Elevating the VW “Bulli”

Feb 5, 2024

How the 3XL elevator from Schmidt Aufzüge Medebach is integrated into the automated production process

images by Hans-Wilhelm Berghoff

In November 2023, your author visited the freight elevator built by Schmidt Aufzüge Medebach (SAM) at the Volkswagen Commercial Vehicles (VW-Nutzfahrzeuge VWN) production facility in Hanover, Germany. The factory tour in a specially manufactured open electric caddy and the presentation of the heavy-duty and high-capacity elevator were accompanied by Andreas Ricken, branch manager of SAM, as well as Manuel Ramos, deputy head of Plant Engineering, and Tobias Salzmann, press spokesman, both of VWN Hanover. The following report describes the technical details of the elevator and its integration into the automated production process.

How the 3XL Elevator Was Created

The need for the heavy-duty and large-capacity elevator with two stops arose at the VW plant in order to transport approximately 20-m-long, driverless transport trains with basic materials and individual components for the production of large-capacity sedans and light commercial vehicles over 6.6 m from bottom to top in a fully automated process. This required a car around 23-m long that could lift a payload of 25 t. The request for the giant lift, officially dubbed the “VW trailer elevator,” was submitted in 2019/20.

The chosen technical solution “hydraulic elevator” with a capacity of 44.35 t = 591 persons plus a car of approximately 55 t complies with EN 81-20/-50. The individual construction was calculated with support of structural engineers at SAM under the direction of Ricken. Planning took around six months. The system was also built in approximately six months in 2021. In between, it took another six months to source the components.

Construction began with the lifting of the load-bearing floor slab in two sections into the hall. The slabs were delivered with heavy-duty transporters and were lifted over the neighboring building with a 300-t crane on a Saturday afternoon under pouring rain. A total of about 100 t of steel was used for the elevator.

How the Heavy-Duty Elevator Is Operated

Certification was carried out by TÜV Nord. The allocation of the weights for the tests (27.5 t plus 10% each) was specifically documented in a diagram due to the size of the cabin. The elevator also has approval for passengers. The emergency call system is connected to the VW security control center. If necessary, evacuation is carried out by the VW fire department or specially trained “elevator attendants” from the plant engineering department.

Energy consumption and the emergency call system are monitored. The data are assembled by the building management system.

Service is carried out by SAM for the first two years during the warranty period. After that, it passes into the hands of VW. Repairs and troubleshooting are carried out by VW’s own personnel. Three trained mechanics and four trained electricians from a total of nearly 200 employees in plant engineering are available seven days a week in an early and a late shift from 05:30 a.m. to 22:30 p.m. All special spare components were purchased with the order and are stored on-site, which was not a major additional expense due to the high proportion of standard components.

What the Heavy-Duty Elevator Looks Like From the Outside

An additional ramp for the vehicles was built around the side of the C25 concrete shaft to increase transport capacity or to compensate for a failure of the elevator — if necessary. The computer controls the route used in automatic mode. Alternatively, the car can also be requested manually via the SAM panel.

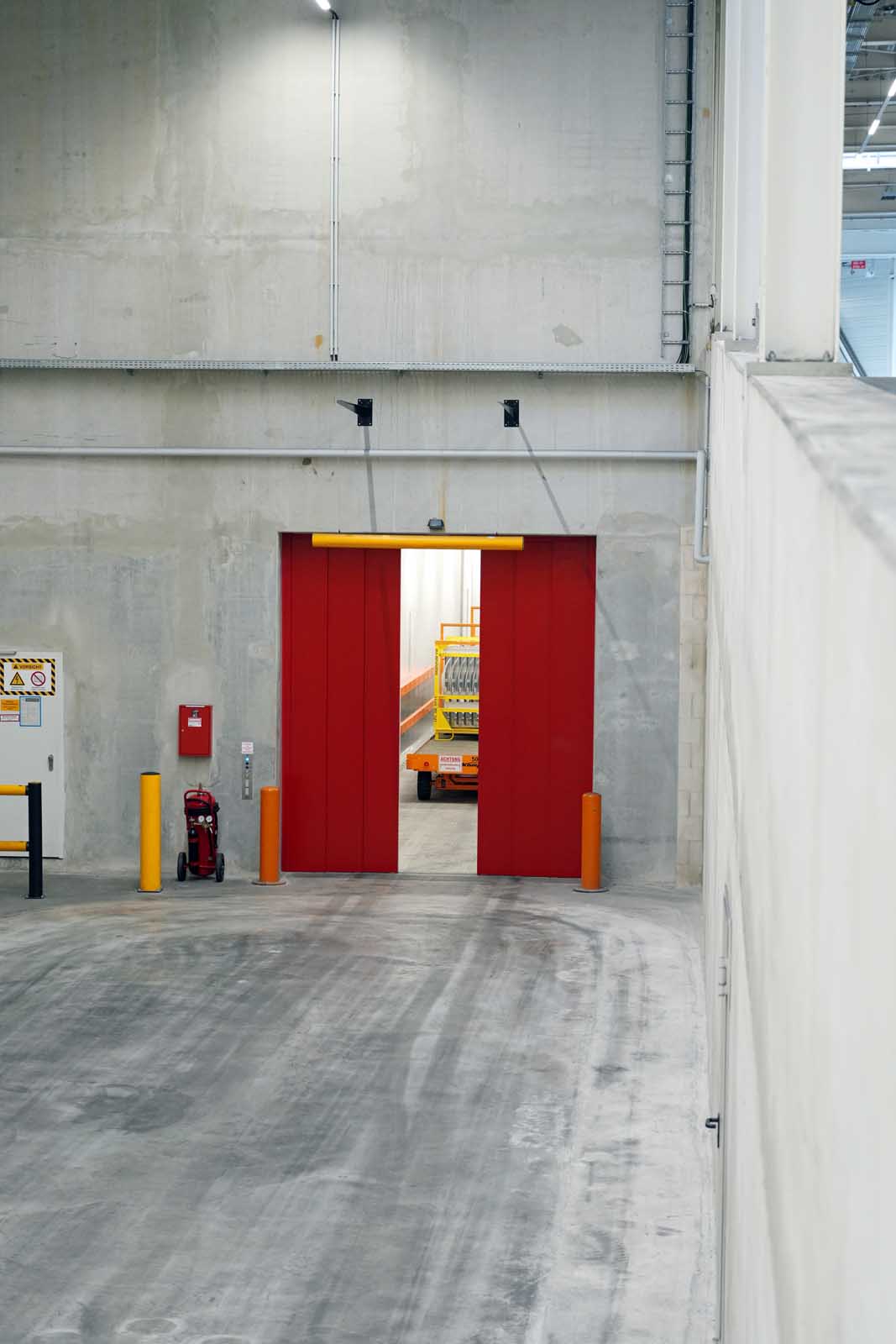

The doors are from Meiller, based on their HD door due to their size. They are 3 m x 3.5 m at the top and bottom and — like all other elevator doors in the factory — are carmine red so that they can be identified as elevators from a distance. Each consists of six centrally closing panels. The threshold is solid material with smudge holes. There is an approach sensor above the door and orange pylons to the right and left of it to protect the doors when entering.

How the Interior of the Large-Capacity Elevator Cabin Is Styled

A traffic light system and sensors control the automatic entry. The door is fitted with several light grids, including a loading light grid to protect the door from being touched by the transporter.

The cabin, measuring 3.1 m wide x 23.1 m long x 3.5 m high with a payload of approximately 25 t, is naturally ventilated. The ventilation strips for air supply are attached at the bottom along the side of the cabin walls. The lamp cases on the ceiling, which are barred for safety reasons, also serve as ventilation into the shaft.

The upper part of the side walls consists of basalt-based sandwich panels. These are fire-resistant and have a low fire load. They are also 3 to 4 kg lighter than sheet steel and environmentally friendly manufactured from a natural material. They have high strength and low echo.

There is a roof hatch in the ceiling to secure access to the shaft when the support bolts are extended. The floor slab is ribbed.

What Is Happening in the Operating Room Next to the Elevator

The elevator control system installed in the operating room at the bottom left of the shaft behind a steel door is also an in-house construction by SAM based on the SIMATIC S7/ET200SP from Siemens. It is pre-programmed for normal operation and autonomous travel. The tractor vehicle calls the elevator automatically when required.

At the rear of the room is the drive system consisting of two hydraulic units from Bucher Hydraulics, each with an electrical power of 45 kW, which drive the four cylinders in the shaft. They are frequency-controlled with power regeneration to meet the VW specification of being “as energy-efficient as possible.” The use of counterweights, which cover around 50% of the 55 t car weight, also serves this purpose; without them an electrical power of 380 kW would have been required. The reduction in the speed of the elevator also serves to improve energy efficiency. The inverter comes from Nidec.

The effective power is metered and averaged for each trip. At the time of the visit, the Janitza display showed 3 x ca. 22 kW; one display was at zero. The average value is ca. 25 A when the cabin is empty and ranges up to a maximum of 228 A. The effective power was negative when the cabin was empty, and the regeneration amounted to 3 kW. Including this trip, the meter showed 2,042 trips so far.

What Can Be Found in the Shaft Pit

Access to the pit is located in the operating room right at the front next to the door on the right. A ladder provides access down to the base slab. The shaft measures 4.80 m in width x 23.80 m in length. The pit is 2.50-m deep.

The drive in the shaft consists of four hydraulic cylinders (diameter 185 mm) with hydraulic and mechanical compensation of the stamps by means of rack and pinion gears to prevent distortion. Approximately 3,500 l of HLP 46 hydraulic oil are filled in and are under an oil pressure of 21.3 bar. The floor of the shaft is designed as a collecting pan in which the landing buffers are placed. To access the car beams, the buffers are dismounted, and the car is lowered.

The four counterweights, each weighing 6.75 t, can be seen. They consist of stacked steel plates. They are arranged symmetrically at each corner, suspended 1:1 on 12-mm ropes and run on 480-mm rollers.

The car is mounted in a steel frame. You can also see the eight statically relevant and two statically irrelevant, i.e., a total of 10 guide rails; for comparison: a passenger elevator has two. They are anchored in the concrete with 50/30 HALFEN-rails.

What Is Placed Above the Car

The car is raised in the middle to balance the steel bridge construction of the car. A continuous beam runs lengthwise across the roof of the car, crossed by 160-mm diagonal bracers.

Four toothed racks stabilize the height of the car in the middle of the sides and, in addition to the hydraulic compensation, mechanically secure it against lowering. They are connected to two torsion shafts. If the car travels away, it is held by the shaft.

The T140 guide rails with 31.8-mm head and the slide rails are clearly visible from the top. The slotted hole serves as a support for the bolts. Here, the counterweight suspension is located, too.

The door swords and door rollers above the door frame are also visible from above.

The shaft has a daylight hatch on the top of the concrete ceiling.

How the Journey Goes

Two trailers with a total weight of 25 t are coupled to a driverless tractor unit. The loaded vehicle is requested by a button from the assembly area. The train, which approaches from the parking lot at a speed of approximately 10 km/h, for safety reasons, projects a warning sign on the ground in front of it — similar to the bluespot of forklift trucks.

In automatic mode, the car picks up the preloaded trolley in the basement where it stands flush on eight support bolts as it enters. Once the train has retracted, the car is raised. With a click, the bolts of the top locking mechanism are retracted. The elevator moves smoothly. A single journey takes about 1 min.

How the 3XL Elevator Is Integrated Into the VW Production Process

The proximity to the adjacent Mittelland Canal, via which materials were received and completed commercial vehicles were shipped, was an important factor in the choice of location for the VW plant in 1955. On March 8, 1956, production of the VW Bus “Bulli” started, which reached a milestone in 2019 with 10 million vehicles produced in Hanover. Today, the German location is a pioneer of automated plant logistics in the group under the motto “Increasing efficiency via automation and digitalization,” in which the heavy-duty elevator described above enables the fully automated just-in-time delivery of components to the robots in the assembly. The plant is the size of a small town with its own restaurants, a “mayor” aka plant manager, a fire department, emergency doctor and ambulance.

The production process, which is lined up like tines on a comb along a “motorway” between the production section and the administration building, begins with the molding plant. Among other things, there is a large-capacity vacuum press from Schuler, which shapes the side panels for the VW bus from pre-punched and pre-cut sheet metal from coils, so-called blanks. The press has the dimensions of a medium-sized horizontally placed apartment building. The tools are changed by crane. At the end of the press, a robot system picks up the pressed parts and sorts them into racks. The pilot project is going so well that a roll-out to the other presses is currently being investigated.

This is followed by a smaller, quieter hall where maintenance and training are located. Some 500 apprentices are being trained in eight trades and seven dual study programs in Hanover.

The degree of automation in the body shop in the adjoining Hall 1 is approaching 93%, depending on the body being built; this means that a total of 50 employees in three shifts plus 1,500 robots for laser welding and cutting, as well as pre-assembly, are each directed or monitored by a single person at computer-controlled control stations on the two lines for the currently three bodies (T6.1, Multivan and ID. Buzz). The employees wear a smartwatch that sends instructions or error messages from the central computer directly to their watch and can even forward errors directly to maintenance if necessary.

Production takes place on three levels: The components move at the bottom, the machines in the middle and the partially finished products are transported above. The eight automated tractors operating in the body shop, known as “Schleppi,” which use the freight elevator, are coupled and uncoupled fully automatically on the middle floor. These vehicles transport components between the logistics areas/warehouse and the body shop from the contractor’s parking lot on the lower floor through the freight elevator or via the ramp into the hall for processing on the middle floor. This is also where the vehicle batteries are changed; during this time, replacement vehicles are provided.

Assembly in Hall 2 is traditionally the area with the most manual activities and therefore also the most employees. A further 40 Schleppis are in use here. They supply the assembly area with purchased parts from other service providers. Up to 130 so-called “flounders” (underride AGVs) are also in operation in assembly. These supply the assembly lines/cycles directly with parts from the so-called supermarkets. The underride AGVs recharge automatically in a station like a robotic lawnmower.

Approximately 300,000 bins are constantly on the move in production. When a bin is empty on-site, an employee pulls a cord, which triggers a new transport and, if necessary, an elevator ride.

In the subsequent final assembly in the neighboring hall, a dashboard pre-assembled outside the plant was being inserted into the body of the electric vehicle by an employee using a manipulator at the time of the tour. The brand aims for 55% of commercial vehicles produced to be purely electric by 2030. The ID. Buzz is already today being handed over to its new owners with a CO2-neutral balance sheet.

Quality control is carried out using cameras and sensors. In addition, all vehicles are then sprinkled with water to check for leaks and driven over a vibrating track.

VW Group

The VW Group, based in Wolfsburg, Germany, incorporates 10 automotive brands from five European countries, plus other brands and business divisions including financial services. According to the 2022 Annual Report, the VW Group is one of the largest private sector employers in the world; including Chinese joint ventures, it employed 675,800 people and generated sales of EUR279.2 billion.

The VW Group English version

The VW Group German version

VW heavy duty vehicles (Volkswagen Nutzfahrzeuge VWN)

In Hanover, Germany, Poznań and Września, Poland, and Pacheco, Argentina, approximately 24,000 employees produce 13 million vehicles per year ranging from the Transporter, Multivan, Caddy, Crafter, Amarok to ID. Buzz and the California models. VWN is also the VW Group’s leading brand for autonomous driving and mobility services.

Since 1956, vehicles have been manufactured at the main plant in Hanover on two production lines plus foundry and production of electrical components, currently employing around 13,000 people. In three-shift operation, around 800 of the purely electrical drive ID. Buzz models for private and transportation purposes, Multivan as a plug-in hybrid for private users and T6.1 “Bulli” as a panel van through to a motorhome (until 2024) have been produced per day since 2022. The plant covers 1.1 million m2, of which 400,000 m2 are built on. A total of 63 elevators plus various lifting platforms are installed here.

Deutsche Aufzugstechnik GmbH (DAT) with SAM

DAT, based in Berlin, has 14 branches in Germany plus two branch offices, including SAM. DAT offers elevator technology for all types of buildings and special systems for special applications, regional service and repairs of elevator systems from all manufacturers, as well as modernization.

Among other things, SAM specializes in heavy-duty elevators as custom-made products with payloads of up to 50,000 kg with forklift loading. The cabin sizes range up to 5 m x 25 m x 4 m (W x D x H); the equipment includes roof hatches, integrated ladders, touchdown devices, traffic lights, vestibule monitoring, load measurement sensors in the floor, etc., and floor coverings made of checker plate, stainless steel, galvanized or sheet steel. Cabin and landing doors are available in heavy-duty versions: landing doors are also available as lifting doors or roller shutter doors. In the 1980s, SAM supplied the largest one-piece hydraulic cylinder with a ram diameter of 680 mm and a length of 35 m to Japan, according to the Guinness Book of Records at the time.

Ricken has been with SAM for 35 years. He previously trained as a technical draftsman. After changing to planning and designing elevators, he completed an additional education as a mechanical technician. He is now branch and engineering manager.

For the English version

For the German version

Get more of Elevator World. Sign up for our free e-newsletter.