Elevators on the Hong Kong-Zhuhai-Macau Bridge

Apr 1, 2020

A tall, tight space on an incline called for careful planning and installation in the towers of one of the world’s longest bridges.

by Shirley Zhao and Peng Jie, EW Correspondent

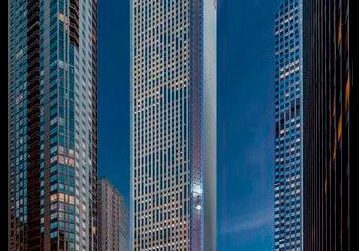

The Hong Kong-Zhuhai-Macau Bridge (HZMB) is known around the world for its giant-scale construction, the unprecedented difficulties throughout its construction process and the application of leading bridgebuilding technologies. At 55 km long, it is one of the longest bridges in the world. Its construction was a milestone project using some of the highest quality standards in China’s bridgebuilding history. The major structure of the bridge was completed in February 2018 and opened to traffic in October of the same year.

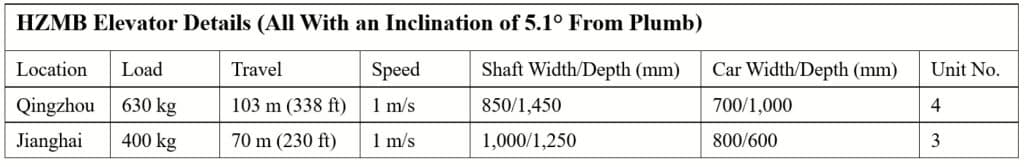

Dongnan Elevator Co., Ltd. designed and installed seven elevators on the bridge’s cable-supporting towers. Four are on the Qingzhou aviation route section, and three are on the Jianghai aviation route section. Built of steel and concrete, the cable-supporting tower in the Qingzhou section stands 170 m tall to hold the cable-stayed bridge section, with its upright structures tilted laterally by 5.1°. The cable-supporting tower in the Jianghai section is roughly 100 m tall with the same structure and shape as the former.

he upright cable-supporting tower structure includes the hoistways for four elevators with a rated load of 630 kg, speed of 1 m/s and travel of 103.2 m. Restrictions included an 850-mm shaft width for a 700-mm-wide car (very small for a conventional lift arrangement). In addition to dealing with the tight spaces, Dongnan was tasked with affixing additional guiding mechanisms for movement of the flexible parts, such as hoisting ropes and traveling cables, as auxiliary devices to the inclined travel.

Planning and Design

The elevators on the tower structure of the Jianghai section have a rated load of 400 kg, travel at 1 m/s over a rise of more than 70 m with 1,000-mm-wide shafts for 800-mm-wide cars. The personnel hatch measures 600 X 800 mm. To overcome the difficulties involved in moving lift materials into the shaft, we paid special attention to issues involving the smaller shaft width and personnel entrance when designing the lift. In the end, we settled on a solution with modular components designed to be dismantled. We also arranged them in the most space-efficient ways possible in the hoistways. These components functioned well after they were reassembled onsite, thus ensuring proper elevator operation.

Dongnan and HZMB Authority designers and builders maintained communication throughout the entire planning and designing phases to determine issues regarding interfaces between bridges and elevators and varied force distributions. We played an active role in coordinating with the designer, CCCC Highway Consultants Co., Ltd., and other bridge designers, builders, contractors and elevator specialists from varied previous successful bridge projects to assess and verify solutions to the HZMB elevator installations. The experts assessed the elevator design and installation methods with valuable views, laying a solid foundation for subsequent project processing.

Installation

The HZMB field team also consisted of experienced technicians and engineers from previous bridge installations. In addition, the company appointed a project manager with extensive project-managing experience in bridge lift installations, along with the assistance of safety and quality supervisors who worked together with the project manager throughout the installation process.

In view of the particularities of the project, components were pilot assembled in the factory to reduce as much onsite work as possible. This also improved efficiency and accuracy in fieldwork.

Throughout the months, the installation team encountered and managed to overcome other difficulties such as undersupply of electrical power, work at high altitudes above seawater, confined workspace, insufficient ventilation and high temperature.

Acceptance

Upon completion, Dongnan sent inspectors specialized in bridge elevators to the jobsite to carry out preliminary manufacturer examination. The company also consigned the inspection to the Guangdong Special Equipment Inspection Institute, which conducted an overall inspection on the performance and safety of the installations, which gained acceptance.

Get more of Elevator World. Sign up for our free e-newsletter.