Elevator a perfect match for striking visual arts center in northern Spain.

Centro Botín is a major new visual arts center in Santander, Spain, commissioned and financed by the Fundación Botín, a philanthropic Spanish institution founded in 1964. The building, in an urban setting that links the city to its waterfront, was designed by renowned architect Renzo Piano. As well as offering the people of Santander and the wider region of Cantabria a wonderful gateway to the arts, the center strengthens the city’s social and cultural appeal through a striking new attraction in an inviting location. When this building was conceived, it was a given that the vertical-transportation (VT) system would have to match its elegant form, while maintaining the highest levels of function.

Centro Botín hosts educational and cultural activities. Projecting out into the Bay of Santander, it sits in a strategic location. Once part of the busy docks, the site had ended up as a massive car park for a ferry terminal. Now, it has been restored to life in the city. The building is also right next to the historic city center and adjoins the historic Pereda Gardens. It reconnects the old town to the bay, while the road that once blocked the gardens from the dockside now runs out of sight through a tunnel. This has allowed the Pereda Gardens to double in size, to about 10 acres, and extend all the way to the bay.

Set at the edge of the park, Centro Botín was built half over land and half over water. This means that people strolling in the gardens have an unimpeded view of the bay, with Centro Botín seeming to hover weightlessly at treetop level, offering tantalizing glimpses of itself through the foliage. A series of glass-and-steel stairs and walkways separate the two rounded sections of the building and create new public spaces. Barely earthbound, the building shoots out 20 m over the bay. On both blocks of the building, the façades are covered with 280,000 small and slightly rounded ceramic tiles, vibrant in mother-of-pearl, that reflect the sunlight, the ripple of the sea and the watercolor luminosity of Santander.

The west block is entirely dedicated to showing art, with galleries on two levels that offer views of both bay and park. The exhibition space on the upper floor is lit from above and protected with three layers of roof covering: an outer layer of small, silkscreened glass slats that prevent light from entering the gallery space directly; an intermediate layer of double glazing that weatherproofs the gallery; and an inner layer of small aluminum louvers, controlled by sensors, that adjust the light or black the interior out completely. Beneath the west block, a glazed-in public space contains the restaurant, shop and leisure areas.

The east block focuses on cultural and educational activities. On one side, an auditorium rises to double height and is cantilevered out over the bay — a versatile space for hosting concerts, readings, lectures, festivals and ceremonies, with a terrace that offers stunning views. At its northern end, the education center provides multipurpose spaces designed with maximum flexibility to house activities large and small: from classes and workshops to music, dance and cookery events.

Outdoors, a new amphitheater faces Centro Botín’s west façade. The ground floor of the west block is fully glazed and houses a café/restaurant, a shop and an information center.

The Lift Systems

The building owner, architects and construction managers made it clear what they wanted from the VT provided by IMEM Lifts:

- Strikingly original, made-to-measure lifts with one-off dimensions and a very high load capacity, which would impress visitors and safely handle the transportation of notable works of art, both large and small.

- Top-quality, handpicked finishes for the lift cars

- Components designed and made to measure

- Exceptional safety features

- Stringent temperature-control and air-conditioning specifications

Main Lift System

The main lift, the essential task of which is to transport both passengers and artworks, is located along the central axis of Centro Botín. It is a machine-room-less (MRL) lift with a 6500-kg/86-passenger capacity serving four floors with a travel distance of 20.3 m at a speed of 1 mps. Although there was the clear realization that designing, manufacturing and installing a lift of this significance and speed without a machine room was going to be a considerable challenge, the IMEM team saw from the start that an MRL lift would be, by far, the best solution.

The lift had to take up the minimum amount of space, while avoiding any chance that the technical requirements would restrict the architect’s vision. Doing without a machine room eliminated the need for a structure to house it, which would have disrupted the roof line and been contrary to the aesthetic of the building. The building’s proximity to the Bay of Santander ruled out a ground-level machine room, as this would have required expensive works to protect it from possible water damage. Other features of this unit are:

- A 4:1 roping ratio and a centrally mounted support frame chosen for passenger ride comfort

- Advanced damping materials to reduce vibration: a major priority was to make sure that the weight of the lift system (slightly over 30 T.), its car speed of 1 mps and its traction drive speed of 4 mps did not cause significant vibration in the support structure when the lift car was in motion, which would have seriously affected acoustic purity within the building.

- A state-of-the-art permanent-magnet drive unit: a gearless motor was chosen because it is 50% lighter than its geared equivalent, making handling and installation significantly easier. The compact size of a permanent-magnet motor reduces the space needed inside the shaft, and the gearless configuration cuts energy consumption.

- The glazed car is 5 m tall, and offers glorious views of the Bay of Santander. The car doors and landing doors are built of stainless steel and are center opening, using four 3,600-X-4,000-mm panels. Given their unusual size, both the car and doors were built to measure, and other door and door-entrance components — such as the stainless-steel sills — were specially manufactured for the project.

- The car roof was designed and built to mimic the ceramic-tile cladding of the Centro Botín and incorporates a fabric specifically created for the job. The car flooring is the same as the wooden finish used in most of the building.

- The car is vented to the exterior to control and maintain the temperature difference between the shaft and building interior, as required. The landing doors are smokeproof, and, when closed, prevent any exchange of air between the shaft and building interior. The car is equipped with its own air-conditioning system, which is programmed to match the temperature inside the art galleries. It is fitted with huge panels of thermal glass, measuring 4 X 5 m, which prevent condensation that would otherwise result from the temperature difference between the building interior and exterior.

- The pit is located below sea level. In case of water leakage, it has a water-detection device that activates pumps to remove the water, while simultaneously holding the lift car between floors.

- The lift is fitted with the latest safety measures, such as an automatic releveling system in the lift car and a control system designed to keep the car floor level with the landing during loading. The doors have electronic safety barriers to their full height, designed to ensure damage-free loading and unloading of large works of art.

- The lift system is programmed with different functional modes activated using radio-frequency identification cards: operation as a passenger lift or a goods/passenger lift, independent-service mode, out-of-service mode, controlled access and various others related to the center’s building management system.

- The control system uses artificial-intelligence applications to manage alarms, breakdowns and traffic management.

- The lift is monitored 24 hr. a day and has been designed so that necessary maintenance can be carried out under the safest possible conditions.

The lift’s commissioning date was June 23, 2017. During its first few months on the job, it made an average of 1,000 starts during 11 hr. of travel daily. During peaks in passenger traffic to the art galleries, it is in constant operation. Aside from passengers, the lift has also transported works of art — some of them huge — by renowned artists, including Francisco de Goya, Carsten Höller, Jannis Kounellis, Miroslaw Balka, Tacita Dean and Mona Hatoum, among others.

Secondary Lift Systems

Centro Botín has another lift system, an MRL SilensPro Mega®, built to carry loads of up to 2000 kg at a speed of 1 mps and equipped with a car that, like the 6500-kg lift, was designed to match the design aesthetic of the building. Given that it leads directly to the building exterior, the doors of this lift are fully weatherproofed.

Finally, there are two dumbwaiters that serve El Muelle, the center’s ground-level café/restaurant run by two-Michelin-star chef Jesús Sánchez.

Main Lift Technical Data

- Type: Custom MRL

- Roping ratio: 4:1

- Load capacity: 86 passengers, 6500kg

- Travel distance: 20.33 m

- Number of stops: Four

- Speed: 1 mps, frequency controlled

- Lift car: Single entrance, made to measure in accordance with architect’s instructions. Panoramic end wall, with side walls of stainless steel and 5 m internal height.

- Car dimensions: 3,850 mm wide X 5,000 mm high X 2,800 mm deep.

- Glazing: Self heating, to prevent condensation on inner surface due to the difference in temperature between the building’s interior and exterior

- Floor: The car has the same wood flooring finish as most of the building.

- Roof: The car roof reflects the aesthetic of Centro Botín’s ceramic tiling, in harmony with the design of the gallery block.

- Car operating panel: The car is equipped with two 4-m Dewhurst M-10 REB Braille operating panels.

- Door: The car door is stainless steel with an entry clearance of 4 m high and 3.6 m wide. The car door opening is fitted with a photocell barrier along its full height that protects passengers, artworks and the doors themselves.

- Car frame: The car frame is built of high-resistance steel, resulting in easier installation, reducing the system’s static load. This type of support frame is particularly effective with a 4:1 roping ratio and, in line with European standards, is equipped with a progressive safety gear. The frame is finished in RAL 2009, as specified by the client.

Car Technical Characteristics

- Lift car guide rails: Cold-drawn T140-3/B-model rails, fully compliant with ISO 7465Counterweight frame: Painted in RAL 2009.

- Counterweight guide rails: Cold-drawn T90/B-model rails, fully compliant with ISO 7465.

- Landing doors: Automatic Wittur doors, Taurus model, center opening with four panels and finished in Scotch-BriteTM stainless steel. The doors are insulated against heat loss with a horizontal entry clearance of 3.6 m and vertical clearance of 4 m. The airtight seal between the door panels, and between the panels and door frame, ensure the doors are smokeproof when closed.

- Sill: T100 flush sill and track in stainless steel (AISI 316). Car doors: Automatic Wittur doors, Taurus model, center opening with four panels and finished in Scotch-Brite stainless steel with a horizontal entry clearance of 3.6 m and vertical clearance of 4 m. Opening blocked when between floors.

- Motor: Variable frequency, asynchronous permanent magnet

- Door safety: Optoelectronic light curtain that, along with its associated wiring, is integrated into the door panels and interrupts door closure as soon as it is breached.

- Landing operating panels: 4 m high and equipped with Dewhurst M-10 REB Braille push buttons

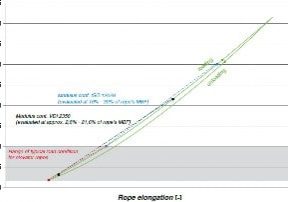

- Lift ropes: Drako 250T IWRC 1570 U sZ with a diameter of 13 mm

- Compensating chain: Drako CB 600 comfortBalance Pawl device: NS 70/100-model safety device, which prevents the cabin from dropping during loading and unloading operations

- Drive system: WTYF380 S20-3500-2: synchronous permanent-magnet gearless motor

- Sheave diameter: 530 mm

- Rated torque: 3,010 Nm

- Maximum power: 45.4 kW

- Current: 103 A

- Rated speed: 1 mps (ratio: 4:1)

- Brake voltage: 220/100 V

- Overspeed governor: SLC LF 30 CA model with tension pulley

- Safety gear: KB 55 SS/EB 75 GS model

- Pit damper mechanism: OB16 model

- Voltage: 380/400 VAC at 50Hz

- Shaft lighting voltage: 220 VAC

- Control system: Altamira II model with distributed modular electronics and CAN bus networking

- Basic characteristics of control system: Single-lift control system, up and down collective; four stops; direct approach system with variable-frequency control; includes phase failure relay and temperature control; control of motor temperature; intelligent control of car speed curve; online monitoring 24 hr. a day; RS485 computer communication port; special control system for loading and unloading artworks; special lift-car control system using contactless smart cards for independent service, out-of-service placement and cancellation of stops

- Applicable standards: EN 81.1 and 81.70

Get more of Elevator World. Sign up for our free e-newsletter.