A look at one of the first angle-changing inclined elevator installations in Seoul.

In October 2009, Dream Forest opened its doors, having been converted from an old theme park for locals called Dreamland. Within the first four months, the park had more than 1.1 mil-lion visitors. It now serves as a leisure facility with a variety of cultural services and is considered a landmark of the Han River. It took two years to build, and the overall design of the new park was selected through an international competition. On the first floor of the visitor center is the design gallery, which provides a view of the city. In front of the visitor center, one can find a seven-tier waterfall. One of the things that makes Dream Forest unique is an outdoor inclined elevator that takes visitors a distance of 67 m to the entrance of the Art Center. Situated in Seoul, the installation was one of the first angle-changing inclined elevators in the country.

Elevators

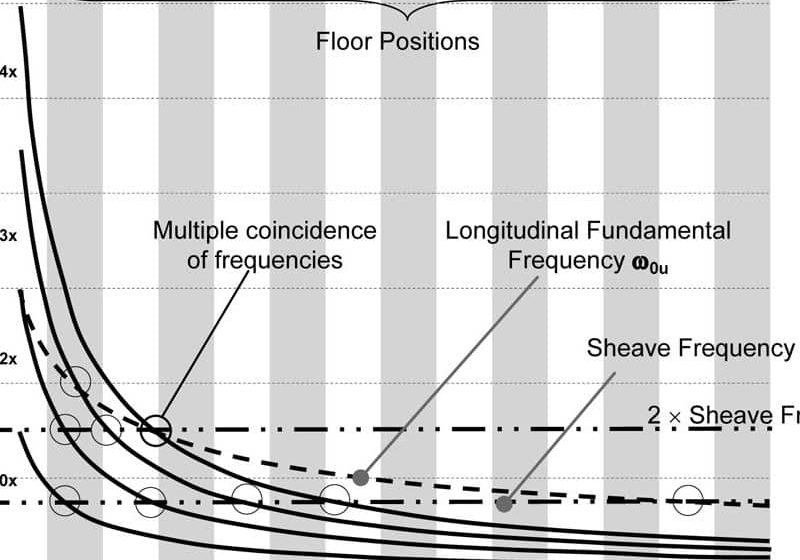

The elevators were designed and manufactured by Hütter-Aufzüge GmbH and installed and serviced by Kumho Elevators of Seoul. In order to ascend to the observation deck, an outdoor inclined elevator at the entrance to the Art Center has to be taken. The elevator has a 20-person (1350-kg) capacity and runs a distance of 67 m. It stops at a halfway point before continuing its ascent. At this juncture, the angle of ascent changes from 21° to 16° and the speed decreases. The entire trip takes more than one min.

The observation tower houses the same 20-person capacity and speed as the inclined elevator outside, but the distance runs 47 m. The outdoor elevator is equipped with a radio-control to avoid a trailing cable. The current is transferred to the car by a conductor-rail system. The change in inclination is se-cured by a hydraulic system that is connected to the control to facilitate a smooth adaptation.

Usually, the cabin and landing doors of inclined elevators are coupled with a mechanical system that allows the car doors to jointly open the landing doors of every floor. This system envisages a motor and a coupling skate for the cabin door, whereas the landing doors are engaged through their own lock. The wireless system allows the control panel to check both cabin and landing doors when they face each other, without any mechanical engagement.

In addition, communication is possible between the cabin and landing doors, even though they operate with independent motorization and mechanics; although the control panel signal arrives only to the cabin door, as with traditional systems. Once the signal arrives, the cabin door transmits it to the landing door, which simultaneously opens. This is possible because of two peripheral small-scale, weather-resistant, infrared receiver-transmitter systems for the data exchange. Due to security reasons, the communication system insulates the motor when the car is running and particularly when the car is not positioned in front of the landing door within the lock release zone.

The communication system is bidirectional and asymmetrical (type: Master<>Slave) with the car door acting as Master and the landing doors acting as Slave. Besides the bidirectional and asymmetrical transmission of opening and closing signals, the system envisages incoming signals from obstacle-surveying devices (such as photocells), which will synchronously work on both car and landing doors. The nudging effect when an obstacle is detected is activated on both car and landing doors, and requires the reopening of both doors, even though only one of them is involved in the obstacle detection. The door lock is installed on both cabin and landing doors, which means the doors cannot be manually opened without the apposite key.

Get more of Elevator World. Sign up for our free e-newsletter.