EOX: Eco-Efficient and Natively Digital

Dec 5, 2022

Interview with Inge Delobelle, CEO for Europe Africa at TKE

Your author (USB) talked to Inge Delobelle (ID), CEO for Europe Africa at TK Elevator (TKE), based in Düsseldorf, Germany, about the newly launched Europe-wide eco-efficient and natively digital elevator for sustainable urban spaces named EOX. The pair discussed technical details of the newly developed system and advantages for customers, as well as difficult times and changes in the elevator industry in Europe.

USB: Ms. Delobelle, would you please be so kind as to introduce yourself to our readers, personally, professionally and concerning your role at TKE?

ID: I am Belgian by birth, but have worked in France and Germany for all my professional life. I am married and have three children. I have degrees in business administration and European enterprise management. My professional experience is quite varied — ranging from investment banking to the steel industry and now to urban mobility. Since 2018, I have been the CEO of TKE’s Europe Africa business unit. Before I took on this role, I worked in various positions at the thyssenkrupp Group for more than 15 years and was previously the CEO of thyssenkrupp Access Solutions (now TK Home Solutions and TK Airport Solutions).

USB: Today, we are talking about your new elevator: EOX. Could you please give us a short first impression of what it is about?

ID: EOX is a green and natively digital elevator, primarily for residential buildings. It is a future-proof fusion of the latest energy-saving and digital technologies, which were previously standards for only mid- and high-rise elevators. In addition to a host of green features, every EOX elevator comes with a comprehensive set of standard digital features, as well as one-click access to more options through a customer portal. All the components needed for any future digital expansion are included from day one, minimising the need for on-site visits.

USB: You had a huge team working on this solution. Where were they based? Who was in charge? Who made major contributions?

ID: As Europe is the first market where we are bringing EOX to customers, our teams in Europe led most of the efforts, but EOX was developed with the collective engineering expertise of TKE experts across the globe. This involved hundreds of colleagues along the entire value chain and the launch markets, from gathering customer feedback, through product development and procurement, to industrialisation at our factories. I am extremely proud of how quickly and purposefully they have worked hand-in-hand to bring EOX to life.

USB: Also, partners like Microsoft and NVIDIA were involved. What were their concrete contributions to the project?

ID: Microsoft, already a long-standing partner to TKE, provides EOX’s cloud infrastructure with integrated Azure cloud computing services. NVIDIA supplies the high-performance computing hardware. EOX is the first elevator coming onto the market which is exclusively equipped with this integrated processor. It is based on a chip that mimics the neurons in the human brain and processes data directly from the elevator in real time. This capability is the essential foundation for any future developments in advanced AI and machine learning.

USB: Let’s return to the EOX and its three main features: eco-efficient, digital and residential. What makes this solution so eco-efficient? What are the key figures?

ID: From a global perspective, buildings and the construction sector combined are responsible for almost one-third of total global energy consumption and nearly 15% of direct CO2 emissions. Most buildings are being constructed in the residential segment, thus, smart solutions like EOX reduce emissions and increase the energy efficiency of buildings.

There’s no increasing our digital footprint without further reducing our carbon footprint. The energy-saving features include our new eco-mode which learns and adjusts to traffic patterns, a regenerative drive that feeds energy back into the building and a lighter-weight design. EOX uses up to 28% less energy to move the elevator in the shaft. The lighter-weight materials also contribute toward a lower carbon footprint, as less fuel is required for transporting the elevator from our factory to the customer site.

With EOX’s smart maintenance, we can reduce the number of trips of our technicians by up to 50%, as they have fewer unscheduled visits. To verify all data, an energy-specific dashboard in the customer portal provides the consumption figures. And EOX is produced at our European factories, which run on 100% green electricity.

USB: And why do you call the EOX “natively digital”?

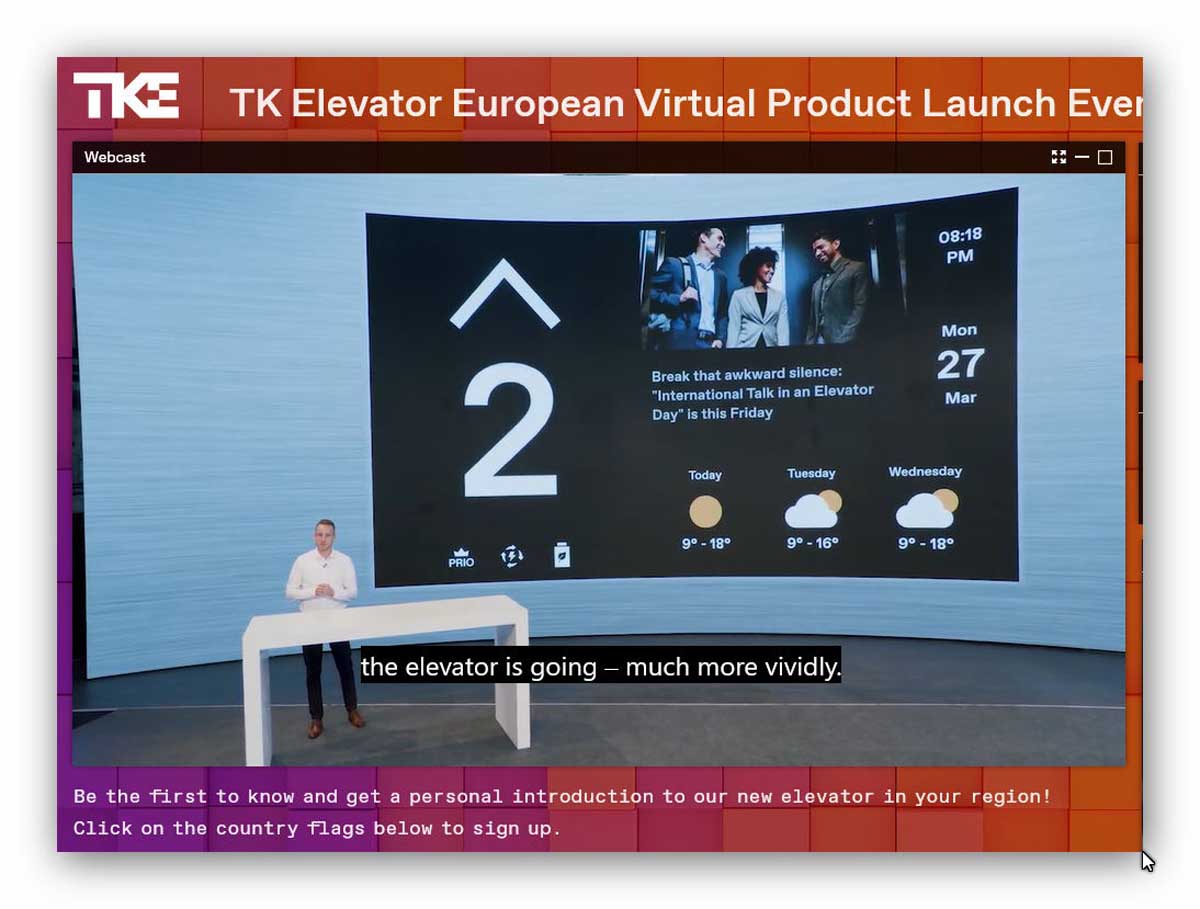

ID: Digital features and benefits are not an add-on but are in-built standard. Every elevator comes with a comprehensive set of hardware that enables the digital features available today, for example, the multimedia screen with its infotainment widgets, an in-cabin optical sensor for improved passenger safety and an accelerometer for monitoring cabin and door movements to prevent breakdowns. TKE’s cloud-based smart maintenance services help to prevent breakdowns.

EOX is designed to evolve and grow with the needs of our customers. It can be easily upgraded without extensive and time-consuming hardware upgrades. Over-the-air software updates for digital components are easily possible and customers get one-click access to advanced options via a customer portal. EOX is also AI ready; when these features become available, the hardware required is already installed.

USB: As a third unique selling prospect, you mention that the EOX is designed especially for smaller residential buildings in urban spaces instead of mid- or high-rise buildings. What is the reasoning behind this change of targets?

ID: In the past, we have been rather underexposed in the low-rise European residential segment. With EOX, we saw great potential to finally bring premium sustainability and digital specs from mid- and high-rise elevators to the standard residential elevator.

The residential segment remains promising. According to UN estimates, the global urban population will grow by more than 60% by 2030 to 5.2 billion people. Europe is already primarily a region of cities and towns characterised mainly by low-rise buildings, and about 75% of the European Union (EU) population lives in urban areas. Although projected urbanisation rates here are not as high as at the global scale, Europe is seeing an expansion of urban spaces.

USB: To go into more technical detail, I would also like to scrutinise some terms which might be understood by some as buzzwords only. Let’s start with “innovative.” What do we see for the very first time in elevators, especially concerning digitalisation?

ID: There’s a difference between “connected” and “natively digital.” While the first is something we put “on top” of a conventional elevator, the second means that the entire product is born digital and equipped with the most essential hardware already as standard. This is the case with EOX. In addition to the already mentioned new digital features, it is equipped with a digital emergency system with VoIP cellular dialer enabled for the future introduction of video and chat communication, as well as our AGILE Mobile solution for passengers to call the elevator cabin from a smartphone.

USB: In the last few years, following VDI 4707 and ISO 25745, energy-efficiency has come a long way. What are the EOX specifics?

ID: The ISO standard was the benchmark by which we were guided, but we tried to go beyond this. Right from a regenerative drive that feeds energy back into the building’s grid, to LED lighting in the cabin, to reduced cabin weight for less energy requirements to operate in the shaft, to name just a few.

USB: And what about sustainability in general, e.g., materials and CO2 footprint?

ID: With EOX, we use lighter-weight materials, which resulted in a 300-kg weight reduction from our previous standard offering in the same segment. This means less fuel required for transport to client sites, which will result in an over 10% reduction in the associated CO2 emissions on average. We will shortly publish an Environmental Product Declaration (EPD) to give full transparency on the carbon footprint of the EOX along its lifecycle.

USB: From the offer, I would like to turn around to the process from the customer’s point of view. The demand to integrate elevators into the building management system is rising. How does EOX comply?

ID: We integrated APIs that will enable EOX’s connectivity to other applications, for example to existing building management software.

USB: In which form will you deliver the planning data to, e.g., architects and facility managers?

ID: In countries where EOX has been launched, our sales representatives stand ready to provide architects and building developers with all the relevant data sets they require. We are currently readying a global tool for cabin design and product planning to be launched in the next year.

USB: Are there any special needs for the installation of the EOX system?

ID: No, there are no special needs for installation. On the contrary, we sought to optimise the packaging and installation methodology to make it as easy as possible for our installation teams as well as for our customers.

USB: And what about the use of the elevator and its maintenance. What do we need to know?

ID: Our cloud-based smart maintenance — for which EOX comes “plug and play”-ready — provides intelligent data analytics. It results in increased uptime, enhanced service quality, less paperwork and real-time equipment transparency. Independent of the type of maintenance contract with TKE, every EOX owner benefits from advanced troubleshooting as well as notifications and critical alerts.

Through its smart sensors and connected components, EOX can collect real-time data to calculate the remaining lifetime of each of the elevator’s key components, determining which parts will require maintenance, readjustment, repair or replacement — and when. Door movements, speed, number of trips and power-ups, car calls — all this and more are aggregated and sent to the cloud where algorithms analyse it for patterns and determine the “health” of the elevator. This data-driven approach has the power to cut elevator downtime by up to 50%.

USB: To sum it up, which advantages to architects, planners, builders, managers and passengers of residential buildings does the new EOX offer?

ID: The machine-room-less lift with the controller in the door jamb frees up additional space and gives architects more flexibility in the design of buildings. EOX’s energy-saving features also give architects the surety of a sustainable choice in terms of efficiency. A tool that enables energy calculations for BREEAM certifications is available; further certifications for sustainable buildings, such as LEED or DGNB, are in the pipeline. New cabin designs and planning tools will be available in 2023.

For building managers, I already mentioned the advantages of the customer portal, the low energy consumption and the advanced digital features, including setting up critical alerts. For digital updates, the lift offers integrated connectivity and a powerful computing unit. In this way, the digital services of the EOX can be expanded and improved in the future.

Users will also benefit with infotainment available on an integrated multimedia display — including the local weather and news headlines. They can call on an elevator via their smartphones and will benefit from increased uptime thanks to EOX’s smart maintenance offering.

USB: At the end, let’s take a wider view of the elevator industry in general. One might gain the impression that there are more hindrances than opportunities nowadays. Take, for example, COVID-19. What influences, like for instance staff shortages, and thus delays, does it have on the development of new products and their placement on the European market?

ID: Over the past couple of years, the building and construction industry was indeed impacted, and we saw several new installation projects being postponed. But, for the most part, these two years have proven the high resilience of TKE’s business. During the COVID-19 pandemic, our maintenance teams, managers and engineers did a tremendous job to continue servicing our customers, ensuring the safety of our elevators and escalators, as well as the health of our employees. With regard to the development of the EOX, we have kept all our planned timelines, and we will continue to deliver on our further developments.

USB: Another problem might be the shortage, and thus price development, of materials and components. How has TKE handled this?

ID: There are, of course, supply chain constraints and material inflation costs. We have been dealing with these for a while already and do our best to mitigate their impacts through robust planning and supplier management. There is also increased caution in the construction industry. However, for TKE, low-rise residential buildings are still a relatively untapped market segment in Europe, and we believe there is potential for us. So, we remain confident we will weather these challenging times.

USB: Last but not least, the energy crisis will become more serious during this winter. Already the number of orders for contractors has started to go down. What provisions do you expect on the part of TKE and the elevator industry in general?

ID: First of all, the current energy challenges underscore the need to have more energy-efficient mobility solutions in our buildings, such as EOX. TKE’s business model itself is not overly energy intensive. The largest portion of our energy consumption is related to fuels for our service fleet, and we have been working on converting our fleet to electric cars for quite some time. As far as our orders in Europe are concerned, they have increased in the first nine months of our financial year 21/22 compared to the same period before. We are clearly benefiting from our strong position in infrastructure and our strength in service and modernisation.

USB: Do you see any positive influences and effects coming up in the industry?

ID: We are in a business that is as strong and durable as the buildings in which we operate our products. Looking ahead, the road to becoming more energy efficient is already showing a lot of promise, and it still has a lot of potential for improvement. We also see a lot of impact and effects from the digital transformation of our industry’s technology — from the products themselves, as well as the solutions through which customers and passengers can interact with them. I believe this will continue to have a big influence on the evolution of our business.

TKE’s European Product Launch on 6 October

TKE sent out an invitation to a virtual event where they showed a sophisticated pre-recorded video dealing with many aspects of the new EOX. Most of the people involved either in the development or sales of the new EOX were actively involved in the event (in alphabetical order):

- Jorge Alvaro, senior vice president, New Product & Supply Chain, TKE Europe Africa

- Vincent Della Valle, COO, TKE

- Inge Delobelle, CEO, TKE Europe Africa

- Johannes Gresser, Global Product Lifecycle manager — Digital Solutions, TKE

- Ilka Ilieva, senior manager, Digital Transformation, TKE

- Victoria Myers, Communications & Business Support, International Technical Services, TKE Europe Africa

- Philippe Pereira, Sales manager, TKE France

- Nils Schwindling, Sales manager, TKE Germany

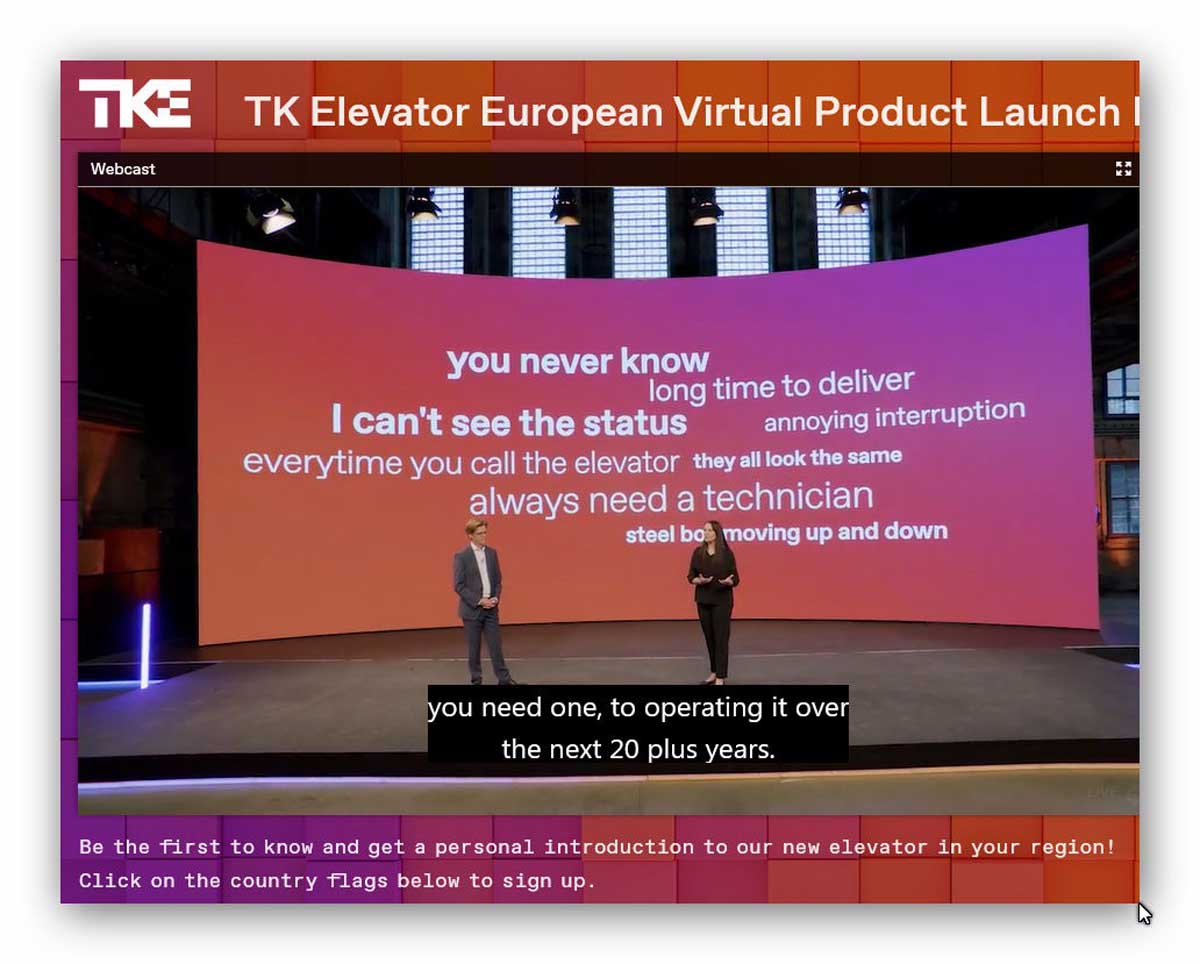

In the video, TKE told the story of the new EOX product and its main features. TKE made a study on what its customers expect of the elevator of the future such as, “I can’t see the status” or “always need a technician.” As a result, the new product, which is mainly aiming at residential buildings, became a package that’s green and digital — without any compromises on safety.

The EOX actively saves energy and prevents breakdowns. The strong digital unit is delivered “plug-and-play”-ready to connect to the net and the cloud/server. Drivers and controllers, as well as the powertrains, are produced in the EU. As a truly European product, all information can be accessed through a customer portal in all languages.

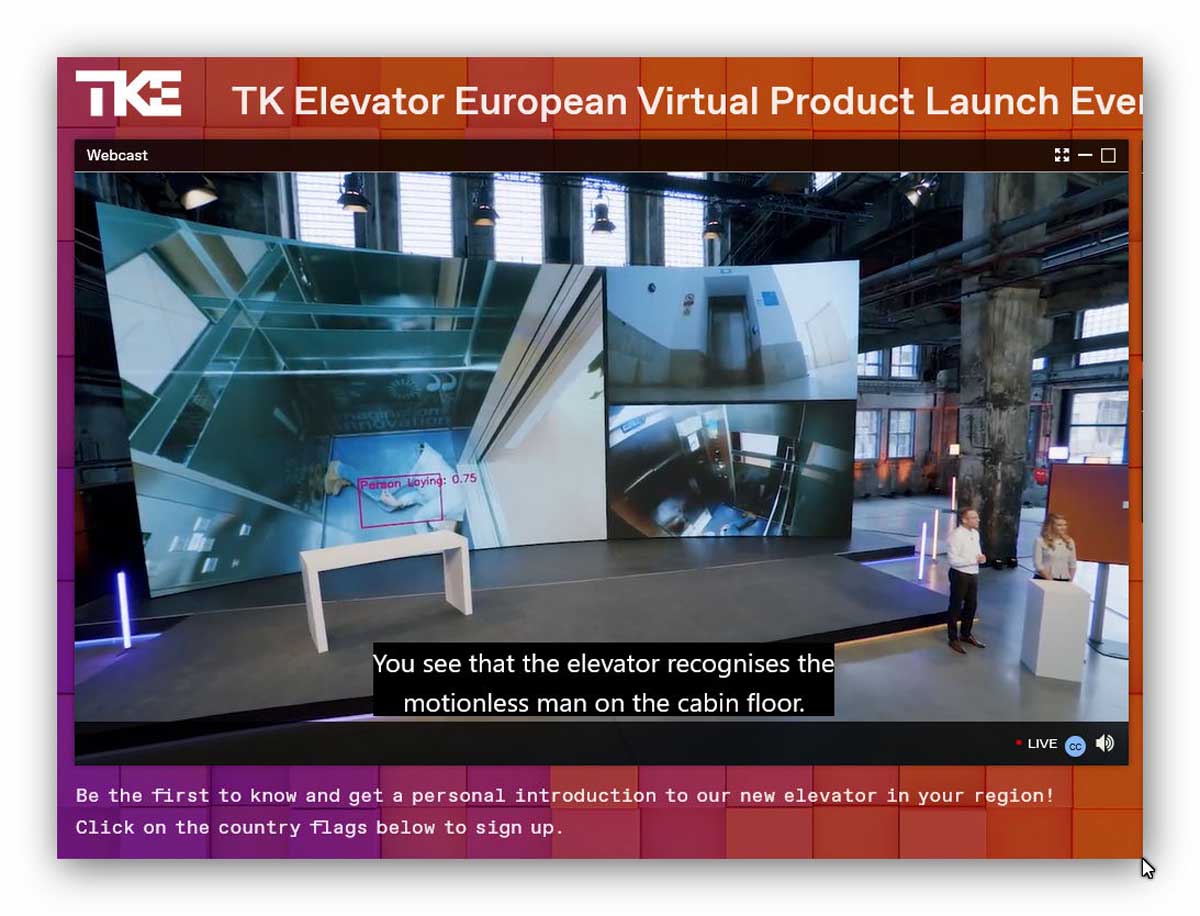

At the end of the presentation, TKE provided a glimpse into the future. The EOX can be adapted to AI elements without hassle. For example, for visual safety, sensors can listen and watch to improve the safety of the passengers, handicapped people can speak their destination and a helpless person on the floor of the cabin can be detected and a call for help initiated.

Learn more at the EOX microsite or access the digital brochure.

Get more of Elevator World. Sign up for our free e-newsletter.