Digital Transformation Helps Put People First

Nov 1, 2017

Otis rolls out app-based, connected Global Service program.

Nearly 165 years ago, Elisha Graves Otis created the world’s first safe elevator and founded a company with the goal of moving people safely to their destination. Along with developing and manufacturing elevators, the Otis family personally provided service to ensure that every unit continued to run smoothly, efficiently and, most importantly, safely. Today, Otis remains committed to delivering this service to customers.

Otis technicians spend 60 million hours every year servicing and maintaining two million elevators and escalators in about 200 countries and territories. This global scope offers unparalleled breadth — and an opportunity. To continue to be the global leader, we needed to transform our global service operations to unify our team with a state-of-the-art digital infrastructure. And, we needed to commit financially, as this marked one of our largest-ever investments in engineering and information technology.

As Otis’ first-ever head of Global Service, my primary goal was to bring this transformation to life. In my charge to my service leadership team, I posed the question: “Where are we now, and how are we managing higher customer expectations?”

We took an inside-out approach to find the answer. We worked closely with our customers to understand their perspectives across their entire experience, creating journey maps and identifying “pain points.” We also listened to those on the ground — our service technicians — during global focus groups and ride-along sessions to understand their challenges.

This hands-on research revealed that technicians spend only half of their time with customers and servicing units. The other 50% is spent on necessary, yet “nonproductive,” activity. This included driving to facilities or sites, obtaining supervisor approvals and sourcing information and parts.

We also discovered that regional differences created a matrix of diverse service processes and tools globally. For example, our Asia service technicians were using mobile tools that were different from those used in the Americas; meanwhile, some regions had no mobile tools. This presented challenges for providing customers with consistent, top-quality service, regardless of where their units are based.

Next, we asked, “How do we evolve to keep pace with the two billion people we move every day, while maintaining our human touch?”

We know that customers want always-on, proactive service; more information; and a seamless experience. Our technicians want a real-time view of the entire service process and to spend fewer hours on tedious administrative tasks.

So, we asked our technicians to help us find the answer. We created an employee incubator program, designed to nurture and grow promising initiatives. Otis employees funneled their ideas for improving service to an innovation team made up of Otis people and industry experts. The team refined and implemented employees’ best ideas and made them the basis of a dynamic digital ecosystem that connects customers, technicians and partners.

As a result, we are equipping our 31,000 service technicians across the globe with iPhones loaded with Otis-built service apps that replace conventional bulky equipment and tools, and allow technicians to respond to a variety of customer-service needs. These apps enable service personnel to inspect full systems, quickly diagnose issues, order parts on the spot, provide immediate feedback to the customer and communicate with other Otis technicians across different countries.

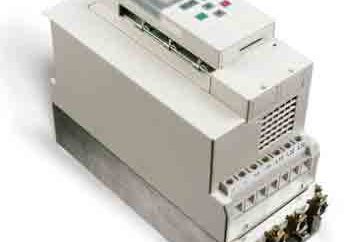

For example, technicians previously carried around a corded service tool, affectionately called a “brick,” to inspect elevator units and diagnose issues. Today, the functionality of the brick is rolled into an easy-to-use app that includes embedded diagnostic information about an elevator. Mechanics can also find and order parts from the jobsite with the tap of a button, eliminating the need to return to the branch office.

To further expand this digital ecosystem, we’re also taking machine connectivity to the next level. Thirty years ago — before big data was even an industry term — we launched a technology called Remote Elevator Monitoring (REM). REM collects performance data from roughly 330,000 connected elevators, using phone lines and sensors to send equipment data to Otis so our teams can remotely see, analyze and support maintenance issues. Today, we’re leveraging the Internet of Things to build on REM. We’re wirelessly connecting elevator units and using cloud-based technology, machine learning and equipment-health mapping to predict issues before they occur. We’re ensuring our service teams and customers can access their information in real time. This puts our technicians’ entire working world at their fingertips, which improves their ability to keep customers’ equipment operating.

It’s not about doing more with less; it’s about reducing unproductive processes, while putting more focus on user experience:

- For technicians, this means more time to provide the highest level of personalized service that keeps people moving safely.

- For customers, this means technicians will know them by name, identify problems with their equipment before they occur and reach them faster with full repair information in real time.

- For passengers and riders, this means more peace of mind to go where they need to without delay.

In the end, the solution was simplicity. Our digital transformation is more than just data, algorithms and technology. Digital tools are only as good as the people who use them, and that’s why our people-first approach will continue to deliver more efficient, safer and personal service by empowering the people on the ground — the service technicians.

Get more of Elevator World. Sign up for our free e-newsletter.