Before the electronic age, lifts were managed by control panels made with electromechanical switching elements (relays, contactors). The wiring diagram of these elements, in other words their electrical connection, was in the form of logic circuits. The task performed in these systems was nothing more than determining the direction of movement of the motor based on the incoming call and preventing the doors from opening during the movement. In systems with electromechanical switching elements, safety control was also very low, limited to a few functions. In general, these functions were limited to almost three items such as stopping the movement when the safety circuit was opened in motion, preventing movement under overload and not allowing movement if the well limits were exceeded. The activation of the speed regulator that controls over-acceleration or the parachute system and the hose burst controls in hydraulic lifts were done completely mechanically and located outside the control panel. These functions would interrupt the safety circuit and only notify the control panel.

Although the use of the lift has increased over time, the safety functions that were actively used for a long period of time, until the widespread introduction of electronics into lift control, have not changed significantly. Safety in lifts continued as the three main functions mentioned above until the 1980s. High-rise buildings, skyscrapers, hotels and buildings with special functions, which were built thanks to the existence of the lift, experienced serious implementation problems when they entered operation. The lifts did not perform as desired; people had to wait for a very long time for the lift on the floor or had to go to unnecessary floors in the lift. All these problems led engineers working in this field to transform lift control panels into a more intelligent structure. First\, full-load and minimum-load functions were introduced. The full-load function prevents the lift from unnecessary stops on the floors; the minimum-load function prevents unnecessary starts.

In the pre-electronic era, the biggest development in lift control systems was the design of collective lift controls. Before the advent of these systems, lifts only worked as simple controls, accepting and processing only one call at a time. In the collective lift system, the records are stored in the control system and they are processed in the order of movement depending on the type of control. This feature contributed significantly to solving the traffic problem in high-rise buildings. The other side of the coin was the difficulty of building these systems without electronic memory, using only electromechanical elements. In these collective control panels made with electromechanical elements, almost twice as many elements were used than in simple control panels, and therefore the electrical connections inside the panel were quite numerous and complex. This complexity was not a big problem during the production of the panels, as it was done by those who designed the board or knew the circuitry well. However, finding a failed element or a metal contact that has lost its mechanical sensitivity in the machine room was very difficult in these complex systems and these systems could only be actively used in buildings maintained by lift companies that could employ highly qualified personnel. That is why the use of these panels often remained restricted to the private buildings category.

The development of electronics and its use in industry first manifested itself in the partial use of electronic components in lift controls. In the early stages, there were boards made partly with logic circuits or with relays placed on a printed circuit. These were the versions of the circuits in the control panels made without using microprocessors and software, which were mostly made with electromechanical elements, and adapted to printed circuit boards with some simple additions.

Designed with electromechanical elements, these control systems emerged as highly successful transition products when they were well engineered and pioneered the introduction of electronics into the lift in the 1980s. Since these types of products are a direct translation of the circuits used in previous applications onto printed circuitry, they were able to reach the market with very short development and testing times. In parallel with the rapid market expansion of these products, microprocessor-based electronic control panels have also started to enter the market. Since the products designed with microprocessors had memory and software, lift controls were now open to all types of developments.

The first significant impact of the advent of microprocessor-based control systems was to make group control available to practically everyone. The group control, which allows lifts to share tasks in passenger transportation, was made easily with software. Electromechanical-based group controls had been built before the microprocessor application. However, these systems were very expensive, both because of their complex structure due to the use of multiple products (relays or contactors) and because of the need for much more qualified personnel in the sector due to maintenance and repair difficulties. Now, the group control was available in every building with two lifts. With the integration of electronic systems into lifts, the cost of operating multiple lifts installed in buildings as a group became much more economical and technically easier.

The active use of electronics in control systems has led to a reconsideration of safety in lifts. In the past, the decision-making in the control panels was made only by electromechanical elements, but now the decision-making task was transferred to microcomputers. With the appropriate software installed on the microcomputer, anything could be done. These developments signaled the new conveniences that electronics would bring to control systems, while at the same time paving the way for safer lifts. However, the feasibility of these developments could only be possible after they were controlled by certain disciplinary rules. These new developments have driven the lift standards to be redefined. Some of the safety clauses in the revised standards were written on the basis that there was now a microcomputer in a control system, and the EN81 standards are an early example of this. It was not impossible for the safety requirements of EN81-1/2 to be fully met by an electromechanical control board, but it was very difficult in practice. The majority of the new safety provisions introduced by the current EN81-20/50 standard relate entirely to control functions. It is now apparent that the development of lifts will largely depend on the development of software.

The development of electronics has also improved motor drive technology. Stepless speed motor control systems developed in this way paved the way for the creation of high-speed lifts. With these developments, motor speed controllers and lift control systems have become more efficient by communicating with each other. Lift control system manufacturers have taken this development to the next level and integrated these two products into a single integrated control unit. With this development, the lifts have become more performant in operation, while making the implementations more economical and more technological.

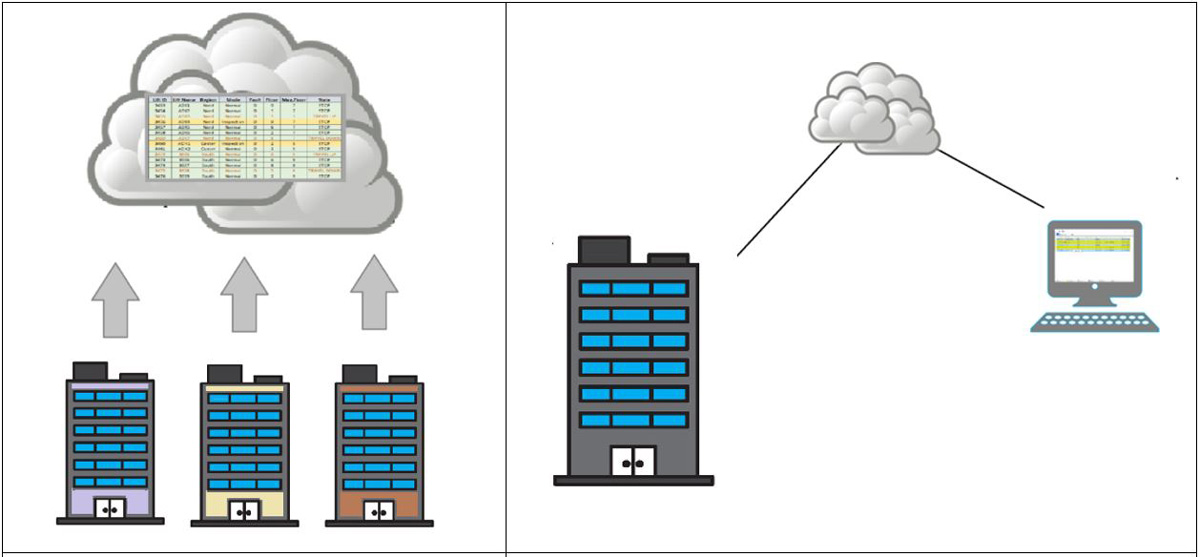

Parallel to the proliferation of the internet and the use of remote control in all electronic control systems, lift systems have also been affected by this trend. In the early periods, a communication network was established between the computer and the control panel via the internet. In systems where emergency telephone communication was via a landline or not used, additional hardware was required to connect the lift to the internet, which was an additional expense and, therefore, it did not attract the expected demand. Nowadays, emergency telephones are used extensively over GSM, and as a result, every control panel has an internet access point, and these developments are spreading the use of communication over the cloud. The presence of communication over the cloud has also paved the way for IoT (Internet of Things) in lifts.

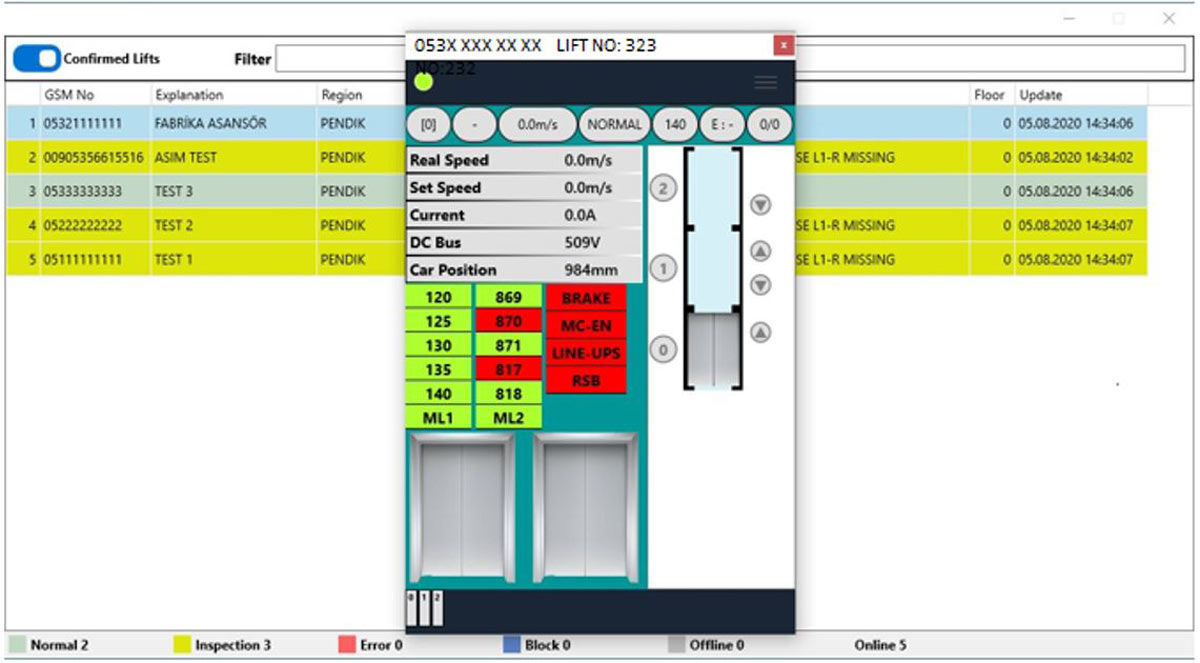

Remote access to the lift control panel and IoT are completely different concepts and their functions are also different. Remote access is used to examine and change the parameters of the control panel and to monitor its current status. In other words, it is equivalent to using the screen and keypad of the panel over the internet without being near the lift control panel. In the early days, this was done with a dial-up modem without using the internet, and with the widespread use of the internet, this connection started to be made over the internet. Today, remote connection to lift panels is usually done via the cloud. Monitoring the lift remotely, viewing its status and examining past errors allow lift maintenance companies to have detailed technical information before intervention in case of a malfunction. This will help the maintenance personnel to be prepared for the exact problem they will be responding to, or in some cases, to solve the problem remotely. The maintenance personnel can remotely monitor the movement and response of the lift by giving a call if they wish. They can print the malfunction and the parameter list of the lift or get an electronic data table to be used in reports to others. Anyone who has ever remotely sent a command to a device or monitored its status can easily understand the utility and usefulness of this function.

Having an internet connection point in every lift opens entirely new doors that we can use for completely different purposes. All lifts connected to the internet send their status instantly to the database on the cloud. This is called a heartbeat. A cloud-based management program also reviews this incoming data and sends a message including the failure details to the maintenance personnel in charge of the lift as soon as it detects a faulty lift. In this way, the personnel in charge of the lift will be aware of the malfunction before the people in the building even know about it, and if they wish, they can connect to the lift and get more detailed information.

In addition to the cloud software being able to communicate directly with the lift personnel, this application can also be actively monitored via monitors in the control center of a site or building complex.

A new topic that is being intensively studied today is likely to open up even more horizons than these two applications. Again, with software running over the cloud, all past state data of all lifts sending data to the cloud are analyzed and the behavioral changes of the lift are calculated. The numerical increase in the number of failures in the functioning of lifts is analyzed. If it is determined that the failures in any function increase systematically, it is concluded that malfunction will occur in this function in the future, and this information is reported to the lift maintenance company with numerical values. This way, before a permanent failure occurs in the lift, the parts that are starting to fail, but not yet completely preventing the movement can be replaced or readjusted, and the necessary intervention can be made before the lift is out of service. This is called predictive maintenance.

Predictive maintenance is the ability to know, with a high degree of accuracy, when a failure is likely to occur sufficiently in advance, after receiving and processing the necessary data from machinery or equipment. In other words, it is just-in-time maintenance. A predictive maintenance system actually means detecting a future failure before it happens. This feature not only increases customer satisfaction and enables planned and controlled intervention by the maintenance company, but it also protects other parts that may be affected in the event of a malfunction, as it prevents any malfunction from occurring. As a result, the cost advantage of planned and controlled intervention instead of intervention to a sudden failure will bring significant advantages in both building costs and maintenance costs in the long term.

Get more of Elevator World. Sign up for our free e-newsletter.