The process of creating and using a Maintenance Control Program is explained.

Beginning with the publication of the ASME A17.1-2000 Safety Code for Elevators and Escalators, a written Maintenance Control Program (MCP) is required to be in place to maintain the equipment in compliance with Section 8.6. From a simple viewpoint, a document that complies with Requirement 8.6.1.2.1 may look similar to the maintenance log typically found in the elevator machine room. However, seldom will any other existing document, i.e., maintenance and testing logs, manufacturers operation and testing guide, or a generic standard maintenance tasks and procedures document, serve as a written MCP.

Compliance with the requirements contained in ASME A17.1/CSA B44 Safety Code for Elevators and Escalators Safety can sometimes be a painstaking task, not necessarily in its entirety, but often in part. Compliance with many of the requirements can be difficult, firefighters’ service operation, for example. A17.1/CSA B44 is an ever-evolving document. Often, after there is a complete understanding of the purpose of the requirements, compliance is easier to achieve.

The Process

ASME A17.1/CSA B44-10, Requirement 8.6.1.2.1 prescribes an MCP shall be provided, with the document in compliance with Section 8.6. Requirement 8.6.1.2.1 is followed by Requirement 8.6.1.2.1(a)(1) (a)-(f), which goes on to establish the criteria upon which the MCP shall be based. It states, in part, the maintenance procedures and intervals for the equipment shall be based on:

- Equipment age, condition and accumulate wear

- The design and inherent quality of the equipment

- Equipment usage

- Environmental conditions

This requirement makes each MCP unique to the equipment for which the MCP is created. Although many elevators in a single location may have the same design, capacity, speed and usage (all of the above characteristics), an MCP is required for each unit.

For a better understanding of what is required when creating a written MCP, the following breaks down Requirement 8.6.1.2.1:

- “A written maintenance Control Program shall be in place . . .”

- “To maintain the equipment . . .”

- “In compliance with Section 8.6.” The primary aspect of the task of creating a code-compliant MCP.

8.6.1.2.1 also requires another document that complies with all the requirements contained in Section 8.6. However, not all the requirements contained in 8.6 are going to apply to all types of equipment. A17.1-2010/CSA B44-10, Section 8.6 includes four subsections: “Maintenance,” “Repair,” “Replacement” and “Testing.” “Maintenance” is then broken down to prescribe requirements based on the type of equipment (i.e., electric and hydraulic elevators, escalators, moving walks, etc.). Therefore, the word “applicable” comes into play when creating an MCP. It is doubtful that a certified inspector is going to violate an MCP document for an electric traction elevator, because the document failed to include the means and methods for skirt/step index testing for escalators. Thus, requirements that apply to escalators or moving walks need not be included in an MCP for an electric or hydraulic passenger elevator. Second, many of the requirements of 8.6 are basic in scope. Examples include:

- Requirement 8.6.1.6.7 requires that damaged or missing signs be replaced.

- Requirement 8.6.1.5.1 states the code data plate will comply with 8.9.

- Requirement 8.6.2.1 states repairs shall be made with parts of at least equivalent material, strength and design.

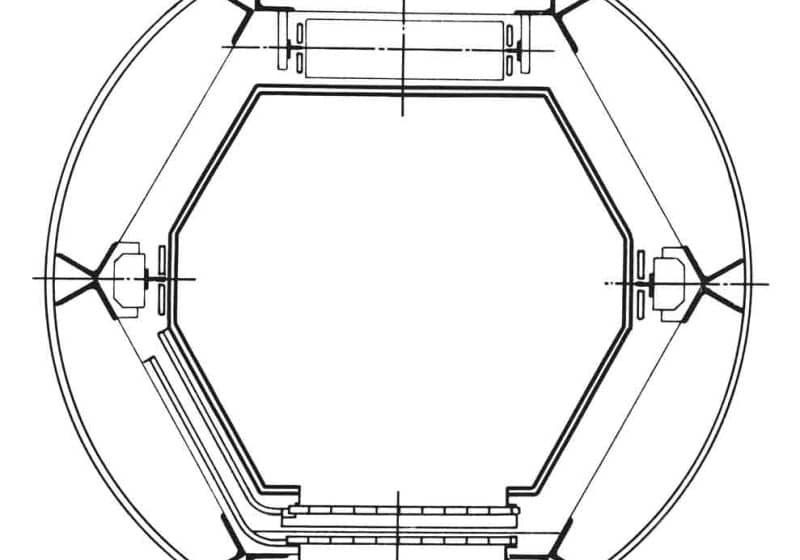

Just like many tasks that seem complicated at first, the task of creating a written MCP becomes easier once Section 8.6 is understood in its entirety. In the aforementioned examples, we stated that Requirement 8.6.2.1 requires replacement parts be of an equivalent material, strength and design. Most will agree the maintenance service log will probably indicate when brake linings are replaced on an electric elevator, but it is unlikely to clearly state the material, strength, design or manufacturer of the linings, unless, of course, it is modified to include written documentation that indicates compliance with Requirement 8.6.2.1: Equivalent Material, Strength and Design of Replacement Parts.

An excerpt from John Koshak’s Maintenance on New Technology Designs (available at www.elevatorbooks.com), provides, in detail, the many factors that must be considered when creating a written MCP for the many different types and designs of equipment, including machine-room-less elevators (ELEVATOR WORLD, May 2010). The article illustrates comparisons between the limited amount of information typically found in a maintenance check chart; the vast amount of technical knowledge, training and experience needed to properly perform maintenance, repair and adjustment on a wide variety of old and new vertical-transportation equipment; and the technological advances that have taken place in the industry. Koshak’s publications provide valuable and beneficial information that should be studied by industry technicians and professionals.

Starting Point

Requirement 8.6.1.2.1 (a) (1) (a)-(f) provides a “starting point” for creating a code-compliant written MCP. First, the person or company creating the MCP should have comprehensive knowledge of all the aforementioned aspects of the equipment for which each MCP is created.

The existing standard maintenance tasks and procedures and/or the manufacturers service, adjustment and testing manuals may not be substitutes for a written MCP; however, those documents may prove to be valuable to creating one. Additionally, the call-back logs, testing logs, manufacturers’ recommendations for Safety Integrity Level-rated devices and any unique procedures required for testing and servicing the equipment (and, obviously, the applicable A17.1 code edition) will all be valuable resources when creating the MCP, especially in regard to equipment manufactured and installed using new technology.

Additional important documentation is the installation date, the code at the time of installation and any alterations that have taken place since the equipment was installed. This information directly relates to Requirement 8.6.1.5 of the MCP, which requires having a code data plate that complies with Section 8.9.

Similar to the requirement for having an MCP, when the requirement for a code data plate first came into effect, many elevator companies were unsure how they would comply. To assist with the requirement for having a code data plate, codedataplate.com was introduced to the vertical-transportation industry. The website was created 10 years ago by John Rearick, consultant and longtime industry veteran. The company provides a valuable service that assists contractors with compliance by researching the codes and code editions based on the information provided by the contractors, especially in regard to alterations performed on the equipment. The website also provides various other data plates and inspection tags specifically as required by the code. It assists vertical-transportation companies and service contractors with the tools needed to achieve compliance in regard to having a code data plate for every elevator they service.

In summary, the first step in creating a code-compliant written MCP is to gather the basic information about the equipment (or at least have the information available for reference) and be prepared to utilize the knowledge of person(s) familiar with the equipment – typically this will be the technicians who service the unit(s). All are valuable documents when creating the MCP for each unit, individually.

Documenting the Proper Information

As mentioned, existing documents will likely become part of the task of creating an MCP. However, considering the vast amount of information included with these materials, it is important to know what information should be included in the MCP document and how it pertains to the requirements of Section 8.6. By reading and understanding what each (applicable) requirement of Section 8.6 requires for compliance, those responsible for creating a written MCP can more accurately and efficiently provide the information required. Examples include:

- Requirement 8.6.4.5.1 requires safety devices be lubricated and free of rust, corrosion and dirt that can interfere with the operation of the safety.

- Requirement 8.6.4.5.1 does not necessarily require the MCP document to include the makeup of the cleaning solvents or types of cleaning tools that will be used. It is not asking if the work will be provided by a team or by the individual route mechanic. Nor is it necessary to document the company safety procedures in regard to accessing the safety components.

- Requirement 8.6.4.5.1 requires the service company confirm in an MCP that the safeties be kept lubricated and free of rust, corrosion and dirt that can interfere with the operation of the safety.

For equipment operating in a corrosive environment, Requirement 8.6.1.2.1(a)(1)(d) indicates that if a unique or special process or product is required to maintain the cleanliness and lubrication of the safeties, that process or product should be included in the written documentation that applies to Requirement 8.6.4.5.1, including the frequency of service/maintenance actions.

WMCP Forms

Similar to the way codedataplate.com created a valuable tool for service companies to use for achieving compliance with the requirement to have a code data plate, a new product exists that also assists service companies in creating a code-complaint MCP.

Written Maintenance Control Program, (WMCP) forms created by Vertical Assistance LLC and available at www.elevatorbooks.com provide such a tool. Each WMCP form is uniquely applicable to equipment type. Additionally, each form contains requirements specific to the applicable code edition, 2003 through 2010.

WMCP FORM E-100 (2010)

The WMCP forms are downloadable files that service companies can use to indicate (in writing) how their maintenance, repair, replacement, testing and adjustment actions will conform to each applicable code requirement in Section 8.6. The WMCP forms establish a foundation for creating an MCP, as opposed to trying to adapt or configure other documents into one. After completing the WMCP document, it can be printed and stored in the appropriate location for the benefit of the inspectors expecting to find a code-compliant MCP. As conditions change with the equipment, the file can be revised as needed. What makes WMCP forms especially valuable is that each form is designed to be unique to the equipment in question.

Combining Standard Maintenance Tasks and Procedures with WMCP Forms

It is possible that service companies’ standard maintenance tasks and procedures already address a large portion of the requirements of Section 8.6. However, it remains a requirement that an MCP is in place for each individual unit and be unique to the equipment for which it is created. In this case, the two documents may be combined into one document that meets the MCP code requirements and serves as a document for technicians to follow when performing routine and periodic maintenance and testing tasks.

An example of how a service company’s standard maintenance tasks and procedures were joined together with the WMCP forms was achieved by Elevator Compliance HT Solutions Inc., a vertical- transportation consulting and inspection company based in Gulf Breeze, Florida, and owned by Bill Reardon. Reardon explains how he assisted a client with creating an MCP for all the units the corporation services, in partnership with their overall standard maintenance tasks:

“One of the services provided by my company is to build standard processes with efficiency and forward motions at the forefront. I have found within my 34 years of experience, vertical-transportation-industry task management allows for a 90% standard and 10% custom, as a rule of thumb. This seems to hold true for all facets of the industry. Working specifically on maintenance tasking, it is important to always plan flexibility [into] your standards. Working with Vertical Assistance and [its] WMCP templates has brought solutions to a complex task. The template offers the complete buffet line of code standards required, but also offers a live feature to easily customize that remaining 10% of the units or property personality. The WMCP is required by code to be ‘unit and property specific’ and capture the differences from standard. To my knowledge, there is no other WMCP template of its kind. It has been a pleasure working with Vertical Assistance and their documents. When you are faced with developing WMCPs for thousands of units, you certainly appreciate the user-friendly design. If you have any questions of my experiences using these templates, please e-mail me at [email protected].”

Creating a code-compliant MCP may not be a simple task or process. However, the task becomes easier to achieve upon having a clear understanding of what the MCP must contain, based on the requirements of Section 8.6. By utilizing the proper tools and resources available, creating a code-compliant MCP is less difficult to achieve than it may initially appear.

There is no question that creating a written MCP document raises the bar of responsibility for companies. There is an ongoing discussion as to who owns the document. Regardless, Requirement 8.6.1.2.1 is not intended to be a safety-code requirement that, by default, exposes proprietary information an organization employs in the competitive vertical-transportation service industry. It prescribes a minimum level of maintenance, repair, replacement, adjustment and testing requirements that must be adhered to as part of the overall purpose of A17.1, “To provide for the safety of life and limb, and to promote the public welfare.” Rather than be placed in a reactive position where an MCP must be created to clear a violation cited by the inspector, it is in the best interest of the service company (and, especially the owner of the equipment) to be proactive in creating a document that will be recognized as a code-compliant MCP.

References

[1] John Koshak, Maintenance on New Equipment Designs – Application of MCP Requirements for Elevators Including MRLs.

[2] John Koshak, “Continuing Education: Maintenance, Maintenance Control Program” (EW, May 2010).

[3] ASME A17.1/CSA B44 Safety Code for Elevators and Escalators, Requirement 8.6.1.2.1 (2003-2010).

[4] ASME A17.1-2010/CSA B44-10 Safety Code for Elevators and Escalators, Requirement 8.6.1.6.7, Requirement 8.6.1.5.1, Requirement 8.6.1.2.1(a)(1)(a)-(f), Requirement 8.6.1.5 (2010).

[5] ASME A17.1b-2009/CSA B44 09 Safety Code for Elevators and Escalators, Requirement 8.6.1.4.1.2 (2009).

[6] American Society of Mechanical Engineers WMCP Forms E-100, H-200, ESC-100.

Get more of Elevator World. Sign up for our free e-newsletter.