Certification of Doors According to Safety and Fire Rating Standards: A Worldwide Perspective

May 1, 2011

Already accepted in many countries, the acceptance of safety and fire rating standards is growing. Shared rules and codes enable continuous improvements and increasing safety levels for lift installations.

Safety and fire rating standards such as EN 81-1/2 and EN 81-58 are already accepted in many countries, and their acceptance is growing; shared rules and codes enable global product-development processes for big lift-component manufacturers, driving continuous improve-ment and increasing levels of safety for lift installations.

Establishing local production companies that share the same global manufacturing organization means that cost and safety advantages are being made accessible to the local lift market.

EN 81-1/2: A Worldwide Standard

EN 81-1/2 is recognized worldwide as a standard with a high safety level. It is demonstrated that about 75% of new installations in the world are made according to EN 81-1/2 (sometimes with small national modifications). The worldwide diffusion of EN 81-1/2 allows the collection of feedback from a wide field and from many different installation situations. The effects of this diffusion are a continuous improvement of the standard and an increas-ingly higher level of safety

A factual demonstration of the two aforementioned effects is the forthcoming revision of EN 81-1/2 that will bring into use the new EN 81-20 and EN 81-50; EN 81-20 contains general design requirements for passenger and goods passenger lifts, while EN 81-50 contains descrip-tion of the examinations, calculations and tests of lift components.

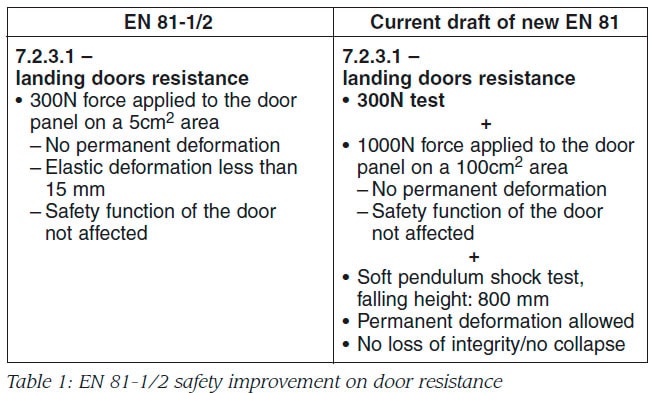

This new revision will ensure a higher level of safety by introducing new requirements for all lift components. An example is the mechanical resistance of landing and car doors: the forthcoming EN 81 will push the development of even better door products. Under the new EN 81-20, all doors will be subjected to pendulum testing in the factory as part of their design; moreover, their mechanical strength will be verified by an additional 1000N force test (Table 1). New requirements will also be introduced for car door toe guards, car door locks and emergency un-locking keys; light curtains will become mandatory when kinetic energy during closing movement is less than 4J.

Due to the diffusion of EN 81-1/2, during the develop-ment of its forthcoming revision, the AH 17 subcommittee was specifically created in order to take comments from non-European partners (China, India, North America, Korea and Australia). As a worldwide code, it has brought many advantages for manufacturers and end users:

- Safety level is guaranteed independently from the place of manufacturing.

- Use of shared rules and codes for product safety makes export activities much easier.

- Local sourcing of lift components is also made easier when dealing with big architectural projects managed by international building companies and architects.

- Local sourcing of lift products compliant with the same rules and codes also means less shipping and import expenses, and a low carbon footprint for environ -mental sustainable development.

EN 81-58 to Enforce Compartmentalization

Fire resistance of landing doors is crucial to enforce compartmentalization of the lift shaft and avoid fire prop-agation in the building. The role of fire-resistant lift land-ing doors is to prevent fire, smoke and gas leakage from entering the well and being transferred to another floor. Fire resistance of landing doors is particularly important due to the chimney effect: higher hot gas leakage rates occur between landing doors at different levels, compared with rooms placed at the same floor.

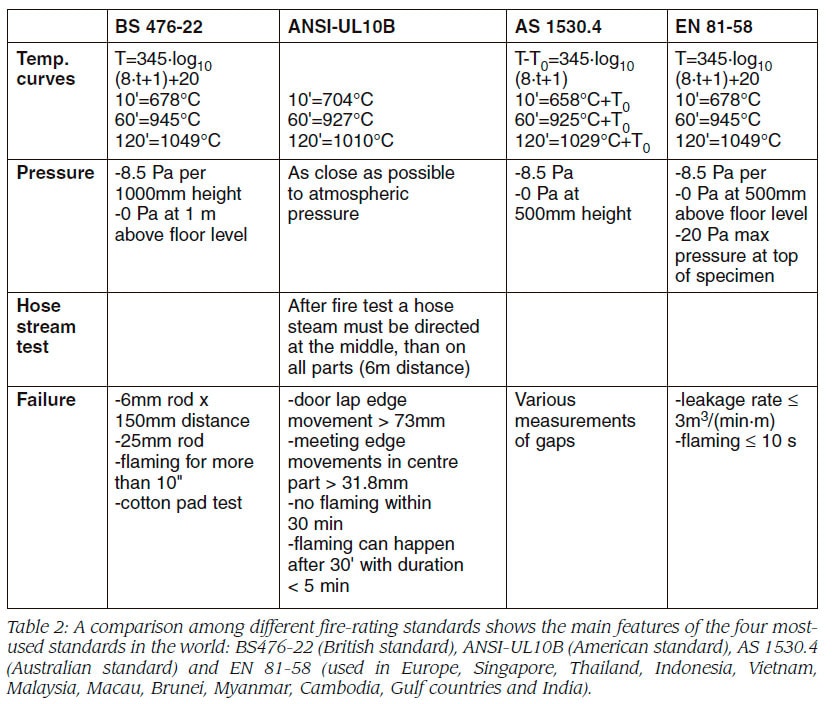

EN 81-58 has been widely accepted as a reference standard for fire resistance of lift doors, and more coun-tries are likely to accept it in the future (Table 2). Having superseded many European standards for lift doors, EN 81-58 has brought several advantages to the lift market:

- No technical differences in the design of lift resistance throughout the different markets

- Reduced number of tests needed to sell fire-resistant landing doors

- Objective evaluation of integrity criteria by making use of calibrated measuring equipment during tests

Essential Fire-Resistance Criteria according to EN 81-58

- Integrity: The criterion is satisfied as long as the leakage rate per meter width of the door opening does not exceed 3 m3/min. Integrity shall be considered to have been lost by the occurrence of sustained flaming (more than 10 s).

- Thermal insulation: The criterion is satisfied if the average temperature rise does not exceed 140°C and the maximum temperature does not exceed 180°C.

- Radiation: The criterion is satisfied as long as the measured radiation does not exceed the value of 15 kW/m2, measured as specified in EN 1363-2.

The above are assigned to the corresponding resistance times in minutes (i.e., E120, EW60, EI30).

Conclusion

The lift-components business is a regulated market where norms and codes drive the product development. Nevertheless, the best manufacturing companies, while following the criteria set by those standards, are still able to differentiate their products by a more intensive and extensive R&D activity setting more ambitious targets:

- A safety level higher than the level set by norms and codes

- A safety level in line with the level set by norms and codes but reached with low extra costs on finished products. (In this case, extra costs due to increased safety levels are not transferred to the end user).

Get more of Elevator World. Sign up for our free e-newsletter.