Bharat Bijlee

Dec 4, 2022

This Industry Dialogue looks at the history and growth of Bharat Bijlee and the company’s role in Atmanirbhar Bharat.

Nakul P. Mehta (NM), vice chairman and managing director, Bharat Bijlee, highlights the significant share of domestic manufacturers in the vertical-transportation (VT) industry focusing on aspects that will further boost the Prime Minister’s vision of Atmanirbhar Bharat in conversation with Sheetal Shelar Patil (SSP).

SSP: There is a greater emphasis on “Made in India” across the nation; to what extent is this visible in the (VT) industry?

NM: The Indian elevator market in 1996 was just 7,000 units annually. Since then, it has grown to about 75,000 units per year, with an installed population of 600,000 units, making it the second-largest VT market in the world. India’s first elevator was reportedly installed at the Government House in Calcutta (now Kolkata) in 1892. In the years that followed, and as patterns of urban development evolved, several international elevator firms grew active, either with subsidiaries or through licensees or agencies. Most global elevator OEMs are now established here and have offerings that cater to multiple market segments.

Also, for many decades now, domestic manufacturers have made a robust contribution to the industry. Some have grown sufficiently in scale and maturity to rival multinationals in size and capability, while many others occupy niches and cater very effectively to their chosen market segments.

It is also significant that the elevator component industry was virtually non-existent 15 years ago, with major VT companies relying largely on in-house manufacturing. Now, as strategies have evolved with global trends, specialized component manufacturers supply to OEMs and to contractors across segments, and often compete directly with imports. Here again, domestic manufacturers already have a significant share of the market.

SSP: How has Bharat Bijlee exemplified this concept in its brand positioning and approach?

NM: As an Indian company, and one of the pioneers of electrical machinery manufacturing in India, we have always believed that we have a role to play in the industrialization of our nation. To us, this has meant continually upgrading our capabilities in design, process and management methods to provide products and solutions for the Indian and overseas markets. Sometimes this has meant the judicious use of foreign technology, but we are proud that we have a strong track record in offerings that are “Indigenously Designed, Developed and Manufactured.”

We also actively work with industry bodies and policymakers, notably in the promotion and adoption of energy-efficient products to reduce greenhouse gas emissions and industrial energy consumption. A recent success in this area has been the Government’s 2017 Quality Control Order prohibiting the manufacture and sale of electric motors below minimum levels of efficiency. This is an excellent example of how industry and policymakers can work together to make a real difference.

The VT industry in India already has great depth of experience and capability; it has world-class manufacturing facilities and has been an innovator and early adopter of new technologies.

— Nakul Mehta, vice chairman and managing director, Bharat Bijlee

SSP: How have the company’s various offerings made a tangible impact on the VT industry?

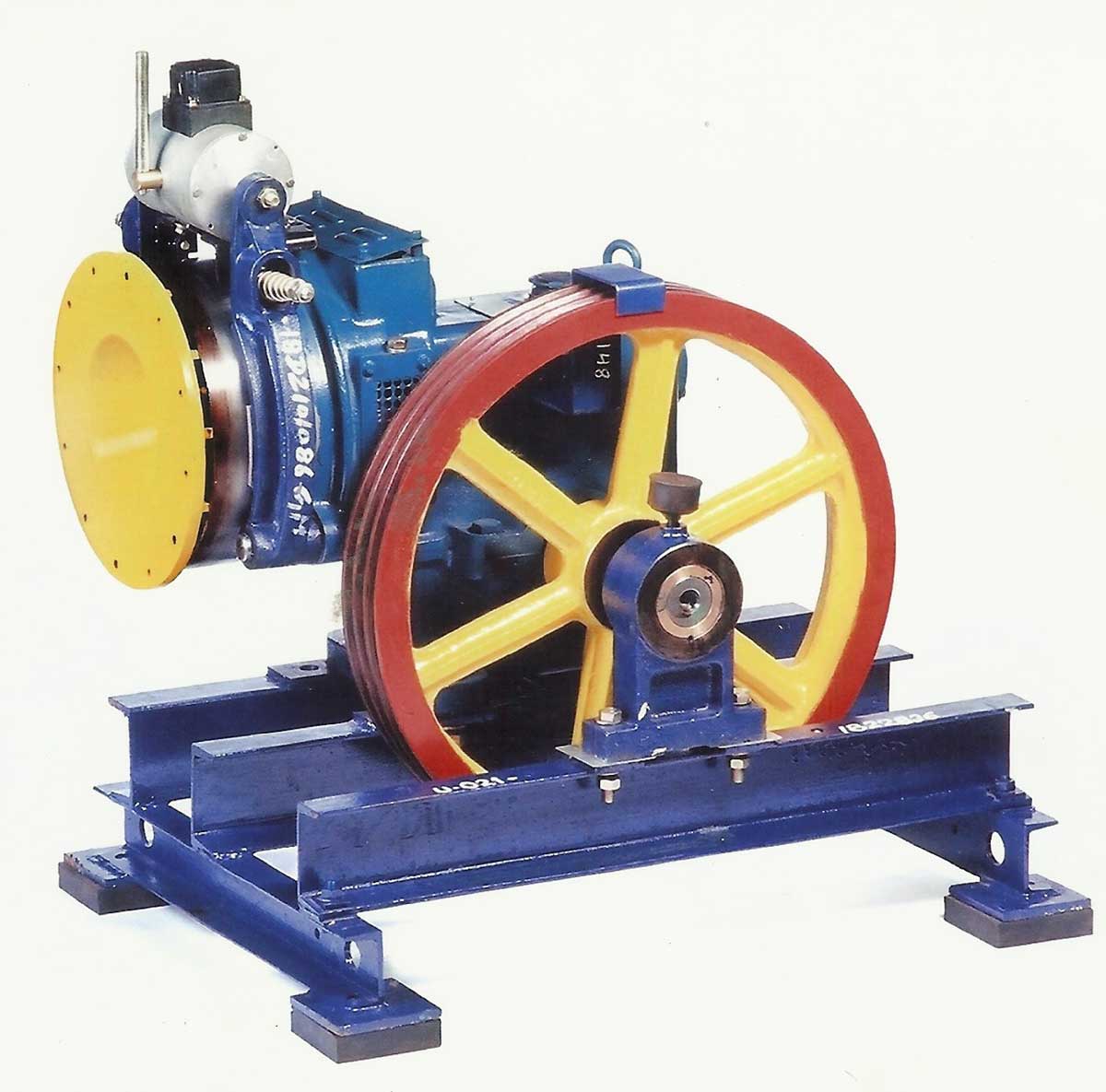

NM: Between 1973 and 2004, operating under the brand name Olympus, we were one of India’s elevator majors. In 2007, we identified gearless synchronous elevator machines as a new line of business for Bharat Bijlee, leveraging our understanding of elevator applications with more than six decades in the manufacture of rotating machines. In 2008, in partnership with Permagsa of Spain, we became, perhaps, the earliest manufacturer of permanent magnet (PM) gearless elevator machines in India.

Technology is evolving at a rapid pace, and our goal is to continuously innovate with ongoing product improvement, as well as first-principles development. Our partnership with Permagsa is a synergistic one, with regular exchange of design and engineering inputs.

Our current range is the series of GreenStar and SynchroTorq machines spanning applications from home lifts to 3000-kg goods lifts that are designed to perform optimally with the contractor’s preferred drive system.

We have an established position in the Indian market, and it is one that we always try to consolidate. We also have a reasonable export footprint, with customers in continental Europe, and in this, we realize that we are ambassadors for India. The Indian Green Building Council-Certified Green plant we built in 2018 was expanded earlier this year to double our manufacturing capacity.

SSP: What are some of the challenges that need to be overcome to facilitate Atmanirbhar Bharat and raise it to a greater level?

NM: The Atmanirbhar Bharat mission is best seen as a far-reaching concept to make India “a bigger and more important part of the global economy”; the platform for this is a set of sustainable policies that encourage self-reliance rather than self-sufficiency. This initiative is intended to boost domestic manufacturing while recognizing the participation of foreign investment and technology.

India has a growing and sizable domestic market, but it is argued that a major driver of success will be an emphasis on exports. For this, a strategic and holistic approach to competitiveness and free trade may be more beneficial than a tactical approach of incentives and duties, or of exercising greater discretionary authority over commerce. At a more specific level, identifying and prioritizing sectors where India has a comparative advantage would logically lead to impactful actions for institutionalized skill development, logistical support and access to technology. Global history has shown that the Government itself can directly play a vital role via the unified promotion of exports and by ensuring close collaboration between policymakers and exporters.

SSP: What suggestions would you offer to give the “Made in India” concept further impetus (a wish list of sorts)?

NM: The VT industry in India already has great depth of experience and capability; it has world-class manufacturing facilities and has been an innovator and early adopter of new technologies. It is well placed to fulfill the Atmanirbhar Bharat mission. The ongoing initiatives to harmonize Indian Standards with International Standards is an important step in the right direction. Conformity with the relevant Standards in letter and in spirit is crucial, and wider adherence to performance and safety standards will benefit all stakeholders. It can also open avenues for domestic component manufacturers to expand their export footprint. Once there is a wider perception — to match the reality — that these products are reliable and compliant with relevant Standards, there is an opportunity for India to become a preferred source for OEMs overseas.

Nakul P. Mehta holds a Bachelor of Science and a Master of Science in engineering mechanics. He joined the company in 1984 and has been one of the managing directors since 1990. He has wide experience in electrical engineering and elevator businesses and has been active on various industry bodies and associations.

Get more of Elevator World. Sign up for our free e-newsletter.