Longtime consultant discusses role in designing vertical-transportation systems.

This paper was presented at Elevcon Berlin 2018, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 22, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers.

This article explains the preconditions for becoming an elevator consultant and the necessary professional ethics, such as the need to be independent and neutral. It recounts your author’s 45 years as an elevator and building consultant, giving details about particular projects, describing work done in different standardization committees and looking at changes in technology over the past 50 years.

Duties of the Consulting Engineer

When I was a young engineer, I worked in a large company, and my job was to sell elevators in Frankfurt, Germany. In addition to advising different building owners, I also advised major consulting companies. I made specifications and price comparisons for consulting firms and included my own quotation.

If an elevator company consults a building owner, the building owner knows the elevator company is not neutral. That’s OK. But, a consultant has to be independent and neutral. When an elevator company performs the work for a consultant, it is not OK. The consultant has deceived its client.

With this in mind, in January 1972, I ended my work for the elevator company and began to work as an independent elevator consulting engineer. Before this time, there were no independent elevator- specialist engineers in Germany, possibly not even in Europe. My goal was to help clients find the best solution for vertical transportation, without in any way being influenced by elevator company sales campaigns.

In Istanbul in 2004, my friend and colleague Ami Lustig spoke about the duties of an elevator consulting engineer. His fundamental message was:

“The elevator consulting engineer has only one goal, and that is to help his client achieve a safe, modern vertical-transportation system specifically designed to meet his particular requirements.”

That’s my belief, too. An independent elevator consultant is paid by the client and nobody else. A good elevator consultant needs to be trusted by clients and elevator companies alike.

On the basis of independence and professional ethics, my company expanded in the span of 45 years from one person to 18, with offices in Oberwesel/ Rhine, Frankfurt, Madrid and Berlin. We are currently working on 10 high-rise towers, two airports (not in Berlin) and many others.

Working as an Elevator Consultant, Example 1

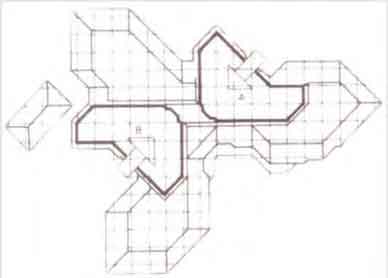

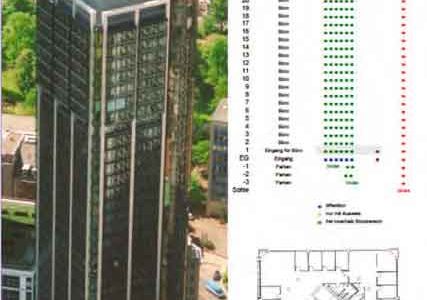

Deutsche Bank bought this project (Figure 1) under construction, after the foundation was finished. In each tower, a high-rise group and a low-rise group with four elevators in each were planned, and a contract to install the elevators was awarded to a known German elevator company. The client asked me two questions:

- Are four elevators for each group enough?

- Is the contracted elevator company able to install effective elevators?

My answer to both questions was “No.” Firstly, for a good elevator service in both towers, the high-rise and low-rise groups would have to have five elevators each, and, secondly, the contractor was not able to install effective elevators — they didn’t have effective doors. At the time (in 1978), effective doors were not available on the market, which meant that elevator companies had to produce all components themselves. The contractor had doors with a locking bolt, and it took a very long time for the doors to lock.

The contractor lost the job but received generous compensation. I was commissioned to design the elevators. As a result, there are two elevator groups with five effective elevators in each group (with excellent doors) in each tower (Figure 2).

Working as an Elevator Consultant, Example 2

We designed the elevators for a new building for a semi- governmental institution. We arranged the tender, and I checked and evaluated the offers we received. In my assessment for the client, I listed the advantages and disadvantages for each offer; also, that one elevator company was not able to fulfill the technical conditions. I had to go to the client’s board member responsible for the new building, and he told me a member of the German Parliament would come to him with the request to award the contract to the company I had disqualified. I was told to write him my reasons for the disqualification. I did, and it was clear to me that my letter would immediately go to the company I had rejected.

Years later, the director of this company came to my office, and we spoke about my letter. He said he had thought badly of me for weeks and then changed his mind, believed I was right and proceeded to eliminate the deficiencies I had criticized.

Working as an Elevator Consultant, Example 3

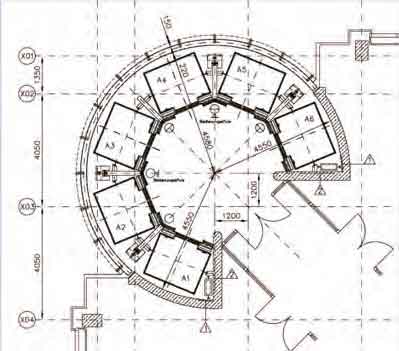

Eurotheum (Figure 3) is a very small building. During the architectural competition, the architects had the idea of arranging the elevators at the corner of the building in the direction of the crossroad. The vertical traffic analysis resulted in a need for six elevators, which we arranged in a 270° circular arc. The architects won the competition with this solution.

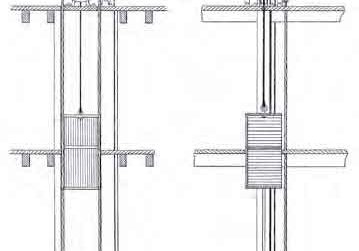

Figure 4 shows the Eurotheum hoistway with the cars and counterweights. Two counterweights are fixed at the concrete walls, and four are fixed on the end of the hoistway beams. The hoistway beams are jib booms. We designed, dimensioned and fixed the jib booms.

This solution means there is no connection with the glass façade, and any deformation of the façade by wind poses no consequences for the hoistway beams. Another advantage was that it was possible to install the elevators independent of the façade installation.

At the time, 1996, there was only one company offering destination control systems. To get at least three offers, we had to make our elevator traffic analysis for conventional control systems. To get a reference project with destination control, the aforementioned sole provider made the best offer and won the contract. It was the first high-rise building with elevators with destination control.

When the Eurotheum was finished, the European Central Bank rented floors one-21. Its entrance was on floor 1, so it got an additional stairway and elevator in the entrance hall of the building. There was a public bar on floor 22, and there were apartments on floors 23-29. All tenants and visitors to the building can use any of the six elevators without meeting people from other parts of the building. This is one of the possibilities offered by destination control systems.

Costs

When we design the elevators for a building, the client needs to know the cost for the elevators, so we have to make a cost calculation. The bid sums of the elevator companies are usually a little higher, while the order sum is a little lower.

One time, some years ago, the bid sums were more than 100% higher than our calculated sum. The offers were collusive. We found a new company to perform the job with costs a little higher than our calculated costs.

Preconditions

Preconditions for becoming a consulting engineer for elevators are a good technical background and reputation, and knowledge of:

- Elevators

- Costs for elevators

- Technical regulations for elevators

- Technical regulations for buildings

- Buildings

- The elevator market

- The advantages and disadvantages of the diverse products offered by elevator companies

Standards

To get the best possible information about technical rules, I worked for the German Institute for Standardization (DIN), the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN). Hoistway dimensions were already standardized in the 1970s. For elevator experts, it’s better to have big hoistways, while for building experts, the hoistway must be as small as possible. ISO 4190 requires only plus tolerances for hoistway width and depth. The building regulations for hoistway dimensions require plus/minus tolerances.

The members of the standardization committees are almost all members of elevator companies, so the standardizations are good for the elevator companies. For DIN, I was the only elevator consultant. For ISO, Simha Lustig and I were the only elevator consultants; all other committee members were employees of elevator companies. One time, Simha Lustig and I tried to win approval for a norm for a 2.1-m-depth car with 1.4-m (or 1.35-m) width and 1-m center-opening doors. The members of elevator companies rejected this.

For CEN, working on the revision of EN 81-72, I was the only elevator consultant. EN 81-72 requires that a run from the firefighter entrance floor to the highest floor last no more than 60 s. For a 200-m travel height, an elevator needs a speed of 4 mps. To reduce the suction effect behind the running car, I tried to get a speed limit of 3 or 3.5 mps for firefighter elevators. The suction effect behind the running car can draw smoke into the hoistway. At the end, we have a limit, but 4.5 mps is too high for my intention.

ISO 4190-6 “Lifts — Passenger lifts to be installed in office buildings, hotels and residential buildings — Part 6: Planning and selection” is currently in revision. One of the goals is to make simulations from different companies more comparable. We can standardize the input for a simulation, but the output with different simulation software will not be comparable. We spoke during Elevcon Lucerne and Elevcon Miami about this problem, but there is, as yet, no solution.

In Germany, we are working for a new DIN norm, “Acoustical design for lifts,” in response to the demand for less-noisy apartments.

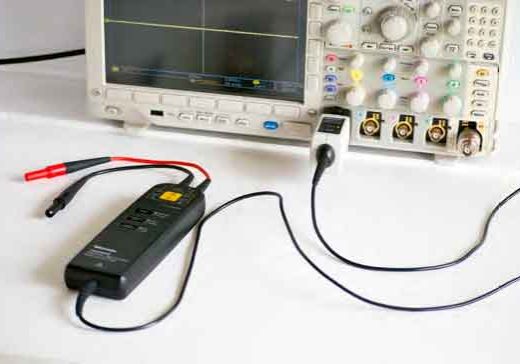

Energy Consumption

About 15 years ago, my friend Friedhelm Meermann said we have to do something about the high energy consumption of elevators. Meermann was a retired police officer and worked as a consultant for quality management for small elevator companies, as well as for my consulting company. I first met him in a VDI working group he convened. At the time, energy consumption of elevators was not very important to me. The percentage of the energy consumed by elevators in a building is very low. We asked elevator companies about the energy consumption of their offered equipment. The result was disastrous. None of the elevator companies knew anything about energy consumption of their products. Then, two major elevator companies made energy measurements with new and old elevators in Switzerland.

As a result, the old elevators with relay control systems had the lowest energy consumption. The energy consumption of the old elevators in standby mode was nearly zero, whereas the energy consumption of the newer elevators in standby mode was much higher.

Meermann was convenor of the VDI 4707 working group, and the new rule was finished in December 2007. After that, VDI 4707 sheet 2, energy consumption of elevator components, was published. Over the past 10 years, energy consumption of elevators has dramatically declined. Meermann, initiator of the VDI 4707, died last December.

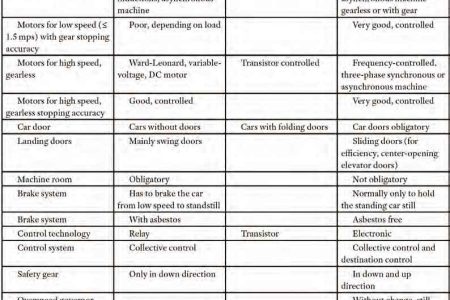

Changes in Elevator Technology Over the Past 50 Years

Many elevator components have changed in this time, as noted in Table 1.

*“Stop lost time” is the time an elevator needs to make a stop. See Elevator Technology 6, Elevcon 1995, Hong Kong, “Elevator doors for comfortable and efficient elevators.” The term “stop lost time” is defined by Jappsen Ingenieure to obtain provable and comparable quality characteristics for traffic calculations and tender documents. Three measurements are required:

- Time (t1) from A to B without stop (e.g., 20 s.)

- Time (t2) from A to B, including one stop in the middle between A and B (e.g., 32 s.)

- Door open time (t3) (e.g., 4 s.)

Get more of Elevator World. Sign up for our free e-newsletter.