Company Spotlight: Adams Elevator Equipment Co.

Jul 1, 2015

Innovation has always been the cornerstone of Chicago supplier’s philosophy.

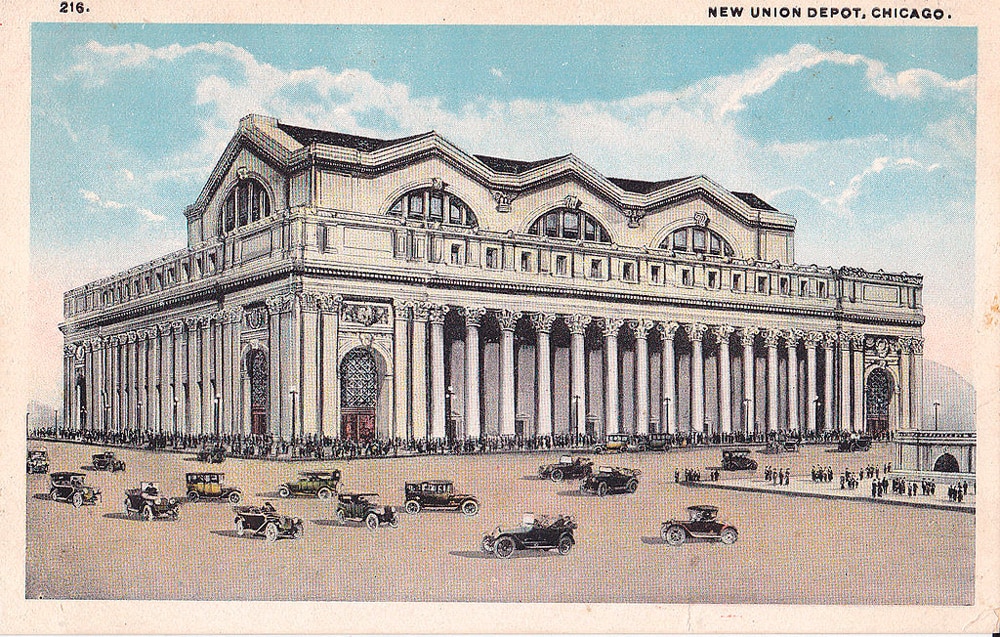

Marking its 85th anniversary in 2015, Adams Elevator Equipment Co. has come a long way from when it was founded by two enterprising mechanics at Chicago’s Union Station who began to manufacture their own elevator parts after being frustrated by a lack of reliable outside sources. What was then Adams Manufacturing Co. had the busy train station as its first and primary customer. It supplied the station with a handful of key elevator parts made in a small storefront opened in 1930 at the intersection of Clinton and Madison in the heart of downtown Chicago — a spot that is today dominated by glittering office towers.

Over the next decade, the two entrepreneurs, James Adams and Joseph Coulombe, oversaw sales and manufacturing, respectively, at what was one of the first independent elevator parts suppliers in the U.S. Inventory and customers have grown exponentially since then. General Manager Rick Stumpf elaborates:

“Since those early days, several milestones have marked Adams’ path from two-man shop to global player. In the early 1960s, ownership changed hands, and the company became known as Adams Elevator Equipment Co. The product line exploded to include replacement parts for every major OEM, inspiring a move to a more spacious, suburban facility in Skokie, Illinois.

“In 1981, Adams had its next breakthrough with the introduction of its patented Survivor® pushbuttons. The product line ballooned, and Adams Elevator stood alone as the undisputed leader in parts and fixtures. More and more parts paired with more and more demand required the gradual addition of more locations until 1994, when all operations were consolidated into a 150,000-sq.-ft. facility in Niles, Illinois.”

Adams still provides elevator parts to Union Station, but through the station’s service contractor. Primarily working in the U.S. and Canada, Adams counts among its customers equipment owners, government agencies, universities and hospitals. Elevator service contractors are the company’s bread and butter, however, Stumpf states.

Adams team members stay connected to their core customers by, among other things, actively supporting and participating in industry trade shows and other events including ones put on by the National Association of Elevator Contractors, Canadian Elevator Contractors Association, NAESA International, International Association of Elevator Consultants and the Elevator Escalator Safety Foundation. “The interaction and networking at these events complement the regular customer contact we have through our sales team,” Stumpf observes.

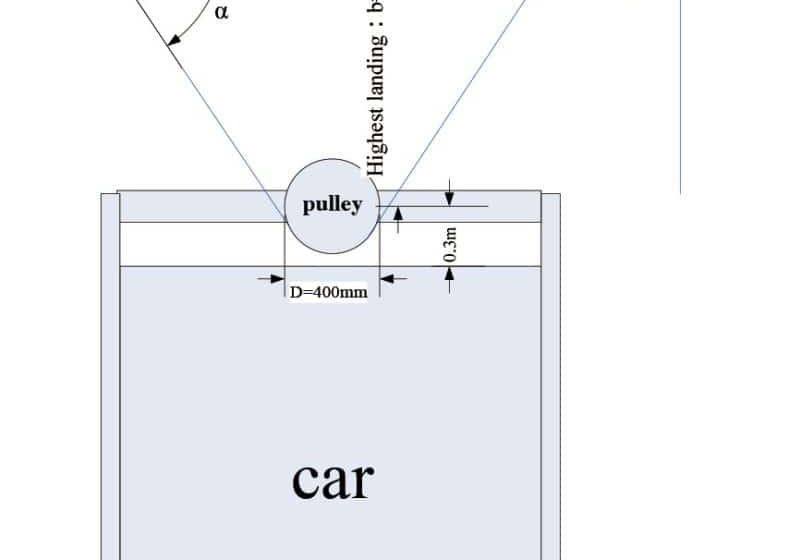

Adams’ growth can be attributed to identifying and adding products in response to customers’ evolving needs, Stumpf says. Products address service, maintenance, modernization and repair and include an array of exclusive items: the original Survivor pushbuttons, GateKeeper™ light curtains, the LifeJacket® plunger/gripper system, HatchLatch® door restrictor, SilentMove™ Digital Landing System, SafetyStrip® escalator skirt brushes, and safety barricades and cab handrails made by Lustre Products.

What was then Adams Manufacturing Co. supplied Chicago’s Union Station with a handful of key elevator parts made in a small storefront opened in 1930 at the intersection of Clinton and Madison in the heart of downtown Chicago.

Numerous repeat customers have come to rely on these products. For example, John DeVincentis, manager of Coastal Elevator Service Co. in Jacksonville, Florida, estimates he has installed approximately a dozen LifeJacket systems over the years. DeVincentis recalls a particular instance when the system came to the rescue:

“We got a call from our customer, a nursing home, saying that something triggered the LifeJacket locking system. When we examined the issue, we discovered that there was a fluid leak in the jack system and, therefore, a loss of pressure. The LifeJacket sensed this and did its job, ceasing elevator operation.”

Adams explains that, while the nursing-home incident was not considered a catastrophic failure of the cylinder, gone undetected it could have led to a life-threatening situation. The company elaborates:

“Elevator inspections do not include direct inspection of the in-ground cylinder, and while other critical components may pass inspection today, they may fail tomorrow. The LifeJacket is designed to catch any unseen or unexpected problems that may lead to hydraulic failure — at a fraction of the cost of a cylinder replacement. These issues include valve failure, corrosion, electrolysis, cylinder rupture and all other types of hydraulic failure that result in loss of pressure.”

Demand for products such as the LifeJacket and Adams’ ability to respond to such demand are among factors driving its growth. Stumpf points out that the more installed units there are, the more business there is for companies like Adams. “The installed base is constantly increasing around the world,” he notes, adding that besides its core customers in the U.S. and Canada, it has repeat customers in South America, Europe, the Middle East, Asia, Africa and Australasia. A few years ago, Adams introduced its online catalogue, shop.adamselevator.com, which has also increased business.

There are approximately 50,000 items available in Adams’ Maumee, Ohio, distribution facility on any given day, which inevitably results in having 95% of the parts its customers need available, ready to ship. Approximately 20,000 orders flow out of the center each month. Adams’ salespeople have decades of experience each, and that makes transactions easier for customers, according to Stumpf.

The product line exploded to include replacement parts for every major OEM, inspiring a move to a more spacious, suburban facility in Skokie, – Adams General Manager Rick Stumpf

So what is the company’s biggest challenge moving forward? “Staying ahead of industry trends and identifying new technologies that will provide new solutions to the ever-changing demands of the elevator service and maintenance industry,” Stumpf says. Adams has a strong track record in this regard, he states, noting the company has been a “proving ground” for industry innovators who not only conceived many of the items that make up the current inventory, but are also leaders in their own right throughout the industry. Stumpf is confident Adams is ready for anything the future might throw at it, saying:

“As we celebrate our 85th year, we can proudly say that our constant product innovation and progress in areas such as e-commerce and logistics has Adams primed for whatever demands the rapidly evolving global marketplace presents our customers.”

Get more of Elevator World. Sign up for our free e-newsletter.