Central-Mid-Levels Escalator and Walkway Systems

Feb 1, 2021

submitted by Andy Cheung, Anlev Elex Elevator Ltd.

Bringing new technology to the longest outdoor covered escalator system in the world

The Central-Mid-Levels Escalator and Walkway System in Hong Kong, which was inaugurated in 1993, is a tourist attraction and commuter service and the world’s longest outdoor covered escalator and walkway system. It consists of a series of 18 escalators and three inclined moving walks connected by footbridges. Situated in the heart of the city, it spans nine streets from Des Voeux Road to Conduit Road, covering more than 800 m and elevating 135 m through the street hillside.

Some 25 years of relentless service to the community had taken its toll, leading to a need for modernization. Anlev Elex Elevator Ltd., a subsidiary of ATAL Engineering Group, was appointed by the Government of the Hong Kong Special Administrative Region Transport Department and Electrical and Mechanical Services Department (EMSD) to carry out this work in March 2018. Its 12 phases are to be complete in August 2022.

The project involves a unique community of diverse stakeholders: local and expatriate residents, tourists, businesses, young children and elderly. For a transportation system serving more than 78,000 people daily, shutting down escalators for the duration of the project is out of the question. After detailed study and meticulous planning and public consultation, the project commenced to modernize the escalators with the latest energy-efficient features, such as efficient motors, variable-speed drives, LED lights for better illumination and service-on-demand functions. It is expected that the colorful LED lights installed along the units’ skirt panels will create interesting photo opportunities for tourists.

Engaging the Community

Community engagement is a vital aspect of this extraordinary project. Anlev updates users and the neighboring community every step of the way and alerts them well in advance of the need to make detours. A 24-h customer service hotline handles inquiries.

Tough Conditions

Part of the system straddles busy roads, while an extremely narrow worksite made it difficult to deploy truck-mounted cranes without disrupting traffic and pedestrians. Each task had to be planned with meticulous precision and the utmost consideration for the many stakeholders. Technical challenges included:

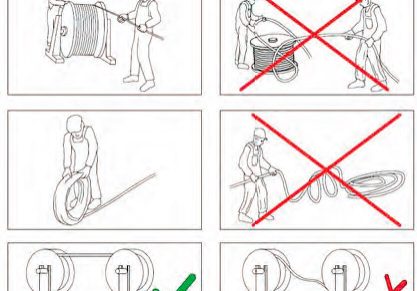

- The very narrow worksite and physical constraints posed by the existing system, such as the escalator canopies: as the client requires the canopies be untouched, the usual method of lowering the escalator by crane into the shaft from above and installing it as one piece would not work. Our solution was to cut each escalator into pieces (none longer than 3.6 m) and insert them from the two ends of the covered space, then reconnect the pieces during installation. This complicated the installation process and necessitated additional logistical arrangements.

- Likewise, each old escalator must be cut into four to six pieces before it can be moved to the ground. This involved further detailed planning.

- Part of the system straddles busy roads, while an exceedingly narrow worksite makes it difficult to deploy truck-mounted cranes without disrupting traffic and pedestrians going about their daily business.

- The lack of data about the system, particularly during the initial design stage, made the team rely on daytime visual observations and physical surveys at midnight to obtain data for this stage.

The project team took just four-and-a-half (instead of the usual six) months to replace the escalators featured here. This included preparation, installation, testing and commission, inspection and trials of each unit.

Use of Technology

TS as a Measuring Tool

As this was a modernization project, the existing infrastructure of the system could not be dismantled or modified. Also, the system has high daytime usage, so data about the system was hard to obtain. Instead of using the traditional measuring methods that require workers to do it manually, our team used total station (TS), a tool commonly used in civil engineering, to measure the escalator’s shaft dimensions for the initial design. For the workers, this method was also a safer approach to the required measurement operations. We hope this application sets a precedent for other industry players.

Tailor-Made Escalator Footsteps

In light of the extremely limited working space, special escalator footsteps are designed to act like bridges on the “work-in-progress” escalators. These footsteps are customized to be “one size fits all” so they can be recycled for use in future stages of the project.

Smart Locks Backed by Mobile Apps

A smart-lock device that comes with a mobile app is used to monitor the temporary distribution board. As the device allows only licensed technicians to access the distribution board, it helps safeguard workers. Its conveniences include Bluetooth operation and cloud data storage.

Quality Control

Anlev designed and manufactured the equipment for this system at our own factory in Nan3jing, China. We received the highest rating in safety and quality performance for seven consecutive years in the Performance Rating Scheme from EMSD (since the scheme began in 2013). In 2018, Anlev won the Hong Kong Management Association Quality Awards’ Excellence Award.

Sustainability

In addition to training on environmental friendliness and the installation of green vertical transportation, the following measures were implemented:

- Air: Anlev has assessed the types of air pollution that might be generated from the work and implemented corresponding measures to mitigate the impact to the public.

- Noise: Soundproof insulation was set up along the site to minimize noise pollution, and all noisy work was conducted between 10 a.m. and 5 p.m. on weekdays.

- Waste management: A trip-ticket system was adopted to ensure proper disposal of construction waste from the worksite.

Safe So Far

As of the time of this submission (when 12 of the 21 units over seven phases had been completed), there was no reportable accident relating to this project since our work commenced in 2018.

Get more of Elevator World. Sign up for our free e-newsletter.