In general, elevator control systems consist of parts that stop the machine, when required, by regulating the motor movement that controls the electric equipment of the elevators. While minimum specifications of control systems are defined by the standard, manufacturers may produce controllers of various designs and specifications. Operating principles may differ significantly in terms of communication methods, control efficiencies and other features.

History

Control systems have made great progress over the years, especially in terms of speed and communication. Until the early 1980s, and even into the late ’80s for some manufacturers, elevators used relay-controlled modules for data communication and for some simple interfaces in controllers. In this type of controller, which still exists today, control and output data is achieved via relay contact. Although it seems like a quite old technology, this system has some advantages in comparison with today’s controllers. For example, no software is used, so it is protected against software crashes or printed-circuit card errors, which are frequent problems with modern controllers. Moreover, relay-controlled systems are very long-lasting in general. They can last for 50-60 years, as long as the relays are changed when needed. The biggest disadvantage of these systems is their high hardware costs and high energy consumption. Moreover, they require a large area and long-term maintenance. The number of relays increases incrementally with the number of floors, and more labor is needed for handling and installation requirements.

In the early 1980s, manufacturers started using microprocessor-based controllers. Starting in the 1990s, these controllers began to take the place of the old ones. With this type of controller, the data received by sensors in the shaft, landing call buttons, indicators, shaft communication systems and other electrical equipment is processed through the printed-circuit cards and converted into commands, with data communication provided by cables between the cards and related equipment. Input-output data is managed by PLC-based control devices. Today, such systems are still used, including in elevators with fewer stops. We may see a great number of printed-circuit cards and cable terminals in these controllers, which were manufactured mainly in 1990s and early 2000s.

Starting in the early 2000s, CANBus technology began to be used in elevator controllers. CAN (Controller Area Network) technology is widely used, mainly in automotive industry and various industries. Although this system was developed in ’80s, it took time to be applied to elevator controllers. In general, CANBus allows the routing of related units from a single data line through a central control unit and a microprocessor (Master-Slave). All of the system’s hardware (landing call buttons, indicators, sensors, shaft communication systems) transfers to and receives data from the mainboard via two wires. The data is processed in line with the order of priority and managed by the mainboards, where the central processor is located. Therefore, it is possible to achieve savings from the number of cables. Less space is occupied and the cost decreases. Moreover, this system is less affected by impacts, and troubleshooting is easier. As a result, almost all controllers use this communication protocol today.

Basic Standard Requirements

Elevator controllers should meet the below-mentioned specifications as defined in EN 81-20:

- They should send the cars to the bottom and top floors.

- Dynamic tests shall be arranged so they can be carried out from outside of the well.

- The control system should be provided with means to prevent the lift from answering landing calls.

- At the least, the direction of the movements of the car, the reaching of an unlocking zone and the speed of the car should be directly observed.

Due to the requirement that suggests elevator tests should be carried out without the need to enter the well, a test menu is needed. This menu should contain proper instructions for the tests, which should be carried out when the elevator is running, such as the buffer stroke test, cabin parachute test, testing each brake set independently, final limit switch test and rupture test. If an external tool is used for reaching these parameters, as this tool is considered as a “special tool,” it should be safeguarded in the immediate surrounding area of the lift installation.

The certification of elevator controllers is finalized with a Type Examination Certificate.

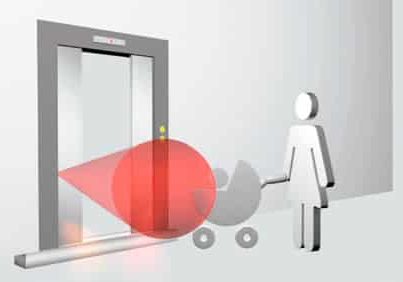

Controller Types Based on Landing Call Methods Conventional Controllers

These controllers are used for managing one or more elevators. The elevators are brought to the required floor through an exterior call. Then, the required floor is registered in the car. With group controllers, the car that is nearest to the floor where the call is registered takes off to answer the call.

Group controllers may serve eight elevators. If the number of elevators increases, then the manufacturers use tailored solutions.

Car operating panel and call buttons

Destination Selection System With this type of controller, the destination floor is selected by dialing from an external keyboard only. Unlike conventional controllers, this system directs the elevator that can reach the floor fastest, not necessarily the nearest elevator. It generally supports up to 10 elevators. If there are more elevators, the manufacturer should provide a tailored solution.

Additionally, there are hybrid solutions where these two types are controllers are used together. The destination selection system is preferred in high-traffic buildings. Office buildings are proper places for such type of application.

However, it is not suitable for all office buildings. Traffic analyses show that, excluding exceptional cases, at least four elevators should be used to so these controllers will be more efficient compared to conventional controllers. Moreover, a destination selection system may increase the average waiting time in low-traffic buildings, when compared with conventional controllers. Therefore, a detailed traffic analysis should be carried out before deciding to use such costly systems.

In general, the controllers used in elevators have various sizes and various electronic infrastructures. Provided that they meet standard requirements for basic security, the manufacturers may produce any type of devices. Before making a choice between the systems, the needs should first be determined properly. Several factors, including what types of calls the system supports, how detailed and durable the failure interface and electrical connections are, and if it is possible to supply printed-circuit cards easily or not, are important in choosing the proper controller.

Get more of Elevator World. Sign up for our free e-newsletter.