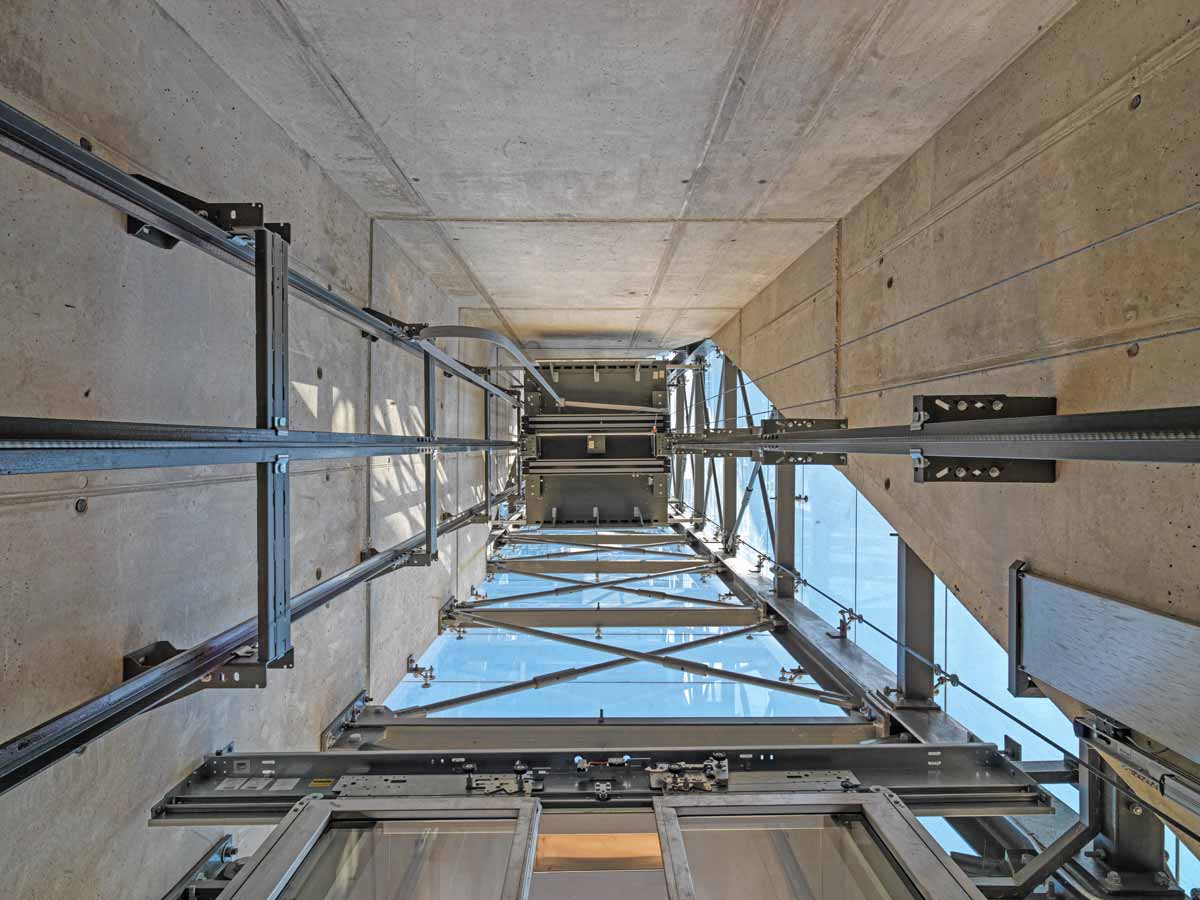

One of the most complicated moments during the installation process was the screwing of fixings to the metal part of the structure. This was justified because, at the bottom, the sides and the back wall of the shaft are made of concrete. As it was ascending in the route of the elevator, however, it was combined with a spectacular metal structure.

Fortunately, the final phase of assembly did not present any notable complications. The team’s opening date was scheduled for the end of the year, and it was in December when, with the support of technical assistance connected to the team through remote telemonitoring of the Schindler CUBE (a connected device that transmits machine data to the cloud as well as streams content, runs apps and makes emergency calls), all the planned configuration parameters could be adjusted. In this way, Schindler was able to deliver the project in the expected timeframe.

Initially, some work, such as the construction of the mechanical structure and glazing, was delayed until mid-July. However, and in agreement with the customer, these activities were postponed until the end of September to protect the operators in charge of the assembly from the high greenhouse temperatures that occur inside these glazed structures during the area’s summer months.

The manufacture of the equipment began on September 9, 2019, and finished on February 6, 2020. But due to COVID-19, the installation was delayed until September 28, 2020. After three months of intense assembly work, quality tests were satisfactorily completed on December 21, 2020, and the inauguration of the Schindler 5500 took place on May 8, 2021.

Schindler Ahead

The Schindler 5500 installed in Mahón is powered by Schindler Ahead. Products that feature this technology use Schindler’s Internet of Things Elevators and Escalators (IoEE) platform, where the data collected is used to improve activity, response times and passenger comfort.

The Schindler Ahead system, presented by Schindler at the 2018 Digital Enterprise Show (DES), offers a variety of options. Its added value lies in the improvement of maintenance and communication between customers and users, in areas such as accuracy and reliability of the service. For example, customers who have the ActionBoard application and computers connected to the Ahead system can consult and receive the status of the equipment in real time, with access to different personalized information. In parallel, technicians receive alerts immediately with access to a digital database of advanced information.

In addition, Schindler equipment can incorporate digital, customizable and innovative solutions, which allows passengers to enjoy the elevator from a perspective never seen before, while offering information and entertainment services, such as Ahead DoorShow or Ahead SmartMirror that display up-to-date advertising and practical information on elevator doors, among others. In short, the digitalization of Schindler Ahead provides a wide range of options that improve the sensory experience of the passenger.

Another particularity that Schindler highlights about this elevator is that it is a special case, since it only has two stops in 25 m of travel (With a speed of 1.6 m/s, it manages to make the trip in just a few seconds). For this special circumstance, the company’s team of engineers designed an automatic rescue device (ARD) to solve entrapments in the event of a power outage. To do this, the elevator underwent several tests by Schindler’s quality department, simulating supply cuts, without load, with half load and with more than 1275 kg in the cabin. These tests were successful, and were certified by Bureau Veritas, demonstrating the validity and usefulness of this ARD for the Schindler 5500 of Mahón.

The elevator cabin is designed to ensure the greatest user comfort. In addition to having air conditioning, the equipment incorporates a system that coordinates the activity of certain components to vary the power that is injected into the machine depending on the users inside. In this way, it is possible to make the start and braking as smooth as possible. Also, both doors have light beam optical curtains, capable of detecting even a pet that can access the cabin during the door-closing process.

The system is also prepared to resist vandalism and has multiple controller configurations. For example, the elevator will stop automatically if the temperature is too high inside the glazed shaft, or the firefighter option can be activated in the event that a rescue and automatic return to the desired point is necessary.

Additional Benefits

The initial objective of the project was to connect the port with the old town of Mahón. The elevator was the key piece that facilitated the movement between both points, and that also served to decongest other access points such as the stairs, which were overloaded when the port received cruise ships with thousands of tourists. In addition, this vertical-transportation equipment would help the elderly or disabled individuals move between both points more easily.

In addition to meeting all these practical objectives, the facility has revitalized the area, becoming another tourist attraction from which to visualize the port and the coast through a panoramic experience. According to data obtained by Schindler’s TOC (Technical Operation Center), the elevator makes an average of 800 trips a day. This means that, since its launch, it has made approximately 30,000 trips or travels more than 600 km in a month. In addition, users and tourists regularly share videos and images of the Schindler 5500 on social media, as it is among the city’s tourist attractions.

Vertical Ecology

Schindler is committed to the environment and its care. Therefore, in the Mahón project, ISO 50001 has been specifically integrated, and the project has been certified in terms of energy efficiency, such as for ISO 14001. In addition, the elevator incorporates the Class B efficiency certificate, according to VDI 4707.

Schindler works toward the highest standards of quality and guarantees. From the initial offer to completion of the Mahón project, numerous efficiency standards for which Schindler is certified were taken into account.

It has the necessary processes and management systems in place to achieve the sustainability and energy-efficiency objectives established for each project, such as LEED and BREEAM 4 certifications. Sustainability and efficiency have long been two essential aspects for Schindler, since buildings are responsible for one-third of overall energy consumptions, as 20% of CO2 emissions. In this regard, the company has managed to improve the environmental performance of its products and processes by more than 50%, thanks to its optimized choice of materials, efficient planning and agility in installation and preventive maintenance. It is important to mention that 95% of the used material is recyclable. Relevant improvements in terms of packing have also been realized.

Other examples of similar features to the Mahón panoramic elevator developed by Schindler are the Vizcaya Ferry, the Moncloa Lighthouse (Madrid) and the Mirador Schindler Tower (Seville).

Get more of Elevator World. Sign up for our free e-newsletter.