ELEVATOR WORLD in the U.K.

Feb 27, 2023

A look at William C. Sturgeon’s visit to London in September 1964.

On 28 August 1964, ELEVATOR WORLD founder William C. Sturgeon departed Mobile, Alabama, on a five-week vertical-transportation (VT) industry tour of Europe. His tour began in Vienna, Austria, followed by stops in Italy, Switzerland, West Germany, Denmark, and — his last stop — the U.K. He arrived in London on 24 September.

Sturgeon’s published account of his travels appeared as a two-part article, titled “European Notebook,” published in the December 1964 and January 1965 issues of EW. The articles’ format consisted of the pages of his “notebook” arranged against a background of material collected during his travels (Figures 1 – 4). The account of his visit to the U.K. is reprinted below. Where appropriate, the text has been annotated to provide details intended to situate people, installations and events in a historical context. Other than for clarity, any new editing to the original text is minimal. Your author’s notes and commentary are in italics.

Thursday, September 24 — Copenhagen-London

The Copenhagen airport is one of the most beautiful in Europe, its free port filled with shops selling cheese and other delicacies. At the other end of the flight is the London Terminal — Europe’s busiest, perhaps the heaviest traffic in the world. No place needs a larger commercial airport more. At peak periods it is a shambles within the building and on the roadways leading away.

Friday, September 25— London

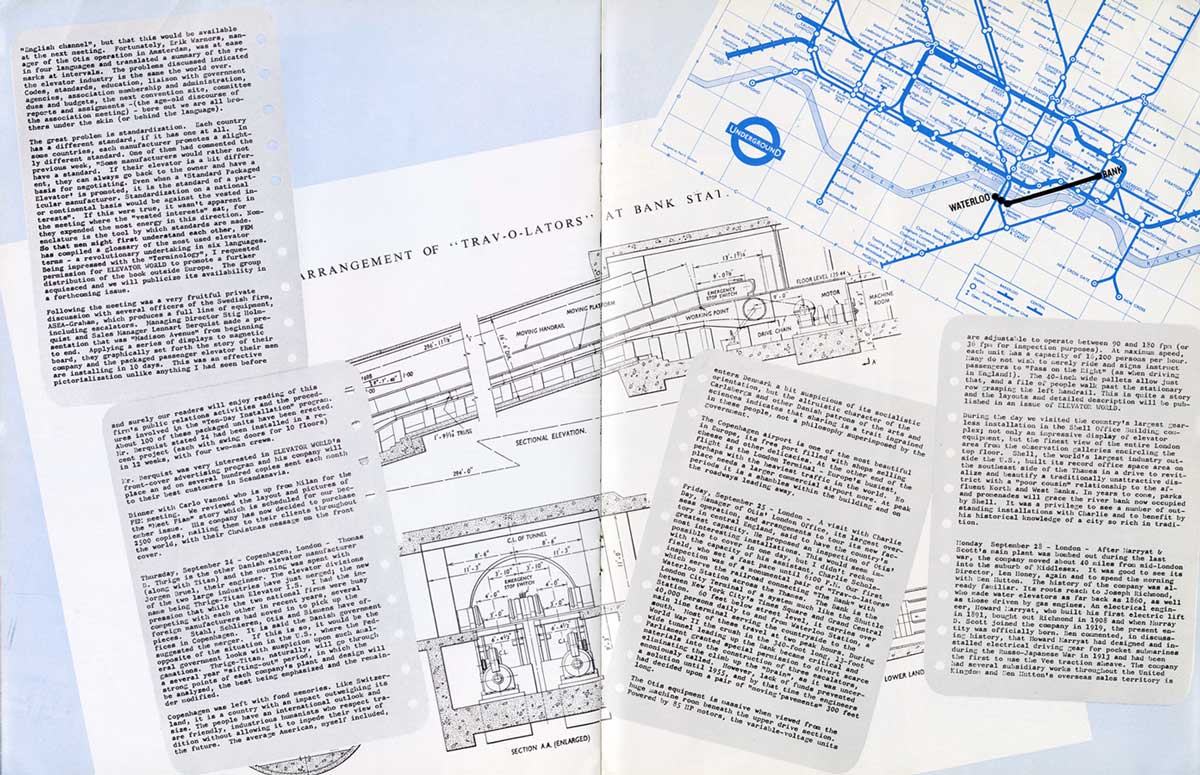

A visit with Charlie Day, manager of Otis’ London Office, its largest over-seas operation, and arrangements to tour its new factory in central England, said to have the country’s greatest capacity. (1) He proposed an inspection of Otis’ most interesting installations. This would seem impossible to cover in one day, but I didn’t reckon with the capacity of his assistant, Charlie Scholefield, who set a fast pace until 6:00 P.M. Our first inspection was of a monumental pair of “Trav-o-laters” which serve the railroad connecting “The Bank” with Waterloo Station across the Thames. (2) The Bank is the London City Terminal of a system much like the Shuttle between New York City’s Times Square and Grand Central Station. 60 feet below street level, it carries over 40,000 persons daily to and from Waterloo Station, a main line terminal serving the countryside to the south. Most of these travel at two peak hours. During World War II the crush in the 340-foot long, 13-foot wide tunnel leading up the Bank became critical and Parliament granted special permission to divert scarce materials into the construction of three escalators, eliminating the climb up the “Drain,” as it was unceremoniously called. However, lack of funds prevented a solution until 1955, and by that time the engineers had decided upon a pair of “moving pavements” 300 feet long.

The Otis equipment is massive when viewed from the huge machine room beneath the upper drive section. Powered by 85 HP motors, the variable-voltage units are adjustable to operate between 90 and 180 fpm (or 36 fpm for inspection purposes). At maximum speed, each unit has a capacity of 16,200 persons per hour. Many do not wish to merely ride and signs instruct passengers to “Pass on the Right” (as when driving in England!). The 40-inch wide pallets allow just that, and a file of people walk past the stationary row grasping the left handrail. This is quite a story and the layouts and detailed description will be published in an issue of Elevator World.

During the day, we visited the country’s largest gearless installation in the Shell Office Building complex; not only an impressive display of elevator equipment, but the finest view of the entire London area from the observation galleries encircling the top floor. (3) Shell, the world’s largest industry outside the U.S., built its record office space area on the southeast side of the Thames in a drive to revitalize and beautify a traditionally unattractive district with a “poor cousin” relationship to the affluent North and West Banks. In years to come, parks and promenades will grace the bank now occupied by Shell. It was a privilege to see a number of outstanding installations with Charlie and to benefit by his historical knowledge of a city so rich in tradition.

(1) Charles Frederick “Charlie” Day (1907-1982) was a fourth-generation member of the U.K. VT industry. His great grandfather, John Marsh Day (1821-1902), joined R. Waygood & Co. (founded in 1833) as a foreman in the 1840s, was made a partner in 1871 and retired in 1887. His son Charles Day (1854-1928) (Charlie’s grandfather), after serving an apprenticeship with Appleby Brothers, joined Waygood in 1871, where he served as works foreman. Upon the retirement of his father, Charles Day became a partner. He retired in 1920; during his career, he witnessed the transformation of the company into Waygood-Otis Ltd. At the time of Charles Day’s retirement, his son, Charles Herbert John Day (1878-1953) (Charlie’s father), was employed as a company director and works manager. Charlie joined the company in 1924 and was named a director in 1955. Otis purchased a controlling interest in 1957, and the company name was changed to Otis Ltd. Charlie was named chairman and managing director in 1961, roles he held until his retirement in 1972.

(2) TRAV-O-LATER® was the brand name adopted by Otis for a moving sidewalk system the company introduced to the public in the late 1950s. The first installation, completed in 1959 in San Diego, California, provided a dramatic demonstration of this new technology. Two TRAV-O-LATERs were placed on a bridge that connected the El Cortez Hotel with the new Trav-o-later Motor Hotel and hotel parking garage. The moving sidewalks were 24 in. wide and 127 ft long. The TRAV-O-LATERs at the Bank Underground Station were, in fact, the second installation of Otis’ new system and, thus, the first in Europe. Work began in 1958, and the installation was completed in September 1960. Each sidewalk was 40 in. wide and 295 ft long.

(3) The Shell Centre, designed by Howard Robertson and built 1957-1962, was one of the first skyscrapers built in the greater London area. The controversial design was criticized by the Royal Fine Art Commission (and others) for its height and modernist architecture. When completed, the center consisted of two independent structures, which were often referred to as the “upstream” and “downstream” buildings, given their placement on either side of the Hungerford Bridge. The main or upstream building consisted of a 338-ft-tall, 26-storey tower, which included a 10-storey U-shaped addition that wrapped around the rear of the tower. The downstream building was a 10-storey L-shaped building. In 1962, the tower comprised the largest office block in the U.K., and it was promoted as the largest air-conditioned building in Europe. It also featured, as noted by Sturgeon, an observation gallery on the 25th floor. The tower or upstream building employed 57 Otis passenger and goods lifts and 12 Otis escalators. The appearance of Shell Centre changed dramatically in recent years with the demolition of the 10-storey portion of the upstream building as part of a redevelopment project completed in 2020, which created Southbank Place.

Monday September 28 — London

After Marryat & Scott’s main plant was bombed out during the last war, the company moved about 40 miles from mid-London into the suburb of Middlesex. It was good to see its Director, Len Honey, again and to spend the morning with Ben Hutton. (4, 5) The history of the company was already familiar. Its roots reach to Joseph Richmond, who made water elevators as far back as 1860, as well as those driven by gas engines. An electrical engineer, Howard Marryat, who built his first electric lift in 1892, bought out Richmond in 1908, and when Murray D. Scott joined the company in 1919, the present entity was officially born. Ben commented, in discussing history, that Howard Marryat had designed and installed electrical driving gear for pocket submarines during the Russo-Japanese War in 1913 and had been the first to use the Vee traction sheave. The company has several subsidiary works throughout the United Kingdom and Ben Hutton’s overseas sales territory is filled with names having exotic overtones — Karachi, Nairobi, Uganda, Auckland, etc. However, his stories of several field trips indicated the romance of selling elevators in some parts of India and Africa might wear rather thin after a few months.

Backed up to the M & S plant is Dewhurst & Partner Ltd., the largest manufacturers of electro-mechanical brakes in Europe and makers of lift control equipment for the trade. Employing upwards of 800, Dewhurst turns out an impressive array, making every element of relays, starters, contactors and other components comprising the most complex automatic control gear. Alan Dewhurst and A.J. “Tiny” Ward explained the operation of three lift controller production lines in which the boards “flowed” along in the latest automated fashion. (6, 7) A battery of five new machine tools linked into a programming device was busy forming small parts, the only human touch being the periodic insertion of a new punch card rescheduling the motions.

Despite all this automation, Dewhurst has one of the finest apprentice training systems. The instruction of young men over a 4-year period is stressed throughout this country’s elevator industry, with strong liaison between the school system, government, unions and companies. The British elevator man, in the shop or in the field, is probably one of the best indoctrinated craftsmen in the world. Elevator World will devote substantial space to a description of the British Apprentice System in the future. Developed over many years, it has aspects of worth for other national elevator industries.

(4) Leonard William “Len” Honey (1902-1987) joined Marryat & Scott after the end of World War I. During his career, he served the firm as chief estimator, production manager and director. Honey’s obituary noted that his “greatest contribution was the introduction of standard lifts and the stocking of components without waiting for orders. At that time, elevator makers in England would design each lift independently with relatively long waiting times for the parts to be manufactured. With Honey’s system, the equipment could be delivered from stock and site construction started as soon as layout drawings were approved. Although the system began with the simplest jobs, it eventually evolved to include high-speed installations with more elaborate control systems. When the British Standards Institute and the Europeans later introduced standardised lifts, it was a relatively simple matter for the Marryat & Scott system to be adapted to include this, also.” (Ben Hutton, “A Lifetime in Lifts,” EW, January 1988). Honey also compiled the first comprehensive account of U.K. lift regulations: Lifts: A Collation of British Legislation and Authoritative Publications Together With Recommendations for Lift Design and Installation, (published by Marryat & Scott in 1946, reprinted in 1948).

(5) Benjamin P. “Ben” Hutton (1913-2002) began his VT career in 1928 with the Express Lift Co. In 1932, he joined Marryat & Scott. Following World War II, he oversaw the company’s extensive export business in Europe, Africa, India, Singapore, the West Indies and South America. Hutton also had an established connection to EW that began prior to Sturgeon’s September visit. In early 1964, Hutton had agreed to write monthly columns for the magazine (titled the “Atlantic Cable”), which, according to Sturgeon in his introduction to the first column, were intended to “acquaint our readers with the activities of the English elevator industry” (EW, June 1964). Between 1964 and 1971, Hutton contributed more than 75 articles on the U.K. lift industry.

(6) Alan Dewhurst (1924-2012) studied engineering at University College, London. Following the completion of his studies in 1949, he served his graduate apprenticeship with the British Thomson – Houston Co., Ltd., Rugby. He joined Dewhurst & Partner in 1951 (the firm had been founded by his father, Melbourne Dewhurst, and Howard Marryat in 1919). He began in the Controller Test Department, eventually becoming department head. This was followed by leadership roles in product design and production. Following the death of his father in 1962, he became company chairman.

(7) Unfortunately, very little is known about Albert John Clarke “Tiny” Ward (1919-1989). He may have been from the Newcastle area; he was mentioned in a newspaper account from 1938 concerning students enrolled in the “Jarrow evening classes” who had recently “passed the examinations held by the Northern Counties Technical Examinations Council” (Newcastle Evening Chronicle, July 9, 1938). Ward’s name was included in a list of first-year electrical engineering students. Details of his career with Dewhurst are equally limited, other than the fact that he was elected to the Board in 1950. Lastly, the origin of his nickname also remains a mystery.

Tuesday, September 29 — London

The Dewhurst tour came to a grinding halt yesterday – the interruption being an attack of “Tourist Illness,” a malady seeming to combine the strongest features of the flu and malaria! After commenting on my green color, Ben advised “everyone gets it sooner or later” and I was “having it later” — small consolation for one feeling as well as looking green. Tiny Ward secured a potion from the chemist (druggist), claiming it had a history of effectiveness dating back to the Crimean War. The ailment was forgotten only while swallowing the black and bitter stuff! Ben, well versed in the Indian and African versions, stated the cause is not contaminated water, as the European countries have purification systems (although unbottled water is rarely served), but new kinds of “local standard germs,” to which a tolerance has not been built.

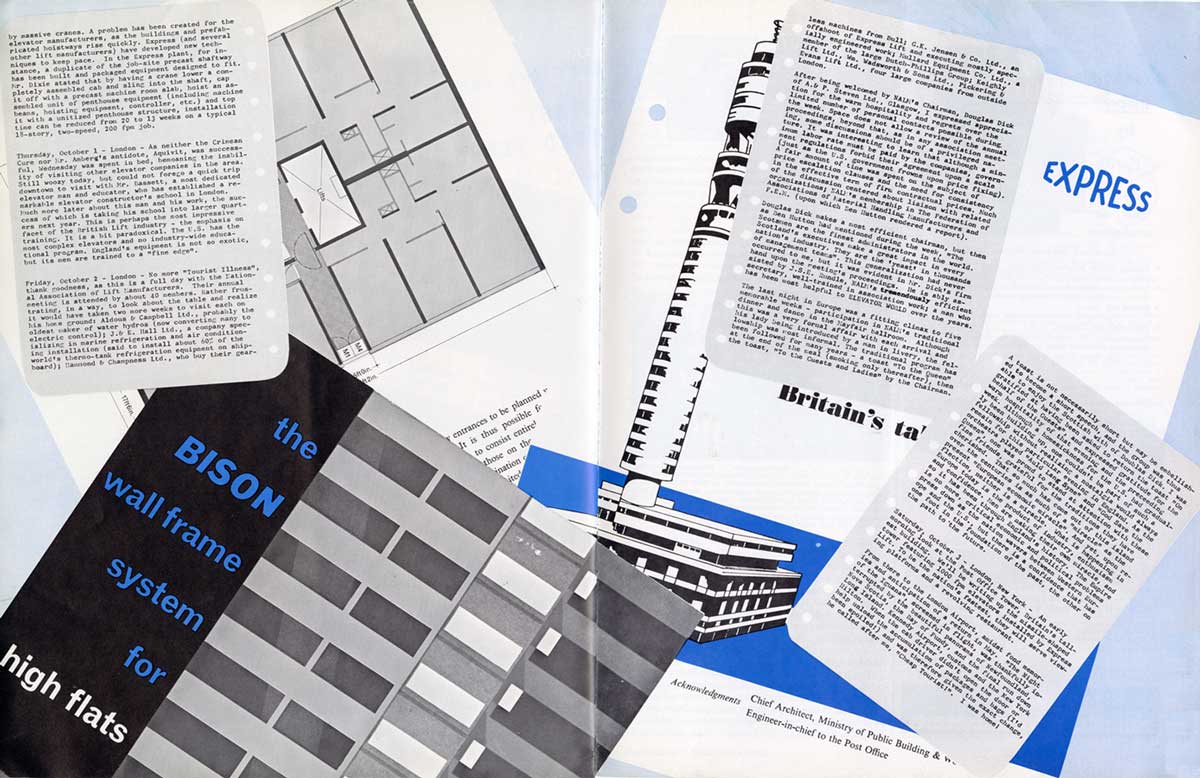

After dosing the “British Standard Germs” with the Crimean War mixture, the day-and-a-half train ride today terminated with a welcome on the Northampton platform by Chris Amberg, Director of The Express Lift Company, largest of the home-owned elevator manufacturers. (8) Mr. Amberg, a hearty Dane in his 70s, reflected in his office on the history of Express Lift. It deserves a number of pages in Elevator World (and will have them later). Sufficient to say, the foundation goes back to Major & Stevens Ltd., a pioneer which listed over 1,500 elevator installations in its 1880 catalog. The present Express Lift entity was formed in 1917 with the financial backing of the General Electric Co. Ltd. (No relation to the U.S.’s G.E.) A little over 30 years ago, Express entered into agreements with Westinghouse International Electric Co. for the exchange of elevator patent and manufacturing information; apparently a very satisfactory relationship, although Express’ close ties with G.E. Ltd. (it purchased all the subsidiary’s shares in 1935) have prompted the use of its design and manufacturing facilities in the instance of geared and gearless motors and MG sets (the V.V. units are of an up-ended type with vertical shafts simplifying availability for maintenance, according to Mr. W.A. Dixie, Director of Engineering). (9) So numerous were the points of interest in the plant, they must be treated in a separate story, but mention should be made of 1, a ceiling-mounted gearless machine offset to one side of the test tower shaftway to reduce penthouse height, and 2, a very neat metal box about 10-feet long by 12-inches by 4-inches, prefabricated, with all car wiring (including car station, junction car below and car top control above). This package unit, finished to match the cab interior, is installed as part of the return panel, greatly facilitating wiring and subsequent trouble-shooting.

Express has developed an interest in the “Bison” and several systems gaining prominence in England (and the Continent), whereby complete apartment house structures are prefabricated off-site with huge sections of floors, walls, partitions, and roofs being placed by massive cranes. A problem has been created for the elevator manufacturers, as the buildings and prefabricated hoistways rise quickly. Express (and several other lift manufacturers) have developed new techniques to keep pace. In the Express plant, for instance, a duplicate of the job-site precast shaftway has been built and packaged equipment designed to fit. Mr. Dixie stated that by having a crane lower a completely assembled cab and sling into the shaft, cap it off with a precast machine room slab, hoist an assembled unit of penthouse equipment (including machine beams, hoisting equipment, controller, etc.) and top it with a unitized penthouse structure, installation time can be reduced from 20 to 13 weeks on a typical 18-story, two-speed, 200 fpm job.

(8) Vitus Hans Christian “Chris” Amberg (1887-1966) was born in Copenhagen and educated at the Danmarks tekniske Højskole (Technical University of Denmark). From 1913 to 1918, he worked for the Western Electric Co. Ltd. in London. He joined the General Electric Co. Ltd. (GEC) in 1920, working primarily in the area of telephone development and manufacturing, eventually becoming head of the GEC Telephone Manufacturing Company in Coventry. In 1936, Lord Hugo Hirst (one of GEC’s founders) asked Amberg to take on the role of managing director of the Express Lift Co.

(9) Unfortunately, very little is known about William A. Dixie (1903-1992). He was employed as a draughtsman with Smith, Majors and Stevens in 1930 when Express Lifts acquired the company. During his career he authored several articles on lifts, including: “Passenger Lifts,” British Engineering (January 1949), “Standardization of Lift Control Systems,” G.E.C. Journal (July 1954), and “The Application of Lifts for Office Buildings,” Architectural Design (March 1955.)

Wednesday, September 30 — London

Sturgeon’s bout of “Tourist Illness” kept him out of action on the 30th.

Thursday, October 1 — London

As neither the Crimean Cure nor Mr. Amberg’s antidote, Aquavit, was successful, Wednesday was spent in bed, bemoaning the inability of visiting other elevator companies in the area. (10) Still woozy today, but could not forego a quick trip downtown to visit with Mr. Bassett, a most dedicated elevator man and educator, who has established a remarkable elevator constructor’s school in London. (11) Much more later about this man and his work, the success of which is taking his school into larger quarters next year. This is perhaps the most impressive facet of the British Lift industry – the emphasis on training. The U.S. has the most complex elevators and no industry-wide educational program. England’s equipment is not so exotic, but its men are trained to a “fine edge.”

(10) The nature of the “Crimean Cure” procured for Sturgeon by Tiny Ward at the chemist is unknown; perhaps a U.K. reader can provide insights on this “black and bitter” remedy. Aquavit is, of course, a well-known cure for all manner of ills.

(11) Regrettably, nothing has been found concerning Bassett’s elevator constructor’s school.

Friday, October 2 — London

No more “Tourist Illness,” thank goodness, as this is a full day with the National Association of Lift Makers. (12) Their annual meeting is attended by about 40 members. Rather frustrating, in a way. To look about the table and realize it would have taken two more weeks to visit each on his home ground: Aldous & Campbell Ltd., probably the oldest maker of water hydros (now converting many to electric control); J. & E. Hall Ltd., a company specializing in marine refrigeration and air conditioning installation (said to install about 60% of the world’s thermo-tank refrigeration equipment on ship-board); Hammond & Champness Ltd., who buy their gearless machines from Bull; G.K. Jensen & Co. Ltd., an offshoot of Express lift and executing mostly specially engineered work; Mullard Equipment Co. Ltd., a member of the large Dutch-Phillips Group; Keighley Lift Ltd., Wm. Wadsworth & Sons Ltd., and Pickering & Evans Lift Ltd. (four large companies from outside London).

After being welcomed by NALM’s Chairman, Douglas Dick of A&P. Steven Ltd., Glasgow, I expressed appreciation for the warm hospitality and regrets over the limited number of personal contacts possible during the week. (13) Space does not allow a review of the annual proceedings, beyond that, as in any association meeting, some discussions should be of a privileged nature. It was interesting to learn that although a minimum labor rate must be paid by the companies, government regulations forbid their agreement upon a scale (just as the U.S. government frowns upon price fixing). A fair amount of time was spent on the subject of price escalation clauses and the need for consistency in the effective term of firm contractual prices. Much of the discussion centered about liaison with related organizations; NALM’s membership in The Federation of Associations of Material Handling Manufacturers and the Federation Europeene de la Manutention (FEM) (upon which Ben Hutton rendered a report).

Douglas Dick makes a most efficient chairman, but then as Ben Hutton had mentioned during the week, “The Scotsmen are the finest administrators in the world. Scotland’s executives make a great impact in every nation’s industry. They are the ‘yeast’ in thousands of management teams.” This generalization had never occurred to me, but it was evident in Mr. Dick’s firm hand upon the meeting’s proceedings. He is ably assisted by J.S.E. Rundle, NALM’s tremendously efficient secretary, well-trained in association work; a man who has been most helpful to Elevator World over the years. (14)

The last night in Europe was a fitting climax to five memorable weeks – participation in NALM’s traditional dinner and dance in the Mayfair ballroom. Although this was a formal affair with each arrival and his lady being introduced by a man in livery, the fellowship was most informal. The traditional program has been followed for many years – a toast “To the Queen” at the end of the meal (smoking only thereafter), then the toast, “To the Guests and Ladies” by the Chairman. A toast is not necessarily short but may be embellished to become a short speech, and the group was thus able to enjoy the Scottish wit of Douglas Dick. I was gratified at having been asked to return the toast “On behalf of the Guests,” and expressed gratitude for the warm hospitality of that evening and the preceding week. Although a homesickness for the U.S had gradually been building up, one couldn’t be part of such a fellowship without realizing a nostalgia would always remain for this particular evening in England. As the orchestra played “Auld Lang Syne” and “God Save the Queen,” one was proud to stand at attention with these fine friends, grateful for the traditions they have cherished. That so much has come out of this island over the centuries is as much of a “miracle” as the present “European economic miracle.” And yet, upon reflection, neither is a miracle. What is happening in Europe today is the product of industry enthusiasm and confidence. Men are making their own miracle, and so it has been through England’s history. The Empire is no more, critical economic and political problems press down as the nation wavers between Western Europe and the U.S., but there is a confidence that has one foot in the foundation of the past, the other on the path to the future.

(12) In April 1931, a committee composed of Nathan Mangnall (Wm. Wadsworth & Sons Ltd.), Howard Marryat (Marryat & Scott Ltd.), T. Lang (A & P Steven Ltd.), John W. Stevens (Express Lift Company Ltd.), Ernest Medway (J & E Hall Ltd.) and George H. Congdon (Etchells Congdon & Muir) gathered to discuss the creation of a lift association. The result of their efforts was the establishment of the National Association of Lift Makers (NALM) in 1932. Additional early members included Aldous & Campbell Ltd., Penrose Lifts Ltd., Pickerings Ltd., Glasgow Engineers Ltd. and John Bennie Ltd. In 1997, NALM merged with the British Lift Association (BLA) to form the Lift and Escalator Industry Association (LEIA).

(13) Unfortunately, very little information was discovered about the career of Douglas Moncrieff Cochrane Dick (1929-2000).

(14) John S.E. Rundle (b. 1906) also remains a mystery. He served as secretary for a variety of engineering organizations prior to joining NALM, including the Associated Electric Traction Equipment Manufacturers and the British Electrical and Allied Manufacturers Association. In March 1963, he sent a detailed account of NALM’s participation in a recent Congress of the Federation Europeene de la Manutention (FEM) to Elevator World, which was published in the letter-to-the editor section (“Report on European Convention”). Rundle’s account included a brief outline of European regulatory efforts since 1960.

Saturday, October 3 — London, New York

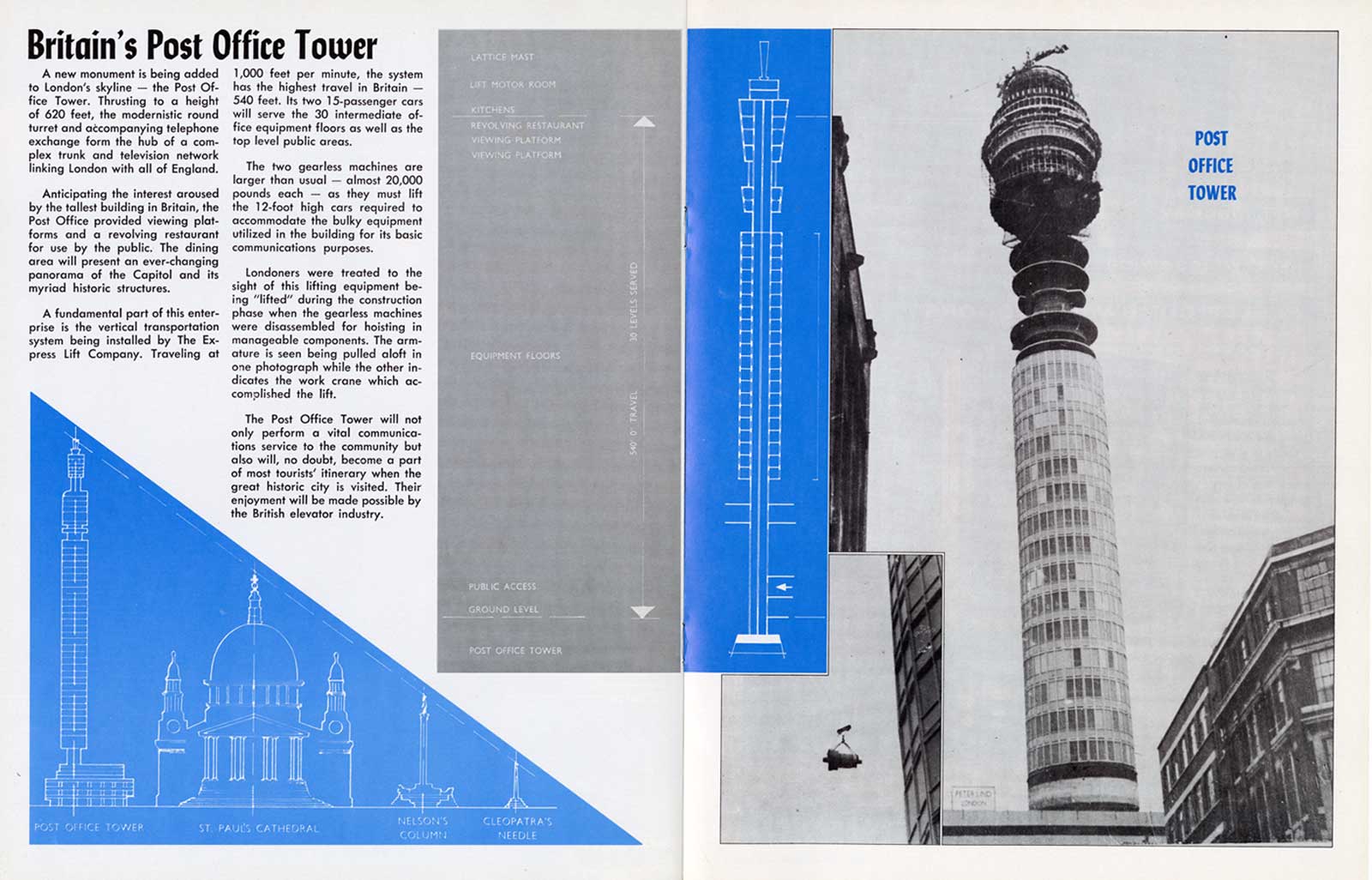

An early morning look at the Post Office Tower, Britain’s tallest building. (15) We’ll be writing up the missile-shaped tower featuring 1000 fpm elevators installed by Express Lift. To be the nation’s fastest, they will serve viewing platforms and a revolving restaurant.

From there to the London Airport, amidst fond memories and anticipation of a return in May. “The Night of the Iguana,” screened in flight, was thankfully interrupted by the beautiful panorama of Newfoundland, Nova Scotia, the Bay of Fundy, and the final run down Long Island. Kennedy Airport, customs and the New York Hilton. When the cab driver didn’t open the door or help unload the accumulation of packages and bags (I’d been spoiled!) and was therefore given the exact change, he called after me, “Cheap Tourist!” I was home!

Men are making their own miracle, and so it has been through England’s history. The Empire is no more, critical economic and political problems press down as the nation wavers between Western Europe and the U.S., but there is a confidence that has one foot in the foundation of the past, the other on the path to the future.

(15) The Post Office Tower (now known as the BT Tower), completed in 1965, was the tallest building in the U.K. until the completion of the NatWest Tower (London) in 1980. It was featured on the cover of the July 1965 issue of EW and was the subject of a brief illustrated article (Figures 5 and 6). The main structure is 581 ft tall, which was topped by an aerial rigging which brought the total height to 627 ft. The tower employed two lifts built by the Express Lift Co., which were designed to carry passengers and equipment. The lifts served 31 office and equipment floors, two viewing platforms and a revolving restaurant on the 34th floor. Each lift had a capacity of 15 passengers, a car height of 12 ft (to accommodate equipment) and a maximum speed of 1,000 ft/min. Each gearless machine weighed almost 20,000 lb. When completed, the lifts had the highest travel height in the U.K. at 540 ft.

Postscript

Sturgeon’s 1964 visit was the first of many trips to the U.K. In April 1965, he returned to Europe for a two-month visit to gather information on prefabricated building system strategies (such as the Bison system referenced above) and their impact on the lift industry. The result of this investigation was a lengthy two-part illustrated article, titled “Packages in the Sky,” that appeared in the 1965 and 1966 EW Industry Index Issues. In 1982, Sturgeon returned to the U.K. for an intensive 40-day visit that coincided with NALM’s 50th anniversary. These trips will be the subject of future articles.

Get more of Elevator World. Sign up for our free e-newsletter.