Industrial forensic chemistry uncovers elevator failure caused by oils.

When your elevator components fail, do you know the cause? If you manage your company’s hydraulic elevator systems, you probably know more about the components than anyone else. Even then, failures can still leave you perplexed as to where to look first.

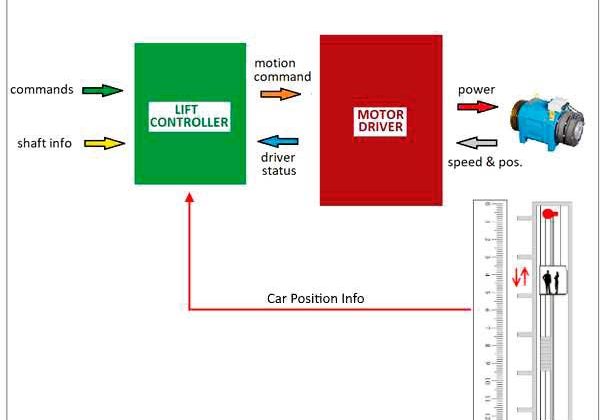

Valves, motors, pumps, power units, etc. are all components that need to be routinely checked for efficient and safe operation. This includes a proper lubrication ritual for all necessary parts of the elevator system. When a failure does occur, elevator managers need to be equipped with the tools or resources to uncover and remediate the issue for continued safe elevator performance. This is sometimes a challenge, as components within elevator systems can be difficult to reach, and the downtime needed for a full investigation can seem too inconvenient for the necessary investment of time and effort.

What Are Hydraulic Oils?

A common practice in hydraulic elevator lubrication involves the use of hydraulic oils. Two of the most common are anti-wear and vegetable-based hydraulic oils.

Anti-wear hydraulic oils are derived from refined paraffinic base oils and fortified with an inhibitor system to ensure proper performance for hydraulic applications. Anti-wear hydraulic oils are generally recommended for use in all hydraulic systems.

Vegetable-based oils are natural esters made up of fatty acids, which determine the oil’s viscosity, pour point and resistance to oxidation. These bio-based fluids are manufactured with specific additives and base oils that make them appropriate for use in a variety of component applications.

While vegetable-based and anti-wear fluids are popular and recommended choices for hydraulic systems, they can pose significant problems if not evaluated properly to fit the design and structure of the application for which they are being used.

Forensic Chemistry and Component Evaluation

When evaluating a failure within the elevator system, it’s important to consider all possible causes. It can be difficult to pinpoint the exact cause, as elevator maintenance providers often opt to replace lubricant for a quick fix, rather than fully investigate. There are, however, third-party companies that specialize in hydraulic elevator remediation and can offer a comprehensive method of deducing failure causes and effects.

Take, for example, a specific hydraulic elevator failure. Upon investigation, the problem was found to be a valve seat, a component within the control valve. The valve was taken apart and examined, and microscopic pitted holes were discovered. Often, this type of failure would end with a replacement of the valve and new lubricant, which would temporarily return the elevator to normal function. Knowing that valve seats do not just develop holes over time, however, made it pivotal to look further to find out what was causing the peculiar corrosion that had led to this failure.

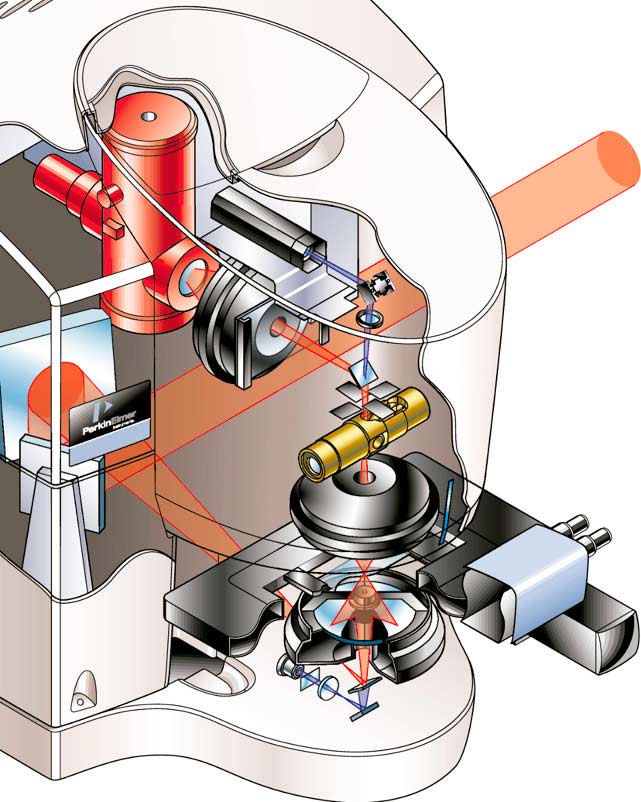

FTIR Microscope Examination

The valve component was examined using a Fourier transform infrared (FTIR) microscope, a specialized microscope that uses a beam path of light and sound to develop a detailed “DNA” path across the entire valve seat. Using, the examiner can determine exactly which chemistries are present in each crevice on the valve component. In our example, there was significant evidence of acid salts, the result of hydraulic oil decomposition caused by oxidation and water reactions. These acid salts essentially eroded the metal over time, destroying the valve seat.

Another failed component examined by the FTIR microscope was an inline filter. The elevator system was experiencing general performance issues, and, upon an initial examination, it was apparent the inline filter was experiencing fluid flow problems. The FTIR microscope found various materials, including decomposed base stock varnish, cellulose or airborne contaminants, and acrylonitrile, were inhibiting the filter’s function. The examination showed that the hydraulic oil used in the system was decomposing into varnish, which, in turn, was attracting airborne contaminants that further clogged the inline filter.

Failure of valve seat and valve inline filter components can cause significant performance issues, including with leveling and transition speed, which can pose safety risks to elevator passengers. Simply replacing the valve or inline filter will only temporarily solve the problem. Without proper investigation, the maintenance program for this specific elevator system would be going through a repeated cycle of valve and inline filter failures, causing inconvenient downtime.

The revelation of the cause of corrosion to the valve component and the varnish production in the inline filter proves that decomposing hydraulic oils can cause significant component failure. With this in mind, it becomes important to adapt and reevaluate a better lubrication solution for optimal performance. A change to a more-stable hydraulic fluid, coupled with system remediation, will improve safety and reliability. With better valve reliability comes more efficient, long-lasting elevator performance that reduces failures, downtime and safety risks of the system.

References

[1] Theissen, H. “Contamination of Biobased Hydraulic Oils with Mineral Oil,” Machinery Lubrication (www.

machinerylubrication.com/Read/28684/contamination- biobased-hydraulic-oils).

[2] Sundin, D. “Selection and Use of Bio-Based Hydraulic Fluids,” Hydraulics and Pneumatics (www.hydraulicspneumatics. com/200/TechZone/HydraulicFluids/Article/False/86940/ TechZone-HydraulicFluids).

Get more of Elevator World. Sign up for our free e-newsletter.