Door Reversal Devices: 1930-1960

May 1, 2014

Fred Anzley Annett (1879-1959), author of Electric Elevators: Their Design, Construction, Operation and Maintenance, provides a critical framework for this introductory history of elevator-door reversal devices. The first edition of Electric Elevators appeared in 1927, and the second edition (with the same title) appeared in 1935. Annett completed the third and final edition in 1959, and it was published posthumously in 1960. This edition featured a revised title that reflected the changing world of vertical transportation: Elevators: Electric and Electrohydraulic Elevators, Escalators, Moving Sidewalks, and Ramps. In the second edition, Annett provided a thorough description of the Westinghouse electric elevators installed in the recently completed RCA Building at Rockefeller Center in New York City. This description included the following statement: “The car and hoistway doors are protected by the Safe-T-Ray, which automatically prevents them from striking or injuring an entering passenger.” Annett, however, provided no additional information on this door reversal system. Thus, this history begins with a slight air of mystery.

Fortunately, the clues required to solve this mystery are readily found, as Annett provided both the safety’s name and its manufacturer. In the late 1920s, Westinghouse Electric Elevator Co. pursued the development of a new safety device intended to reduce the risk of passenger injury in elevators equipped with automatic doors. In January 1929, Luther J. Kinnard and James Dunlop filed a patent application for this new safety, and the patent (assigned to Westinghouse Electric Elevator Co.) was issued on September 8, 1931: “Selenium Cell Door Closer,” U.S. Patent No. 1,822,152. Kinnard and Dunlop described the need for their invention and its basic operational characteristics as follows:

“In operating an elevator having a power-controlled gate, it is desirable to provide some means for preventing the passengers from being injured by a premature closing of the gate while they are entering or leaving the car. Therefore, we have devised a means for preventing the gate from closing until the doorway, or entrance, to the car is clear. This means comprises a suitable light-sensitive device, such as a photoelectric cell and a cooperating source of light, such as an electric lamp, that are mounted in the entrance to the car for operating a safety relay, the contact members of which are included in the circuit for the door-operating mechanism.”

The inventors also stated that it was an “object of our invention to provide for reopening the door or gate and retaining it in such open position for a predetermined length of time when anyone steps into the entrance to the elevator while the door is in the act of closing.” Thus, their invention contained the basic parameters followed in later designs: a means of sensing the presence of a passenger and of holding the doors open for a preset period of time.

In 1932, Westinghouse launched an advertising campaign that highlighted the Safe-T-Ray as one of the critical design features of its new electric elevator. The advertisement included an image of a man exiting an elevator car with one beam of light striking his knee and another striking his arm (Figure 1). The advertisement’s text offered a decidedly nontechnical explanation of the safety: “Light beams are projected across the elevator entrance in such a way that the entering passenger will interrupt the beams. The interrupted beams act magically upon the doors – if open, they remain open, and if closing, they stop instantly and return to open position.” Publicity materials prepared in 1933 for the opening of the RCA Building revealed some of the science behind the “magic”:

In 1932, Westinghouse launched an advertising campaign that highlighted the Safe-T-Ray as one of the critical design features of its new electric elevator.

“Visitors will notice electric light beams projected across the elevator entrance when the cab door is opened. These lights are part of an automatic device known as the “Safe-T-Ray,” and are focused on photoelectric cells in the opposite frame. When the light beam is interrupted by a passenger entering or leaving the elevator, a shadow is cast on the photoelectric cell, and the doors are automatically prevented from closing until the doorway is clear.”

Perhaps the most interesting aspect of the Safe-T-Ray was its visibility, allowing entering and exiting passengers to be aware of this safety device.

In the final edition of his book, Annett acknowledged the continued presence of door reversal systems that functioned in a similar fashion to Westinghouse’s Safe-T-Ray, which he now referred to as “Phototube” systems:

“The light-sources unit is mounted on one side of the car and focused so that its beam is directed between the car and hoistway doors, across the door opening, onto a photoelectric-tube unit mounted on the opposite side of the car. These units generally move with the car and are connected into the door-opening circuit in such a way that if the light beam is interrupted while the doors are closing, the doors stop, reverse and return to open position.”

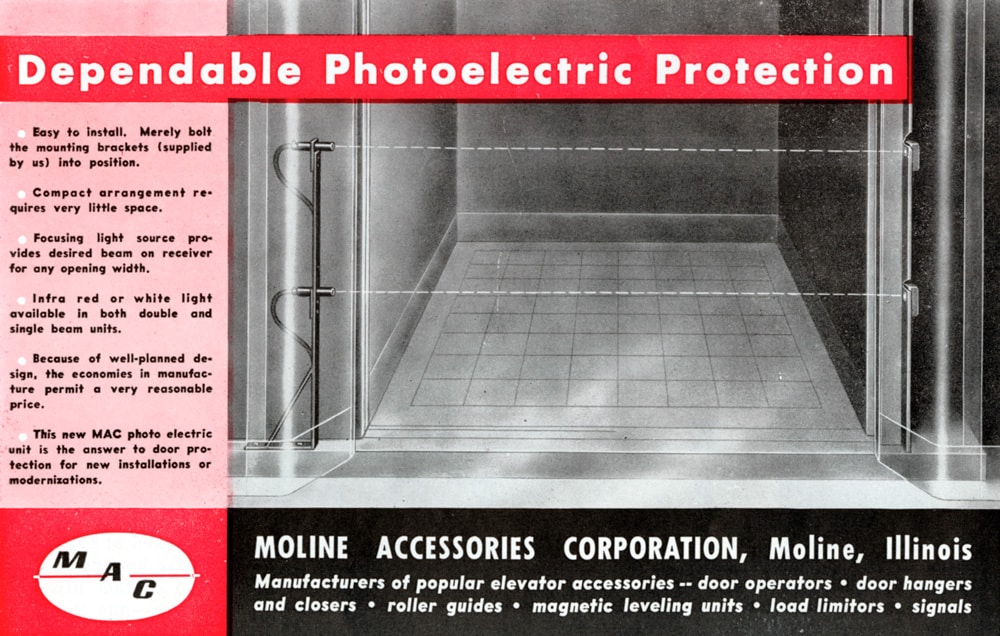

In the 1950s, the presence and apparent widespread use of this type of door reversal system was also reflected in the pages of ELEVATOR WORLD. The March 1956 issue included an illustrated advertisement for the “photoelectric protection” system manufactured by Moline Accessories Corp. (Figure 2). This system featured “infra red or white light available in both double or single beam units.”

Annett also described three additional door reversal systems that were in use in the 1950s: mechanical systems, cold-cathode-tube systems and pressure-plate systems. Similar to the Safe-T-Ray, mechanical door reversal devices had their origins in the 1930s. In February 1937, Cyrus W. Bassett (an engineer employed by Elevator Supply Co.) filed a patent application titled “Sensitive Door Edge Structure” (U.S. Patent No. 2,135,131, issued November 1, 1938). Bassett claimed:

“It is common practice today to employ reversing switches on the forward edge of vehicle doors to effect their reversal in direction of movement in the event they strike an object in closing. The switch is incorporated into a flexible encased housing built onto the door to provide the so-called sensitive edge.”

Their design was particularly aimed at addressing the problem associated with sensitive edge designs that “struck” passengers during their operation.

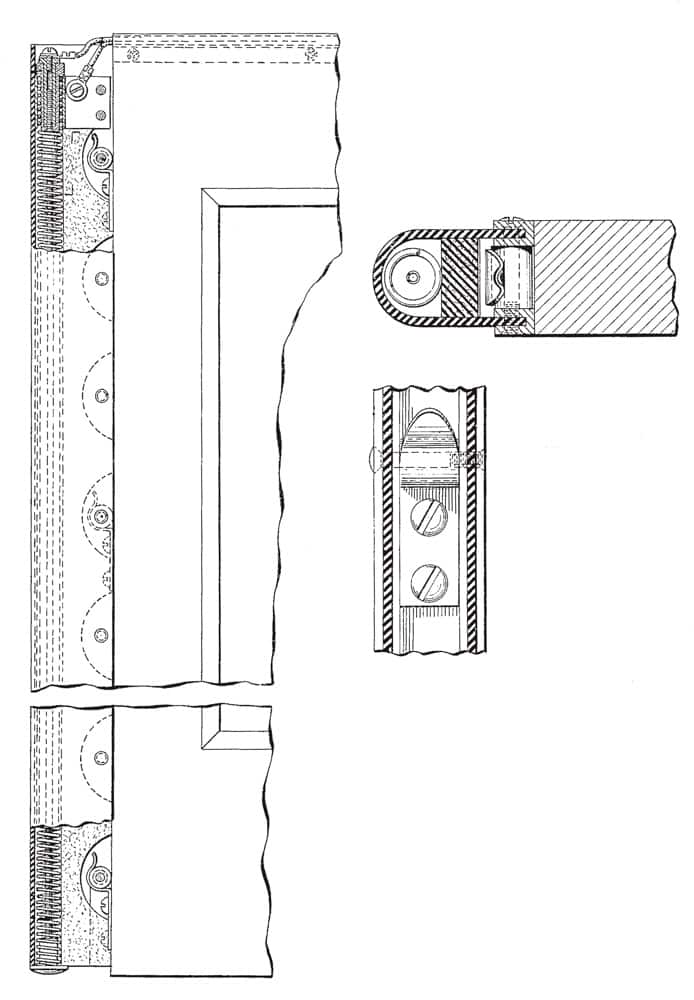

Bassett observed that this device was most commonly employed on subway car doors, claiming, “At the present time, there is a tendency, which is growing, to apply these devices to the edges of elevator and hatchway doors.” A brief survey of the patent record finds multiple patents related to sensitive edge or mechanical door reversal systems and their proposed application to subway cars and other passenger vehicles. However, Bassett’s patent appears to be the first that references the use of this system on elevator doors. His design primarily concerned a system that could be added to an existing car such that it would not detract from the car’s appearance and which comprised “a self-contained unit” that could “be readily mounted on and removed from a door.” The sensitive edge consisted of a flexible rubber projection that triggered an electrical signal as it was compressed (Figure 3). Thus, unlike the Safe-T-Ray, this system was operated via direct contact with a passenger.

The two remaining systems described by Annett were products of the 1950s and developed in response to the increasingly widespread use of automatic operator-less elevators. The cold-cathode-tube system was described as follows:

“[It employs] a series of cold-cathode tubes electrically connected to a metal strip antenna installed on the leading edge of the car door. A black plastic faceplate covers the entire tube assembly to protect it against being injured. These tubes create a continuous electrostatic field that extends from shoulder height to the bottom of the doors. The field curves around the edge of car and hoistway doors to protect passengers against both. This tube assembly connects into the door-opening circuit in such a way that if a passenger’s body comes within four inches of the edge of the doors when they are closing, they will stop, reverse and return to open position.”

The final door reversal system discussed by Annett employed pressure plates or switch mats to reverse the motion of closing elevator doors.

William Henry Bruns and Samuel Davis, engineers employed by Otis, appear to have pioneered the development of this system. Their patent, “Safety Mechanism for Doors” (U.S. Patent No. 2,601,250 dated June 24, 1952), contains the technological basis for this system, as well as the rationale for its necessity:

“It is common practice in present-day elevator installations to effect closing of the doors automatically. In passenger installations in which the starting of the car is under the control of an attendant, the attendant also acts as a guard to prevent passengers being struck by a closing door. However, this is not the case in installations in which the car is started automatically. . . [and] where both the starting and stopping of the car are under the control of the passengers themselves. In many of such installations in which the car door, or both the car door and hoistway doors are power operated, safety devices have been provided for stopping the closing of the door when a transferring passenger or an inanimate object is or is about to be struck. Depending on the arrangement, this softens the blow, or obviates the person being struck, thereby minimizing the possibility of real injury.”

Their design was particularly aimed at addressing the problem associated with sensitive edge designs that “struck” passengers during their operation. The cold-cathode-tube system detected “the presence of a person or object, while the door was still a considerable distance away,” which minimized “the possibility of the person or object being struck.” Other perceived advantages included its silent operation, lack of moving parts, its high range of sensitivity, its “instantaneous” operation, and the fact that the “mechanism is not apparent to users of the car and presents a neat appearance.”

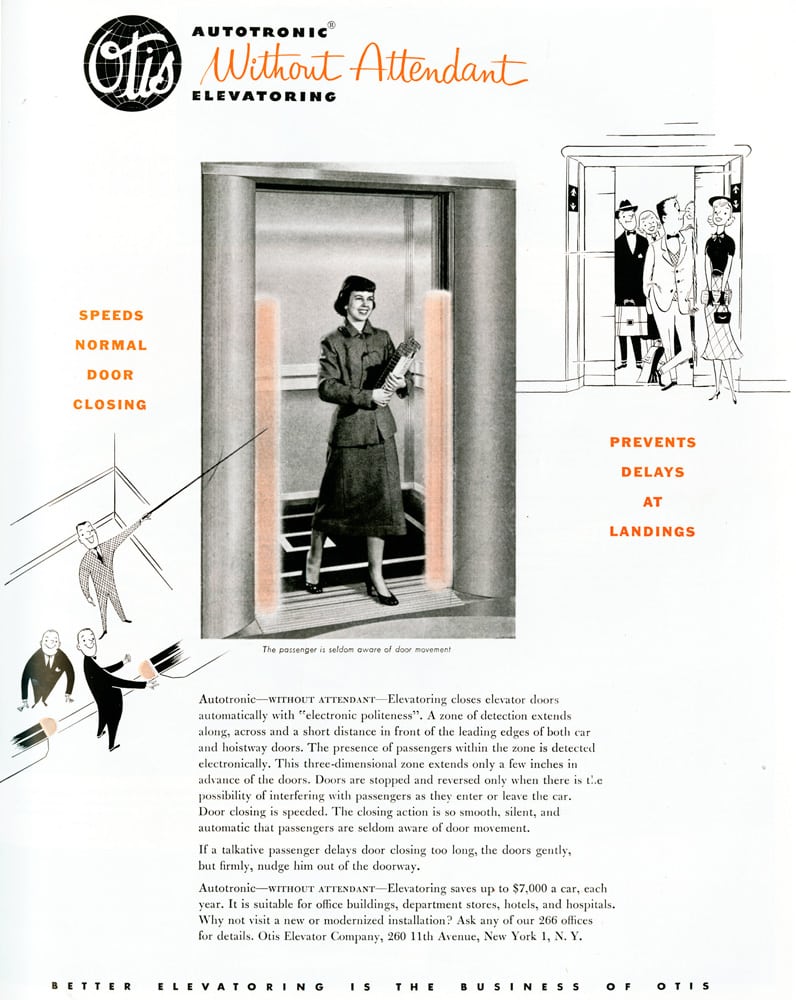

Otis did not, apparently, give its new safety an evocative name. The company simply referred to it as a critical aspect of its new Autotronic elevator system (introduced in late 1952). The advertisements for the safety included several drawings that illustrated, as a light pink haze, the presence of the cold-cathode-tube’s electrostatic field (Figure 4). The text characterized the system as functioning “automatically with electronic politeness.” Its operation was also described as follows: “A zone of detection extends along, across and a short distance in front of the leading edges of both car and hoistway doors. . . . Doors are stopped and reversed only when there is the possibility of interfering with passengers as they enter or leave the car.”

The final door reversal system discussed by Annett employed pressure plates or switch mats to reverse the motion of closing elevator doors. This system had been featured in the November 1956 issue of EW in an article titled “New Safety, New Confidence. . . Pressure Mats for Elevators.” The article, written by Emory W. McDonald, construction supervisor for Mobile Elevator Co., was a winner of EW’s monthly technical article contest. McDonald noted that “electronic safety edges,” such as photoelectric and cold-cathode-tube systems, were an improvement over mechanical/sensitive edge systems. However, while he acknowledged that doors equipped with these systems “do not strike anyone before reopening,” he claimed that “when they start to close. . . they sometimes scare people who are not accustomed to elevators.” The solution to this problem was the pressure mat, which took “all the scare out of door-closing movement.” McDonald described the system’s origin and basic operation as follows:

“For many years, you and I have walked into stores utilizing pressure mats to open doors without, perhaps, thinking of their potential utilization in the elevator industry. But think how efficiently such a mat could be used as a safety edge. We have installed several such units recently and found them to be ideal. The units are located in front of each elevator entrance and wired in parallel with the safety-edge contact. Since it would endanger the public to have high voltage exposed, the mats operate on 6-V relays, which, in turn, operate the safety-edge contact through normally open contacts. . . . Now, if the 6-V relay had normally closed contacts, each time the mat was stepped on, the relay would energize and recycle the door-closing timer. Thus, the time interval of door closing would be delayed until after the last person has entered or exited the elevator car.”

The pressure mats were made of rubber, were 5/16-in. thick and could easily be recessed into the floor (in new construction) or laid on top of existing floors (Figure 5).

The use of pressure or switch mats in door reversal systems was also the subject of a patent application submitted in January 1956 by Knute H. Pierson and Wayne F. Meinhardt (engineers employed by Montgomery Elevator Co.). Their patent “Electrical Control System,” U.S. Patent No. 2,867,291 (January 6, 1959), utilized the same rationale for the use of switch mats as offered by McDonald – that passengers might be afraid to use photoelectric or sensitive edge systems, because timid passengers perceived “thrusting an arm or leg between the closing doors” as dangerous. Pierson and Meinhardt’s patent also indicated that Montgomery had installed switch mats prior to its pursuit of the patent:

“[The] pressure-sensitive mat is located on [the] floor immediately in front of the elevator opening. . . . The presence of a prospective passenger on [the] mat actuates the elevator control circuit to delay departure of the car and permit the prospective passenger to enter. The pressure-sensitive mat preferably extends the entire width of the opening and is of substantial width to enable the prospective passenger to stand on it without being too close to the door yet is not wide enough to be in the path of normal traffic flow along the floor. In one installation, a mat 36 in. in length and 12 in. wide was found to be satisfactory.”

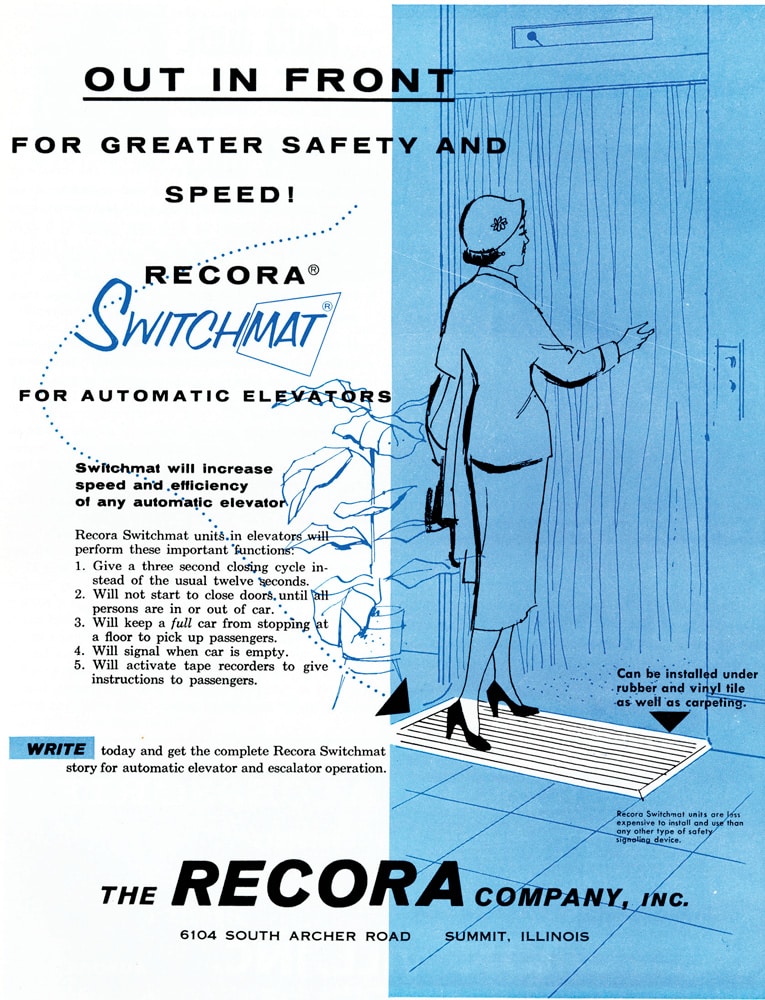

Finally, the June 1957 issue of EW featured an illustrated advertisement (Figure 6) for the Recora Switch Mat for Automatic Elevators, which outlined five reasons to employ its system:

- “ Gives a 3-s. closing cycle instead of the usual 12 s.

- Will not start to close doors until all persons are in or out of the car

- Will keep a full car from stopping at a floor to pick up passengers

- Will signal when the car is empty

- Will activate tape recorders to give instructions to passengers”

The proposed multiple uses of the Recora switch mat prompt questions about its actual use in the 1950s, both as a door reversal device and as an aid to overall elevatoring. The advertisement also included the following statement: “Write today and get the complete Recora Switchmat story for automatic elevator and escalator operation.” This raises additional questions about the use of this technology with escalators.

The variety of systems and the steady pursuit of their development from 1930 to 1960 also serve as a reminder that change – as represented by the introduction of the fully automatic passenger-driven elevator – takes time.

Annett’s descriptions of these door reversal systems also included reminders that this technology was in use during a transitional period in the history of vertical transportation. He makes several references to attendant-operated elevators and notes that both the photoelectric and cold-cathode-tube systems were designed such that, in the case of an obstruction in the doorway or a passenger holding the door open for a long period, “a light flashes on the dispatcher’s panel to warn him that the operation of the doors is being interfered with.” The variety of systems and the steady pursuit of their development from 1930 to 1960 also serve as a reminder that change – as represented by the introduction of the fully automatic passenger-driven elevator – takes time.

Get more of Elevator World. Sign up for our free e-newsletter.