Exclusive Access

Apr 1, 2019

The historic Old Forester Distillery gets a commercial passenger elevator to showcase working still.

By Tim Irvin and Lee Freeland

Photos by Tim Irvin

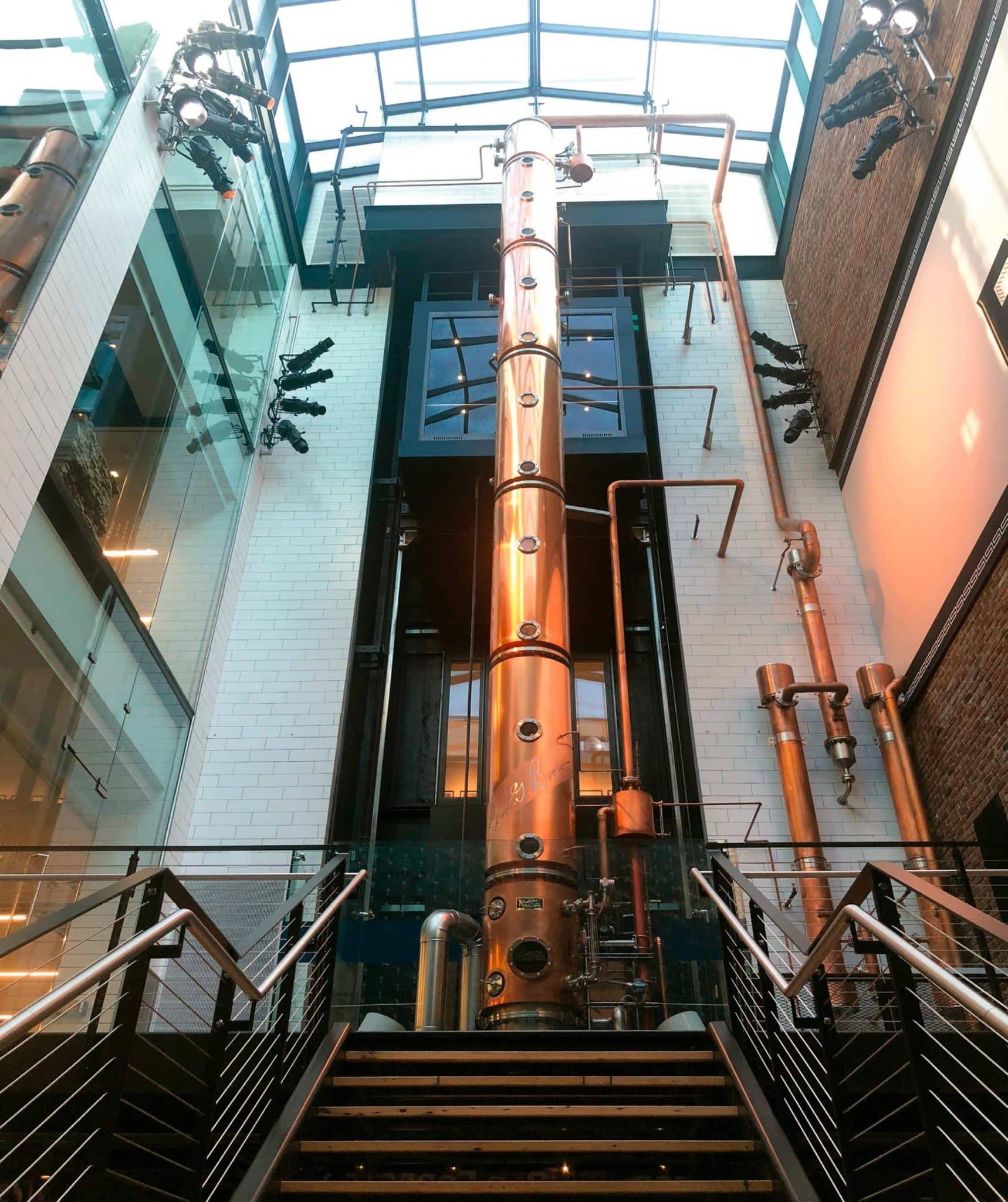

Louisville, Kentucky-based Executive Elevator installed two elevators at the Old Forester Distillery in Louisville. Part of a US$45-million project begun in 2014, the refurbished distillery encompasses two historic properties — 117 and 119 West Main Street.[1 & 2] Bourbon fermentation, distilling, barrel making, filling, dumping and bottling are done here. While it roughly doubles production of the brand, its purpose is mostly to take advantage of the wild popularity of microbrewery/brewery tours as attractions. Thus, a large visitor’s center has been added, and a custom elevator was needed to show off the shiny copper of the floor-to-ceiling still.

The elevator was built between the buildings in downtown Louisville’s Whiskey Row, a block-long collection of Revivalist and Chicago School-style buildings with cast-iron storefronts built between 1852 and 1905. It shared common walls between the buildings, and no onsite storage was allowed. Even laydown areas had to be kept to a minimum; equipment and materials had to be staged and loaded into the job as needed.

Tight planning and coordination were required as equipment was verified, checked and made ready to move into place before leaving the warehouse. Narrow streets on the Louisville waterfront and wharf district were a challenge for moving equipment onsite. As with any large project in a downtown area, careful coordination and planning with the site delivery schedule and the crane operators was an absolute must in mobilizing everything to the jobsite.

Main Observation Car

The main observation car consists of one glass observation passenger elevator with a rated speed of 200 fpm and 7000-lb. capacity. It uses a Hollister- Whitney Elevator Corp. overhead traction machine with 2:1 roping and Innovation Industries, Inc. fixtures. The cab and entrances are from Concept Elevator of Miami, including 7-ft. two-speed center-opening glass doors operated by a GAL Manufacturing Co. MOVFE linear door operator. Its controller is from Pixel.

The large, tall cab and rear glass wall had to be delivered to the site at 5 a.m. to get it inside the building before the usual morning traffic. After carefully maneuvering the crates and components inside the building, getting them to the shaft was another challenge. While most of the components could be carefully angled and taken through a double-width doorway to get to the shaft, physical limitations prevented this method being used for the rear wall due to its size and dimensions. With the back of the shaft being open, the rear wall was carefully slid through a 5-in. opening between fixed scaffold and the new copper still (already installed in place), on to the elevator platform and maneuvered into place. The work and laydown areas kept being relocated throughout the project, which interrupted the flow of the installation.

Service Car

The roped hydraulic service car travels at 100 fpm and has a 7200-lb. capacity. It is an MEI – Total Elevator Solutions unit, also with a GAL MOVFR linear door operator for 7-ft. two-speed center-opening doors, Innovation Industries fixtures and a Pixel controller. Its entrances are from Columbia Elevator Products Co., Inc.

This unit was completed first and operated for construction use to move materials throughout the building when the tower crane was removed. The hydraulic and electric lines were routed and run underground between the remote machine room and hoistway before the lower floor was poured. Due to the logistics of getting the equipment to the shaft and around the other trades, the structural equipment, guide rails, hydraulic jacks and stands were set into the shaft by the crane and protected from the weather before the top of the shaft was installed. The unit serves six landings, including the subbasement. The door openings were designed as one left- and one right-handed 42-in. doors that meet in the middle for the combined 7 ft.

Work on the service car began in mid August 2017 and was substantially completed/tested for construction use at the beginning of November 2017. Installation of the passenger unit then began, and it was tested on February 28, 2018, then turned over at the beginning of March 2018.

“The Ultimate Bourbon Experience”

Old Forester is America’s first bottled bourbon and manufactured by Brown–Forman Corp. and remains the sole continuously operational bourbon producer of the 89 that once shared the neighborhood.[2] Still a family company founded by Old Forester creator George Garvin Brown in 1870, it also makes Woodford Reserve and Jack Daniel’s whiskeys. The two buildings that make up this “new” distillery encompass approximately 70,000 sq. ft. and offer tours, a tasting room, exhibits, bourbon-making demonstrations and event spaces. Formerly warehouses for bourbon barrels from various distillers, the structures were built on or near 1857. The facility joins other Louisville, Kentucky, “bourbonism” tourist attractions, such as the Evan Williams Bourbon Experience down the street.[1 & 2] Though the ninth bourbon attraction in the area, Old Forester’s has been called “the ultimate bourbon experience” by aficionados.[3]

Tim Irvin has been operations manager at Executive Elevator, which serves the Louisville, Kentucky, area, since 2008. In a career dating back to 1990, he was also field engineer at Oracle Elevator and Irvin Elevator Group. He has a degree in Electrical Engineer Technology from Purdue University.

References

[1] Hall, Gregory A. and Shafter, Sheldon S. “Brown-Forman Puts Whiskey in Whiskey Row,” The Courier-Journal (September 25, 2014).

[2] Emen, Jake. “First look: Old Forester Distillery in Louisville,” USA Today( June 13, 2018) (usatoday.com).

[3] Knittel, Tim. “Old Forester on Whiskey Row: The Ultimate Bourbon Experience,” Distiller Blog (December 8, 2018) (blog.distiller.com).

Get more of Elevator World. Sign up for our free e-newsletter.