EN 81-58, Landing Doors Fire Resistance Test

Apr 2, 2024

Dear readers,

In this article, I would like to discuss the EN 81-58 standard and fire resistance tests for landing doors.

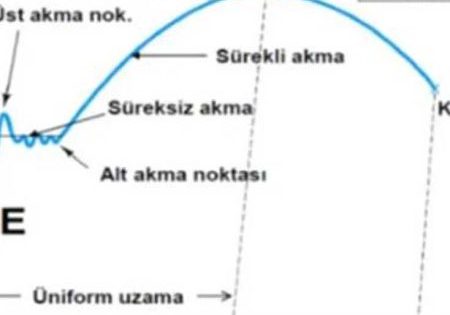

The EN 81-58 standard is a Type C standard, and its latest version was published in May 2022. The standard defines fire resistance criteria as integrity (E), insulation (I) and radiation (W).

The primary criterion in assessing the fire resistance of lift landing doors is their integrity (E). The integrity criterion ends when flames are observed for more than 10 s on the hoistway side. Additionally, after the first 14 min of the test, gas leakage should not exceed 3 m3/min per meter of door width.

To ensure that the thermal insulation criterion is maintained, the temperature on the door panel should not exceed 140 °C. Furthermore, if the side and top panels, which are collectively referred to as the door frame, have a width exceeding 300 mm, the temperature on the panel should not exceed 180 °C. If the panel width is between 100 mm and 300 mm, the temperature on the panel should not exceed 360 °C.

The radiation criterion ends when the radiation exceeds 15kW/m2.

According to the test results, fire resistance classification is done according to Table 1. In the table, E represents integrity, EI represents integrity and thermal insulation and EW represents integrity and radiation. The numbers following the letters indicate the duration/classification for the criteria specified by the resistance letters. For example, if during the fire resistance test criterion E ends at 57 min, criterion I ends at 25 min and criterion W ends at 35 min, the fire resistance classifications for the landing door would be: E45 for E (integrity), EI25 for EI (integrity and thermal insulation), and EW30 for EW (integrity and radiation).

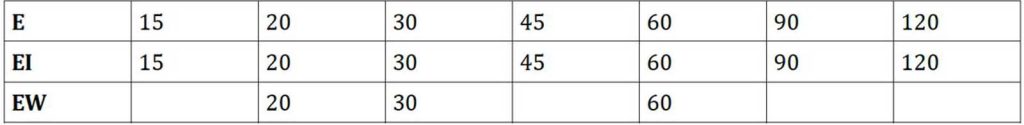

The fire resistance test for lift landing doors is conducted by subjecting the surface of the door facing the landing to heating conditions. Heating conditions should be carried out in accordance with the requirements outlined in the EN 1363-1 standard. According to EN 1363-1 standard, the increase in furnace temperature over time should follow the pattern outlined in Table 2.

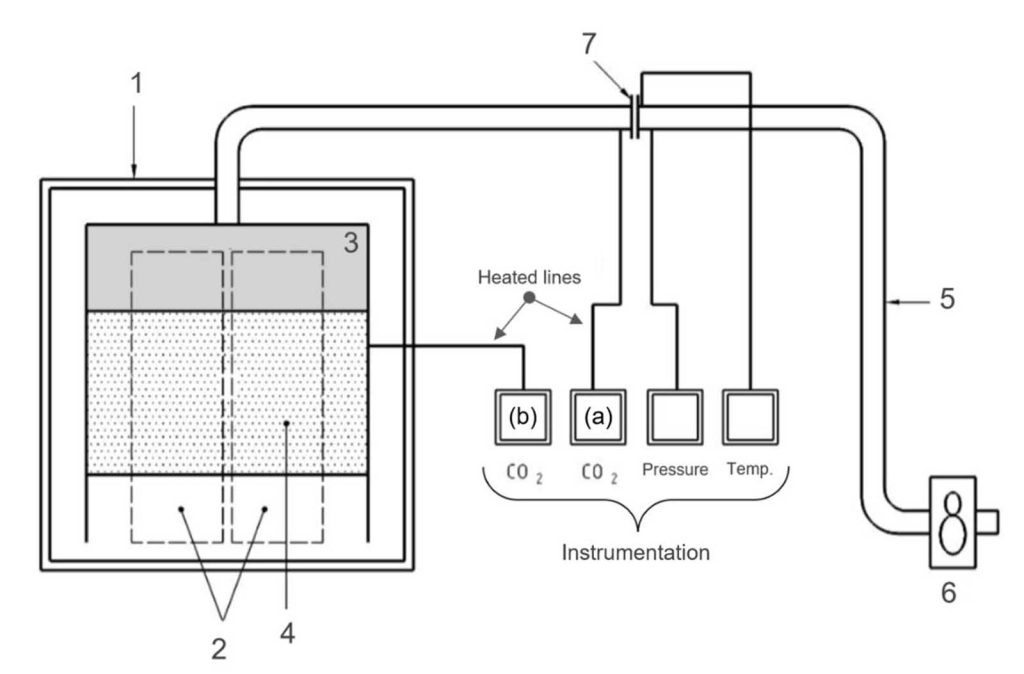

During the test, there would be a positive pressure on the side exposed throughout the height of the door, which leads to furnace gases leaking to the unheated side. There should be a canopy on the side where the leakage accumulates. The gases accumulated here are drawn through an extraction fan and a duct. The change in gas leakage over time is determined by measuring the CO2 levels inside the furnace and in the duct. The test setup conforming to the EN 1363-1 standard is depicted in Figure 1.

- Furnace,

- Testing sample,

- Canopy: To capture the gases emitted from the tested door, the bottom is left open and secured to the side of the furnace that is not exposed.

- Curtain: Curtains made of adjustable fiberglass fabric are fixed to the front and two sides of the canopy to minimize the mixing of gases with ambient air.

- Exhaust pipe: Positioned centrally at the top of the canopy, a metal duct with a diameter of at least 200 mm is connected to the exhaust fan. The total length of the duct should not be excessive, and it should include long, straight sections on both sides of the gas flow measurement device.

- Fan: A fan should be located near the top of the canopy to expel the collected gases.

- Measurement plate: A monitoring system utilizing a measurement plate or equivalent should measure the flow rate, temperatures and CO2 concentration of the gases flowing from the exhaust pipe.

I would like to share some photos related to the fire resistance test for information in Image 2.

The fire resistance test report for lift landing doors should encompass not only the general requirements outlined in the EN 1363-1 and EN 1634-1 standards but also include details of the tested sample, technical drawings of the door, the rate of gas leakage during the test, the timing and duration of flame occurrences, deformation of the door as a function of time, radiation emission as a function of time and the temperature change on the surface not exposed to heat as a function of time. Additionally, it should clearly specify the fire resistance class of the landing door.

I would like to conclude my article with one final piece of information: The test results are valid for landing doors with a width within +/- 30% of the tested door’s width and for landing doors with lesser height.

I would also like to make a suggestion: Determine whether the landing doors used in your project or building conform to the specifications of the tested landing door. While doing so, ensure to compare the characteristics of the sample in the test report with the landing door used in your project, rather than simply checking the fire class label on the landing door.

I wish you healthy and safe days.

Get more of Elevator World. Sign up for our free e-newsletter.