Door Technology for High-Rise Applications

Oct 1, 2015

This paper was presented at  Paris 2014, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 20, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

Paris 2014, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 20, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

(website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

Key Words: Automatic door, high rise, door performances, ride experience, component reliability, specialist approach

Designing, building, installing and maintaining elevators for high rise is not such an easy matter since high performances couple with strict constraints. Design must take into consideration issues and effects that are normally not significant in ordinary buildings. From an elevator component supplier viewpoint, in such situations it’s very important to pay attention to elevator doors, since they are the most critical device in terms of people safety, and also affect the overall system performances; therefore, one of the main concerns is letting the door systems work in the best conditions. In the paper we will define the variables that, in high rise environments, have impact on the door systems and on their operating characteristics in terms of performance, quality, reliability and aesthetic requirements.

1. Urbanization Trends and High-Rise Buildings

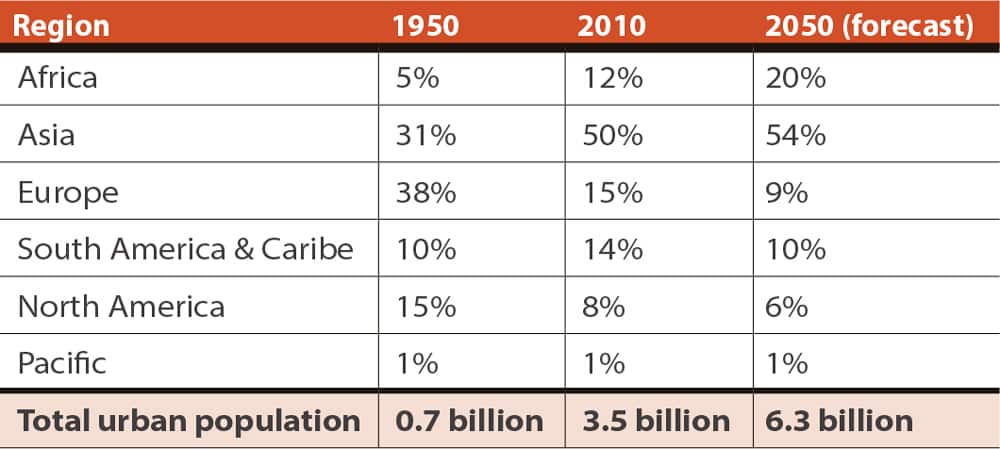

Today’s continuous growth of population and urbanization (see Table 1) together with the development of new materials are pushing architects and constructors to design ever larger and higher buildings. Anywhere in the world big cities are growing more and more vertically and modern multi-functional buildings are true cities on their own, each one with its specific services and transportation needs.

The unstoppable urbanization growth is confirmed by recent international researches and data (UNICEF 2012) that show how the configuration of future cities, the optimization of urban spaces and the design of efficient horizontal and vertical transport systems will be an urgent, strategic challenge for the next 50 years, above all in the fast developing countries of Asia.

- Today, 50% of the world population lives in urban areas. By the middle of this century this figure will reach more than 2/3.

- The urban population is growing constantly: every year increases by about 60 million people, mostly in middle-income countries.

- Asia is home to half the world’s urban population, as well as of 66 of the 100 fastest growing urban areas, 33 of which are in China alone. China’s urban population amounted to 630 million inhabitants.

- Almost 10% of the urban population is living in megacities, (cities with more than 10 million people). 19 megacities have added to New York and Tokyo, which are in this list since the fifties. All except 3 are located in Asia, Latin America and Africa.

The number of tall buildings has grown hand in hand with the growth of population and urbanization. Over the last 10 years buildings over 200 meters have increased in number exponentially (see figure 1). Due to the reduced available space in urban areas, building higher structures is becoming a must, and this, from the elevator industry viewpoint, will require mastering a specific set of skills needed to properly move people and goods within this type of buildings.

2. Vertical-Transportation Systems in High-Rise Buildings

In the construction industry high rises are defined as buildings between 23 m and 150 m. Buildings over 150 m are classified as skyscrapers. The average height of a level is around 4 m high, thus a 24 m tall building would comprise 6 floors (Daniel 2012).

We can say that height is the peculiar characteristic of this building type and then it’s easy to understand why elevators are, and will continue to be, a crucial factor for their successful functioning and why the increase in efficiency of their vertical transport systems can give a wide set of benefits, such as for example better meet the needs of tenants, manage the space in a more intelligent and sustainable way or increase the commercial value of the building.

When dealing with elevators, the concept of high rise sounds a bit different and is commonly related to elevator speed. Till a few years ago, the borderline between standard elevators and high rise elevators was the speed of 2,5m/s. Nowadays we have a more structured segmentation (which anyway is continuously changing): 2,5m/s is a standard speed, 4m/s is considered a commodity high rise, 6m/s a standard high rise, 10m/s a high speed and over 10m/s are very special elevators. Thus 6m/s has turned out to be a normal speed for high rise, and considering the fast technological development of elevator components and materials, this will become even higher in the next years.

So what is expected from an elevator installed in a high rise building? First, it has to get to destination quickly, avoiding the physical exertion of climbing millions of stairs. Second it has to get there comfortably, without people being crammed in a corner or hearing scary sounds during the travel. Last but not least, it has not to break like any other means of transport. Easy to say but difficult to achieve in such a context where physical and mechanical stresses are higher than ever.

Taking into account the above mentioned characteristics, elevator for high rise building must ensure: high performances in terms of speed but also of traffic management and reliability; energy efficiency and sustainability, both in terms of materials and operations; maximum safety in every condition, even during fires and emergencies; excellent design and aesthetic quality through the development of technical and aesthetic solutions that guarantee the full integration of the elevator with the overall building.

3. Elevator Doors for High Rise

High rise buildings have distinctive external, internal and regulatory characteristics that require special skills for the design and construction of their vertical transportation systems as well as of all of their components. Together with the need for longer shafts and higher transport speed, a number of specific factors, which are normally not significant in ordinary buildings due to low speed and air flows, must be kept under control during the design of high rise elevators, considering that high performances have to couple with strict constraints.

In high rise elevator design, the doors play a key role since they are the most critical device in terms of people safety, and also affect the overall performances of the system; therefore, one of the main concerns is allowing the door systems to work in the best conditions.

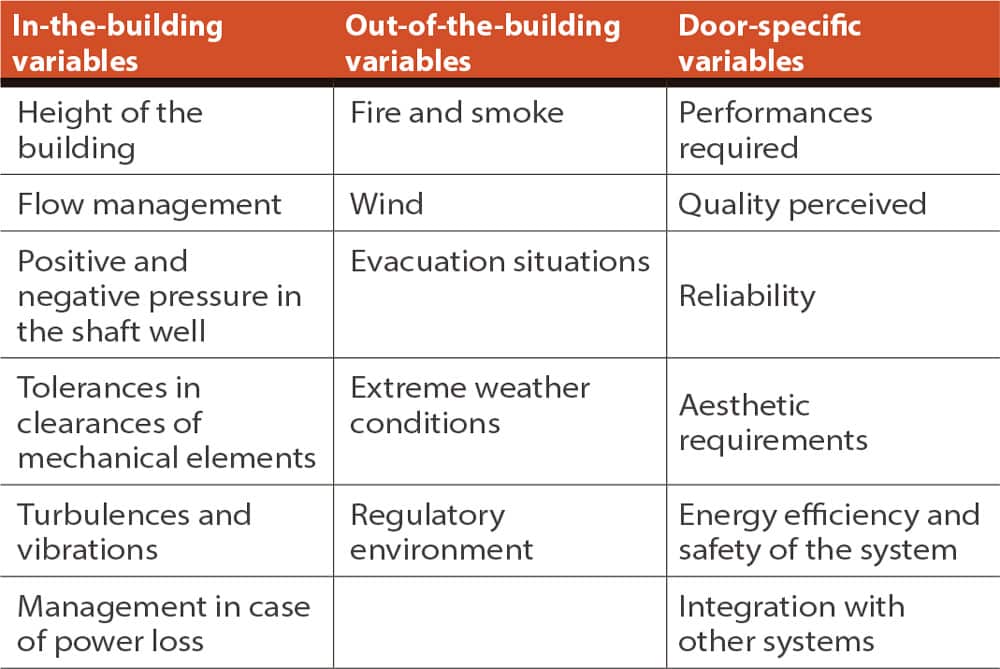

The starting point for achieving this goal is clearly defining all the variables that have impact on the doors systems (see table 2).

The first group of variables identifies the status of the building in terms of structural configuration, population, flow management, etc. Each of these variables is responsible for specific effects that have to be carefully considered. For example the height of the building (i.e. of the shaft well), determines air pressure, which generate stack and piston effects. In such tall shaft-wells in fact, pressure can be so high that doors may experience difficulties in the very last part of the closing phase, resulting in reliability problems if not properly managed.

The influence of external factors must not be undervalued too, affecting door design and thus construction. These variables are normally codified in standards, norms, recommendations, specifications and strongly affect the doors systems. Fire and smoke regulations are probably one of the most critical topic but also the introduction of new standards, such as for example the EN 81-20 and EN 81-50, can considerably impact on elevator door design and manufacturing.

The last group of variables is related to the door systems only, which includes: performances required in terms of opening/closing cycles (which affect significantly travel time), quality perceived (noise, vibrations, smooth profiles), reliability both in terms of call-back rate and preservation of performance and quality over time, energy-saving, safety and aesthetics (design and flexibility to suit different claddings and executions, together with the ability to master glass for example).

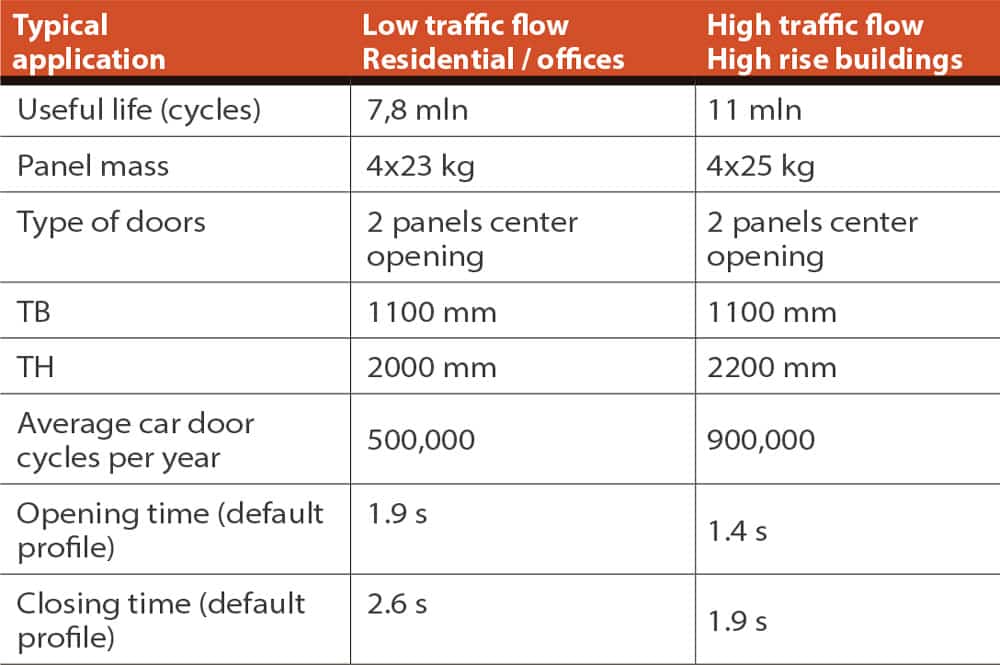

If each specific installation requires elevator doors with distinctive, well defined features and technical characteristics, which are the ones of high rise elevator doors? (see Table 3). From the data of Table 3 we can define their main characteristics as the followings:

- Performances (speed in terms of opening and closing time: 1,4 s + 1,9 s for high rise elevator doors vs 1,9 s + 2,6 s for standard elevator doors)

- Reliability (life cycles)

- Robustness (increased panel masses)

So automatic doors for high speed elevators are designed to reliably move heavy panels in short times and with low noise emissions. To satisfy all these requirements, door manufacturers have developed complete range of solutions, which includes special features of the door drive controllers (adjustable opening and closing speed profiles; real-time moving mass calculation algorithm; speed profile automatic downgrade; stand-by mode; battery back-up) or specific mechanical devices in order to take care, for example, of sealing the cabin and landing doors during the elevator ride (increasing comfort).

4. Specific Door Variables

4.1 Performances

In high rise buildings, traffic flows can be massive and these extremely difficult conditions cannot be managed by increasing the number of elevators installed in the buildings but can be simplified with the development of smart traffic management systems that are based on the analysis of passengers’ travel behaviours and guarantee a better space management (reducing the number of elevators needed to properly serve the building), a drastic reduction of the waiting times and the maximization of the elevator performances.

These results are achieved thanks to the technological development and the performances of each single components of the elevators and to their proper design and integration. Thinking about doors, travel times, door opening and closing speed, regulated by car door drive controllers with different adjustable speed profiles, are, for example, a key variable, which in short rides can have a significant impact on the overall travel time of the elevator.

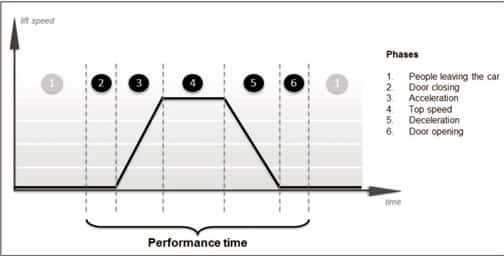

In order to demonstrate this assumption we should start defining what is the performance time of a door system. This can be calculated, through simplified flight time models, as followings (see Figure 2):

- Door closing time

- Acceleration time: the time the elevator spends to reach its maximum speed. Whether or not the maximum speed is reached, depends on the path length between the two stops

- Top speed running time: time spent at the maximum speed (typically 5-6m/s as in standard condition)

- Deceleration time: time for the elevator to stop

- Door opening time

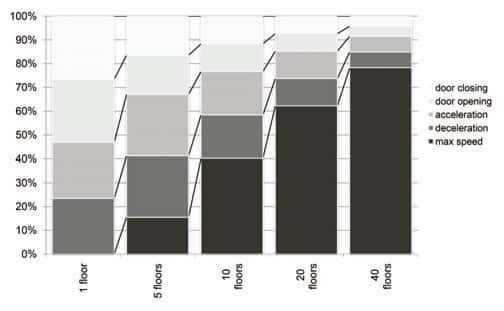

To understand the impact of doors on overall flight time of a high rise elevator, we have carried out five simulations (see figure 3) considering a 40-floor high rise building with 4m inter-floor distance serviced by a standard high rise elevator (6 m/s) with standard high rise elevator doors (door opening time + closing time = 2.3 s). The number of floors between elevator start and stop is shown on the X-axis.

This model is just a simplification, it does not consider for example time spent to fill/empty the elevator, but anyway it can give the idea of the complexity of the problem and of the factors that are impacting on elevator door performances.

In the first simulation we considered a single-floor stop; in this condition, there’s no time to reach the top speed, i.e. there are only acceleration and deceleration phases; the contribution of elevator maximum speed becomes significant at least for a 10-floors run. A first conclusion is that for short/medium distances (up to 10 floors) door speed can contribute up to 50% to the performance time, which is an important figure on overall performances. Of course, going through longer distances, the impact of top speed running time becomes more important. Therefore it’s important to optimise both elevator and door performances in order to get the best results, and not focusing on elevator speed only.

All of these considerations have been taken out for a single run, but just think about what’s happening when considering multiple runs. For example, a person that is waiting at the 16th floor for an elevator that is leaving from the ground and stopping every four floors, will perceive elevator performances for four times. Just think how many stops, how many persons travel through a high rise building per day, per how many days.

4.2 Quality Perceived

4.2.1 Comfort and Noise

The ride comfort is really important in elevators for high rise buildings because vibrations and noises increase together with the increase of the elevator speed and due to differences of pressure in longer shafts. Components selection, setting and installing is the key for reducing the noise level of the elevator system in use, keeping it within acceptable parameters (with peaks of maximum 50 decibels).

In order to tackle this problem, the elevator industry has developed specific mechanical devices that, for example, guarantee the perfect sealing of doors and the complete isolation of the cabin during travel.

4.2.2 Smooth Operation

Door opening speed can be adjusted in terms of performances and fine-tuned for smoothness of the operation (comfort parameter). This results in a very good feeling with the movement of the panels, showing control and precision in each instant of the opening and closing cycle.

4.3 Reliability

Reliability is ever more an essential requirement in high rise buildings, where systems and components are deeply stressed, due to higher pressure (positive and negative) in the shaft, turbulences and vibrations as well as tolerances in clearances of mechanical elements and higher building tolerances, and sometimes must work in non-ideal conditions. Considering that, in high rise buildings, elevators use is more intense than in low-rise one, due to high population and traffic, so their components are more subject to wear out or even break and this can cause damages to other parts of the system, or even worst consequences. In order to guarantee the high service level requested to elevators in this application field, components must be chosen with care, through a network of qualified suppliers and the more sensitive parts must be laboratory tested even for millions of cycles.

4.4 Aesthetics and Design

High rise buildings are among the best contemporary architectures of the world. The design of the building and of its compositional elements is one of the key parameters to define its success. The elevators can be a distinctive, focal point of this type of buildings providing a combination of elegant finishes and all-round visibility – ideal for making the most, for example, of an open hotel foyer or an office complex atrium. High rise vertical transportation systems must be designed, in all of their components, to integrate seamlessly with the buildings, respecting their aesthetic qualities and suiting particular architectural requirements or design concepts.

Shapes, materials, lighting and colours are only the visible part of a wide range of solutions that combine technology with aesthetics. For automatic elevator doors these requirements are satisfied through material selection (full or framed glass panels), panel shape (round doors) and special executions such as doors with hidden bottom tracks or doors with under-driven operators, which comprise exclusive design advantages such as for example reducing the visible size of the car door operator from the floor hiding the elevator door mechanisms under the floor level.

4.5 Sustainability and Energy Efficiency

Another important topic related to high rise buildings and their service facilities, including elevators, is sustainability and energy efficiency. Buildings use energy, and the bigger the building, the more energy it uses (even if some modern skyscrapers have been designed in order to controvert this claim!).

The measurements of the consortium E4 (Energy Efficient Elevators & Escalators), sponsored and supported by the European Commission, show that the vertical transport systems account for between 3 and 8% (E4 2010) of the total energy consumed by the services of a building.

Elevators and escalators are definitely not the biggest energy consumers in buildings but sustainability and efficiency should be ensured at every stage of their life cycle: from design (passengers’ flow analysis, component selection, materials selection) to production (ISO 14001 processes, weight reduction of components, waste management), from use (energy recovery system, energy saving in standby mode, use of class A components) to maintenance (preventive and efficient) and modernization (replacement of complete systems or of components).

4.5.1 Elevator Door Efficiency in Standby Mode

Most of the energy spent by an elevator is consumed during standby mode (between 50 and 70%). Specific solutions allow the reduction of this quota for elevator doors this means the development of parking mode functions managed by the electronic car door drive controllers that leave the skates in open position when the cabin is stopped at the floor, reducing significantly the energy consumed by the overall system.

4.5.2 Maximum Safety

In high rise buildings some risks, such as fire and smoke propagation, are amplified by the structure of the building itself (lengths of shafts and consequent stack effect); poor protective systems of any building equipment can lead to disastrous consequences. So satisfying top safety requirements is a must not only for architects and designers but also for the manufacturers of all the service facilities of the building, including elevator and elevator component manufacturers.

A high rise elevator system must be able to safely manage any emergency and must be designed with special components (fire-resistant; vandal-resistant; etc.) and materials (i.e. non-combustible) that, for example, in case of fire do not permit the propagation of flames and smoke.

International and local standards, norms, recommendations, specifications give some guidelines and hints to design safe components in elevator systems as well as to improve their fire resistance. Firefighters elevators and fire-resistant components are among the solutions that the elevator industry offers to increase the safety in high rise buildings.

5. Conclusions: An Integrated Approach to High-Rise Elevator Component Design

Many different variables must be taken into consideration when designing and manufacturing elevator systems and components for high rise buildings. The problems that an elevator system has to deal with in such an application context are not comparable to any other in the industry.

External and internal variables have to be carefully identified and considered; solutions for each of them have to be developed and integrated in the overall elevator design. Problems and solutions must cover not only the single components of the system but also the interaction between all of them, such as for example cabin and doors integration.

For elevator doors the correct approach is to combine all the technical aspects that are relevant to tackle the application context problems (speed, reliability, perceived quality and comfort) together with the non-technical requirements posed by architects, engineering and construction firms (aesthetics) from the early stages of a project, starting from elevator design to product development, product manufacturing and installation.

Figure 2. Simplified flight time model

Figure 3. Relative composition of flight time in a 40-floor (4m/floor) HR building for an elevator with standard speed (6m/s) and standard HR door

Table 1. Urban population per region 1950-2050 (Courtesy of the United Nations Department of Economic and Social Affairs – Population Division, 2011)

Table 2. Variables that affect elevator and components design in high-rise buildings

Table 3. Elevator door typical characteristics: low rise residential and offices vs high rise buildings

References

United Nations Children’s Fund (2012). The state of the world’s children 2012 – Children in an Urban World, pp. 1-11.

CTBUH (2011). Tall and Urban – An analysis of global population and tall buildings, pp. 1-3.

Jihad S. Daniel (2012). High-rise building construction cycles, p. 4.

E4 – Energy-efficient Elevators & Escalators (2010). Options to improve lift energy efficiency, pp. 1-16.

Get more of Elevator World. Sign up for our free e-newsletter.