For the production environment or in the field

submitted by Reynolds & Reynolds Electronics Inc.

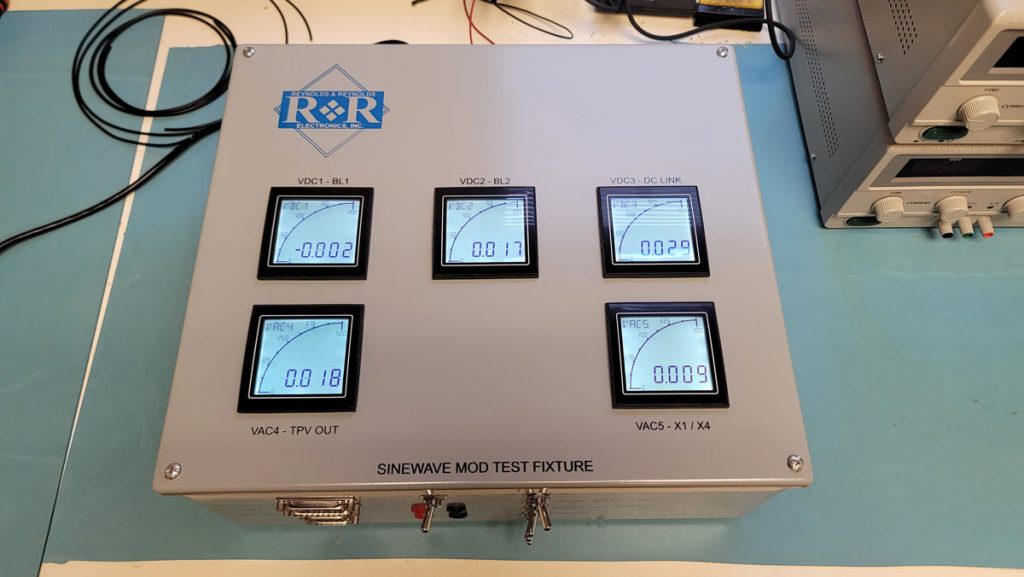

After being a leading provider of battery back-up systems for more than 30 years, Reynolds & Reynolds Electronics Inc. (R&R) now offers custom test fixtures that provide the opportunity to modernize an existing test fixture or create a new test fixture specifically geared toward the needs of the company, product, facility and available space. These custom test fixtures are created to offer improved safety and efficiency for production workers in various industries and to provide a simple all-in-one solution unique to each test station. Options range from small and simple benchtop fixtures to multi-function rack systems.

R&R’s expertise in design, fabrication, assembly, manufacturing and testing has resulted in fixtures with a compact, portable and touch-safe design. These fixtures can be configured in 120 V and 240 V. They provide input/output signals to test and qualify a product’s performance in a simulated environment to ensure that the customer receives their order without defect.

“The idea behind a custom test fixture is that they can be made to test any variety of products with a range of specifications for any production facility,” Daniel Dye, embedded systems engineer at R&R

Frequency, voltage and current meters are mounted directly to the enclosure for easy viewing and measurement. DC power supplies are used to provide a variety of output voltages. Insulated terminals and fuse blocks safely secure wires and connections. Fans and ventilation keep the enclosed internals running cool with minimal noise. Rugged hardware is used for switches, buttons, cabling and connectors, as well as sheet metal powder-coated enclosure boxes with silkscreen labeling for a sturdy construction.

Daniel Dye, embedded systems engineer at R&R who designs these turnkey solutions, said:

“The idea behind a custom test fixture is that they can be made to test any variety of products with a range of specifications for any production facility, with the added benefit of a safety- and efficiency-driven design to help and protect individuals performing the tests.”

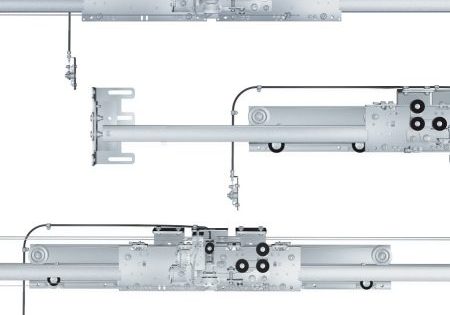

For the elevator industry, this applies to any electronics used in elevator functionality, including operating panels, controllers, indicators, switches, battery backup units, etc. Application can be done in the production facility or in the field, depending on company needs. These test fixtures are intended to test various parts of the elevator individually. R&R provides detailed guides along with simple step-by-step test procedures to train new and existing employees for seamless implementation.

Dye said:

“While engineers will make something that is sufficient to get the job done, we have found that what is provided often tends to lack in safety, ease of use and efficiency. R&R’s custom test fixtures create a safer environment for employees, as well as increase speed and productivity. The product is flexible, and there is potential for a multi-use solution once testing requirements are fully defined.”

Test fixtures are a great tool for production shops and compact enough for a technician’s toolbox.

Get more of Elevator World. Sign up for our free e-newsletter.