Clear, simple steps can mean big savings on maintenance.

If someone said they could clearly and simply explain how lots of money can be saved on elevator rope replacement and related sheave maintenance costs (including associated cost of labor and related equipment), every elevator industry professional would be very interested. For some large elevator service operations, the annual savings is easily in the millions, though any elevator service and installation company can benefit from reading this.

There are three basic and relatively straightforward areas to cover here. The first area of consideration is basic to the installation itself: its original design or its current state or condition (which will be explained). The second and third relate specifically to how ropes are installed. Quite a lot has been written (even in this publication) and covered in industry forums that is very technical about ropes and how they interact with elevator systems. There are complicated lectures about rope interaction with sheaves, elevator designs that put great stress on ropes, and installation and maintenance practices. Most discussion followed these lines. This can all be too complex and confusing. Important things that need to be understood and acted on can get lost in the many details.

Number One: Think About Elevator Installations and Consider How Demanding They Can Be on Ropes.

Many elevator systems today are very demanding on ropes. Many new elevators are designed and subsequently built that way. Some elevators that have been in use for some time can also become more demanding on the ropes.

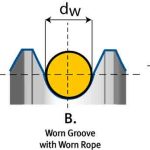

Think about elevators that have a drive-sheave diameter to rope diameter ratio (D:d) of 40:1, which happens to be the ASME A17.1 allowed minimum. Elevators today are heavily used (much more than they were in the past). Some elevators, over time and through wear, have just become more demanding systems (in terms of the demands they put on the hoist ropes). The sheave grooves have worn unequally, and other parts of the system have worn (sheave and deflector bearings, for example) and are now causing vibration (and angles) (Figure 1). The important reality is there are now very many installed elevators that put a high demand on elevator ropes. That higher demand on ropes involves things like groove pressure, bending cycles, the reverse-bend (which industry professionals understand), maximum and varying loads, loading effects of acceleration and deceleration and other technical considerations.

About 15 years ago, a colleague and I worked closely with a chief engineer at one of the major OEMs and came up with a list of at least 24 elevator system factors impacting the performance and life of elevator ropes. We realized that the problem with elevator ropes had little or nothing to do with the manufacture of wire ropes, and that there were many other things we should look at before deciding whether the quality of the wire ropes was the problem. This is something that was not being considered then. The thought was that ropes were just not made as well as they had been in the past. No one considered that the design of the ropes they were using was just not capable of doing what they were expecting.

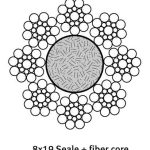

Elevators are more demanding. Many elevators should no longer use the old standard 8X19 elevator ropes that have always been used (Figure 2). High-performance (or high-demand) systems need high-performance ropes. We don’t use economy tires on a high-performance car, yet we still hold the thinking that economy ropes (the old standard 8X19 sisal, or natural fiber core) will work on high-performance and high-demand elevators. But, they don’t, in terms of being able to handle the groove pressure and bending-fatigue demands of many elevators today.

The bottom line, in terms of bending fatigue and life performance, is that we no longer have anything near the rope life we used to have. Instead of something above 10 years, we now have elevator systems in which the calculated rope life, if it is calculated, is far less than 10 years and often around five years or less. We have seen new installations (often modernizations, but also installations in new buildings) where the calculated rope life is two years or even less. This brings us to the other two important areas. If you do one of the other two things wrong, you will experience rope fatigue failures (of 8X19 sisal) in less than one year.

The other two things to know that will save lots of money are fairly simple to state and explain.

Number Two: Never Cause Any Change to the Final Construction of Your Ropes During Installation.

It is surprisingly easy to have a torsional effect, either forcing open or closed, during installation. Think about this while handling ropes and pulling them through a 2:1 installation, for example. In the process of installing, you have to pull the ropes around a car sheave, the drive sheave and a counterweight sheave.

In the process of pulling in rope and maintaining control of it, you may have twisted it (in either the open or closing direction); then, you fix (shackle) the rope at both ends. The rope is now permanently installed; any induced torsion will have a very large impact on the bending and fatigue process. This installation failure can cause more than a 50% reduction on the life of your rope. If your system was already a demanding system (described earlier), you will have a very short life. This is how having to replace a set of ropes in less than one year happens. Only one rope in a set needs to be affected in this way. When one rope fails, the entire set needs to be replaced.

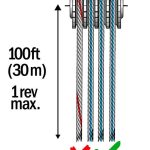

There is a fairly simple diagnostic test that can be done to check for induced rope torsion (Figure 3). Go to the drive machine and watch the ropes as the car is driven from the bottom floor to the top floor and then again from the top floor to the bottom floor. The rope installed must have been originally manufactured with a painted or sprayed line on it. Observe the line as the elevator travels. (A good way to do this is to take a video with the camera on your phone.) Depending on the design/construction of your rope, there should be no more than one to three turns of the rope for about every 100 feet of rope travel. If you can see more turns than this, you have a little work to do. It’s not especially easy, but it can be done. You must turn the shackle of each rope that is twisted in the opposite direction of the twist. Do the best you can to remove the twist. If you don’t, it is guaranteed that you will be back sooner, rather than later, to replace a set of ropes.

Machine-room-less elevators present a special challenge when it comes to observing the rope at the drive machine. You may have to rig up a camera (like those used by sports enthusiasts) so you can look for the twisting remotely.

Number Three: Equalize Your Rope Loads.

Over the years, no industry professional has disagreed with the above statement (Figure 4). The problem is simply in doing it. Most of the old methods for doing it either don’t work very well, are not accurate or consistent, or are so difficult to do (as well as our current systems require) that there just isn’t time to do it. This often means it doesn’t get done. There are now one or two tools that we know of that do a good job at equalization. This article is not about that.

The primary rope-life calculation formula (worked out by Dr. Klaus Feyrer at the University of Stuttgart) allows for +/-12.5% deviation in its formula of the rope loads on elevators. ASME A17.1-2013, Section 8.6.4.1.3 now directs that equal tension of ropes “shall be maintained” within 10%. This is a very lofty and demanding requirement. In terms equivalent to the Feyrer approach, it means +/- just 5%.

High-performance (or high-demand) systems need high-performance ropes.

There is good reason for paying attention to rope equalization. It seems that elevator code writers realized this should not be considered a suggestion; it should be a directive mandate. We also know that when you have twisting in your rope (point number two), you will see the impact (during or after movement of the elevator up and/or down) in the measured load (equalization) of your ropes. The last two “recommendations” are not completely mutually exclusive. But, they can be.

Go out and start saving money (millions in some cases), and stop blaming rope for most problems. Most rope failures are directly tied to the failure to follow the advice in points one, two or three listed in this article, and are compounded by the failure to address a combination of any two. It’s a very expensive and inconvenient problem if there has been a failure of all three.

- Figure-1

- Figure-2

- Figure-3

- Figure-4

Get more of Elevator World. Sign up for our free e-newsletter.