The progressive establishment of a new elevator code in China draws comparisons and contrasts with parts of U.S. code.

by Ning Li, Yihui Ruan, Chi Chen, Wei Li and Mingtao Chen

Unabated economic expansion is creating a huge market for the elevator industry in China, while offering opportunities for industry development like never before.

Since joining the International Organization for Standardization Technical Committee (ISO TC) 178 for elevators, escalators and moving walks, China has taken an active part in ISO proceedings, while maintaining lively communications and continuous exchange with the elevator standardization organizations in Europe, North America and the Asia-Pacific region. In so doing, China is becoming familiar with the technical standards in force in the more advanced countries and regions. Following the demands of a market economy, China is reorganizing its system of standards. This system was, for many years, strongly influenced by state planning. The country is establishing a new system of elevator standards step by step that will comply fully with international standards.

China’s technical standardization committee for elevators is observing developments in international standards with great interest. It feels the most important technical standards originate from the international or European norms. The GB 7588-2003 Safety Code on Lift Manufacturing and Installation corresponds to EN 81, for instance. GB 16899 Safety Rules for the Construction and Installation of Escalators and Moving Walks is comparable to EN 115. A few other government standards are still being compiled — once again, in close emulation of international norms. A system of standards such as this gives the most advanced elevator products easier access to the Chinese market. At the same time, Chinese elevator manufacturers can also enjoy more advantages when entering their products into the international market.

Standards Differences

The Chinese elevator standard is 99% identical to the European EN 81. There are 33 national standards for elevators in China, often referred to as “GB standards.” They are consistent throughout China and are developed for technical requirements.

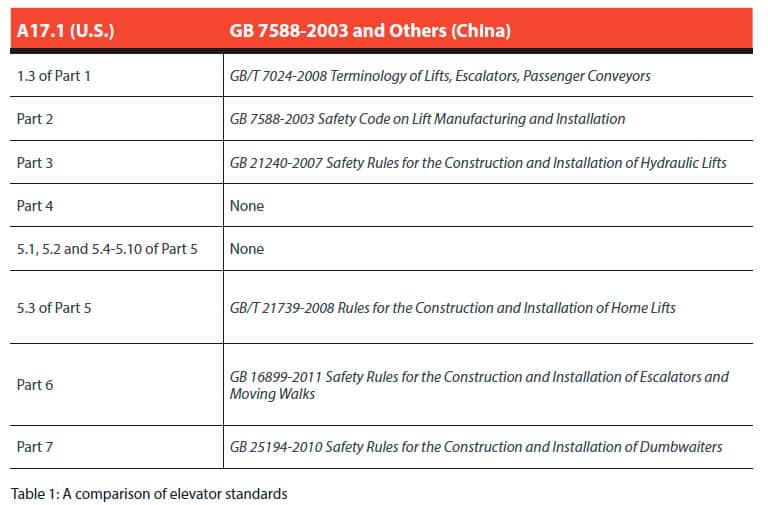

In the U.S., ASME A17.1 covers main safety and component standards for China. The one-to-one correspondence relationship between A17.1 and elevator standards for China is shown in Table 1.

A17.1 lists equipment it does and does not cover. The extent of A17.1’s application is definite. For China, GB 7588 does not apply to hydraulic elevators and service elevators but does apply to passenger elevators, bed elevators and goods elevators with electric traction or positive drive. China’s national standards for hydraulic elevators only list the equipment it does not cover.

A17.1 describes capacity and data-plate requirements in detail, stating that every elevator shall be provided with a capacity plate and a data plate permanently and securely attached. The capacity plate shall be located in a conspicuous position inside the car. It shall also indicate rated load of the elevator and information on its transport on an industrial truck. Data-plate location, size of characters, indicating and material information, parameters of rope, etc. are also outlined in this code.

In GB 7588, the rated load of the lift (in kg and persons) is to be displayed in the car. All labels, notices, markings and operating instructions shall be indelible, legible and readily understandable (and aided by signs or symbols, if necessary). They shall be untearable, of durable material, placed in a visible position and written (at minimum) in the language of the country where the lift is installed. A metal plate shall be securely attached to each safety so as to be readily visible and shall be marked in a legible and permanent manner with letters and figures.

There are some indicating requirements of marking plates for safeties in A17.1. These include the height of letters and figures, the type of safety, the maximum tripping speed for which the safety is permitted, the maximum weight for which the safety is designed and installed to stop and sustain, the force required to activate the safety or rope-releasing carrier (if provided), and the manufacturer’s name or trademark.

In GB 7588, a data plate shall be affixed to safety gears indicating:

- The name of the manufacturer of the safety gear

- The type of examination sign and its references

Rail lubricants or coatings that will reduce the holding power of the safety or prevent its functioning shall not be used in accordance with A17.1. A metal plate as required shall be securely attached to the car crosshead in an easily visible location and shall carry the notation of selected lubricants. If lubricants are not to be used, the plate shall so state. If lubricants other than those recommended by the manufacturer are used, a safety test shall be made to demonstrate that the safety will function. In GB 7588, just the category and specification of the rail lubricants shall be stated in certificate of type test for safety gear (if rail lubrication is required).

In A17.1, the emergency terminal devices include those that reduce speed, which shall not apply the car safety. Only the speed of the car shall be reduced to a point at or below the buffer’s rated striking speed. The type of speed-reducing device, including safety gear, is not outlined or restricted.

On passenger elevators, a stop switch, either key operated or behind a locked cover, shall be provided in the car and located in or adjacent to the car operating panel in the requirements of A17.1. The key is operated only by authorized persons. In GB 7588, a stop switch is not permitted to be installed in the car.

Jumpers shall not be used to bypass hoistway-door or car-door electric contacts in A17.1. GB 7588 doesn’t mention that jumpers are not prohibited to bypass hoistway- or car-door electric contacts, so inspectors can make use of jumpers to bypass the contacts to operate movement of the car, which is very dangerous.

For elevators not fully enclosed, protection at least 2,400 mm high shall be provided on the hoistway sides located 1,500 mm or less from elevator equipment to areas accessible to persons other than elevator personnel. GB 7588 does not refer to the maximum horizontal distance from elevator equipment to areas accessible to those other than elevator personnel.

A17.1 stipulates vertical distance between important structures or parts of the car top (such as sheave or crosshead) and the lowest part of the overhead structure or other obstruction; however, other ordinary structures or parts of the car top are not so important that they are required not to contact with the lowest part of the overhead structure or other obstruction. Top-of-car clearances are different according to whether such assembly appears around the crosshead or not.

GB 7588 makes unified provisions on the vertical distance between any structure or parts of the car top and the lowest part of the overhead structure or other obstruction. Also, GB 7588 does not consider jump out of the car or counterweight as a result of car or counterweight buffer engagement or safety application.

A17.1 mentions that top-of-counterweight clearances refer to such items as the bottom car runby, stroke of the car buffer used or the remaining stroke. GB 7588 does not mention these clearances, only requires that when the car rests on its fully compressed buffers, the counterweight guide-rail lengths shall be sufficient to accommodate a further guided travel expressed in meters, of at least 0.1 + 0.035 v2.

A17.1 states that a stop switch or a disconnecting means be accessible and visible from the point of access to machinery spaces or control spaces for each elevator. GB 7588 only stipulates that a stopping device shall be installed in the pulley room, close to the point(s) of access.

The number of operating devices for inspection operation can be more than nine in related items of A17.1. Also, the operating devices can be set in the car. The number of operating devices for inspection operation shall be no more than two in GB 7588. The operating devices cannot be set in the car in any case.

Conclusion

From this study, we can see many differences in the Chinese and U.S. codes. It is useful for manufacturers in these countries to know the differences. In this way, those from one country can design and manufacture equipment according to the differences and have an easier time exporting it to the other country.

Get more of Elevator World. Sign up for our free e-newsletter.