In this Readers Platform, your author talks about home-elevator safety and how his company’s products supply solutions to the problem.

With news of small children being severely injured or even killed in some types of home elevators, home elevator safety is a hot topic these days. Some incidents are due to poor maintenance, bypassed safeties that allow an elevator to run when it should not or poor installation resulting in a large gap between hoistway door and car gate.

Some issues can be addressed during hoistway construction. Contractors can refuse to give in to owners who insist on aesthetics over safety. A door set into the jamb to minimize the open space between door and gate, where a small child can become trapped, may not look consistent with other doors in the house, but could save a life. This may seem trivial, but in a multimillion-dollar home where every detail is planned and demanded by owner, architect and contractor, changing a doorjamb may be a US$10,000 proposition in material alone. Standing your ground about a 1-in. difference in specifications can be tough, but it could save a life.

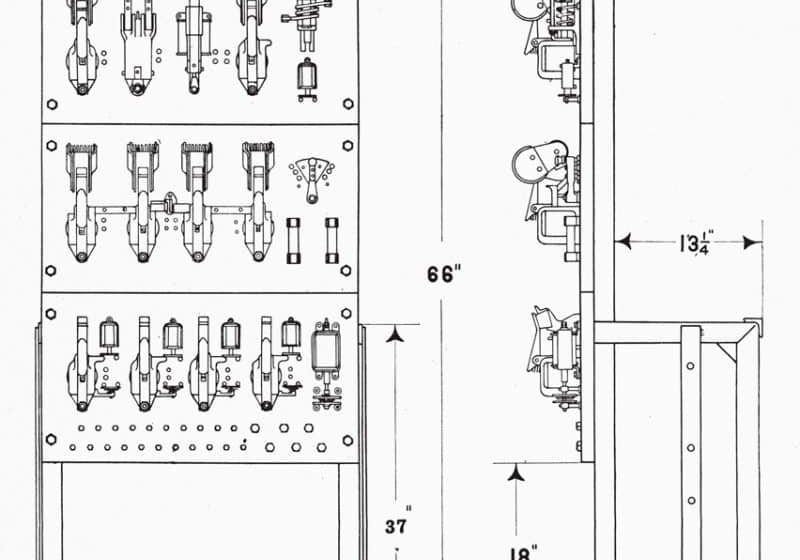

Ensure the hoistway is not only plumb and square, but that doorsills do not protrude farther than specified into the hoistway. This will allow running clearances to be minimal and consistent. Going ahead with a hoistway installation that is not plumb may endanger lives. Besides excessive strain and wear on the system that can cause noise, premature failure and possibly entrapment, the varying gaps between the sill of each floor landing and cab can result in setting the cab farther back on the sling.

If one floor sticks farther into the hoistway than the others, it results in a larger gap in all other stops. At this point, some contractors install a longer sill on those floors to close the running clearance, but this fails to address the fact that the open space from door to gate has increased. In properly functioning home elevators, this gap is where the majority of incidents occur.

Nightmare Scenario

Imagine a six or seven year old playing hide and seek with friends. She is just tall enough to reach the call button in the hall. The door lock cycles, and the child opens the door, puts her back to the accordion gate and manages to close the door. The door lock de-energizes, and the child is now trapped, or the lock latches on the catch before the door is fully closed, allowing more room than the measured 5 in., plus the pockets created by an accordion gate. The child may be trapped, and the door may not even be closed completely.

The child is unable to reach the manual release on the door lock, and at that age, unlikely to even know there is one or how to operate it. As a result, she is unable to open the accordion gate. Her hide-and-seek playmate presses the call button on another floor, and tragedy results.

In this imagined scenario, there is nothing wrong with the system’s interlocks or mechanics. The fault lies in the gate that can flex and create pockets large enough to accommodate a child. There are standards to try to keep this from happening, like the 3-5 in. rule and the use of offset pins on accordion gates to minimize the space created when a gate is extended. However, because of issues such as hoistways built out of plumb or owners demanding aesthetics over code, these tragic events occur several times a year throughout the world. Jurisdictions in the U.S. state of Georgia have already banned the future installation of accordion gates, leaving some companies struggling for options for their customers.

Safety Options

At Rocky Mountain Elevator Products (RMEP), headquartered in Grand Junction, Colorado, we have developed products to address these situations. For door locks that are sloppy, RMEP’s Smart Lock is simple to install. While it operates on the same principle as other locks, the tolerance for latching is very close. This means it will not lock the door until the door is closed and will not allow the elevator to run until a plunger, separate from the latch itself, is depressed by the door. When installed properly, the system will not run unless the door is completely closed, preventing a child from becoming trapped in the instance of a locked but ajar door.

Filling the open space with a space guard is an easy and inexpensive way to ensure the door cannot be closed if anything is filling the open space. RMEP’s door-mounted space guard is adjustable for depth and width to match the needs of any properly installed door and gate. Installing a space guard will keep children from closing the door on themselves but can be an eyesore if mounted to a teak or mahogany door, even if it is seen only when the door is open. However, there are options for those who do not wish to have a space guard sticking out when the hoistway door is opened.

Light curtains are nothing new. They install on the cab or back of the hoistway on either side of the door. Unfortunately, they are expensive, and, in some instances, there is no place for a light curtain and brackets to be mounted in the hoistway or on the cab. RMEP has developed a low-profile, infrared system that can be installed during a routine installation or retrofitted into an existing system. The infrared system will interrupt an existing safety circuit and prevent an elevator from moving while the beam is broken. It is installed into the doorjamb itself, protruding only 1/16 in., and mounted no higher than 32 in. Anyone tall enough to activate the call button and open and close the door would interrupt the operation of the elevator since his or her body will be blocking the beam in the open space itself. This solution is inexpensive compared to a full light curtain, can be retrofitted into existing systems and is visually unobtrusive.

Lastly, we would like to address the accordion gate – that floppy, expensive and finicky operating device that has been a mainstay, but also a bane, of the home elevator. Accordion gates change width as they are opened or closed and create areas of open space that can allow a child to close the hoistway door and become trapped between the accordion gate and hoistway door. Folding panels increase the open space as the gate closes, and the design introduces pockets that can be around 3-1/2-in. deep, allowing a head, shoulder or arm a place to squeeze into and allowing the outer door to close. In the past, some accordion-gate manufacturers tried to lighten the gate and reduce cost by making the hinges non rigid, and an adult could displace the door by leaning onto it, thereby closing the hoistway door.

RMEP has developed a lightweight and rigid wraparound gate that will eliminate such concerns. The gate is capable of opening a full 34 in. on just a 41-in.-wide platform. This rigid panel gate will allow for minimum running clearances with a proper and plumb hoistway.

Get more of Elevator World. Sign up for our free e-newsletter.