Benefits of Intelligent Elevator Monitoring for Operators of Large Elevator Portfolios

Jul 1, 2024

by Philip Molineus and David Mansfeld

This paper was presented at the International Elevator & Escalator Symposium 2023 in Edinburgh, Scotland.

Abstract

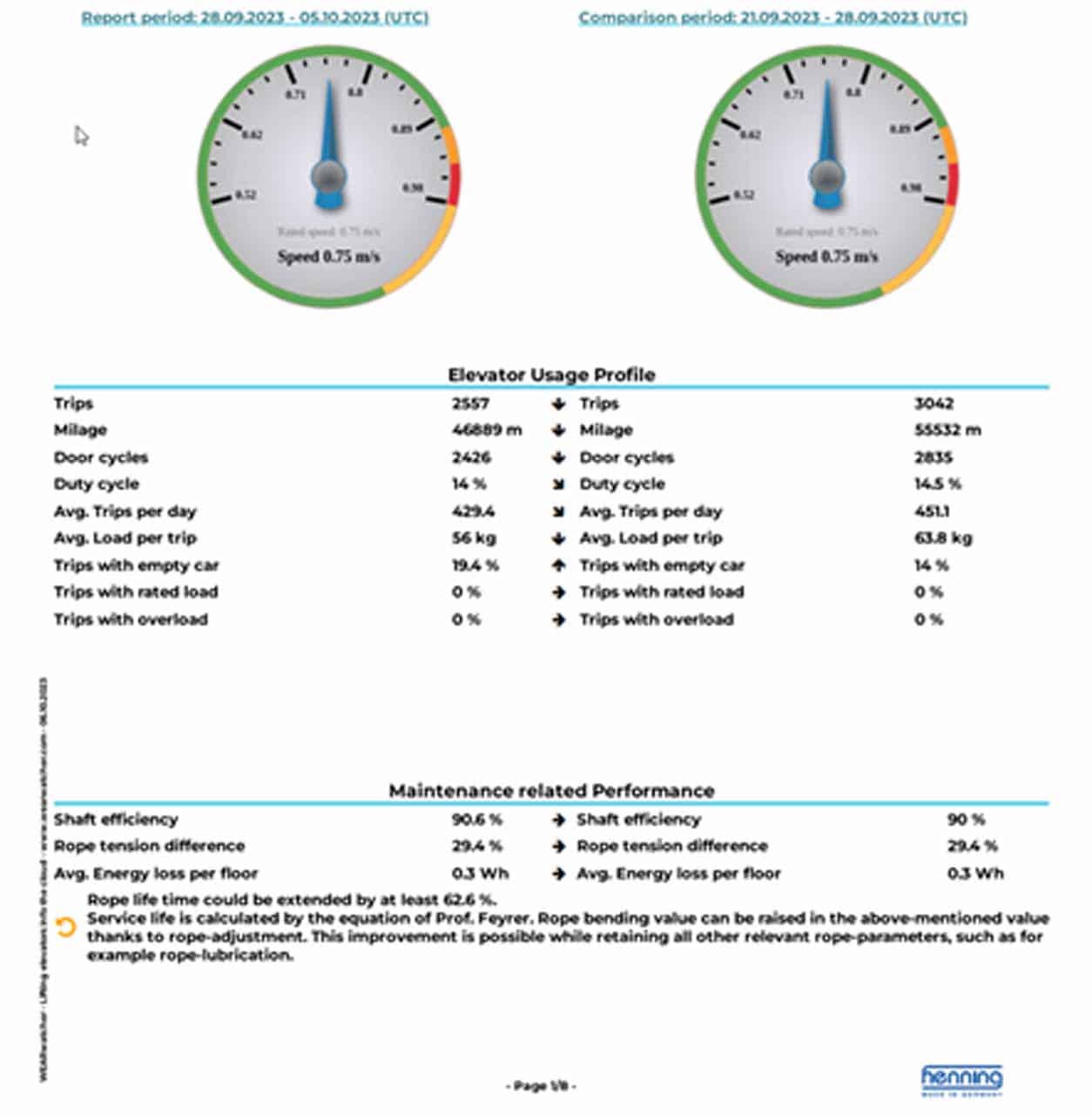

Intelligent elevator monitoring with sensors, edge computing and machine learning offers a variety of benefits to operators of large elevator portfolios, as well as their users.

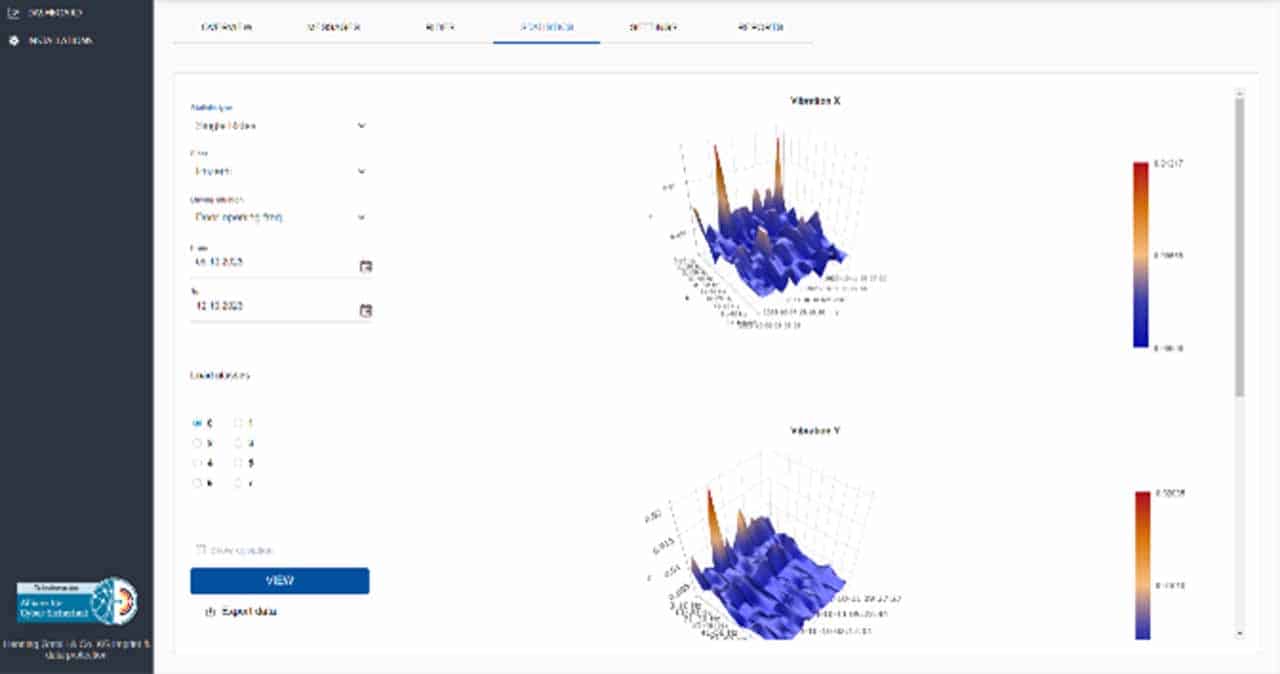

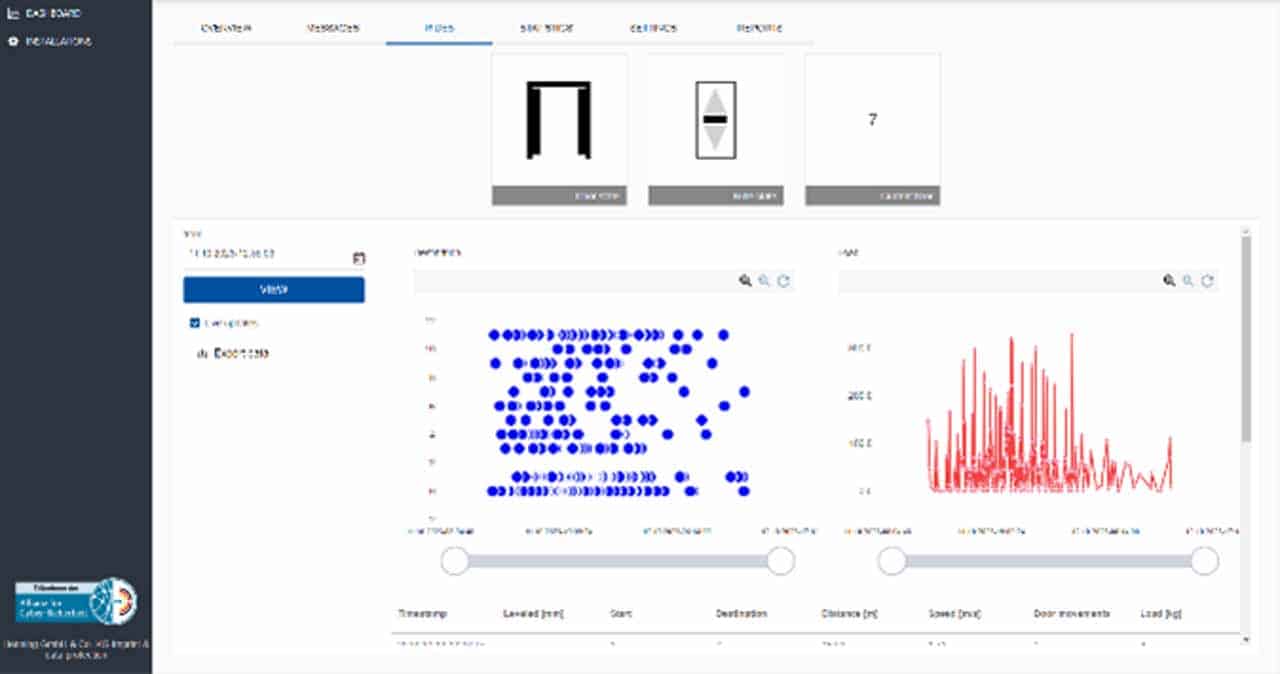

It enables continuous monitoring of the condition of elevators in real time. Through the use of sensors, important parameters such as load, current consumption, acceleration and vibrations can be recorded and, with the consistent use of edge computing, can also be processed directly on-site (without expensive, time-consuming data transfers) into an overall system status.

With the additional use of neural networks and AI, patterns and anomalies in the data can be detected. This processing can even be done (after training the networks over a large dataset) directly on-site at the elevator. This makes it possible to identify potential problems at an early stage and proactively carry out maintenance work before a breakdown occurs. This leads to improved elevator availability and a reduction in maintenance costs.

Intelligent elevator monitoring is an effective way to maximize elevator uptime and minimize downtime.

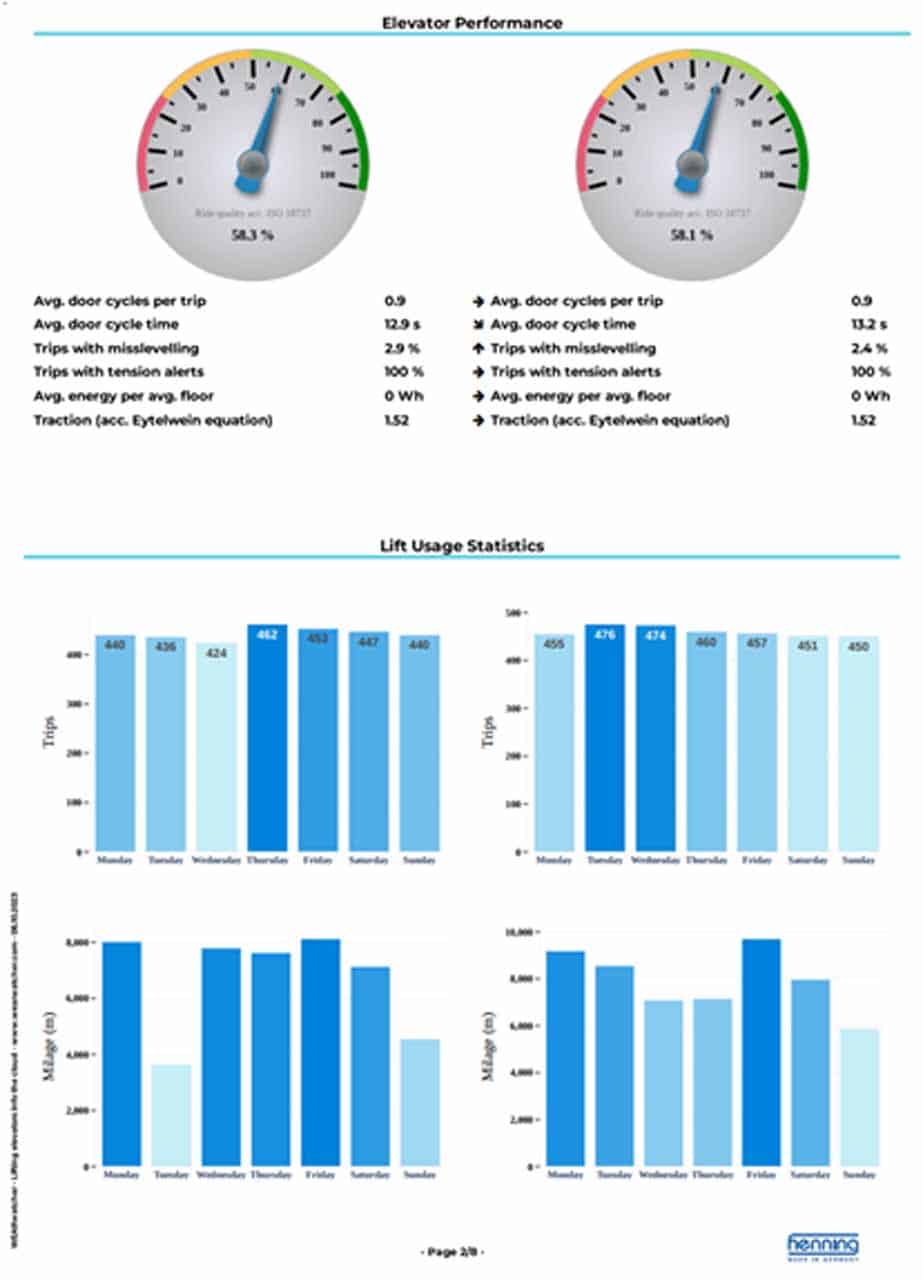

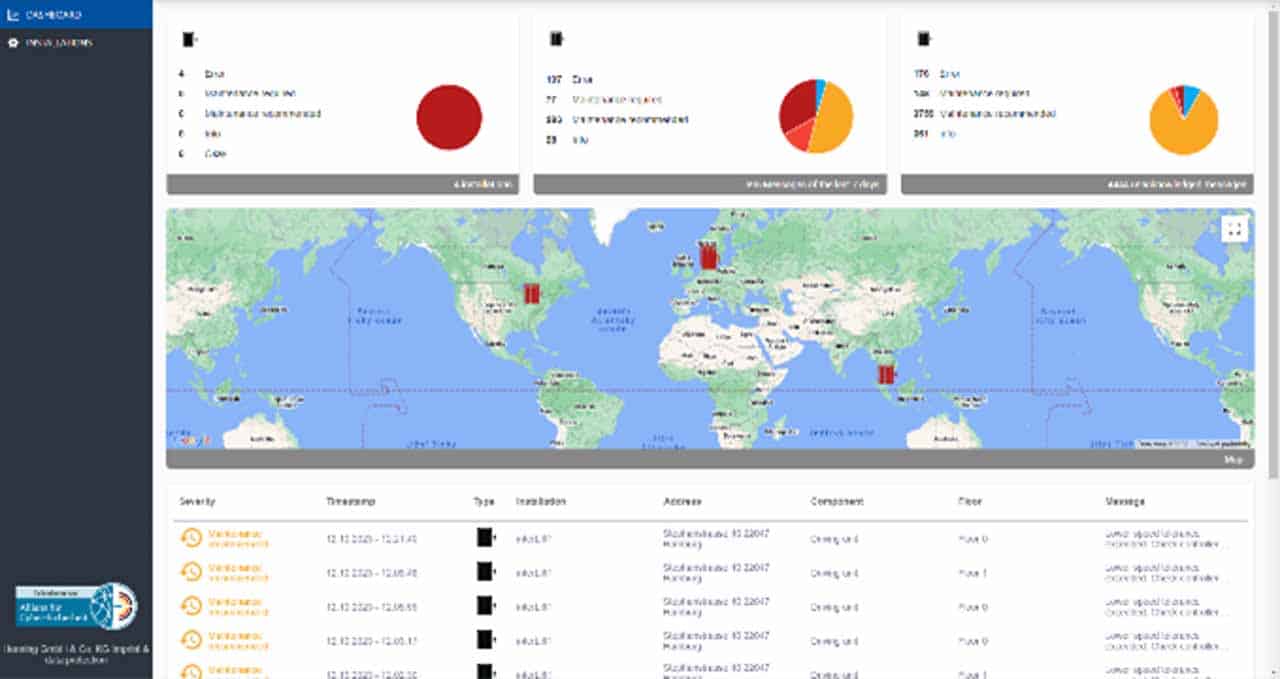

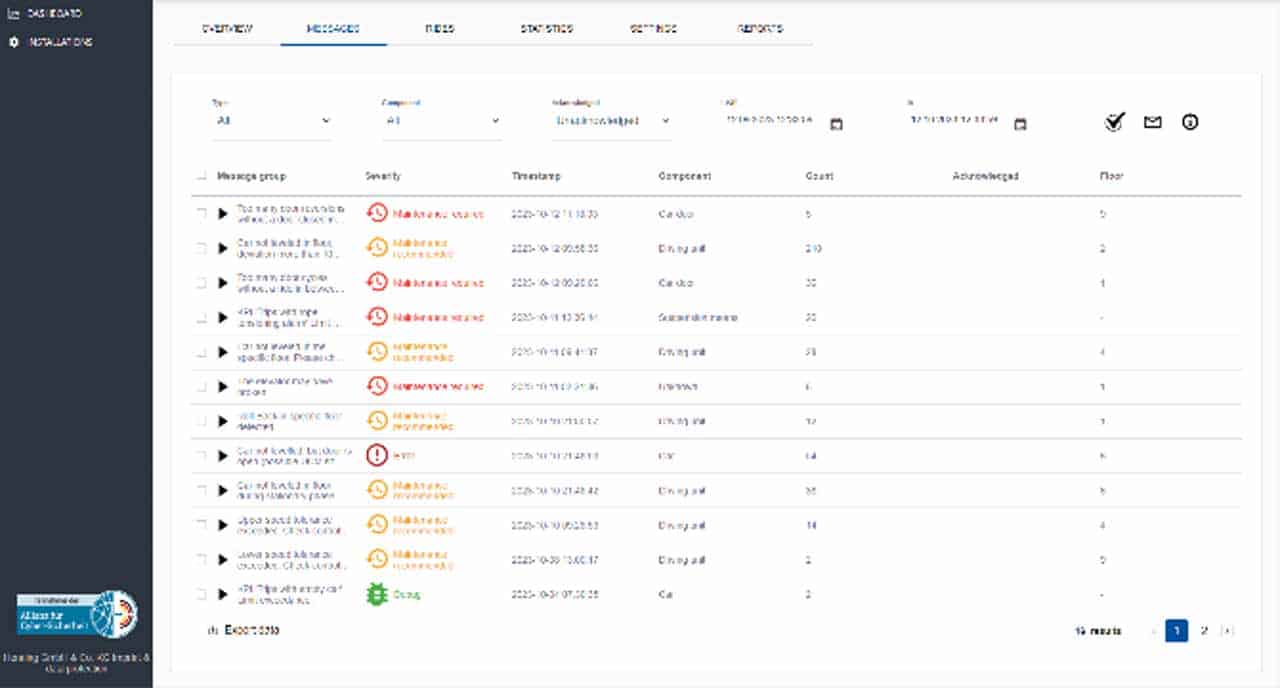

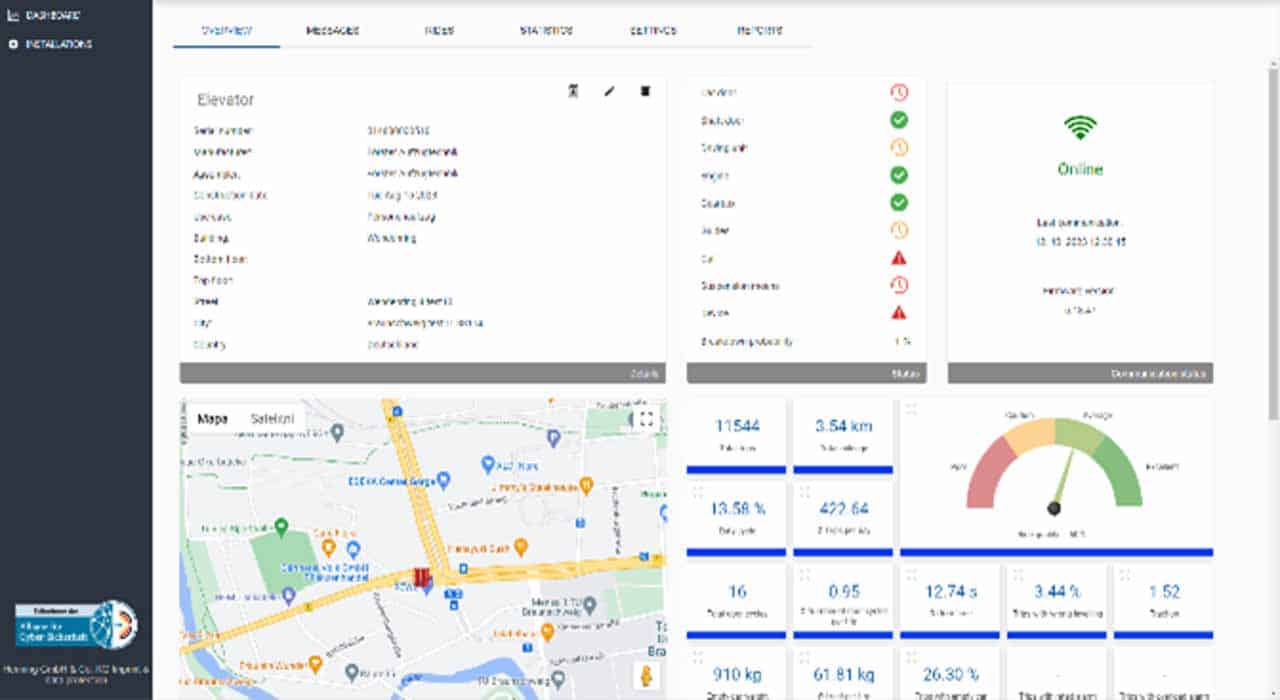

For operators of large elevator portfolios, elevator monitoring offers the added benefit of centralized monitoring and control. The integration of all elevators into a single platform allows the operator to monitor the status and performance of each elevator in real time. This enables efficient resource planning, optimization of maintenance work, optimization of energy consumption, taking of preventive measures and faster response to malfunctions, thus improving user satisfaction.

A secure, flexible and scalable monitoring platform plays an important role in the whole end-to-end (E2E) solution and enables future growth of an elevator portfolio, valuable insight into collected data and further customizations. Integration with other platforms and software solutions via powerful application programming interface (API) meets requirements even from the largest elevator companies and elevator owners.

This technical paper addresses the multifaceted challenges confronted by operators overseeing large elevator portfolios. The focal points include high maintenance costs, unforeseeable breakdowns, lack of transparency, budgeting complexities for repair and modernization and supervision of overall elevator conditions, especially when managing a diverse portfolio featuring systems from various manufacturers and different ages. The paper proposes a solution in the form of elevator-independent intelligent monitoring devices, leveraging sensors, edge computing and machine learning. This approach enables comprehensive real-time data collection, evaluation and monitoring of elevator conditions, fostering proactive maintenance, centralized control and improved operational efficiency.

1. Introduction

Large elevator portfolios present unique challenges for operators, ranging from maintenance cost to ensuring operational safety. The management of these portfolios introduces complexities arising from diverse systems, necessitating a comprehensive solution to address operational challenges. In a world where vertical urbanization is on the rise, the need for a streamlined, proactive approach to elevator maintenance and performance becomes paramount. This paper investigates the various pain points faced by operators and provides insights into mitigating these challenges with the use of intelligent elevator monitoring systems.

2. Pain Points for Operators

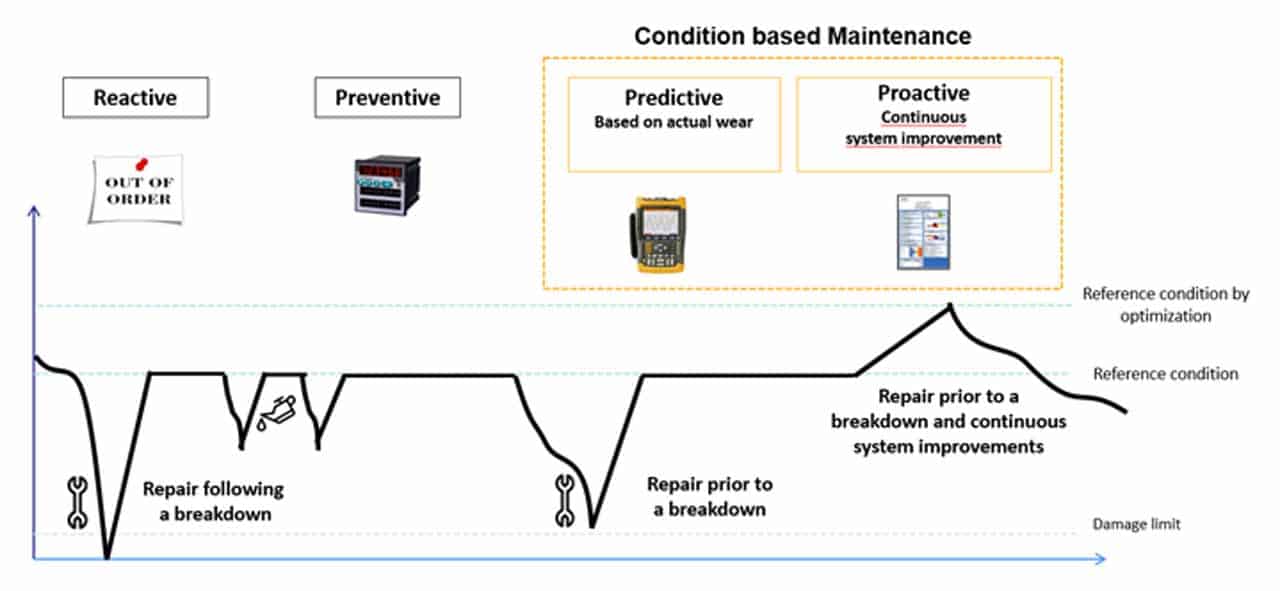

Presently, the standard for elevator maintenance is reactive maintenance and preventive maintenance. These methods are generating several pain points, especially for operators of large elevator portfolios.

a. Unnecessary Maintenance Visits

Current Scenario: Operators often face high maintenance costs due to unnecessary visits, resulting in increased operational expenses.

Causes: Inadequate predictive-maintenance tools, reliance on reactive maintenance and lack of real-time monitoring contribute to unnecessary visits.

b. Unforeseeable Breakdowns

Current Scenario: Unanticipated breakdowns lead to service disruptions, tenant dissatisfaction and increased repair costs.

Causes: Insufficient monitoring capabilities, lack of early warning systems and outdated equipment contribute to unforeseeable breakdowns.

c. Lack of Transparency

Current Scenario: Limited visibility into the elevator system’s health and performance hampers effective decision-making.

Causes: Inadequate data sharing between elevator components, outdated communication protocols and proprietary systems hinder transparency.

d. Difficulties in Budgeting for Repair and Modernization

Current Scenario: Operators struggle with accurately budgeting for elevator repairs and modernization projects.

Causes: Unpredictable maintenance needs, lack of historical data and unforeseen regulatory changes contribute to budgeting challenges.

e. Supervision of Overall Elevator Condition for Operational Safety

Current Scenario: Ensuring operational safety becomes challenging without a comprehensive overview of elevator conditions.

Causes: Limited tools for holistic condition monitoring, lack of real-time reporting and manual inspection processes impede effective supervision.

3. Solution: Elevator-Independent Intelligent Monitoring Devices

Elevator-independent intelligent monitoring emerges as a transformative solution to address the pain points associated with managing extensive portfolios of elevators. These innovative systems leverage intelligent monitoring technologies to provide autonomy, real-time insights and predictive maintenance capabilities, revolutionizing the management of large elevator portfolios. By fostering independence and efficiency, this approach not only enhances safety and reliability but also optimizes operational costs and elevates the overall experience for both building owners and occupants.

To achieve these goals, the monitoring systems make use of the following innovative approaches using the latest technologies:

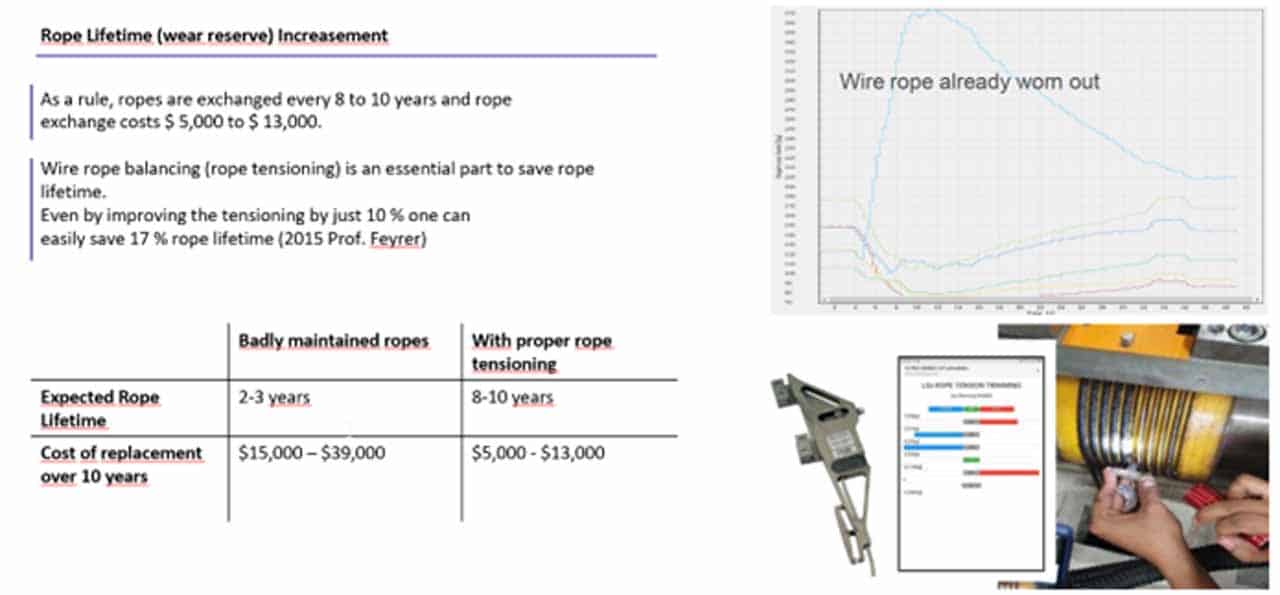

- Real-Time Data Collection: Sensors measure essential parameters, including load and rope tension data, current consumption, acceleration and vibration in real time.

- Edge Computing: Utilizing powerful edge-computing devices ensures consistent real-time data processing without expensive and time-consuming transfers.

- Machine Learning and Neural Networks: Advanced algorithms and AI detect patterns and anomalies, facilitating early identification of potential problems.

- On-Site Processing: Leveraging powerful edge-computing devices enables on-site processing after training neural networks over a large dataset.

- Proactive Maintenance: Early detection allows operators to proactively carry out maintenance, reducing the likelihood of breakdowns.

In detail, this leads to the following problem solutions for the pain points described in more detail above:

a. Unnecessary Maintenance Visits

Solutions: Implement predictive maintenance systems, leverage IoT and sensor technologies and embrace data analytics to schedule maintenance based on actual elevator conditions.

b. Unforeseeable Breakdowns

Solutions: Invest in advanced monitoring solutions, deploy predictive analytics to identify potential issues and establish a proactive maintenance strategy.

c. Lack of Transparency

Solutions: Implement open-source communication protocols, integrate systems for seamless data sharing, and adopt cloud-based platforms for centralized monitoring.

d. Difficulties in Budgeting for Repair and Modernization

Solutions: Establish a robust data-collection and analysis system, collaborate with vendors to predict long-term costs and allocate budgets based on predictive-maintenance insights.

e. Supervision of Overall Elevator Condition for Operational Safety

Solutions: Implement continuous monitoring systems, leverage AI for real-time analysis and automate inspection processes to enhance operational safety.

4. Benefits of Intelligent Elevator Monitoring

- Improved Availability: Proactive maintenance leads to increased elevator availability.

- Reduced Downtime: Early identification and resolution of issues minimize downtime.

- Centralized Monitoring and Control:

- Integration: All elevators integrated into a single platform for real-time monitoring

- Efficient Resource Planning and Budgeting: Streamlined resource allocation based on real-time data.

- Optimization of Maintenance Work: Data-driven insights optimize maintenance schedules

- Optimization of Energy Consumption: Monitoring facilitates energy-efficient operation.

- Preventive Measures: Early detection aids in preventive measures against wear and tear.

- Faster Response to Malfunctions: Immediate response enhances operational efficiency.

5. Improving User Satisfaction

- Enhanced Reliability: Increased elevator availability contributes to user satisfaction.

- Reduced Downtime: Quick response to malfunctions minimizes inconvenience for users.

6. Conclusion

Intelligent elevator monitoring emerges as a versatile and effective solution for operators managing diverse large elevator portfolios. By leveraging real-time data, edge computing and machine learning, operators can enhance elevator availability, reduce maintenance costs and ensure user satisfaction. Centralized monitoring and control capabilities further contribute to operational efficiency, making intelligent elevator monitoring an essential tool for large elevator portfolios, irrespective of the elevators’ age and manufacturer.

Centralized Monitoring Platform as Critical Part of the E2E Solution

A centralized monitoring platform helps operators of elevator portfolios in many ways, and an increasing number of companies tend to use one for their operations. New technologies, evolving business needs and many IT companies have contributed to the development of an environment full of different solutions to choose from, and it is sometimes confusing to select from what is available. When thinking of monitoring platform, it is essential to consider the following factors:

1. Scalability

While projects and operations might start small, they can quickly grow in number as new devices and sensors are added. More devices deployed means more data streams, a higher load and the importance of maintaining the same level of performance without the need to make significant architectural changes. Scaling should be provided by future-proof design to allow smooth performance of even the most complex projects and deployments.

2. Customization and Flexibility

It is quite usual that projects evolve, organizations grow and businesses need change. There might be requirements for new features and functions from time to time. A flexible platform allows customizations and development of tailor-made features and workflows to accommodate needs of different departments within an organization.

3. Security

Recent IT trends have shown that it is not matter of if a system is attacked but when. Devices, as well as networks and systems connected, are possible targets for cyber threats. Choosing a platform that follows the latest security standards allows implementation of security features such as secure transmission, authentication or encryption, which plays an important role when mitigating potential risks.

4. Data Analytics

Data generated by sensors and devices have real value and often represent a company’s values, market valuation, position on the market and future. Robust data analytics, prediction models, pattern recognition or machine learning are tools that provide actionable insights and drive decision making forward.

5. Integration With Third-Party Systems

Organizations often use various IT systems and devices, which need to be connected to provide E2E solutions. API is virtually a must these days in order to meet demand for integration, data sharing and connectivity.

6. Device Management

Managing a large portfolio of devices in a network has its own challenges. Remote monitoring, mass operations (such as firmware upgrade), provisioning and onboarding of new devices are crucial features that are mandatory for every operation.

7. Support and Documentation

In order to meet business requirements and provide customization for specific use cases, documentation, learning materials and support are key factors for developers working with the platform. Access to such information can significantly reduce development time and save money and energy.

8. Cost

Aside from the technical aspects of the platform, cost is usually a key element that needs to be considered. Understanding the cost, licenses, professional services and subscription models is important for budgetary purposes and making sure that the solution is going to remain affordable throughout its entire lifecycle.

When using a platform that is in line with the above-mentioned factors, a company can benefit from many advantages.

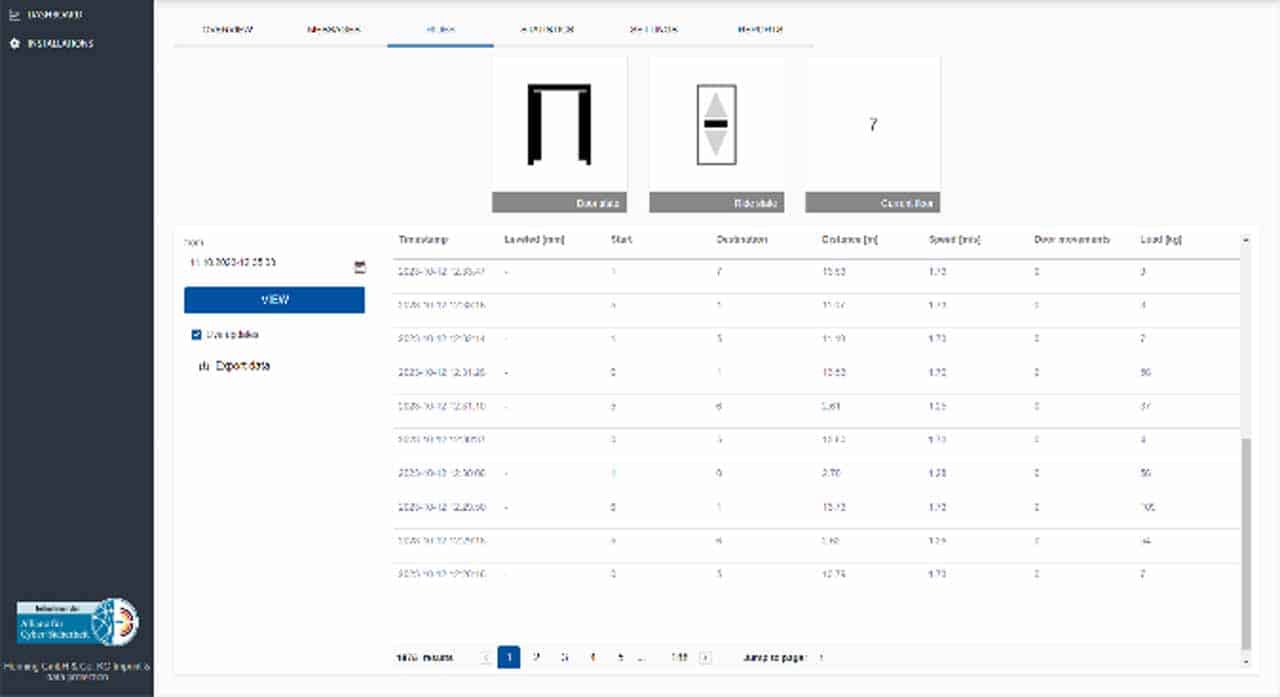

Imagine a scenario in which a technician goes to the site without proper information about what is wrong with the elevator, only to find out once there. If the technician does not have the proper equipment and replacement parts, it might result in a trip to headquarters to pick up what is needed and then back to the site. This obviously has an impact on time, money, efficiency, etc. By providing data and comprehensive reports about behavior of elevators, specific errors and components affected, service teams have everything they need for decision-making purposes, thus improving response times, increasing productivity and efficiency.

However, in order to support the above-mentioned advantages, information and data on the platform must be presented to operation teams in a comprehensive way. There are several points to consider when designing a product and service for the best user experience:

a. Intuitive

Allowing users to use products without needing to read extensive manuals, watch tutorial videos or use any other instructions. This also leads to quick user adoption and genuine desire to use such a product or service.

b. User Centric

While each user might be slightly different and have their own ways to interact with the product, understanding their behavior is a key element in designing a product in a way that is adopted by all.

c. Comprehensive

Data should be presented in a way that allows users to quickly find what they are looking for with minimal effort.

When working with large elevator estates and monitoring their condition, users are challenged to find information quickly and easily. Well-designed products allow users to spot anomalies, issues and errors in a way that lets them get to the bottom of a problem quickly and drill down to a specific elevator for more information.

That effectively leads to situations when operation teams know exactly where the issue is, when it happened, what elevator part is affected (if such sensors are installed), what is needed for replacement or how to rectify the problem in general. Further data from the elevator allows users to check the complete status of the elevator and possibly perform complete service, should that be required in a relatively short time after the visit.

Using data that is available to operations teams leads to improved communication, faster resolution times, increased efficiency, enhanced visibility into issues and tasks, better management of service tasks thanks to predictive maintenance, enhanced customer satisfaction and better utilization of valuable resources.

Elevator monitoring and its benefits are twice as important during critical situations when quick reaction is needed. However, having data available allows more thorough analysis during non-critical times. Collected data is an extremely valuable resource that, when properly analyzed, can be leveraged in many ways, and transformed into the following examples of actions and applications:

- Lifecycle management

- Resource allocation and planning

- Fault detection

- Predictive maintenance

- Performance optimization

- Energy efficiency

- Supply chain optimization

While short time benefits of elevator monitoring can be clearly spotted after a few days and weeks of operations, there are also long-term benefits that can be harder to measure and see at first. Improved operations and effectiveness once the team becomes used to the monitoring platform, customer satisfaction, cost savings and other efficiencies are just few examples.

Conclusion: A monitoring platform plays an important role in the decision-making process of an organization managing large elevators estates. Considering the factors above and choosing a platform that is built on these principles ensures the platform is aligned with long-term company strategy and will fit specific needs and goals. More importantly, the monitoring platform can also be the foundation of company growth and expansion by allowing it to grow in people while maintaining quality, productivity and efficiency.

Get more of Elevator World. Sign up for our free e-newsletter.