A look at how EN 81 has harmonized critical regulations aimed at improving safety throughout the European Union

by Dipl.-Ing (FH) Werner Rau

Standards guarantee that various lift types (configurations) comply with uniform safety requirements. European standard EN 81, which is relevant for lift manufacturers, ad-dresses the safety rules applicable to the construction and installation of lifts and service lifts. While the harmonized standards EN 81-1 and EN 81-2 are currently undergoing revision, Amendment 3 (A3), which improves the safety level of lifts, has already been published. From January 2012 onward, all lifts placed on the market throughout the European Union (EU) must comply with the requirements set forth in A3; i.e., they must be sup-plied with safety devices preventing unintended movement of the car while the car doors are open.

Harmonized standards define the required safety levels. The organizations of the individual EU member states responsible for standardization must then transpose these EN standards into national standards. Euro-pean standard 81, parts 1 and 2, which are currently being revised, provide the basis for these national standards. The obligatory use is scheduled for 2012. The revised standard includes improvements and de-scribes detailed quality requirements for lifts intended to be placed on the European market.

Until December 31, two editions of the harmonized EN 81 standard will exist in parallel. Afterward, the “old” EN 81 standard will cease to provide a presumption of conformity; i.e., EN 81 A3 will define the required safety level from January 1, 2012, onward. The term “presumption of conformity” means that lifts constructed and installed in compliance with the harmonized standards are presumed also to be in conformity with the requirements of the European Lift Directive. The latter regulates the requirements that must be satisfied before lifts can be placed on the market in the Euro-pean Economic Area.

A3 sets forth the requirements to ensure reliable prevention of unintended movement of the lift car while the car doors are open. From January 1, 2012, onward, new lift systems that fail to satisfy the requirements of A3 may no longer be sold in the EU. As far as is known at present, the EU will accept the continued operation of lifts already installed under the grandfathering principle (i.e., existing lifts will not have to be modified). The most important new requirement introduced by A3 concerns a redundant safety system preventing unintended movement of the car triggered by in-dividual faults. This safety system must be certified by an impartial third party and will introduce stricter safety requirements in order to reduce the risk of potentially hazardous states of the lift system.

The EN 81 series of standards ap-plies to lifts driven by traction sheaves, drum and chain drives, and hydraulic lifts. These lifts must serve specific levels, have a lift car intended for the transport of persons or persons and goods, and move along rigid guides inclined at an angle of no more than 15° to the vertical. The standard defines the safety rules applying to lift construction and installation. Testing of the safety device preventing unintended movement of the car is effected within the scope of the conformity assessment required for placing the lift on the market.

However, at periodic intervals, the recurrent inspections of lift systems will also verify compliance with the requirements defined in A3. For this purpose, the installation company must provide instructions for testing the safety device.

The Machinery Directive and Its Effects

While the fundamentals of the standard have remained almost unchanged, recent years have seen the publication of new amendments – e.g., A3 and its predecessors, Amendments 1 and 2. These amendments were drawn up to cater to technical innovations and legal developments. For example, the new European Machinery Directive 2006/42/EC, which came into effect on December 29, 2009, re-quired changes that have since been specified in A3. The Machinery Directive applies to lifts with a maximum nominal speed of 0.15 mps intended for the transport of persons and includes additional requirements concerning captive connecting elements for protective covers. In accordance with A3 and in conjunction with cessation of the presumption of conformity of the previous EN 81, new lifts placed on the market from January 1, 2012, onward must be equipped with a safety device preventing unintended movement of the car. This concerns unintended movement from the landing as long as the landing door is not locked and the door of the lift car is not shut.

The safety device must reliably identify and stop any such unintended movement. However, unlike the over-speed governor for upward movement, the safety device is not limited to braking action. Instead, its individual components must interact to stop the lift within the maximum permissible stopping distance in any load condition. Manufacturers opting to use braking systems that control the lift car via friction between the friction pulley and the means of suspension must also take traction into consideration. In addition, the safety devices may only stop the lift car within the maximum permissible stopping distance if the movement away from the landing is unintended – i.e., if the car had previously come to a halt. An important factor is that the stop-ping distance comprises more than the mere braking distance. All distances covered during delay periods, detection and reporting of the unintended movement must be taken into account.

Components Aligned to Each Other

Safety testing can either relate to the lift as a whole or to individual components. The challenge in this context is to optimally align the individual parts of the safety device to each other to ensure that the lift is brought to a halt within the stopping distance. In addition, there may be varying delays in detectors and actuators or in brake activation. Testing and identifying all these influences in one single type examination is next to impossible.

To protect the lift car from unintended movement, the lift must be equipped with an autonomous safety device. This may only be part of the normal drive system of the lift if it is subject to certain exemptions or conditions defined in the standard. If this is the case, the lift components must be of redundant design and self monitoring. When the machine brake is used as a safety device, “self monitoring” can constitute verification that the brake engages or releases properly, or testing of the brake force at regular intervals.

How Safety Devices Are Tested

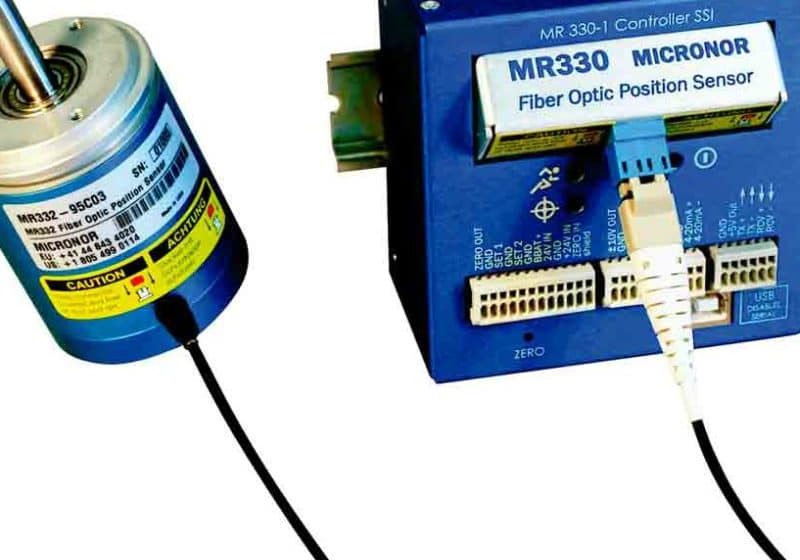

Safety devices to prevent unintended movement of the car generally comprise sensors, signal transmission by the control system and actuating elements (a braking device). The interaction of the individual elements can only be verified in a completely installed lift system. As lift systems often comprise components made by many different manufacturers, the assembly company must ensure before the assembly of the lift that these components will also fulfill the requirements when interacting with each other later. In this context, the future application and service conditions of the lift should be taken into consideration as early as possible. The individual components in safety devices in accordance with A3 (sensors, triggering unit and braking unit) may either be tested in a summary type examination (which is of advantage for specimen lifts) or by means of type examination of the individual components.

As testing of the whole safety de-vice comprising detection, actuation and braking elements is impossible in the majority of cases, type examination of the individual components may prove expedient. Given this, the definition of clear interfaces is of paramount importance. In any case, the installation company that assembles the individual components in accordance with the design of its lift system must include an analysis proving that the assembled safety device (comprised of sensors, signal transmission and actuating elements) meets the criteria set forth in the standard. Simulation of a worst-case scenario (e.g., breakage of the gearbox) is impossible in the majority of cases. Given this, the company assembling the lift must carry out case-by-case risk assessment, identifying other applicable tests to ensure that the lift will stop safely even in a worst-case scenario. The lift manual must include the test procedure to be applied in recurrent inspection. Type examination also includes verification of the efficacy of this test procedure.

Type Examination –Two Possible Approaches

In accordance with the EN 81 standard in conjunction with the position statement of the Notified Body, there are two possible approaches to type examination. The first approach refers to type-examined lift types and tests the complete safety device in specimen lifts under highly unfavorable conditions. Within the scope of this test, the manufacturer must verify that the safety device complies with all requirements (maximum stopping distance and maximum deceleration) and that the system can be approved for the tested scope of application. Where appropriate, the lift is also subjected to inspection and proof of suitability for simplified lift testing (final approval testing and recurrent inspections).

The second method of type approval concerns the unlimited scope of ap-plication (type examination of individual components). In this approach, the experts test the individual parameters of the elements in the safety de-vice relevant for determining stopping distances and deceleration. Are the interfaces between the individual elements of the safety device or the defined interfaces with other components appropriate?

TÜV SÜD Industrie Service GmbH has made preparations (within the scope of conformity assessment) to carry out type examination of these safety devices in accordance with EN 81 and played a significant role in the development of the position paper by the Ad Hoc Working Group for Safety Components of the Notified Bodies for the Lift Directive, which describes the requirements for the testing of these safety components. Given this, TÜV SÜD experts can react quickly to possible changes in safety trends and offer targeted sup-port to lift operators and manufacturers with the implementation of the new requirements.

Conclusion

Another amendment to the harmonized EN 81 series of standards has further improved lift safety, changing the handling of safety requirements for lifts. A3 to the harmonized EN 81 standards has updated the safety levels to the state of the art and adopted the requirements resulting from the new Machinery Directive 2006/42/EC. The standards harmonize critical regulations aimed at improving safety throughout the EU. Reliable type examination and the testing of safety devices must also consider the interaction between the individual components.

Get more of Elevator World. Sign up for our free e-newsletter.