How the groundbreaking Hong Kong Energy Code was created, leading to a section on elevator energy efficiency.

The first code of practice related to energy in Hong Kong is perhaps the Code of Practice for Overall Thermal Transfer Value (OTTV) in Buildings published by the Hong Kong government in 1995. Then, a task force was established in 1997 by the Electrical and Mechanical Services Department (EMSD) of the government to draft codes of a similar nature but on different building systems, under which the Subcommittee on Lift (Elevator in North America) and Escalator Code of the Energy Efficiency and Conservation was formed.

Such a code had been followed by the industry on a voluntary basis until 2012, when the statutory Building Energy Code (BEC) was enforced.

Your author may be the only member who has been participating in the creation of the aforementioned documents from day one until now. This article will present a brief history of elevator code growth in Hong Kong and its parallel development in Europe. Technical considerations related to the code and some associated research works by the author will be discussed, which may be useful to elevator engineers who intend to design, install, operate and maintain green elevators.

Development History

Since the 1973 Oil Embargo, there has been a global concern regarding the shortage of fossil fuels, and, therefore, energy conservation had been a hot topic in the 1970s and 1980s, though the concern at that time was in no way comparable to that of the present. The earlier situation was only an issue because the deficiency of fuel was considered a problem for the future. Thus, few people were willing to sacrifice economic growth for the sake of minimizing energy consumption. It is well known that energy consumption of a nation highly reflects its gross domestic product. Now, besides the limited supply of fossil fuels, the major problem is climate change. Using fossil fuels to generate electricity implies putting millions of millions of metric tons of carbon dioxide into the atmosphere.

A consultancy study in 1991 initiated by the Energy Efficiency Advisory Committee of Hong Kong found that if the envelope of a building were constructed to a suitable OTTV, electricity demand from air-conditioning (and, thus, the emission of greenhouse gases from power generation) could be reduced. Hence, the Building Authority of Hong Kong published the OTTV Code in 1995[1] to limit the amount of heat transfer through the building envelope during the late spring/summer/early fall period, when the average outdoor temperature is higher than that indoors. The code has been mandatory since its implementation.

In 1997, a task force was established by the EMSD to draft a series of four sets of codes of practices under four subcommittees: Lighting,[2] Air-Conditioning,[3] Electrical Services,[4] and Lifts and Escalators.[5] By 2003, another code[6] (in addition to the four prescriptive codes just mentioned) had been published. This one was based on system performance and simulation. All five codes had been operating on a voluntary basis until 2012, when they were combined together into one document.[7] In the years between, there had been several revisions, but the basic concept remained unchanged.

Basic Concept of the CoP

Statistically, lifts and escalators account for 3-8% of total electrical energy consumption of commercial buildings, while it is the dominating consumer of the public areas of high-rise residential buildings. The Lift and Escalator subcommittee of the task force to draft the Code of Practice for Energy Efficiency of Lift and Escalator Installations (CoP) (of which your author was a member representing the Hong Kong Institution of Engineers) faced a big problem in 1997, when it was established that we, as a pioneer in this area, did not have any reference. The subcommittee then determined five main areas of the CoP, as follows:

Maximum allowable electrical power of lifts, escalators and moving walks

- Traffic analysis and zoning

- Lift system control

- Energy management

- Power quality

Problems included how to define the maximum allowable electrical power and their desirable/practical values for power usage. For lifts, we decided the maximum allowable power be measured when a fully loaded car is running full speed in an upward direction. This definition is still in use today. For practical values, letters asking for technical data were sent to all Hong Kong representatives of elevator manufacturers and maintenance contractors. Unfortunately, the response from the market was unsatisfactory, while the general reply was that no such information was available from the manufacturers.

To clear this hurdle, a government engineer worked with your author to launch a secret plan to push the industry to respond. We made use of fundamental laws in mechanics to derive equations to estimate such power based on friction losses during traveling, hydraulic losses, dynamic losses during acceleration and deceleration, potential energy transfer and regeneration, etc. under different conditions, then sent them to the industry for comments. Had the response again been poor, these theoretical values (which would not be favorable to manufacturers) would have been enforced. However, practical and reasonable values were soon received and tabulated in the CoP (Figure 1). The draft code was issued in 1998, while the first version was published in 2000.

For high-rise buildings, traffic-analysis-based design in terms of round-trip time (RTT), system handling capacity and zoning was required in the first version but waived in the 2005 edition. For lift-system control, lift operation standby mode was required during low traffic. Energy management called for the installation of metering devices or the provision of a simple connection to such devices to measure such parameters as voltages, currents, energy consumption, total power factor, power and maximum demand. This energy management requirement remains valid.

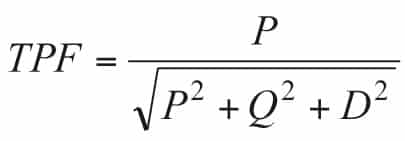

Particular emphasis was placed on the regulation of two electrical parameters of a lift, escalator or moving-walk drive. Total Power Factor (TPF) is defined as:

TPF was limited to a lower boundary of 0.85. Here, P is active power (in kW) consumed by the drive with respect to the fundamental component of 50 Hz in Hong Kong; Q is the reactive power (in kVAr) consumed by the drive with respect to the fundamental component; D is the distortion power (in kVAd) contributed by all other current harmonic components. Technically, the denominator is equivalent to the “apparent power” drawn by the drive. This requirement is still valid in the updated CoP, but there is an issue of the practicality related to measurement, which will be further discussed in Part Two of this series.

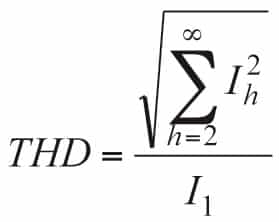

Total Harmonic Distortion (THD) is defined as:

Here, Ih refers to the harmonic component of the current drawn by the lift, escalator or moving-walk drive, while I1 is the fundamental component. A table was included in the CoP that governed the maximum THD (%) against the fundamental current rating of the lift drive. For example, the limit was 35% for most lifts operating with a fundamental current of 40-80 A. This requirement is still valid in the updated CoP, but there is an issue related to the practicality related to measurement, which will be further discussed in Part Two. By controlling these two parameters, the electric power quality would be satisfactory, and less heat loss would occur along the electrical power transmission and distribution system.

Parallel Development in Europe

In 2006, a working group was established by the European Lift Association to address the question of elevator energy efficiency. In 2007, the European Commission initiated a study to look into the subject. The first set of guidelines dealing with the energy performance of lifts on a national basis in Europe, VDI 4707, was published by the Association of German Engineers. This code aimed at classifying elevators based on their energy consumption and enabling easy calculation of the typical energy demand of a lift installation based on its operational profile. The goal was to adopt a simple approach to compare the energy performance of different lifts. The first draft of VDI 4707 appeared in 2007; the first formal edition appeared in 2008, and the final version – Part 1 on “Lift Energy Efficiency” – was published in late March 2009.

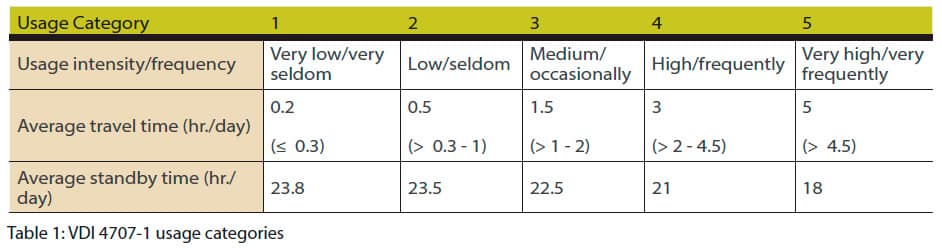

There are two classes of concern in assessing energy consumption: the travel or operational class and standby class. The travel energy is measured and categorized in one of seven grades, from “A” to “G,” while the standby energy is also measured and categorized in one of seven grades. Both classes are then combined to form the overall class or grade, class “A” being the best, and class “G” being the worst. These are based on three more parameters: nominal load (in kg), travel (in m) and usage intensity. Usage intensity is classified into five categories (Table 1). In other words, comparison of energy-efficiency classes is only possible by considering lifts belonging to the same category of usage. A lift in category of usage one consumes less than 50 W during standby and no more than 0.80 mWh/(m-kg) during travel is to be classified in Class A.

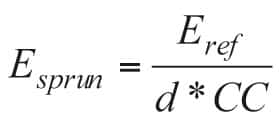

To measure the travel or operational energy, a reference run is conducted with an empty lift car going up from the lowest floor to the top floor, then back to the lowest floor (i.e., both up and down). The total distance traveled is represented by d (in m), and the contract (rated) capacity of the car is CC (in kg). The total energy consumption, Eref, during these two journeys is measured and normalized to the specific energy during the reference run, Esprun, by using the following equation:

This method of measurement is also recommended in a later International Organization for Standardization (ISO) standard.[8] The main criticism to this measurement is that it places less emphasis on the high power consumption during acceleration and deceleration. Thus, it may be unfair to low-rise buildings. Readers must note that the whole concept is on measuring the performance of the lift drive alone, quite similar to the counterpart section of the Hong Kong Energy Code. The distinctive contribution of intelligent supervisory control is ignored, whereas the main energy savings actually could be a result of intelligent passenger dispatching. This is another point that will be discussed in Part 2 of this series.

Measurement of standby energy consumption is straightforward, which can be conducted 5-10 min. after a run. EN 81 allows the switching off of the lights inside the car when the car is idle with car doors closed to reduce standby energy consumption. However, frequently switching discharge lamps on and off significantly reduces their life.

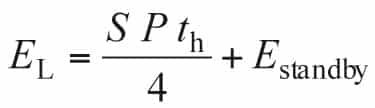

Internationally, the draft ISO/DIS 25745-1[8] was published in 2008, and its latest version was published in 2012. It provides a calculation to estimate lift energy consumption using the following equation:

where:

- EL is the energy used by a single lift in one year (in kW X h).

- S is the number of starts made per year.

- P is the rating of the drive motor (in kW).

- th is the time to travel between the main entrance floor and the highest served floor from the instant the doors have closed until the instant they start to open (i.e., half a reference-run trip cycle) (in s.).

- Estandby is the standby energy used by a single lift in one year (in kW X h).

- The equation relies on a number of assumptions and has several disadvantages:

- The building has a uniform floor population.

- The number of up stops are equal to the number of down stops.

- No allowance is made for regeneration.

- No allowance is made for the actions of the traffic controller. (Single units only are considered.)

- No significant number of stops is made below the main entrance floor.

- No additional energy for travel through an express zone is taken into account.

The Latest CoP

The CoP was made mandatory with the publication of BEC in 2012[7] by incorporating all five aforementioned codes, the most recent of which is performance based. The CoP 2012 on lifts and escalators has four purposes:

- Reducing power consumption through imposing maximum allowable electrical power of motor drives

- Reducing losses in the utilization of power through imposing requirements of minimum allowable total power factor, and limitations on decoration loads and standby mode in lift operation

- Reducing losses due to associated power-quality problems

- Providing appropriate metering and energy-monitoring facilities for better energy efficiency management

The conditions of limiting the power consumption of lifts, escalators and moving walks have been discussed before. For traction lifts, classification is based on rated load and rated speed. For hydraulic lifts, classification is only based on rated load, as the speed is usually rather low. For escalators, classification is based on nominal width, rise, speed and type (nonpublic service, public service and heavy duty). For moving walks, classification is based on nominal width, length, speed and type (nonpublic service and public service). Total power factor and power quality in terms of total harmonic distortion have also been discussed.

The latest CoP includes several new requirements versus the 2000 edition. The lift decoration load is governed, as the use of heavy materials for in-car decoration wastes energy. The allowable decoration load D with respect to the rated load L is governed by the following equations in Table 2.

During low traffic periods, a parking mode must be available for at least one lift in a group or bank. The ventilation/air-conditioning system serving a lift car has to be stopped when the car is idle for some time.

More to Expect in Part Two

A universal indicator, proposed by your author some 10 years ago for benchmarking elevator energy performance, which takes care of both the drive and supervisory control, is now included in the technical guidance of the code for reference by elevator engineers. The indicator and related developments will be discussed in Part Two of this series. It shall also discuss various practical methods by which to deal with clauses in the CoP of Hong Kong and address some problems with selected clauses. Additionally, an energy-saving method for elevators developed by the author will be discussed.

References

[1] Building Authority, Code of Practice for Overall Thermal Transfer Value in Buildings, Hong Kong, 1995.

[2] Electrical and Mechanical Services Department, Code of Practice for Energy Efficiency of Lighting Installations, 1998.

[3] Electrical and Mechanical Services Department, Code of Practice for Energy Efficiency of Air Conditioning Installations, 1998.

[4] Electrical and Mechanical Services Department, Code of Practice for Energy Efficiency of Electrical Installations, 1999.

[5] Electrical and Mechanical Services Department, Code of Practice for Energy Efficiency of Lift and Escalator Installations, 2000.

[6] Electrical and Mechanical Services Department, Performance-Based Building Energy Code, 2003.

[7] Electrical and Mechanical Services Department, Code of Practice for Energy Efficiency of Building Services Installation, 2012 (www.beeo.emsd.gov.hk/en/pee/BEC_2012.pdf).

[8] ISO/DIS 25745-1, Energy Performance of Lifts, Escalators and Moving Walks, Part 1: Energy Measurement and Verification, 2008.

Get more of Elevator World. Sign up for our free e-newsletter.