Abstract

The geography of Turkey bears the traces of several earthquakes that have occurred in history. The importance of structural measures against earthquakes, after the 6.9-magnitude earthquake that took place in the Aegean Sea on October 30, 2020, has once again come to the forefront. With 84% of the geographical area of Turkey being first-, second- and third-degree risk regions, 90% of the population lives in earthquake-prone areas. In Turkey, when it is considered that the high rate of urbanization and the population grew faster in these regions, it is understood that each year greater numbers of people remain under the threat of earthquakes. Addressing earthquakes by increasing the strength of buildings only through structural measures does not coincide with the earthquake reality. Regardless of how resistant the buildings are, there are always risks related to non-structural elements, and damages caused by these elements may result in many injuries and loss of life as well as economic detriments. For this reason, it is necessary to use suitable equipment and elements within buildings in areas facing earthquake risks.

In this article, the adequacy of elevators — one of the non-structural elements of buildings — against seismic shakes, is discussed. Also, technical information and research findings regarding elevator systems with low probability of damage and high reliability is conveyed to minimize the negative effects that may occur in the elevator system during seismic shakes. In light of this information, it is concluded that hydraulic elevators, with earthquake resistance 11 times greater than that of traction elevators, can be used safely in seismic areas. It is also reported that elevators with safe machine room should be preferred in middle and high-rise buildings, and the most problematic elevator type to be used in seismic areas with high risk of damage is machine room less elevators (MDA).

1. Introduction

Elevators are one of the most expensive types of equipment for buildings, but perform a very important function. However, they also have a variety of mechanical and electrical/electronic components that are known to be delicate and prone to damage during an earthquake. Elevator damage that may occur during earthquakes can cause economic losses due to repairs, re-commissioning and stoppage of vital operations, as well as causing passengers to trap in the cabin or even victims of fatal cases. At the same time, it is especially important that elevators in critical structures such as hospitals and public buildings not be damaged during an earthquake and remain operational after such events. Accordingly, while taking protective and preventive measures against seismic events, the selection and installation conditions of vertical-transportation systems such as elevators and escalators becomes as important as production technologies used in buildings.

Buildings are exposed to oscillations caused by ground movements during an earthquake. Depending on earthquake magnitude and the ground composition, these oscillations and shakes can damage elevators in the building. The EN 81-77 standard lists necessary precautions for elevators to be installed more safely in seismic areas. However, the application of the EN 81-77 standard does not guarantee a damage-free elevator installation in seismic-danger areas. While applying this standard, care should be taken to select elevator systems with the highest level of safety and lowest possibility of damage against seismic movements. One of the important criteria in elevator selection for seismic areas is that people trapped in the cabin can be rescued easily and safely. Due to damage to the building equipment such as gas and water layouts and danger of fire, the rescue operation should be carried out immediately and in a simple way. Considering that aftershocks may continue for months, entrapment situations can be experienced frequently. It is therefore of great importance that rescue operations against entrapments can be performed easily and reliably. The most important source of information for selecting suitable elevators for seismic zones is found in reports and articles published after previous earthquakes. To prevent or minimize the damage caused by earthquakes to elevator systems, and taking into account past data, it is necessary to choose elevator systems with a low probability of damage, where EN 81-77 standard can be applied easily and cost-effectively

2. En 81-77: Elevator Safety In Seismic Zones

As a result of a series of studies conducted since the 1964 Alaska earthquake, the elevator design code has been significantly changed.[1] Safety norms developed for elevators and escalators in seismic areas to achieve minimum damage in transport systems involve preventing the car from colliding with the counterweight through seismic sensors, structuring the elevator rails to be more flexible, developing new brackets and rollers, developing structural support frames that allow the elevator to move in during an earthquake, and other measures.[1, 2] Despite the application of structural improvements to new and existing elevators, they can be unacceptably damaged, even in medium-sized earthquakes (6-7.1 on the Richter scale).[2]

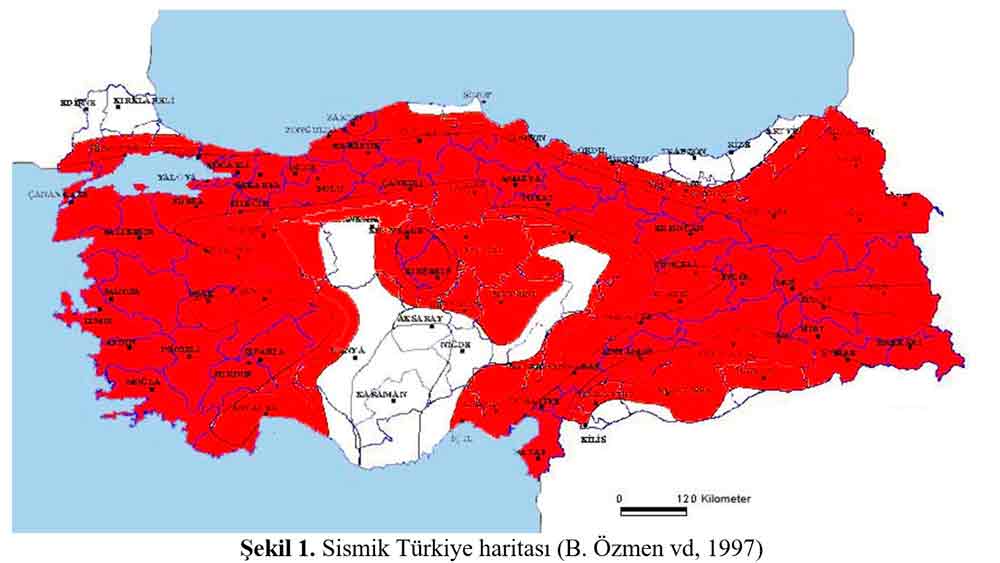

The seismic map of the area under risk of earthquakes up to grade 3 in Turkey is shown in Figure 1. This map illustrates that elevators will be built in 84% of Turkey must be manufactured to withstand seismic movements. More than 50% of industrial facilities in Turkey have been located in the first-degree, while, 25% of them have been in second-degree risk zones. It is important to design equipment and elevators in medical, communication, transportation and public buildings in these densely populated areas to continue to provide vital services after an earthquake.

The EN 81-77 standard, prepared to ensure elevator safety in seismic areas, formulates the structural reinforcement and additional measures required in elevators based on the design acceleration value. The weakest link of the standard is that it leaves the choice of the design acceleration value to the elevator owners and installers. Although it was stated in an article published after the Van earthquake[9] that cables and ropes were damaged during seismic movements because of tangling with the brackets inside the hoistway — especially regarding machine-room-less elevators (MRLs) — the EN 81-77 standard found it unnecessary to require precautions against rope snagging in buildings 20 meters in height or lower. Thus, it is inevitable that the standard can create a false perception that it supports MRLs. Although it has shortages, it is certain that if the EN 81-77 standard is applied consciously, it will significantly prevent seismic damages in elevators. The objectives of this standard are:

To prevent loss of life and injuries

Avoid being stuck in the car

Preventing damage

Preventing environmental pollution

Reducing the number of elevators out of service

While the EN 81-77 standard determines the necessary conditions, it avoids suggesting more suitable elevator types for seismic zones, instead leaves the choice of this to the elevator owner.

3. Reasons Of Elevator Damages In Seismic Zones

Reasons for the damage of elevators, even after medium-sized earthquakes, include:

- The current safety norm is not sufficient for elevators in seismic areas.

- Installing the wrong type elevators in seismic areas

- The failure of local authorities to fulfil their sanctionary duties in seismic zones or restrictive effects of existing regulations.

In reality, the causes of the damages could be one or all of these. Risk analysis of the safety norm (EN 81-77) may have been left flexible for unforeseen reasons. Responsibilities of local or central authorities are out of the interest of elevator engineers, at this point. Therefore, the source of the problem is that the appropriate elevator type is not preferred in seismic regions. What is missing here is determining the most suitable elevator types. By giving the priority to these types of elevators, the risks, the damages that may occur and the economic losses can be minimized. Conditions expected from elevators suitable for seismic areas are:

- A low risk of damage caused by earthquakes

- Rescue operation that can be carried out safely and easily

- Easy re-activation and low maintenance cost after seismic activities

4. Elevators’ Resistance Top Seismic Movements

The most important factors that cause damage to elevators in seismic areas involve existence of the counterweight and the location of the drive unit in the building. Elevators with a counterweight are more likely to be damaged. In traction elevators, the counterweight load is calculated as the car weight plus 40-50% of carrying capacity and constitutes the heaviest part of the elevator system[3] Therefore, when the brakes are released, the counterweight tends to move down. On the other hand, counterweight is not preferred in hydraulic elevators. In the few applications where it is used, the counterweight represents 50% or less of the empty car weight. This is because the downward movement of the hydraulic elevator occurs with the weight of the car.

During an earthquake, the top floor shakes at a higher amplitude than the ground floor. For this reason, mounting the drive unit and equipment on the top the building creates a more critical situation and causes more damage. Due to seismic shakes, the machine group, car rails, counterweight rails, brackets and guiding groups are the components that are most easily damaged in traction elevators.

Because hydraulic elevators are carried by the foundation of the buildings, they are less affected by shaking during an earthquake. Another reason for the high resistance of hydraulic elevators against earthquakes is that the hydraulic cylinder absorbs the oscillations and shaking that occur during the earthquake, thus eliminating damage that may occur. Due to these features, hydraulic elevators are the most suitable elevator type for historical and old buildings without requiring structural reinforcements. This is because the elevator weight is carried by the foundation; therefore, the building is not overloaded and it is less likely to get damaged during an earthquake since the shakes are largely damped by the cylinder.

The counterweight and the car, which are the heaviest parts of the elevator system, cause great inertia forces on the rails due to their large mass, causing damage and derailment. The most common damages are the release of the counterweight from the rails in the hoistway and collision with the car (Figure 2). The derailment of the counterweight and its collision with the car are among the most encountered damages at the elevator installations that were recorded after the 1999 Izmit earthquake (Figure 2-A).[1] According to a research report published after the 2011 Van earthquake, in almost all elevators examined, counterweight problems were responsible for more damage than any other cause.[9] Other damages seen in traction elevators (with and without machine rooms) after both the Izmit and Van earthquakes are;

- Damage to the ropes and/or coming off the sheaves

- Counterweight segments falling onto the car (Figure 2-B)

- Ropes getting snagged in the hoistway and breaking (Figure 2-C)

- Broken or damaged rail brackets,

- Governor cable hanging,

- Roller/sliding guides broken or loose,

- Compensation cable coming out of their grooves or damaged,

- Some hoistways collapse and the car buried in the pit.

In the earthquake that occurred in the Aegean Sea on October 30, 2020, it is understood from the sliding/roller guides shortage in the elevator market in the following days that traction elevators were heavily damaged, largely arising from the counterweight problems.

The use of a seismic switch that detects the primary waves of the earthquake (P waves) and brings the cabin to the next floor by moving it away from the counterweight, while cutting energy of the elevator if more dangerous shock waves (S waves) arrive is enforced by the EN 81-77 standard when the design acceleration value is greater than 4 m/s². However, when the eartquake epicentre is close to the building complex — in other words, when the time between P and S waves is too short — it may not be possible to avoid damage. Against this, a series of protective measures in the safety norm is taken to prevent derailment of the counterweight. However, these methods cannot guarantee stopping counterweight damages, even when increasing the cost, and cannot be compared with the advantages provided by a system without a counterweight. In examinations conducted on 822 traction elevators in Izmir’s Çiğli region, it is seen that the problems arising from the counterweight, which cause further complications in traction elevators, take the first place among the other 20 important points.[5]

Another factor that threatens the safety of traction elevators is rescue operations, which must be performed by competent people following a laborious task. If the elevator has a counterweight, the direction of movement of the car – after the brakes are released – depends on the weight of the car. If the car does not move and is in balance, the movement of the car must be achieved through use of a manual-lever, which is a time-consuming method.

Buildings in earthquake-prone areas are generally low-rise because high-rise construction near fault lines is limited by central or local authorities. This opens up an opportunity for the use of hydraulic elevators in earthquake zones. Improvements to ensure safety against earthquakes and prevent damage[1, 2] require costlier solutions for traction elevators. The reason being that traction elevators with their existing constructions have a higher risk of damage.

4.1. Hydraulic Elevators

Hydraulic elevators are normally suitable for low-rise buildings up to six stories and generally have no counter-weights. The cabin is moved directly or indirectly by the hydraulic piston driven via the hydraulic power unit. In this case, usually, an additional machine room is used. However, in some cases, machine-room-less solutions may also be preferred. The safe machine room can almost invariably be created at the entrance or first-floor level. It does not need to be directly next to the hoistway. The hoistway dimensions of hydraulic elevators are up to 20% smaller than traction elevators because they do not have counterweights, and the location of the hydraulic cylinder in the pit can be achieved in many different ways. Therefore, they offer more living space for the buildings.

The central piston application (direct action), which requires a cylinder well in the ground, is one of the simplest mechanisms that allows reduced loads on rails. By means of indirect action, which has a rope-pulley arrangement, it is possible to reach higher floors without a need for expensive telescopic cylinders and deep cylinder well in the pit. However, in this case, an additional brake system is needed.

Risk of damage: Hydraulic elevators have superior safety statistics compared to machine-room-less or conventional traction elevators. Hydraulic elevators have proven to be a safer option, especially in earthquake-prone areas. In an investigation made in 4472 traction and 6176 hydraulic elevators after the Seattle earthquake (6.8 Richter), which took place in February 2001 and whose results are given in Table 1, it was found out that permanent damage occurred in 504 traction and 66 hydraulic elevators [6]. In other words, 11% of the traction elevators were damaged at varying rates, while only 1% of the hydraulic elevators were damaged.

The main reasons that hydraulic elevators are 90% damage-safe are:

- Hydraulic cylinder largely damping seismic shakes

- Not having the counterweight

- Being carried by the building foundation and less affected by high amplitude oscillations

Hydraulic systems have fewer components than traction systems. The fewer the components, the simpler the installation and the lower the risk of breakage and/or failure. In addition, as the hydraulic drive elements operate completely in oil, risks related to abrasion and corrosion are mostly eliminated. For these reasons, hydraulic elevators are more reliable than traction elevators, and their installation is easier. In addition, hydraulic elevators can be designed independently from large elevator companies. Therefore, they are more convenient in terms of usage cost. Since all the necessary parts can be obtained readily from the hydraulic industry, these systems have a healthy competitive environment in spare parts supply and service.[8]

Rescue operation: Rescue operation in hydraulic elevators can be easily performed by building residents without the need for experienced staff or technical service. The rescue process can be done without going into the pit or up to the top floor. Lowering the car to a floor level is done simply from a machine room, which can be located on the entrance floor, via a manual lowering button or lever. With a small hand pump option, the car can also be raised up when desired.[7] In hydraulic elevators, the manual self-rescue systems, which can be applied inside of the cabin, were developed as alternative means to be used in case of entrapments in the car.[11]

Main advantages of hydraulic elevators are:

- The elevator load is carried by the foundation of the building, whereas it is carried by the building itself in traction elevators (Figure 3).

- The hydraulic machine room can be easily positioned at the entrance or first floor for service or rescue purposes.

- The rescue operation can normally be done within a few minutes by informed building members. (Figure 4-b).

- Installation and service costs are low, and alternative companies can provide better and more affordable service (instead of the installing company).

- Their resistance against earthquakes is 11 times greater than that of traction elevators.

- Hydraulic elevators do not have counterweights that become dangerous during an earthquake.

- Hydraulic elevators can be installed in historical and old buildings without additional suspension load.

- They have high reliability against breakage caused by the drive system.

Earthquakes can also damage the electricity, gas and water lines of buildings and cause dangerous situations, such as explosions, fire, and floods. These dangers can further increase the loss of lives. Elevators that are installed in seismic areas must be able to withstand seismic forces during earthquakes and remain active, at least until the rescue operations of passengers trapped in the car are completed. Passengers may have to be rescued without delay due to aftershocks, fire, gas leaks or other reasons. In such cases, it would not be realistic to wait for the fire brigade or responsible personnel to arrive to rescue passengers. Therefore, during the selection of elevators in seismic areas, the requirement for easy-rescue of passengers trapped in the cabin should not be ignored.

4.2. Machine Room Traction Elevators (Mr)

The most suitable elevator type for mid- and high-rise buildings, where hydraulic elevators cannot serve in seismic areas, is traction elevators with a machine room. These are often equipped with a counterweight system that reduces energy consumption. These systems can be planned with or without gearbox, which affects energy consumption and movement quality. A separate engine room is required, and the engine room is usually positioned above the hoistway. Since all the necessary parts for these systems can be obtained from the industry, it creates a healthy competition environment.[3]

The main advantages of traction elevators are:

- Traveling at higher speeds is possible

- Counterweight helps reduce energy consumption.

Risk of damage: The risk of damage is frequently seen in traction elevators due to possessing a counterweight, the drive unit being located over the hoistway and having more complex installation, as mentioned in the above text.

Rescue operation: Rescue operations in these elevators should be carried out by experienced personnel, otherwise it may cause fatal consequences (when the brakes are released, the car can move in either direction depending on the load in the car). Having a separate machine room is advantageous for repair and service, but rescue operations are difficult in case of fire and smoke leaking into the staircases and the hoistway.

4.3. Machine-Room-Less Traction Elevators (Mrl)

MRLs, those with drive units are suspended in the hoistway, are the type of elevators frequently used in mid- and low-rise buildings. With the development of permanent magnet (PM) motors, which eliminate gear-reduction systems and increase the efficiency of the system, MRL elevator machines have become more compact. In addition to the noticeable economy of PM machines in size and weight, their dynamic properties, such as high stability and precision, strong torque and low speed, precise control of the rotor position, have found significant application in elevator drive systems and have enabled engineers to make traction elevators without machine rooms. Since these systems do not contain gears, MRLs do not have a lubrication problem and their energy consumption is lower.[10] Asynchronous engines with gear-reduction systems are also widely used in MRL systems today. Their main advantages are:

- A machine room is not required. The drive unit is suspended inside the hoistway,

- Less energy consumption

Risk of damage: In addition to the risks that conventional traction elevators have, there is a risk of the elevator machine and suspension system being damaged, due to the drive unit being exposed to high amplitude oscillations, or falling onto the car during an earthquake (Figure 5). In addition, there is a risk of ropes snagging and breaking due to their close position to components in the hoistway .

In MRLs, the tendency to place some of the control equipment inside the hoistway further worsens the safety conditions. The dampness and pollution rate in the hoistway, reaching 81%,[5] is harmful to electro-mechanical and electrical/electronic equipment.

Rescue operation: In MRL installations, rescue operations may differ with respect to the suspension method of the drive unit inside the hoistway. The process requires experienced staff. When a manual action is required in emergencies such as gas leakage or fire, finding experienced staff and quick rescue operation will be difficult. A technician or fire brigade will not have experience with most installations encountered, and rescuing passengers will become more difficult and riskier in case of danger.

When it comes to maintenance and spare parts, the customer is heavily dependent on the supplier in many ways, which can have a worrying effect on prices.[8]

5. Challenges In Implementation

According to the Scheduled Areas Construction Regulation published by the Ministry of Environment and Urbanization in 2017, it is stated that architectural projects should also include the elevator project. The regulation has a strict attitude at the point of elevator selection, and requires the complete reapproval of the architectural project in order to correct an improper elevator choice, especially in earthquake zones. Since this situation requires the repetition of a long bureaucratic process, it obscures the replacement of elevators that are not suitable for earthquakes in the current project. Unfortunately, since the architects and contractors do not have enough information about the most suitable elevator types and their applications for earthquake zones, in most cases elevator choices cannot be made correctly. The multinational elevator companies that dominate the market, through their active sales networks, commercialize unsuitable elevators in their product range for earthquake zones at very modest prices. These companies form their strategy of profitability through their maintenance and service networks. In the preparation phase of an architectural project, architects and contractors can unintentionally put the householders at risk by purchasing an elevator at an attractive cost, which can cause weaknesses against earthquakes and high service charges later on.

Hydraulic elevators are not included in the product range of multinational companies in Europe and Asia, and are offered to the market by a limited number of small and medium-sized elevator companies worldwide. The main reason for this is that companies do not have sufficient technical infrastructure and human resources regarding hydraulic elevators, or else they are facing difficulties in establishing the technical groundwork. It is not possible to overcome the deficiencıes in this area with the devoted support of existing hydraulic companies. Therefore, while the relevant regulations were published, Turkey — located right in the geographical region where seismic activities occur — must examine negative effects of earthquakes as a whole, considering economic, social, cultural, and political impacts. It is necessary to add non-structural equipment, such as elevators and escalators, to the measures and executions developed to prevent damages to the buildings. In this context, modification of the Scheduled Areas Construction Regulation to allow only the reapproval of the new elevator project will create a healthier solution. In the current situation, building owners must comply with the architectural project in order to avoid long bureaucratic procedures during the elevator installation phase that would cause unsuitable elevator types to be applied in earthquake zones.

Leaving the determination of the design acceleration value to the building owner and the elevator company, foreseen in the EN 81-77 standard, affects the elevator preliminary project calculations and creates a grey area for the reliability of elevator installations in seismic areas.

6. Results

Some 84% of Turkey’s land is under high risk of earthquakes. In order to prevent seismic damage to elevators, which are the most expensive equipment of the buildings, primarily the elevators with less risk of damage should be preferred. Through this means, elevator safety is increased and economic losses can be minimized.

In addition to their high safety and reliability, hydraulic elevators have proven in the past 50 years that they are the most cost-effective and easily installable elevators. Hydraulic elevators, which can be used in buildings up to six floors, are the most suitable elevator type in seismic areas and have superior safety records versus traction elevators. The main factors that make hydraulic elevators safer are that their load is carried by the foundation of the building, their cylinder systems provide a damping effect, they have a simpler construction, not having a counterweight and they offer quick and easy rescue possibility by building residents.

In medium and high-rise buildings, the use of traction elevator with a machine-room provides superior safety compared to MRLs. Considering the risks in seismic zones, the abandonment of the machine room creates a riskier situation in terms of safety. Decision-makers in the vertical-transportation field can prevent life and economic losses by encouraging the use of safer elevators, especially in seismic areas.

It is necessary to add an amendment to the Scheduled Areas Construction Regulation, which eliminates bureaucratic difficulties and eases changing the elevator type determined in architectural projects in order to use more suitable elevator types in earthquake-danger areas.

Informing architects, engineers and contractors about the correct elevator selection in seismic zones is an issue that needs to be addressed urgently.

Get more of Elevator World. Sign up for our free e-newsletter.