Asansör Istanbul 2011 – Conference

Aug 1, 2011

A recap of the events, discussions and presentations held at Asansör 2011

The exhibition included a two-day conference organized by AYSAD, which saw great attendance for the seminars and keynote presentations. A minimum of 50 people attended each session, with standing room only for at least one session. The content for the seminar program was coordinated by AYSAD, which gathered a number of world-respected European code-and-standards chairmen, along with local and national Turkish spokesmen, to participate in the congress.

The first day began with a gathering of European spokesmen who addressed the topic of “The Revisions of European Codes and Standards.” The first presentation was given by Paolo Tattoli, chairman of CEN TC 10 WG1 WT5, who spoke on the current state of codes and stan-dards regarding lifts in seismic areas (prEN 81-77). Tattoli stated that the aim of this seismic standard is to avoid loss of life, reduce injury, avoid passengers being trapped in an elevator after a seismic event, avoid damage to equipment, reduce the number of lifts out of service and avoid environmental problems. The draft of the current standard covers two aspects summarized as design of systems and components, and behavior of the lifts in case of earthquakes (how they must react during and after an earthquake).

Tattoli explained the need for subdivisions of lift installations by categories, considering, in particular, one of the most important elements – design acceleration. Design acceleration is the function of peak ground acceleration and other factors (type of soil, importance of building factors, the natural vibration period of the building and other parameters stated in EN 1998-Eurocode 8). This value has to be provided by the owner of the building.

Another important component to consider is a guide-rail system that, when used on seismic installations, includes:

- Increased stiffness of guide rails

- Guide-rail joints and attachments must comply with requirements of EN 81-1 and EN 81-2, and should withstand the loads and forces generated by the design acceleration.

- Car and counterweight retaining devices, where provided, must be used as frame support in guide-rail verification.

Guidelines for the installation of Retaining Devices, include:

- Defined lift categories as protection measures for car and counterweight (or balancing weight) should be provided, with retaining devices able to hold the frame on its guide rails.

- Retaining devices should be placed in such a way as to distribute loads in a similar way as the guide shoes.

- Retaining devices will either be integrated or mounted close to the guide shoes.

Behavior of the lift should be considered in two important situations – in the event of failure of the normal power supply and in seismic mode, which looks at how the lift should perform after the detection of an incident by a seismic trigger. Tattoli explained that seismic mode is the same as the Seismic Detection System, and the following are relevant to that situation:

- A Seismic Detection System should be provided for lifts with counterweight or balancing weight in seismic lift Category 3.

- The seismic detection system is part of the building, provided by the building owner.

- Where the seismic detection system is used exclusively to control the lift, it should be placed in the pit of the lowest lift in the building adjacent to load bearing structural members.

Seismic mode occurs after the activation of the seismic detection system and is expected to perform in the following ways:

- All registered car and landing calls will be cancelled, and new calls will be ignored.

- A lift with automatic power-operated doors, when parked at a landing, will open the doors, remove the lift from service and keep the door open.

- A lift with manually operated or nonautomatic power-operated doors, if parked at a landing, will remain in this condition, and be removed from service with the doors unlocked.

- A lift in motion will reduce the speed or stop and proceed to the next landing in the up or down direction with maximum car speed of 0.3 mps. At landing, operate as described in steps 2 and 3 above.

The primary wave-detection system was then considered by Tattoli, who stressed that if a primary wave-detection system is provided and activated (but no activation of the seismic detection system), the lift will operate as described: “A lift parked at a landing will remain in this condition for the next 60 s. If during this time the seismic detection system is activated by a seismic signal, the lift will go into seismic mode; otherwise, the lift will be automatically switched back into normal operation.”

As part of the presentation, Tattoli laid out the reasons why EN 81-77 does not consider the counterweight dis- placement device as in A17, and these are set out as follows:

- All lifts (whatever the seismic lift category) are required to install retaining devices, which must ensure the covering of a minimum of 5 mm of the guide rails during an earthquake.

- It is required that guide-rail joints and attachments withstand normal forces included by an earthquake (i.e., those induced by the design acceleration).

- For lift Category 3, a seismic-detection system that, when activated, puts the lift in seismic mode is re-quired.

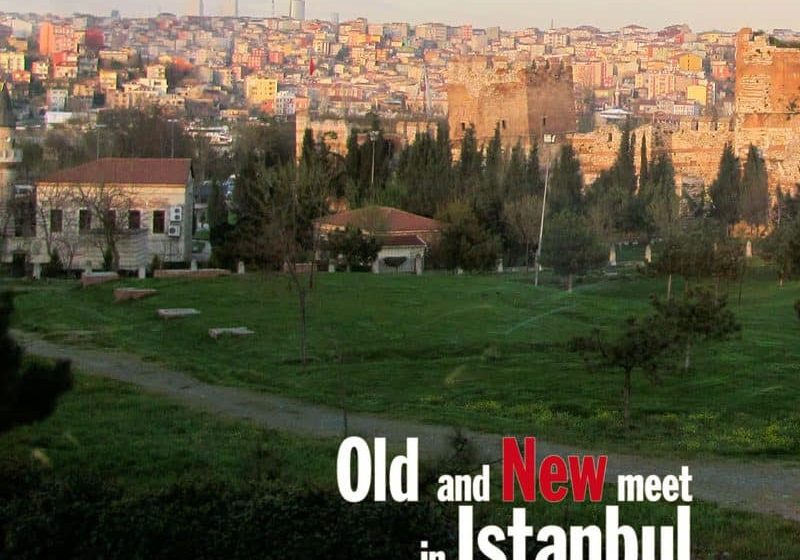

This was a very comprehensive and fitting opening presentation for the Asansör Congress, as Istanbul is a key area for seismic activity and has been progressive in the application of the EN codes and standards. Following the Asansör Congress, an earthquake struck in Lorca, Spain, again strengthening the relevance of this code.

The afternoon session was comprised of two parts. The first consisted of a detailed presentation about EN 81-1/2 A3 Amendments, which included expert input by Wolfgang Adldinger and Ian Jones with a perspective from a Notified Body represented by Liftinstituut. This was chaired by Selcuk Dikmen, past president of AYSAD. The second half of the afternoon session included a de-tailed look at the EN 81 family of codes, examining where, how and when all the different elements fit together in this growing code-and-standards framework. Esfandiar Gharibaan, chairman of CEN TC 10, Christian de Mas Latrie, chairman of ISO TC 178, and Jones, chairman WG1, were moderated by Michel Chartron, president of the European Lift Association. This grouping comprised an influential panel of presenters who gave the audience an educated overview on the state of EN 81, including a comprehensive presentation by Jones.

The morning session on the second day focused on two market-based presentations, one given by Fabio Liberali and the other by Undine Stricker-Berghoff. Liberali’s presentation focused on the state of the lift market and manufacturing in Italy, where there is a difficult situation between real-estate and lift companies. Liberali explained that many Italian engineering companies and lift manufacturers were making efforts to enter into the Chinese market, with some success. Regarding the home market, he explained that there was little high-rise development in Italy, so new installations were down. How-ever, the potential for modernization is great, with many lift installations over 30 years old. Then, Stricker-Berghoff, Verband Für Aufzugstechnik managing director, gave an overview of the status of the German market and the driving forces and influences that are active in 2011. She also highlighted the underlying economic and social trends in the country, which include the continued effects of reunification and the demands of social policies. Who would have thought that there was an oversupply of housing stock in Germany today and that the population is in decline?

The afternoon session on day two saw final presentations and a final panel that included representatives from the Turkish government and lift industry. The panel looked at the application of the Safety Norm for Existing Lifts (SNEL) in Turkey from a Turkish perspective. AYSAD President Tunc Timurkan was the session moderator and introduced the panel, which consisted of Zuhtu Bakir, Sefa Targıt, Ercument Hizal and Dikmen, to the audience. The lift professionals on the panel had also served as past presidents of AYSAD, so they were fully aware of the members’ needs. It was clear that the SNEL initiative was being embraced; however, it would not be easy to drive this safety initiative. The process had begun, and many issues would be discussed and developed. Bakir, from the Republic of Turkey Ministry of Industry and Trade, was pleased with the congress and the issues it raised and brought to attention. He expressed the view that the lift community is seen as leading the field and that other sectors could learn from the experience gained in applying the SNEL initiative.

The Asansör Istanbul 2011 Congress was a great success due to the combined efforts of many individuals, in-cluding Selahattin Durak, Bora Gulan, Ersan Barlas, Hizal, Dikmen, Ulvi Kadakal and Targıt. The strength of the Turkish lift industry is that there are many enthusias-tic industry professionals. We look forward to seeing the results of their efforts at the Asansör Istanbul 2013 Congress and Exhibition.

Get more of Elevator World. Sign up for our free e-newsletter.