Experts work on ways to keep ground shaking from causing vertical-transportation disasters.

In the beginning, a new panorama elevator in Hamburg, Germany, regularly stalled — even without earthquakes, but also without protective measures for the elevator. When a large vessel passed the St. Pauli jetties, the waves would propagate in the sandy soil on which the long-stretched building stands.

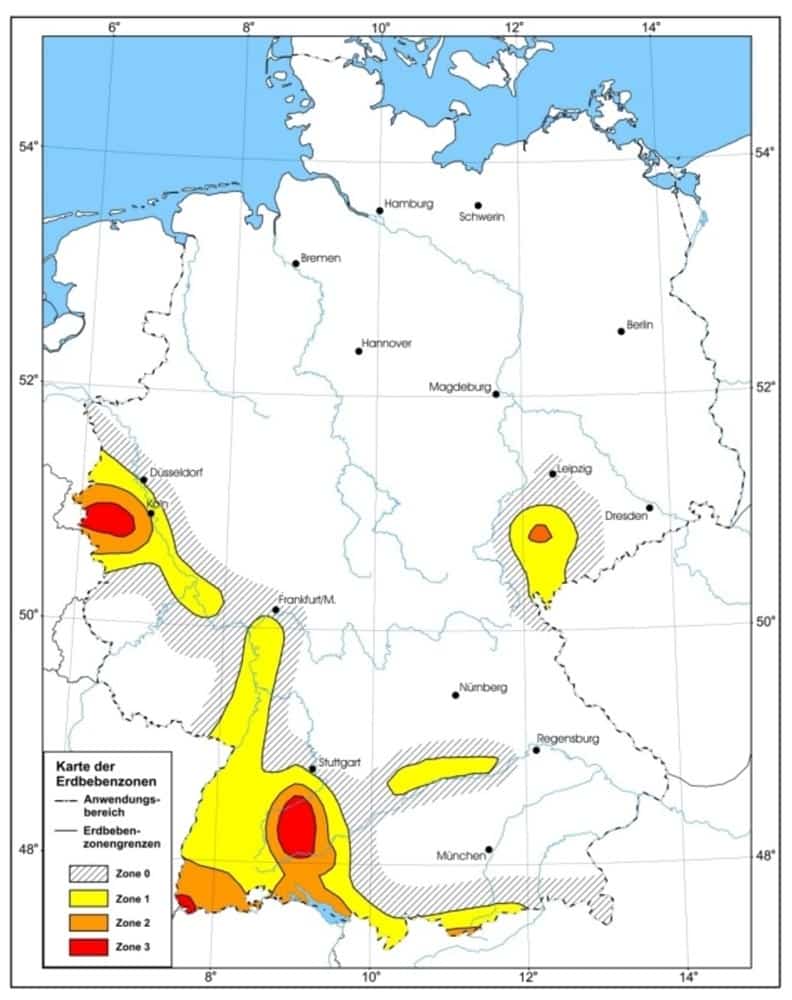

However, earthquakes now occur more frequently than expected in Germany, Austria and Switzerland. In the 30 days leading up to February 10, the earth shook in and around Germany five times, with a magnitude of 3.0 or higher on the Richter scale and 31 times between 2.0 and 2.9, which people can still perceive. Relevant for buildings or elevators are the earthquake zones 0.0 white to 3.0 red marked in the figure.

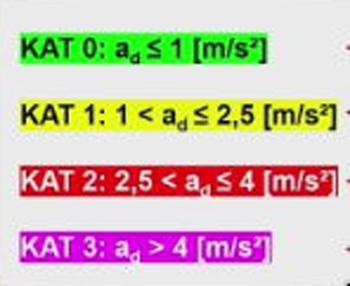

Ing. Stephan Störmer from TÜV Austria and chairman of the Austrian Committee 017 “Elevators, Escalators, and Moving Walks” of Austrian Standards International A.S.I. delved into the topic of “Risk Factor Earthquake: Safe in Elevators?” at the last TÜV Austria Elevator Day. Close to that event, the most violent earthquake in Austria of the past 20 years, with a magnitude of 4.6., occurred on March 30, 2021. The calculating method of the European standard EN 81-77:2019 for the dimensioning of elevators under earthquake conditions is based on that of the EN 1998-1 “Eurocode 8: Design of Structures for Earthquake Resistance.” The aim of the standard is to protect human life, limit damage and maintain the function of elevators in structures after the impact of an earthquake. The standard defines four categories, 0 to 3 of resistance to earthquakes for elevators. The dimensioning acceleration, as a result of a calculation taking into account a wide range of parameters, determines the assignment to one of the four categories. “We take the application of the standard very seriously in Austria,” Störmer said. Especially in the case of critical infrastructure and intensively used buildings, such as hospitals, for whom operation of functioning elevators are crucial, the risk factor for earthquakes and, of course, the needed countermeasures must be taken into account. “The possible consequences shall neither be underestimated, nor tolerated,” Störmer said.

Also read: Twenty Years of TÜV AUSTRIA Lift Day

Götz Metzdorf, structural engineer at Goldbeck Rhomberg in Austria and long-time chairperson of ISO TC 178 Working Group 6 Study Group 6, “Lifts and Escalators Subject to Seismic Conditions,” lists four planning steps for an earthquake-proof elevator:

- Clarifying the interfaces of the elevator and building, according to EN 81-77 and with the architect(s) of the building

- Consideration of regional influences on the building and, thus, for the elevators via the national annexes (NA) to EN 1998-1

- Simulations and calculations (e.g., by 3D-FEM) for machine anchoring, ropes, car and escalator frames, among others

- Special seismic dimensioning which, for example, in Vienna — due to the different reference ground accelerations for northeastern and southwestern Vienna — leads to different requirements for elevators in buildings.

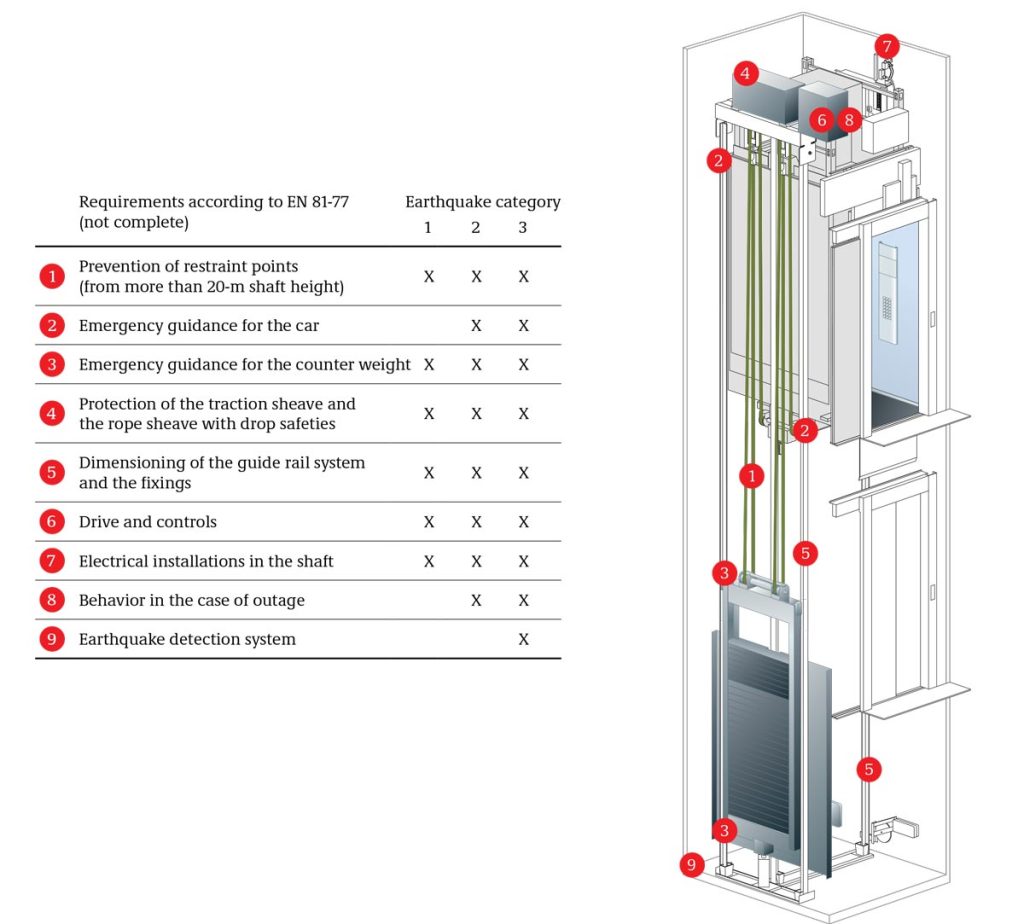

The resulting measures for the elevator are listed in EN 81-77, depending on the earthquake category, in order to prevent possible damage to elevators caused by earthquakes, such as the elevator manufacturer KONE reports in excerpts: “Rail supports were broken or have been damaged. Overspeed governor cables were broken. Roller guides were broken or came loose.”

Using simulations, such as Design of Experiments (DOE) and Failure Mode and Effects Analysis (FMEA), faults are identified in the design phase, and technical measures are taken to remedy them for future use of the elevator or escalator products. According to Metzdorf, common examples include vibration simulations for elevators and escalators in taller buildings, natural frequencies and deformations of escalators.

According to the VDMA planning guideline, architects should provide the elevator manufacturer with the following information: Seismic zone, building ground class and, if applicable, bedrock class, according to EN 1998-1 NA, significance coefficient of the building and dimensioning or reference ground acceleration. “If the civil engineer includes earthquake safety in his structural calculations of a new building from the very beginning, additional costs of no more than one percent can be expected,” notes Swiss elevator manufacturer Schindler. Metzdorf looks to the future: “BIM (Building Information Modeling) will contribute to cooperation between the crafts, for example by passing on the necessary dimensioning parameters, or deformations of the floor levels.”

In addition to planning, particularly important — according to Metzdorf — is also good quality management in manufacturing and construction. Calculated and drawn is an ideal state of the elevator or escalator: “To ensure safety, the gap dimensions between relatively moving parts, in particular, must be maintained, both in the workshop and after transport of the components on the construction site.” This can prevent fingers, clothing or children‘s feet from being pulled in between the door and the shaft or escalator steps.

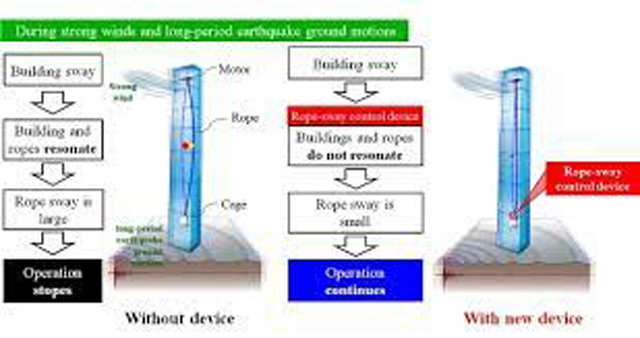

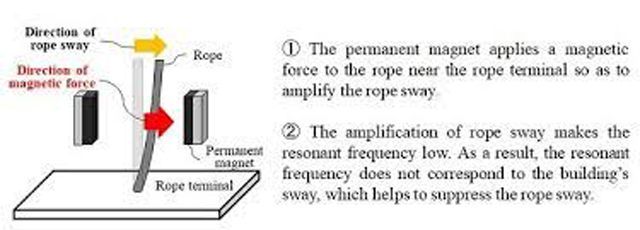

At earthquake category 0, no additional technical measures are yet required in the elevator; the number and type of technical interventions on the elevator increase up to earthquake category 3. More recent developments offer new possibilities. For example, Mitsubishi Electric Corp. in Tokyo has developed a device with a permanent magnet that “passively controls the swinging of elevator ropes in high-rise buildings caused by high winds or longer-lasting earthquakes. By allowing elevators to continue to operate under such conditions, the new device helps stabilize elevator operations, and contributes to better operating comfort.” Elevators Travasso AW GmbH in Switzerland takes care in its earthquake-resistant elevators to position the counterweight so “that it can’t come out of the guide rails, so you won’t be hit by the elevator car in an earthquake.” The shaft components made by Jäger Betonteile in Mengen, Germany, are connected to each other in earthquake-prone areas — for example, in a tight-connection manner.

Crucial to the development and use of earthquake-proof elevators and components are not only their design, but also tests. For example, TK Elevator (TKE) has equipped its 246-m test tower at Rottweil, Germany, with an active 240-mT pendulum at 193 m for damping. This can also set the tower swinging so that development engineers can simulate wind or earthquake loads.

Metzdorf emphasizes his belief that even in the event of earthquakes, passengers in the elevator will not be harmed if the requirements of the standards are met. “The rope will not swing loose, even in quakes outside the standard strength because of the restraint points. The elevator will safely travel the remaining 4 to 5 m to the next floor. The escalator is switched off at the moment the quake occurs.”

Get more of Elevator World. Sign up for our free e-newsletter.