East Rail Line Cross-Harbour Extension

Jan 6, 2023

Teamwork, creativity and determination bring a challenging project to fruition.

Escalators, New Construction – Hong Kong SAR

submitted by Twinky Chai,

Otis Elevator Co.

Project Description

With approximately 4.6 million passenger journeys each day, Mass Transit Railway (MTR) is a major public transport network serving 7.3 million people in Hong Kong SAR. The commissioning of the East Rail Line Cross-Harbour Extension was truly a milestone for Hong Kong SAR railway network development. The strategic heavy-rail East Rail Line Cross-Harbor Extension, now carrying 530,000 passengers daily, stretches across 16 stations along a route spanning approximately 46 km. Opened in May 2022, it extends the line by connecting the old terminal at Hung Hom Station to the new terminal at Admiralty Station (now a mega-interchange station) via the new Exhibition Centre Station.

The last leg of a larger project, the East Rail Line that connects the Chinese mainland border now stretches across the Victoria Harbor to the central commercial, convention, exhibition and financial business areas on Hong Kong Island. This allows passengers from the Northeast New Territories and Central Kowloon to travel directly to Hong Kong Island without having to change lines, significantly reducing the commute time and enhancing the overall railway network of Hong Kong SAR.

Passengers using Admiralty Station (which has been in use for 40 years) can now interchange between four railway lines at the underground levels of the new extension. The expansion was a technological marvel of engineering, coordination and construction. Exhibition Centre Station is a brand-new station located in the business, convention and cultural hub of Wanchai North.

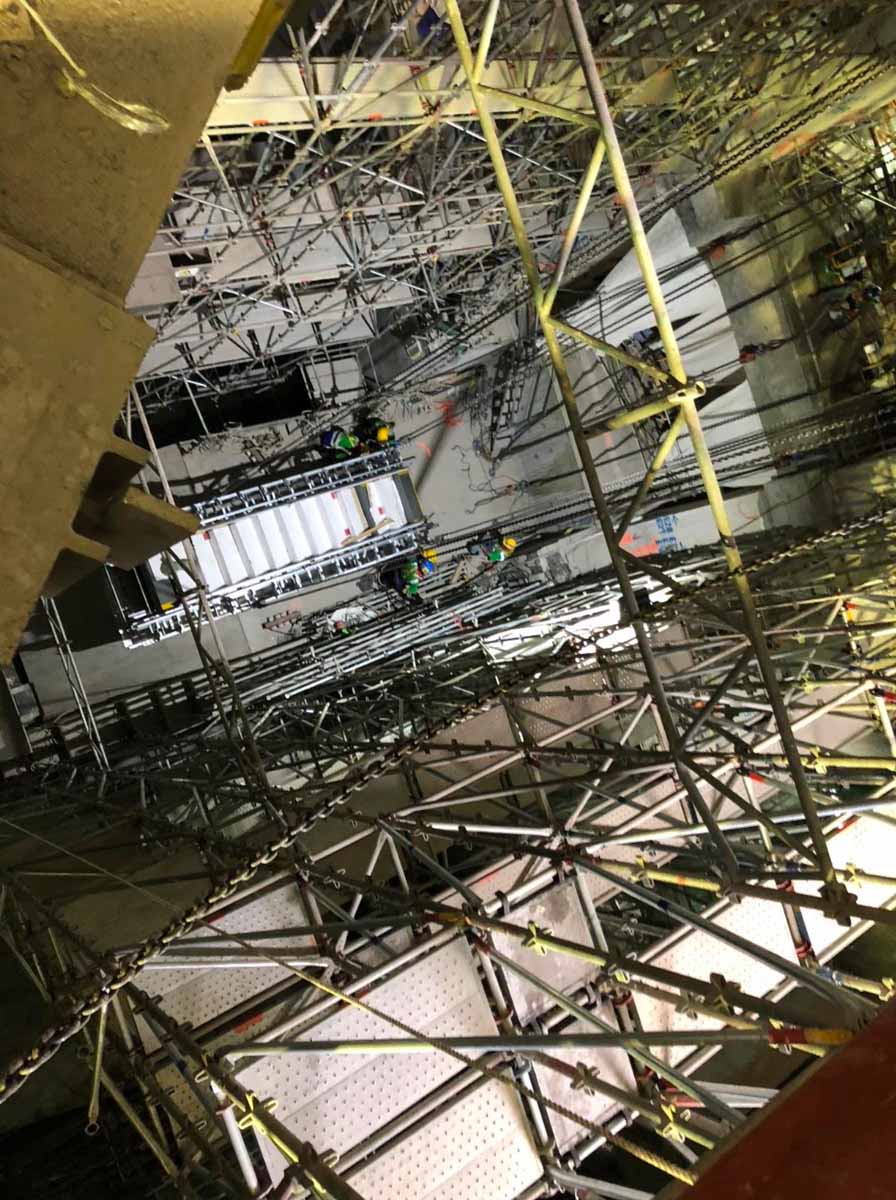

To transform the existing Admiralty Station into the mega interchange station and new terminal of the East Rail Line, a new extension was built that required an excavation down to 50 m with a depth of roughly 17 stories. Workers removed some 650,000 mT of rock. Approximately 4,000 mT of steel structure and 40 supporting columns were used to systematically transfer the load sequentially under the existing lines as work progressed. A major challenge was performing the work to remove debris and bring in construction material amidst numerous buildings and heavy traffic in the surrounding area of the city. Through it all, rail passengers in the station’s levels above the job site were virtually unaware of the work going on below, nor did the work impact any existing schedules.

Exhibition Centre Station is the only new station opened together with the commissioning of the East Rail Line Cross-Harbour Extension. This three-story, underground station connects the reinstated public transport interchange and the Wan Chai Footbridge network, and has greatly enhanced the mobility and convenience of the passenger and pedestrian area.

Otis played a major role in helping bring this railway connectivity to Hong Kong SAR, including by providing 42 escalators located in the Admiralty and Exhibition Centre stations as part of the second phase of a larger project.

Transportation System Description

Otis faced its own set of challenges in making Phase 2 a reality. One of the most daunting hurdles the team faced was the complexity of equipment installation under the existing and operating Admiralty Station, a mega and critical interchange station moving thousands of passengers daily to other railway lines. Otis Hong Kong Associate Director of New Equipment Patrick Ting said:

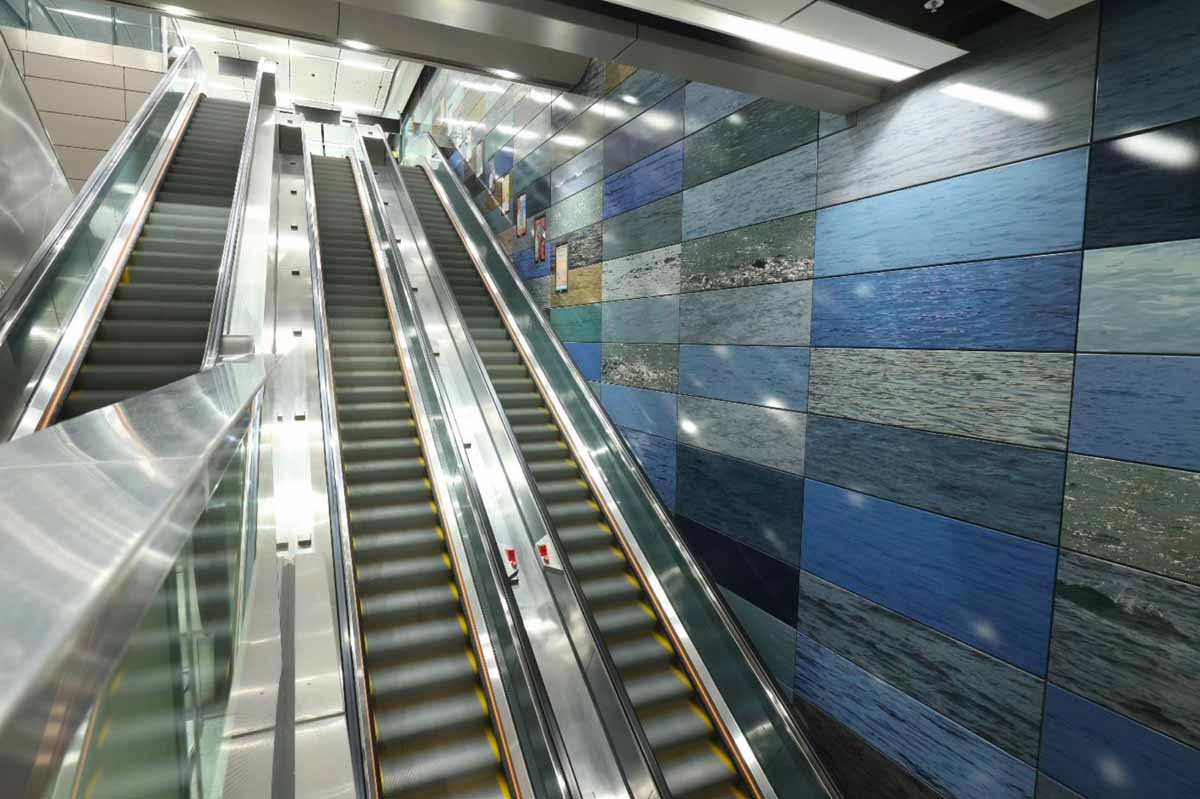

“The 42 advanced-technology Otis escalators on the project are a critical part of the transportation system to move passengers from concourse to transfer to the lobby or other railway lines efficiently. The extra-long escalators installed within the deep atrium of Admiralty Station are particularly important. Installing them safely, efficiently and on schedule was our primary goal.”

A goal well met, according to the customer, MTR Corporation Ltd. In a letter to Ting, MTR Project Manager Tim Leung wrote:

“I would like to thank all the Otis members of your project team for their efforts in completing the work [in a] timely [manner] and in good condition, despite the many challenges we faced and overcame together during this process. . .It was a great collaboration for our team members to work with your project team. The level of professionalism and dedication that they exhibited. . .has helped us [in] overcoming a lot of challenges for a quality delivery.”

To ensure the safety and comfort of passengers using the operating railway lines, the Otis team developed a detailed project plan, constantly reviewing it to align with its customer’s latest schedule. While collaborating seamlessly with MTR on the build, at the same time the team worked closely with all relevant contractors, suppliers and vendors to ensure smooth site coordination and minimize the impact of the pandemic and other unexpected challenges.

To handle high traffic volume and ensure convenient passenger interchange between levels, the Otis engineering team worked closely with an Otis China manufacturing facility to design and build a custom escalator system more than 20 m in length to connect the new extension to different levels of Admiralty Station (recognized as the busiest interchange station in Hong Kong SAR, even before the extension).

Five of these extra-long escalators were part of Admiralty Station’s upgrade. The Otis team had to ensure the custom units met stringent product quality standards, fit exacting installation requirements and secured an Approval-in-Principle (AIP) letter from Hong Kong SAR regulators. The AIP letter is required when new features are incorporated into and/or change the application conditions of equipment models already approved. Given the tight construction deadlines, the AIP was critical to the schedule of the project. To accomplish this, Otis built an escalator prototype in the factory and arranged a visit with the customer, a third-party reviewer and factory experts to provide recommendations.

Construction of the new station levels so deep underneath the existing station structure presented its own challenges. Seamless project coordination among all parties was critical, given the schedule and challenging construction environment. That called for accurate and “just-in-time” delivery of material, while still being agile enough to accommodate ad hoc changes; strong support from the Chinese manufacturing facilities for the custom builds and prototype testing; and a relentless commitment by every member of the project team (with team members’ industry experience averaging more than 20 years).

While hoisting and moving new equipment down to the lower levels was challenging in and of itself due to a limited access “window” through which to lower material, the placement of support columns and scaffolding along with other contractors working in the area, it was particularly difficult for the 20-plus-m escalators to be placed, as they had to be lowered in multiple pieces and sections before being reassembled below.

Because the station was still in operation during construction and the area around it was a congested business district, it was difficult to transport material and perform crane work during work hours, forcing the need for much of this work to be done at night. Apart from collaborating seamlessly with the customer, the Otis team also worked very closely with all relevant contractors, suppliers and vendors to ensure good site coordination to minimize impacts from the pandemic and other unexpected challenges. The COVID pandemic was particularly severe in Hong Kong SAR, resulting in strict rules on treatment, testing and quarantining. This made staffing issues on an already extremely challenging construction build even more difficult.

Now that they’re installed, the escalators offer the customer and the passengers who use them the advanced technology and outstanding quality promised by one of the world’s leading manufacturers of escalators and moving walkways. The units feature an exceptionally smooth and quiet ride thanks to a closed-loop, polymer guidance system in conjunction with the handrail drive system that minimizes friction and wear, as well as maximum safety and comfort, thanks to the handrail and step speeds being rigorously synchronized.

The escalator units at the Admiralty stations are equipped with a speed selector switch, providing the operation an option to change the rate of speed when necessary. In addition, the escalators feature energy-saving operation modes, including intermittent operation and “stand-by” variable-frequency operation based on passenger detection by a radar sensor. The escalators are also equipped with ride-through facilities in which they’re able to sustain operations even if power supply voltage dips for a short period, which can minimize the risk of passengers falling. Richard Tsia, director of New Equipment for Otis Hong Kong SAR, Macau, and Taiwan, said:

“With a mission of ‘Keep Cities Moving,’ MTR is known for stringent quality requirements and a focus on comfort, safety and reliability. At the same time, as such a visible and important project, the performance of facilities at the stations is under public and regulatory scrutiny. Our construction team’s dedication, the collaboration of the New Equipment and Service teams and an overall strong commitment to service excellence helped us overcome a spectrum of challenges and bring our customer’s vision to reality, as well as meet passenger needs. This is a significant accomplishment that we all should be proud of.”

Louis Lau, chief construction manager — SCL E&M Services, Capital Works Business Unit of MTR Corporation Ltd., added:

“I would like to express our appreciation to Otis for their professionalism and dedication throughout the entire project. It is a good demonstration by Otis for their commitment to safety, quality and service excellence to allow them to complete the work on time and in good condition, despite many challenges. My thanks to the Otis project team for supporting us to accomplish such an important project.”

Credits

Owner: MTR Corporation Ltd.

Developer: MTR Corporation Ltd.

Architect: MTR Corporation Ltd.

Designer: MTR Corporation Ltd.

Planner: MTR Corporation Ltd.

Equipment Manufacturer: Otis

Component Supplier: Otis

Get more of Elevator World. Sign up for our free e-newsletter.