Federal Reserve Modernization, Washington, D.C.

Jan 1, 2013

2. Elevators, Modernization

submitted by Jack C. Higgs, Quality Elevator Co., Inc.

The Federal Reserve in Washington, D.C., contracted Quality Elevator Co., Inc. to modernize five Westinghouse gearless traction machines and one geared traction machine in the historically sensitive areas of the Eccles Building. The design of the building is grounded in Greek and Roman architectural elements. When completed in the late 1930s, it was originally four stories. In the 1970s, a fifth floor was added to its center.

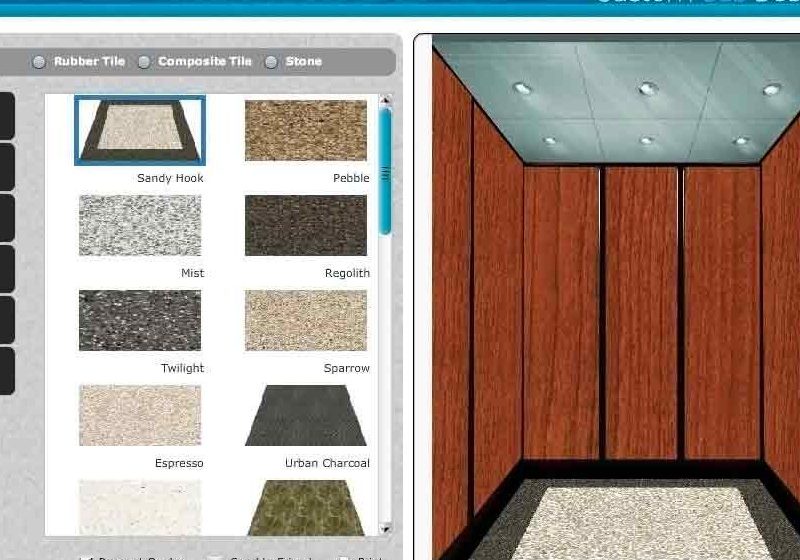

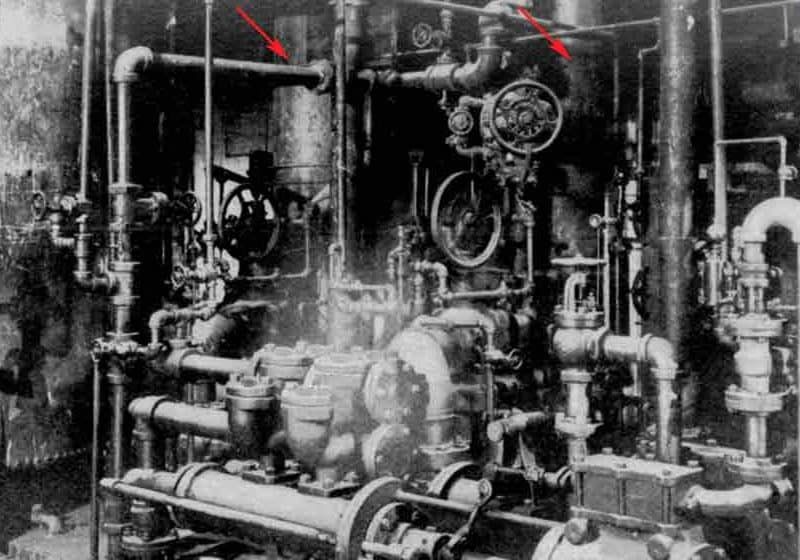

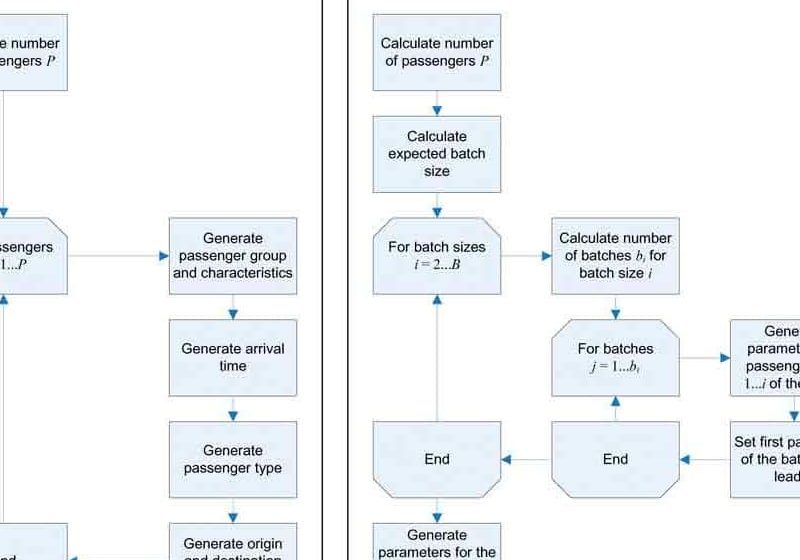

As part of the latest modernization, Quality Elevator was tasked with updating the existing 208-VAC controller feeders to supply 480 VAC to the new AC permanent-magnet (PM) machines. The most unique challenge of the project was the two basement gearless machines. Quality Elevator redesigned the existing floor-mounted DC hoist motor and adapted the new Imperial AC PM machine to the existing machine room. The new machine was inverted, while maintaining alignment with the existing roping system. Quality Elevator assembled a design team of local engineering firms – Ancona Associates, Motion Control Engineering’s (MCE) Machine-Room-Less Engineering Department and Imperial Electric. The company determined the force of the ropes on the AC PM machines must pull toward the mounting feet. To accomplish this, rotating the machine 90° and maintaining alignment with the existing infrastructure and clearances were required.

The logistics of mounting the new machines required fabrication of a custom bedplate and fastening the new machine to the existing structure without overloading the building structure. To accomplish this, California-based MCE and Imperial Electric designed a bedplate and mounting system that would place the stresses on both the building structure and machine within the designed criteria.

The overhead machines came with their own set of design requirements, as building access to the overhead machine room was cut off as a result of a fifth-floor addition in a 1970 renovation. The existing penthouse was surrounded by the new office space, which could not support the movement of elevator equipment across the flooring system. The solution was to create an access hole in the roof of the Federal Reserve to allow the demoed Westinghouse machines and control systems to be removed, and new machines and controls brought into the building. Quality Elevator created an enclosure that would allow removal of the cover to crane equipment in, and seal and secure the access point when complete.

Converting the Eccles Building power was accomplished by bringing power from a building from across the street, also owned by the Federal Reserve and connected by a utility tunnel. The route to the penthouse machine room utilized the old incinerator flue chase.

Installation

Part of the work, beginning in September 2010, was updating the remote-monitoring system to interface with the new equipment. This conversion allowed Quality Elevator to take full advantage of the energy savings associated with the AC PM machines. The most unique aspect of the project was that two of the gearless machines were set up adjacent to each other in the basement.

After consulting with Imperial Electric and MCE, it was determined the force of the ropes on the 525 PM machines must pull toward the mounting feet. The machine had to be rotated 90°, which would require the design loads to be transferred from the original design (from the floor) to inverting the machine and placing the load onto steel structure and retaining the existing rope alignment. As torque reactions created during hard stops of the elevator had been a design concern, a buffer with a soft rubber stop that would absorb and limit the motion of the machine was added.

Presenting Quality Elevator with another challenge were four additional elevators being modernized in a machine room above the elevators with narrow access. The drop hole put in place when the equipment was new had since been blocked with a coffered ceiling in the elevator lobby that could not be disturbed. After gaining approval from the Federal Reserve to create an opening in the roof of the machine room to allow crane access, the company determined the opening needed to be not only watertight and secure, but also unnoticeable from the surrounding buildings. The machine room also required modifications, such as relocation of switchgears, ship’s ladders and walls for safe, convenient access to the elevator equipment. Both the geared and gearless machines were placed on raised platforms above the controller space.

The specification for the custom remote-monitoring system required a “Silent Mode” for special meetings. In this mode, the elevators would run with no directional chimes or voice annunciation (visual annunciation only). Then, there was the issue of how to link the three remote machine rooms to a central location. This required monitoring integration into the existing infrastructure in the building. This was a significant hurdle, as the infrastructure had to follow high security protocol. Working closely with the Federal Reserve Information Technology Department, these challenges were overcome, and the project was completed in July 2012.

Get more of Elevator World. Sign up for our free e-newsletter.