Applying ISO 8100-32:2020 to Rated Load and Available Car Area

Dec 1, 2021

Standard solves previous matter by allowing different approaches in traffic analysis when selecting capacity.

Abstract: ISO 8100-32 for elevator planning and selection of passenger lifts was published in 2020. The earlier standard, from 1984, covered residential buildings, whereas the 2020 standard is extended to also cover hotels and office buildings. This article briefly introduces the method of the ISO 8100-32:2020 standard for selection of the rated load.

Introduction

Elevator traffic analyses always deal with people, not with elevators’ rated load. Elevator planning is based on building population and assumed traffic peaks occurring during the day. In the calculation method, up-peak traffic is used to calculate elevator round-trip time in all types of buildings. In the calculation, the average number of passengers inside a car – Pcalc – when the elevator leaves the lobby, is used. Due to the saturation of waiting times, and for comfort reasons, Pcalc is assumed to be 80% of the maximum number of people in the car. Thus, for safety reasons, the maximum number of people allowed in the car — the rated passenger capacity, P — must not exceed Pcalc/0.8. From the round-trip time, elevator handling capacity in up-peak can be determined. The calculation method aims at defining Pcalc, which fulfills a desired up-peak design criterion for handling capacity, e.g., in office buildings it should be at least 12% of the population in 5 min. Handling capacity shows how many passengers an elevator can transport within a time unit, and it is often shown in percentage of the building population in 5 min.

As most of us have experienced, elevators cannot always accommodate the rated passenger capacity shown by the manufacturer’s label inside the car. For safety reasons, the platform area of a car does not increase linearly by the number of passengers. This is made on purpose to prohibit overloading of cars. The rated loads and rated passenger capacities, according to ISO 8100-30:2019, and the maximum available area of elevators, defined by ISO 8100-1:2019, are shown in Table 1.

| Rated load (kg) | 450 | 630 | 800 | 1000 | 1275 | 1350 | 1600 | 1800 | 2000 | 2500 |

| Rated passenger capacity (persons) | 6 | 8 | 10 | 13 | 17 | 18 | 21 | 24 | 26 | 33 |

| Maximum available area (m2) | 1.30 | 1.66 | 2.00 | 2.40 | 2.95 | 3.10 | 3.56 | 3.88 | 4.20 | 5.00 |

ISO 8100-32:2020 solves the previous matter by allowing both approaches in traffic analysis when selecting the rated load. According to the standard, the rated load can be selected based either on the average passenger mass or on the average passenger area.

Rated Load Selection Based on Passenger Mass

The rated load and the maximum number of people in a car, however, have a correlation: rated passenger capacity is obtained by dividing the rated load, Q, by the average passenger mass, m. According to ISO 8100-30:2019, the average mass of a person is 75 kg, although the average weight of a person varies according to the gender, age, cultural differences, etc. Therefore, the elevator will always be able to carry the mass of as many persons as defined by the rated passenger capacity.

In selecting the rated load, Q, based on the average number of passengers inside a car – Pcalc – the rated load, should exceed the mass of the maximum number of passengers in a car:

The rated load of elevators follows the Renard series. The load series in kg are shown in Table 1. In the traffic analysis, the rated load for the calculated value is selected from the load series. As an example, for the average of 19 persons, with the maximum of 24 persons inside a car, the calculated load value is 19×75/0.8 = 1781 kg, and, from Table 1, the rated load of 1800 kg is selected.

Selection Based on Passenger Area and Mass

In ISO 8100-32: 2020, the method based on area uses passenger area – Ap – of 0.21 m2 per passenger, as an example. This figure, like the average weight of a person, varies culturally and according to gender and age. CIBSE Guide D Transportation systems in buildings (2020) introduces body area index (BAI) that is scaled to the body weight. According to the BAI, considering the whole world, the body area is 0.17 m2; in Asia, 0.16 m2; in Europe, 0.20 m2; and in North America, 0.23 m2. The ISO 8100-32:2020 standard states that local norms and practices can be used to select the average area per person other than 0.21 m2.

To ensure sufficient area for the maximum number of passengers inside the car, the available car area, Ac, should exceed:

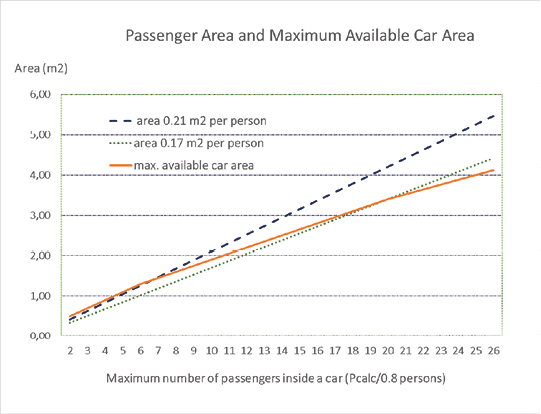

The rated load is selected according to maximum available area shown in Table 1. If the area-based method suggests a smaller rated load than the mass-based method, for safety reasons the rated load based on mass is selected. The car areas for different rated load values are depicted in Figure 1. In the figure, the areas required by P, passengers, are shown for the 0.17 m2 and 0.21 m2 per person. The required area of 0.17 m2 per person is very close to the maximum available area of an elevator. On the other hand, the platform area based on 0.21 m2 per person is much bigger than the maximum available area. Using the same example as previously, with 0.21 m2 per person, the required maximum available car area will be 19×0.21/0.8 = 4.99 m2, and, according to Table 1, the 2500-kg rated load will be selected. In the same manner, for 0.17 m2 per person, the maximum available area should exceed 4.08 m2, and, from Table 1, the rated load of 2000 kg will be selected.

Conclusion

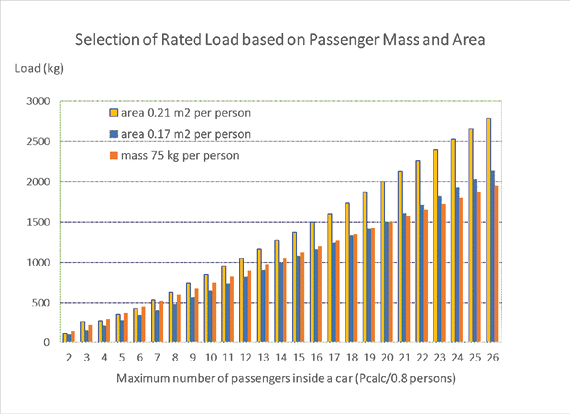

Selection of rated load based on mass and area of a person is shown in Figure 2. As could be expected, the rated load becomes about the same with the method based on average mass of 75 kg, and average area of 0.17 m2 per person. For the average area of 0.21 m2 per person, bigger cars with higher rated loads are needed.

In the traffic analysis report, the method used in selecting the load must be mentioned, as well as the assumed average area of a person. A more sophisticated method in traffic analysis is to use simulation to determine handling capacity and passenger waiting times. In addition to the handling capacity, simulation reveals differences of diverse control systems for the simulated traffic patterns.

References

[1] CIBSE, 2020. CIBSE GUIDE D: Transportation systems in buildings, CIBSE Publications.

[2] ISO 8100-1:2019, Lifts for the transport of persons and goods — Part 1: Safety rules for the construction and installation of passenger and goods passenger lifts

[3] ISO 8100-30:2019, Lifts for the transport of persons and goods —Part 1: Safety requirements for passenger and goods passenger lifts

[4] ISO 8100-32:2020, Lifts for the transport of persons and goods — Part 32: Planning and selection of passenger lifts to be installed in office, hotel, and residential buildings

Get more of Elevator World. Sign up for our free e-newsletter.