Otis India president provides perspectives on the issue theme.

Every elevator has safety systems like alarm bells, emergency lights and emergency buttons. Additionally, various safety features can also be installed, such as automatic rescue devices, infrared door curtains, closed-circuit TV cameras and load- weighing devices. Safety factors also include frequency of maintenance and annual inspections.

OTISLINE® is a call center that offers support when it’s needed most. The service puts passengers in touch with experts trained in every aspect of a unit’s operation and what to do when an issue arises.

Otis India has been a strong advocate of having uniform codes that need to be enforced throughout the country for the security and safety of passengers.

Regulation

India has separate regulations for different states, and some states do not have any statutory regulations. Otis India has been a strong advocate of having uniform codes that need to be enforced throughout the country for the security and safety of passengers.

Maintenance

Otis India is helping customers around the world prepare for the safe reopening and continued maintenance of their buildings through touchless elevator technologies; purification products, including UV and other germicidal lighting; predictive maintenance; and other products designed to combat the spread of germs and promote social distancing.

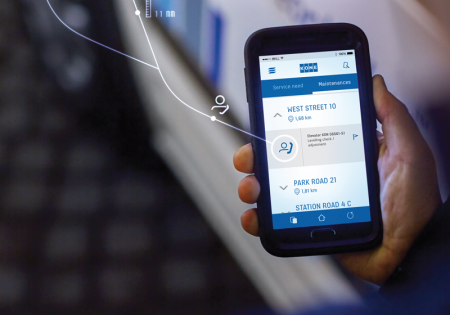

In addition, technologies like Otis REM® (remote elevator monitoring) and the Otis ONE™ Internet of Things service can help improve elevator uptime. Otis ONE analyzes data from sensor-equipped elevators to forecast trends and recommend proactive, predictive maintenance, resulting in fewer shutdowns and improved elevator uptime.

Technology

As part of our digital transformation, we have empowered our service teams, as well as customers, by:

- Equipping field professionals with iPhones and a suite of customized apps

- Placing sensors on top of elevators to collect data and offer real-time updates on their performance

- Providing customers access to transparent and real-time data on their elevators’ performance

We have built a powerful digital ecosystem that allows us to manage maintenance history, account details and other data in real time, so when customers ask about servicing a unit, we can confidently provide solutions that are transparent and accurate.

This information also helps our field professionals. Instead of receiving a service call and arriving with little to no information, they will be notified and briefed on the issue prior to arriving. These insights help them arrive with the tools and parts needed to get equipment up and running faster.

We are harnessing the power of data analytics, machine learning and cloud computing to predict and prevent possible issues and prescribe service.

Advanced modeling enables us to assign elevator predictive modeling, and health scores ensure our customers can see more about their equipment’s health to help plan for future maintenance costs.

We are harnessing the power of data analytics, machine learning and cloud computing to predict and prevent possible issues and prescribe service. With these, we are able to analyze trends on our hundreds of thousands of connected elevators to create advanced algorithms that can predict performance trends.

With remote monitoring and predictive analytics, we can concentrate resources on the elevators that really need attention. In times past, we’d send a field professional out to check an elevator for routine, scheduled maintenance. This meant checking elevators that didn’t necessarily require service. Now, instead of our customers having to call us about an equipment issue, we’re able to alert them before a potential problem arises.

Servicing

It is generally recommended to continue to have the OEMs maintain their equipment for the following reasons:

- Access to original spares: customers can rest assured of getting original spare parts, therefore ensuring quality and the best replacement for their equipment. This equates to longevity, better safety and better performance. Otis has service stores located across the country to facilitate availability and timely delivery.

- Constantly up-to-date and trained field professionals: Otis knows its own products well. Otis field professionals are able to deal with any problem the equipment may face. Personnel undergo rigorous training before they are assigned independent duties. Provided with continuous training, coupled with a sensitivity to safety, our field professionals are constantly updated with new techniques, tools and equipment.

- Wide network of service centers: Otis India has one of the country’s largest service networks, spread across 800 towns and cities, which means our field professionals are across the country. Should customers face an issue, they can reach out to Otis India’s centralized helpline, which will dispatch the nearest Otis professional to ensure entrapments or call-backs get responded to quickly.

- Robust maintenance processes: safety is of paramount importance at Otis. Therefore, we have regular inspection processes for elevators, preventive maintenance at regular intervals, audits and regular checks to ensure that all the safety switches and features are operational during every visit.

- Upgrade options: an OEM knows its equipment well and is up-to-date on the latest technological upgrades. This makes companies like Otis the best partners in recommending needed equipment upgrades to ensure the technology is up to speed with the current changes.

Get more of Elevator World. Sign up for our free e-newsletter.