Door Driver With Increased Safety and Predictive Maintenance

Apr 1, 2020

This Product Spotlight introduces a door driver with wireless connectivity and remote monitoring.

by Emre Köroğlu and Mehmet Emin Ercan

This article was first presented at the 2019 International Elevator & Escalator Symposium in Las Vegas. For more information on December 7-8, 2020’s event in Amsterdam and to participate, visit www.elevatorsymposium.org.

According to elevator accident statistics, the elevator shaft is a considerably dangerous working area for those who carry out installation and maintenance. Despite strict safety regulations, work-accident risk is still high, because workers keep working under risk. To reduce accident risk in the shaft, the factors or causes that increase maintenance workers’ worktime in the shaft need to be minimized. Adjusting and checking the door-driving parameters during installation or maintenance is one of the reasons workers must work on top of the car, inside the shaft.

From this point of view, providing workers with remote access to the door driver will keep them outside the shaft, in a safe area, during the job. On the other hand, unnoticed potential failures of elevator components pose another risk factor for accidents. Thus, failure prediction is one of the most important maintenance issues. Before a breakdown or an accident, each critical component of the elevator should be checked in detail against potential failure.

Remote elevator monitoring systems have started to be applied in today’s elevators for predictive maintenance. In these systems, the traceability features of elevator components could be considered a key that helps technicians make proper predictions about potential failures. To make monitoring inspection possible for door parts like the driver, motor, rollers, guide shoes, etc., the door’s operational data, which would provide an idea about the status of these parts, could be obtained and logged. The aim of this article is to present how these features are ensured by a door driver equipped with such properties as wireless connectivity, data logging and integration with remote elevator monitoring systems.

Introduction

Nowadays, advances in technology such as computers, the internet, smartphones and artificial intelligence have caused all electronic systems to change and renew at a dizzying speed. This rapid change in technology has made it necessary for further development of elevators. Compared to the past, many innovations have been introduced in elevator systems to improve operator and passenger safety. High-rise buildings and the increase in the number of elevators worldwide have increased the risk factor. For this reason, internationally accepted norms and standards have been established and strict measures taken.

Looking at U.S. Department of Labor (DoL) data, these measures have significantly reduced the number of accidents reported over the years.[1] However, in the fourth quarter of 2018, the Center for Construction Research and Training published a troubling report compiled from data released by the DoL. The report, covering 2003-2016, noted the number of deaths in elevator-related accidents tended to increase over the years.[2] Another study of elevator safety was carried out in China in 2018, in which Zihan Ming and others found that more than 60% of elevator accidents were caused by standard maintenance and use, and that maintenance is an important factor in hidden hazards in lifts.[3] The Lift and Escalator Industry Association, which provides data on a wide range of issues related to elevator accidents, conducted a detailed statistical study published in the U.K. in 2016. Figure 1 shows where elevator accidents occurred by percentage.[4]

Considering this data, we can make the following conclusions:

- Although safety precautions taken to prevent accidents happening during lift operation helped reduce accidents, the risk of death has increased in accidents that occurred.

- To estimate hidden hazards during daily maintenance and use, new methods are needed, in addition to existing methods.

- Most accidents occur in working environments that require physical contact with elevator parts, such as the cabin top, shaft, shaft pit and machine room.

Merih Asansör A.Ş. of Ankara, Turkey, has developed a new cabin-door driver that enables remote control and monitoring of cabin doors, which is a critical safety component for elevators. This product, which records the door’s past operating data and contributes to the estimation of hidden risks, is designed to contribute to improving operator and passenger safety.

System Components

The door-controller unit’s general design and connection diagram are shown in Figure 2. If the operator wants to use the device manually, there is an integrated 2.4-in. thin-film-transistor liquid crystal display that can be controlled by the six navigation buttons connected to the processor. System inputs consist of four isolated power inputs. Two are 10-28 VDC; the other two are 24 VDC-220 VAC. The device’s relay-contact outputs have no voltage difference (dry contact).

A microcontroller with 72 MHz speed and 256 KB of program memory from the STM32 series[5] was selected for the system. Several sensors are connected to the microprocessor to measure data, such as voltage, current and temperature. The system has a WiFi module that uses the universal asynchronous receiver/transmitter connection protocol for wireless connection. It is possible to update the device with a USB 2.0 connection. There is a buzzer on the card for alerts. The electrically erasable programmable read-only memory stores data collected from the sensors.

System Overview

System Capabilities

Developed to contribute to the improvement of elevator safety and maintenance requirements, the door driver allows operators to remotely access the system in areas where there is a risk of accidents during maintenance. In this way, the door driver makes it possible to set car door variables (pressure, speed, door direction, etc.) from a safe distance. Remote access to the door driver will eliminate the need for the maintenance worker to be on top of the car or in the shaft to access the door driver.

Because the door driver can store data records, the operator can examine records and perform fault prediction and predictive maintenance. With the recorded operating information from the cabin door, the maintenance operator can predict the risks of malfunctions and potential accidents. Also, with the help of real-time data displayed, maintenance personnel will be able to instantly monitor faults occurring during door operation.

With the integration of the system into the remote-monitoring systems currently applied in elevators, the door driver can share many details of the door. Thus, the drive system will increase the monitoring capability of the central system. It is also possible to add desired features thanks to the door driver’s extensible structure.

Operating the System

The overall appearance of the door drive is shown in Figure 3. When the drive is applied for the first time, the wireless connection broadcast must be manually started from the device menu. After connecting to the interface and after 10 min of inactivity, the device switches off the wireless connection and resumes normal operation.

The operator can connect to the driver via a personal computer, tablet or smartphone. The phone or laptop must be at a distance that enables one to see the network on which the door controller is broadcasting (an average of 5 m). After connecting to the network, it is necessary to access the interface screen (application programming interface [API]) to manage the door driver. The address bar of the web browser to be applied is accessed by entering the internet protocol (IP) defined specifically for the door driver. Usually, this is 192.168.x.x.) It does not matter if the IP number is the same for each device, but it is recommended IPs be different for elevators installed in the same building. On this screen, the maintenance person can access the main menu by entering the username and password. A screenshot of the application interface is shown in Figure 4. The device can connect to only one IP address at a time via a wireless connection. In this way, two operators cannot connect and use the device at the same time.

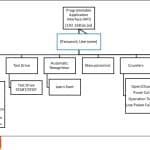

Figure 5 shows the block diagram of the device’s API menu. The movements of the door can be controlled by the settings in the device. The best possible comfort values of the door may be achieved by adjusting the variables in this interface. The device supports six languages and shows real-time information about voltage, torque, temperature, speed and door direction on the opening screen. Variables that need to be defined depend on the properties of the door to which the device is installed and are arranged in the settings menu.

Innovation

The Internet of Things (IoT) concept, which emerged in recent years, is an innovation in which elevator-sector applications are also seen. As a concept, IoT is based on the logic that objects share information with each other using various communication protocols and form an intelligent network system.[6] The elevator industry has been developing applications that follow elevators registered in a centralized system via wireless local area network (LAN). In these systems, various data, such as floor-leveling accuracy, floor and cabin call history, waiting times and elevator alarm records, are observed and recorded. In systems where remote access is possible, the monitoring center can contact passengers trapped in the cab in the event of a stop or power failure and provide status information. They also detect the malfunction and inform maintenance and repair personnel before a malfunction complaint occurs.[7-9]

The door driver developed by our company displays the error numbers and power usage of the landing doors in the elevator system. The device informs maintenance personnel on the status of the doors (for example, when the bearing or belt is forced, or when the amount of power the door driver consumes increases). In this respect, the door controller stands out as an economical predictive-maintenance product.

The device allows maintenance personnel to perform their duties from a safe point, preventing the maintenance worker from spending time in areas where there is a risk of impact, crush or fall. This innovation is important in reducing safety risks in elevators and paves the way for further solution ideas.

When the data stored in the device is checked, personnel can intervene in potential failures expected to occur without waiting for user notification. This ensures the elevator continues to serve without interruption.

Results and Conclusion

Merih Asansör developed a cabin-door driver using known and easily applicable techniques such as wireless connection, remote access and data storage. Accessibility options have been increased with the cabin-door driver, and wireless control capability from a safe distance has been provided. Without entering dangerous working areas, maintenance personnel can control the system variables via wireless connection to adjust the device for the comfortable and safe operation of the door.

The door controller has an internal memory that can store information such as the number of power outages and malfunctions that occur during door operation. Storing door data in the memory allows the operator to observe and correct past breakdowns and errors in the elevator when periodic maintenance is performed and take precautions against future errors, even if there is no existing fault.

Cabin and landing doors in elevators are moving system components that prevent passengers’ contact with the elevator shaft during use, and control their entrance and exit. Proper operation and monitoring of cabin and landing doors ensure passengers are transported safely. The door controller, when integrated into existing remote-monitoring systems, will become a critical component that will provide detailed data flow as to whether the elevator doors are operating correctly.

- Figure 1

- Figure 2

- Figure 3

- Figure 4

- Figure 5

References

[1] OSHA (www.osha.gov/pls/imis/accidentsearch.html?p_message=

Your%20search%20returned%200%20results.&acc_description=&

acc_abstract=&acc_keyword=”elevator”&sic=&naics=&officetype=&

office=&startmonth=&startday=&startyear=&endmonth=&

endday=&endyear=&inspnr=).

[2] www.cpwr.com/sites/default/files/publications/Quarter4-QDR-2018.

pdf

[3] Ming, Zihan. “Elevator Safety Monitoring System Based on Internet

of Things,” iJOE − Vol. 14, No. 8 (2018).

[4] Lift and Escalator Industry Association. “Accident Statistics” (2016).

[5] ResearchGate. “Internet of Things-IOT: Definition, Characteristics,

Architecture, Enabling Technologies, Application & Future

Challenges” (2016).

[6] Brown, Geoffrey. “Discovering the STM32 Microcontroller,” June 5,

2016.

[7] KONE. (kone.no/Images/7199-kone-elink-anleggsdata-

oversikt-heiser-rulletrapper_tcm29-18662.pdf).

[8] Otis.(files.otis.com/otis/en/sg/contentimages/REM%205.0%20safety.

pdf).

[9] thyssenkrupp. (max.thyssenkrupp-elevator.com/assets/pdf/TK-Elevator-

MAX-Brochure_EN.pdf).www.merihasansor.com

Get more of Elevator World. Sign up for our free e-newsletter.