A popular networking event by CTBUH London

The Council on Tall Buildings and Urban Habitat (CTBUH) arranged a very popular networking event, a boat trip along the Thames, on 14 September.

Participants from the fields of engineering, architecture, interiors and consultancy, as well as lift manufacturing, enjoyed a glorious evening in the lingering summer heat. One hundred and twenty people boarded the Golden Jubilee boat for a cruise along the river Thames, taking in the buildings along the way while having a unique opportunity to network with colleagues from the construction industry. As the boat set off upriver from Temple Pier at Westminster, participants were given three presentations, all touching upon the CTBUH motto of “Towards Sustainable Vertical Urbanism.”

First up was Chris Edgington, associate director at Arup. Chris started with his experience over the last 10 years of developing 8 Bishopsgate, a 50-storey building completed in June in the City of London.

Chris talked about the shape of the building and why it ended up looking like it does. The viewing corridor included St Paul’s, and key points on Fleet Street also had an impact on where it was possible to build in the area. The design of the building was changed in a second planning stage, resulting in 50 floors instead of the originally planned 37.

8 Bishopsgate has approximately 6,000 people using the space around the building at any one point in time with 23 lifts moving people around in it. The building is 96% electric and has energy performance A, which Chris stated is remarkable for a building of its size. There are also three terraces providing outdoor space that is normally quite difficult to achieve in a tall building.

Chris reinforced that the project was the result of teamwork, and collaboration with all partners was hugely important. During the design process much thought went into considering how every element of the building could fulfil more than one function, if possible. Chris also talked about self-finishing and the importance of doing such a good job with the building itself that it is possible to have everything on display rather than covering up the structures, reducing the amount of embodied carbon in the process.

Between stages 2 and 3 of the building process, there was a significant reduction in embodied carbon. He talked about how the foundation was optimised and made more secure, how the structural solution enabled a cantilever to come out over the footway and the use of a hybrid bracing system section that allowed for less steel weight to be put in.

Chris also encouraged everyone to go to the public viewing gallery at the top of the building for uninterrupted views of St Paul’s Cathedral and, across the river, south London.

8 Bishopsgate facts

- 47 office floors

- 52,900-m2 net office area

- 204-m tall

- The Lookout at level 50

- Three outdoor terraces

- 23 lifts

- 940 bike spaces

- 200-seat auditorium

Next up was Andrew Taylor, head of Specifications and Sales at Lindner Group. He introduced his chosen topic — net zero — by highlighting that the construction industry is responsible for up to 40% of carbon emissions. There is a strong need to look for fit-for-the-future, sustainable products, healthy spaces, flexible concepts and cradle-to-grave support.

Andrew focused on the Environmental Product Declarations (EPD) that have come to define the construction industry’s drive for net-zero emissions. Most companies use EPDs to measure, compare and evaluate materials and products to offer sustainable solutions for their clients. Although Andrew praised the use of EPDs, they have potential drawbacks. Something that resonated strongly with Andrew was from an article in the New Civil Engineer where the need to urgently simplify and streamline sustainability information was stated.

Andrew gave an example of how one of their floor materials had been deemed as having higher embodied carbon compared to another supplier, whereas the opposite was true. This was a result of using different units to measure when comparing the same item.

Andrew continued by stating that the process around EPDs also needs to be reviewed. The verification process can be somewhat drawn-out, resulting in companies not being able to prove in time that the system that has been put forward does enable net zero. He did state that EPDs have contributed to everyone being better able to understand the environmental footprint of construction projects and completed buildings.

Andrew also touched on the circular economy and the need to reuse, recycle and repurpose. Sometimes there are unexpected challenges with this. In one building where a newly laid floor needed replacing, it was taken up very carefully to allow for re-use. Having been laid once, however, it was officially considered waste and, due to regulations, it was not possible to export it back to the head office in Germany.

In summary, fit for the future means a wider perspective than looking at just the product, but also the whole industry.

Last to present was Steve Davidson, technical director at Parmarbrook. Steve talked about retrofitting existing structures, especially high rises. He also discussed what lessons can be learned for new structures.

He first explained the term “embodied carbon”: the carbon emissions associated with the entire life cycle of a building, from material extraction, construction, through to the eventual demolition of the same building. It is important to look at embodied carbon, as this can be a substantial part of a building’s life cycle emissions. Focus in the industry has often been on operational carbon emissions.

When retrofitting, one has a unique opportunity to maximise the value of the carbon already invested in the structure. Steve talked about Portland House, a 30-floor retrofit of an existing structure in Victoria. Among the challenges of any retrofit is how to maximise the capacity of the existing frame and the foundation. The latter is fundamental to the cost of carbon.

Steve mentioned the importance of really getting to know and unlocking the existing structure. In the case of Portland House, there was access to archive material, helping in this effort. This meant the possibility to develop and pass a structural strategy on to the rest of the design team already in stage 1, facilitating the work of developing a sustainable building.

Steve also mentioned briefly that the best retrofitted building on the market right now is the Empire State Building in New York. Energy consumption was reduced by 38% and the building’s carbon footprint was greatly reduced. This shows that historic buildings can be sustainably retrofitted. In London, Canary Wharf is currently seeing many firms relocating, leaving vacant stock that needs repurposing.

Steve also touched on how one can apply lessons learned to new builds. First and foremost, collaborative design and brainstorming by the team are important. Make sure to allow for adaptive reuse of space. Sometimes the best structural forms come from carbon-effective designs and flexibility in space. Celebrating sustainable design can have a massive public impact, making the general public proud of the building.

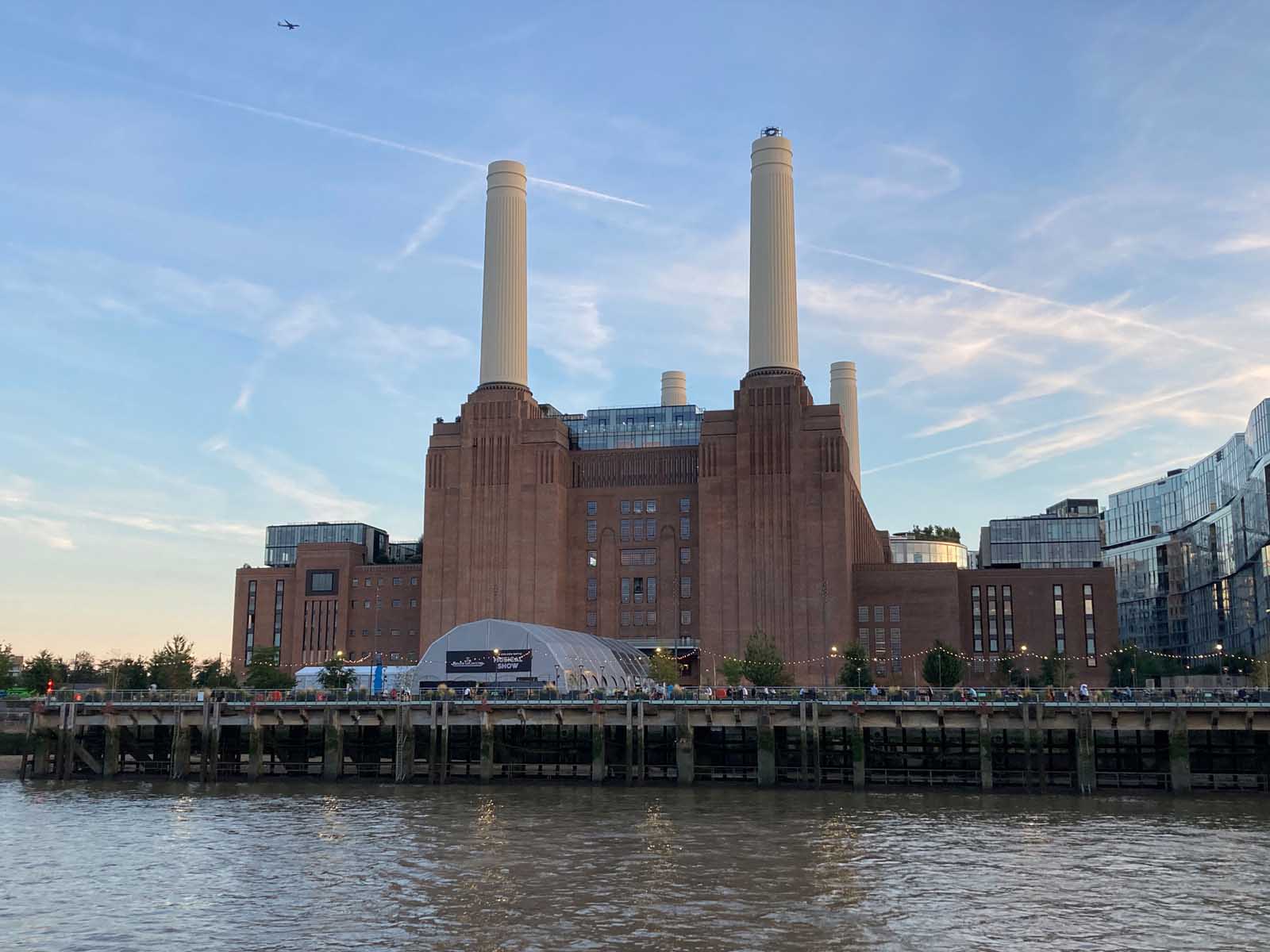

As the presentations ended, the boat was approaching Battersea Power Station, treating everyone onboard to a magnificent view of the sunset being reflected off the river.

Seeing the city from the river gives a very different perspective of the buildings. The boat trip was a journey in two parts with the first part during daylight hours. The second half was after sunset, allowing participants a different view of the city. It inevitably led to discussions about the extent of lit-up buildings, in particular office buildings with hardly anyone in them, and that much could be done in terms of saving energy in this respect.

Some of the buildings mentioned during the presentations were subsequently pointed out by the speakers as we cruised past them. The boat took us past the City of London, Bermondsey, Canary Wharf and onto the Greenwich Peninsula, before circling back to Tower Bridge Pier and subsequently returning to Temple Pier. With many people onboard having been involved in one way or another in many of the tall building projects throughout the years, unexpected insights were brought up, such as how to deal with sliding snow on one building or how to facilitate continuity when handing over the management of a completed building.

About CTBUH

CTBUH is the world’s leading nonprofit organisation for all those interested in the future of cities. It explores how increased urban density and vertical growth can support more sustainable and healthy cities, especially in the face of mass urbanisation and the increasing effects of climate change worldwide. The relationship between policy, buildings, people, urban density, urban space, interior space and infrastructure is key. To sign up for future events, visit ctbuh.informz.net/ctbuh/pages/uk_futureleaders

About Arup

Arup is a global collective of designers, engineering and sustainability consultants, advisors and experts dedicated to sustainable development and to using imagination, technology and rigour to shape a better world.

About Lindner Group

The Lindner Group is one of the leading companies worldwide for the building envelope, interior fit-out and insulation. The company offers a comprehensive range of disciplines as a full-service provider for nearly all applications.

About Parmarbrook

Parmarbrook is an engineering company who works closely with leading architects, developers and contractors to design, engineer and deliver buildings of all forms. These range from large-scale residential developments, commercial offices, education, hotels and major mixed-use schemes.

Get more of Elevator World. Sign up for our free e-newsletter.