“Elevators That Side-Step”

Jan 1, 2015

Unique turn-of-the-20th-century horizontally shifting elevators saw use in the Boston subway.

The May 15, 1906, edition of the Street Railway Review included an article titled “The Atlantic Street Station of the East Boston Tunnel,” which described one of the stations built to serve a recently completed section of the Boston subway. The article included a detailed examination of the elevators designed for the station, described as: “without doubt the most interesting feature of the equipment of this station, for in some ways, they are probably different from any other elevators in the world.” Readers of the July 1906 issue of Popular Mechanics found, in addition to the magazine’s typical array of entertaining articles about airships, innovative bridge designs and other industrial subjects, an illustrated article titled “Elevators That Side-Step.” This article introduced the broad American public to the Atlantic Station elevators, which were described as having cars that “side-stepped” – or, perhaps more accurately, as referenced in an illustration caption – “zigzagged.” Finally, in December 1921, Popular Science published an article titled “Elevators That Run on a Curve,” which also discussed this installation. However, in spite of their introduction and coverage in the professional and popular press, these elevators essentially disappeared from the historical record after 1921, and their destruction in 1949 removed all physical evidence of their existence. Fortunately, the story of these unique elevators is one that can be rescued from history’s “lost and found.”

The horizontal shift, or “side-step,” resulted from the desire to have a compact street-level station with as small a footprint as possible.

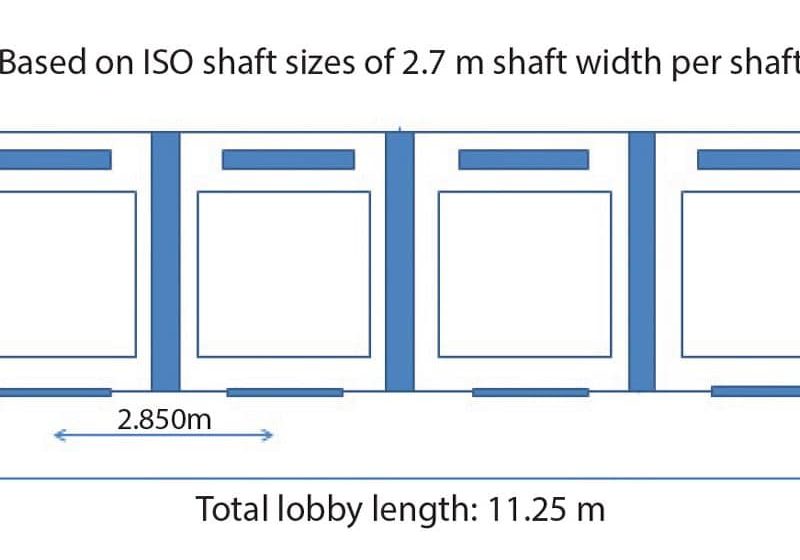

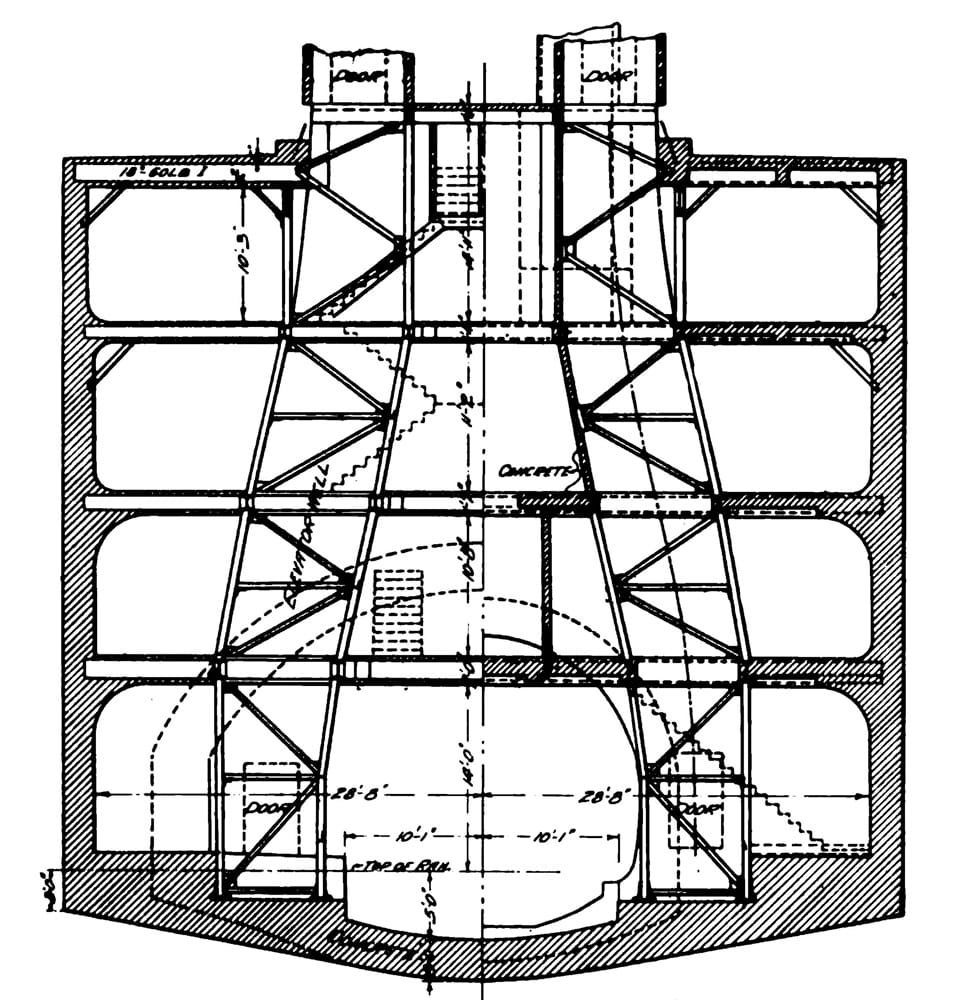

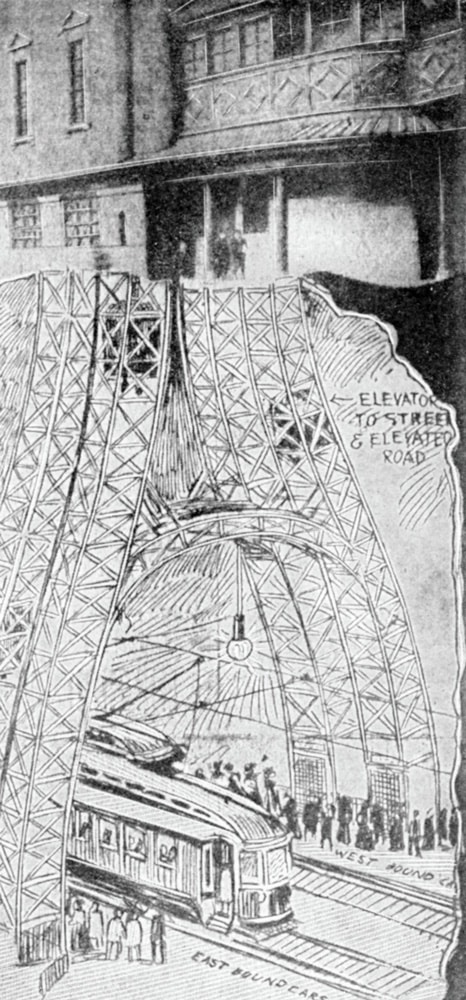

The East Boston Tunnel of the Boston subway, built between May 1900 and December 1906, connected Scollay Square in Boston to Maverick Square in East Boston. The Atlantic Avenue Station (the current Aquarium Station) was one of three stations that served the new subway line. The station was designed to meet three distinct needs: provide street-level access to and from the subway, provide street-level access to and from an adjacent elevated train line and facilitate access between the two transportation systems. The solution to this complex program was a station that housed four elevators, divided into two banks, which served three landings: the subway platform, the street level and the elevated train station (connected to the Atlantic Avenue Station via a bridge). The subway platform was located approximately 56 ft. below grade, and the elevated station was 14 ft. above grade; thus, the elevators’ vertical rise equaled 70 ft. In addition to moving vertically, the elevators were also required to move 6 ft. horizontally during their journey. This horizontal shift, or “side-step,” resulted from the desire to have a compact street-level station with as small a footprint as possible.

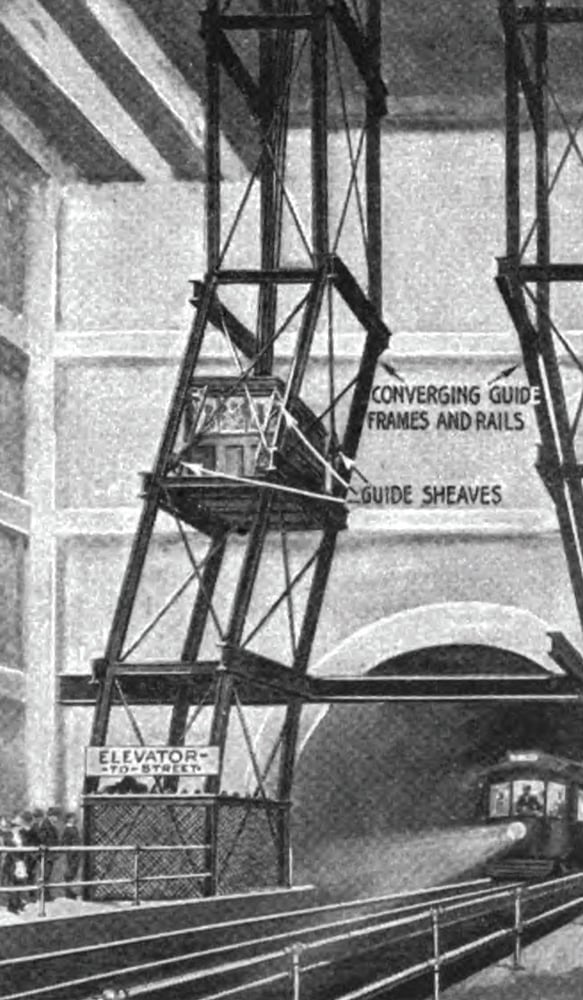

At the subway platform, one bank of elevators served each direction of travel. Thus, they were separated by two sets of tracks, which equaled a distance of approximately 24 ft. Due to the presence of the tracks and the limited size of the platforms, the elevator cars included doors that faced away from the tracks and onto small lobby/circulation spaces. At the street and elevated train levels, the elevator banks were arranged in a normative manner – with their doors facing each other and separated by a 12-ft.-wide lobby. Thus, as they traveled upward, each car was required to move 6 ft. toward the opposite elevator bank. This movement was accomplished via diagonal shafts – approximately 22 ft. high – that provided the transition between the lower and upper vertical shafts. The shafts featured wooden guide rails that gently curved as they transitioned between the vertical and diagonal sections.

The cars that traveled along this path were equally unique, in that each was equipped with three doors. Each car was 11.75 X 6.25 ft. in size and had a capacity of 40-50 passengers. They featured two primary sets of doors located on the long sides of the car that facilitated passenger movement from the subway platform to and from the elevated train platform and the street-level station. The third door, located on one of the short sides of the car, allowed passengers to exit at the subway or street level as other passengers entered. The doors were operated by compressed air and were under the control of the elevator operator, who was responsible for directing traffic in and out of the car.

In March 1904, the Boston Transit Commission awarded the Atlantic Avenue Station elevator contract to Whittier Machine Co. The contract specified four electric elevators that would operate at a speed of 250 fpm. By June 1905, Whittier had completed the construction of the shafts installation of the car and counterweight guides, and had “nearly completed the installation of the hoisting machines and controllers in the machinery loft.” The machinery loft occupied the entire top floor of the street-level station. By this date, Whittier had also installed one of the steel car frames and had begun limited test runs. The commission reported that the tests indicated that “the special features of the plant [had] been successfully worked out and that no noticeable shock or jar will be felt when the cars are running at full speed on the curved portions of the guides.” The elevator installation was completed by January 1, 1906, and the Boston Evening Transcript reported that the elevators were being tested “in order that full assurance of safety may go with their opening to the general public.” The newspaper also noted the elevators were “being run with heavy loads from morning until night, partly as a test of their strength and safety, and partly to limber up the machinery.”

While the reporter’s reference to the need to “limber up the machinery” may indicate a somewhat unsophisticated understanding of elevator technology, the initial tests must have yielded questionable results, because they apparently continued for the next three months. The Street Railway Review reported that during this period, the cars were often run 10 hr. a day carrying a load equal to “120 lb. per sq. ft. of net platform area.” The goal was to demonstrate the ability to maintain a sustained traffic efficiency of 40 round trips per hour. During this time, the cars were also subjected to safety tests. A typical test involved loading a car with 6,000 lb. of pig iron and cutting the hoisting ropes. In one test, the car fell 12.5 in. before the safeties engaged; it came to a complete stop 27.5 in. from the test starting point.

The elevator engines employed a worm gear to drive a winding drum. The electric motors were described as 575-V compound wound motors capable of delivering 87.5 HP. Each motor was “controlled from its respective elevator car through a separate controlling panel” and “equipped with circuit breaker, electromagnetic contactors, etc.” They also featured an “electromechanical brake on the main shaft,” and each car was equipped with “two triple-grip safeties” that were “brought into action” by an Otis safety governor. Oil safety buffers were provided for the cars, and counterweights and auto-stop switches were located at the top and bottom landings. Each car was also equipped with a phone that connected with the machinery loft, and it was possible to operate the cars from the loft, if needed. The staff required to operate the system included two electricians assigned to the machinery loft and four elevator operators.

The station was opened to the public on April 4, 1906. To accommodate anticipated traffic demands, the elevators operated according to the following schedule: from 6:30-9:00 a.m., two westbound elevators and one eastbound elevator were in operation, and from 4:00-6:30 p.m., two eastbound elevators and one westbound elevator were in operation. The Boston Evening Transcript reported that, although the elevator system seemed to work efficiently, its design likely proved challenging for some users:

“Though the arrangement is simple, it doubtless will take a long time for the public to understand the premises fully and to avoid mistakes. There is no chance for making mistakes when coming to the station from [the subway], as the passenger has no choice, then; there is only one exit on each side, that through the elevators. Entering the station from the street or elevated [train], it is different, because then, the passengers have access to the elevators on both sides and frequently descend in one that takes them to the wrong track. There is no connection between the platforms at the bottom, so that if a mistake is made, it cannot be rectified, except by going up again and taking an elevator on the other side. This may be done without paying an extra toll.”

It is of interest to note that, while stairs existed that provided access to and from both lower platforms, they were intended for use only by station employees. In November 1906, the Boston Post published a brief update on the Atlantic Avenue Station elevators. It reported the elevators, which had “traveled swiftly” when the station opened, now moved at a “more leisurely” pace, and passengers were complaining they occasionally missed their trains due to the elevators’ slower speed.

The remarkable sidestepping/zigzagging/curving elevators that served the Atlantic Avenue Station were dismantled in 1949 and replaced by escalators. Fortunately, sufficient visual evidence has survived that permits a general understanding of this extraordinary design. Of course, this information also raises questions about specific details of its construction and operation:

- Given the presence of three doors in each car, how did the cars engage the guide rails?

- How did the counterweights travel through the shaft?

- What was the normal running speed, and did the cars truly operate with “no noticeable shock or jar” as they slalomed up and down the shaft?

While additional research may eventually provide answers to these (and other) questions, this brief article has, hopefully, served the purpose of bringing this “lost” elevator system back into the narrative of vertical-transportation history.

Atlantic Avenue Station elevators (“Elevators That Side-Step,” Popular Mechanics, July 1906)

Atlantic Avenue Station elevators (“Elevators That Run on a Curve,” Popular Science, December 1921)

Atlantic Avenue Station elevators: plan of platform level (“The Atlantic Street Station of the East Boston Tunnel,” Street Railway Review, May 15, 1906)

Atlantic Avenue Station elevators: plan station at street level (“Eleventh Annual Report of the Boston Transit Commission,” 1905)

Get more of Elevator World. Sign up for our free e-newsletter.