Conserving Resources

Sep 1, 2020

Roland Bechmann (RB), managing director and partner at international engineering consulting firm Werner Sobek AG, shares insights on sustainable design and VT-related aspects with your author (SSP).

SSP: How would you describe your approach toward sustainable design? What are its basic principles?

RB: Building and operating our built environment accounts for 39% of all emissions of climate-damaging gases, often referred to as greenhouse gases. Thus, the building industry bears a huge responsibility for the climate crisis. At the same time, many people in the world lack access to decent accommodation, a healthy work environment, schools, hospitals, etc. This means we have to build more, not least because the world population is continuing to increase. Our approach to sustainable design, therefore, is to build more with fewer resources and emissions. This includes emissions released during the production phase, i.e., the extraction and manufacturing of building materials and components, as well as the construction process itself. These activities, along with maintenance and disposal, account for “embodied emissions.” When considering an office building with high energy-performance standards over its lifespan, only about half of the emissions are accounted for by the building’s operation. The other half can be classified as embodied emissions.

SSP: What themes set your project designs apart?

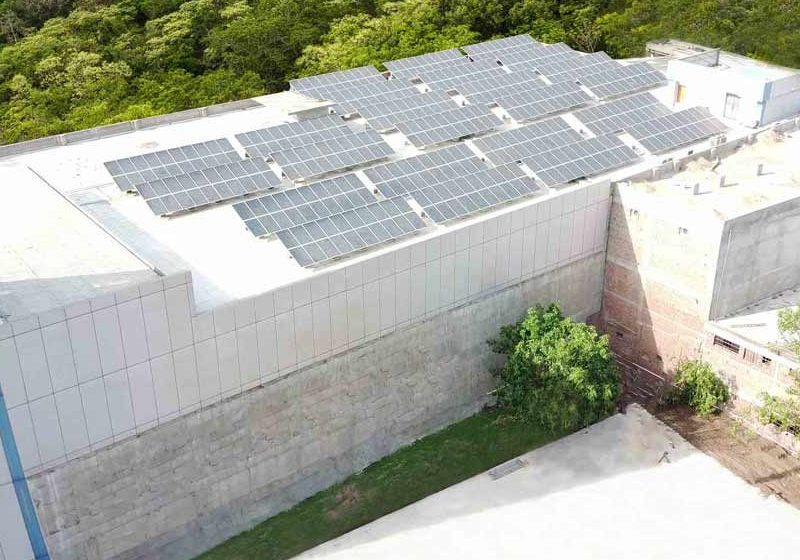

RB: Our roots lie in the field of lightweight engineering, so we place a strong focus on minimizing the materials needed to construct a building. Equally important for us are materials that are recycled, following the principles of lightweight design and the circular economy. In addition, we track all emissions potentially caused by a building from the beginning of the design process and use this tracking to reduce gray and operational emissions. As a result, we can design buildings that emit about 30-40% less than typical buildings. To make them fully carbon neutral, we then implement sustainable energy production elements, such as photovoltaic cells.

SSP: What importance do you give to vertical transportation (VT) when designing projects?

RB: Especially in tall buildings, elevator design and the choice of the elevator system are crucial for reducing emissions. First because of their operational energy demands, but just as much because of their space requirements. The latter often govern the entire floorplan layout and, therefore, the overall building design. At the same time, the social aspects of a sustainable building design are strongly influenced by the choice of VT. How do people get to their workspaces? What is the atmosphere like when strangers meet?

SSP: What challenges and opportunities are faced vis-à-vis sustainable design when it comes to incorporating VT?

RB: The challenges and opportunities are in finding a system that allows building visitors to feel good while using it, while finding a system with limited emissions.

SSP: Can you name some specific projects incorporating VT that are role models of sustainable design and could be emulated in India?

RB: We designed a test tower in Rottweil, Germany, for thyssenkrupp. In it, thyssenkrupp is running the first MULTI, a ropeless elevator that fully relies on magnetic engineering. Once systems like this are on the market, they have the potential to totally change building design.

SSP: What are your observations regarding the approach toward sustainability in design, materials, etc. when it comes to projects in India?

RB: All that we have discussed before about minimizing operational and gray emissions is extremely relevant to India due to the high demand for good construction. For India, I see a strong potential in focusing on buildings that have a high level of prefabrication and that use local and sustainable materials, such as timber.

SSP: How can the benchmarks of sustainable design incorporating VT be raised? What are the essential elements and processes?

RB: Rather than having different benchmarks, we should focus on monitoring emissions over the entire lifecycle of a building. Relating this figure to the square meter gives us a number that is a simple benchmark and easy to compare. This number should be just as important as a sustainable rating system, such as Leadership in Energy and Environmental Design.

SSP: What trends do you foresee in workplace design?

RB: The trend of creating open and flexible workspaces will continue, especially since the COVID-19 pandemic has made working remotely even more acceptable.

SSP: Will advanced technologies change the way lobby areas, elevators and escalators are positioned and operated?

RB: Rather than having one central lobby for a building, designs will change to multiple access situations in the elevator system — maybe on different floors, maybe connecting to sky bridges. If systems like MULTI evolve, cabins will move horizontally and vertically, which will allow designers to connect them directly to the public transportation.

SSP: Social distancing is going to be a key aspect and is expected to increase waiting time for elevators. How can this be managed effectively using design?

RB: Waiting time for elevators was an issue even before the necessity of social distancing emerged. Unfortunately, it has never been experienced the way it could and should be: a brief period in a busy day that gives you time to relax or socialize. From my perspective, we will see a combination of digital tools that provide a much better prediction of demands, much faster systems and improved lobby design and waiting-time scenarios.

About Roland Bechmann

Roland Bechmann is managing director and a partner in international engineering consultancy Werner Sobek AG. Born in Berlin, Bechmann moved to Hanover, Germany, where he studied structural engineering. Upon earning his diploma in 2000, he began working at Werner Sobek Stuttgart and rose to be appointed principal, then general manager, before accepting his current position. Among his duties, Bechmann leads the department of competitions and is a specialist of project management, lightweight structures and steel construction. He has extensive experience in various important high-rise projects, such as ADAC Headquarters in Munich, Germany, and the 400-m-tall Olympic Tower in Nanjing,China. He has led other complex and large-scale projects, such as World Expo 2017 in Astana, Kazakhstan, and the underground railway station in Stuttgart. Since 2013, Bechmann has been a country representative with the Council on Tall Buildings and Urban Habitat and, since 2017, a member of the Baden-Württemberg Chamber of Engineers Committee for Competitions and Contracting.

Get more of Elevator World. Sign up for our free e-newsletter.