Mother India Forming Pvt. Ltd. Chief Operating Officer Dhirendra Sankhla (DS) shares views on the issue theme with your author (SSP).

SSP: What have you observed as the key growth drivers elevating the vertical-transportation (VT) industry in India over the years? How would you describe the role of Mother India Forming in this regard?

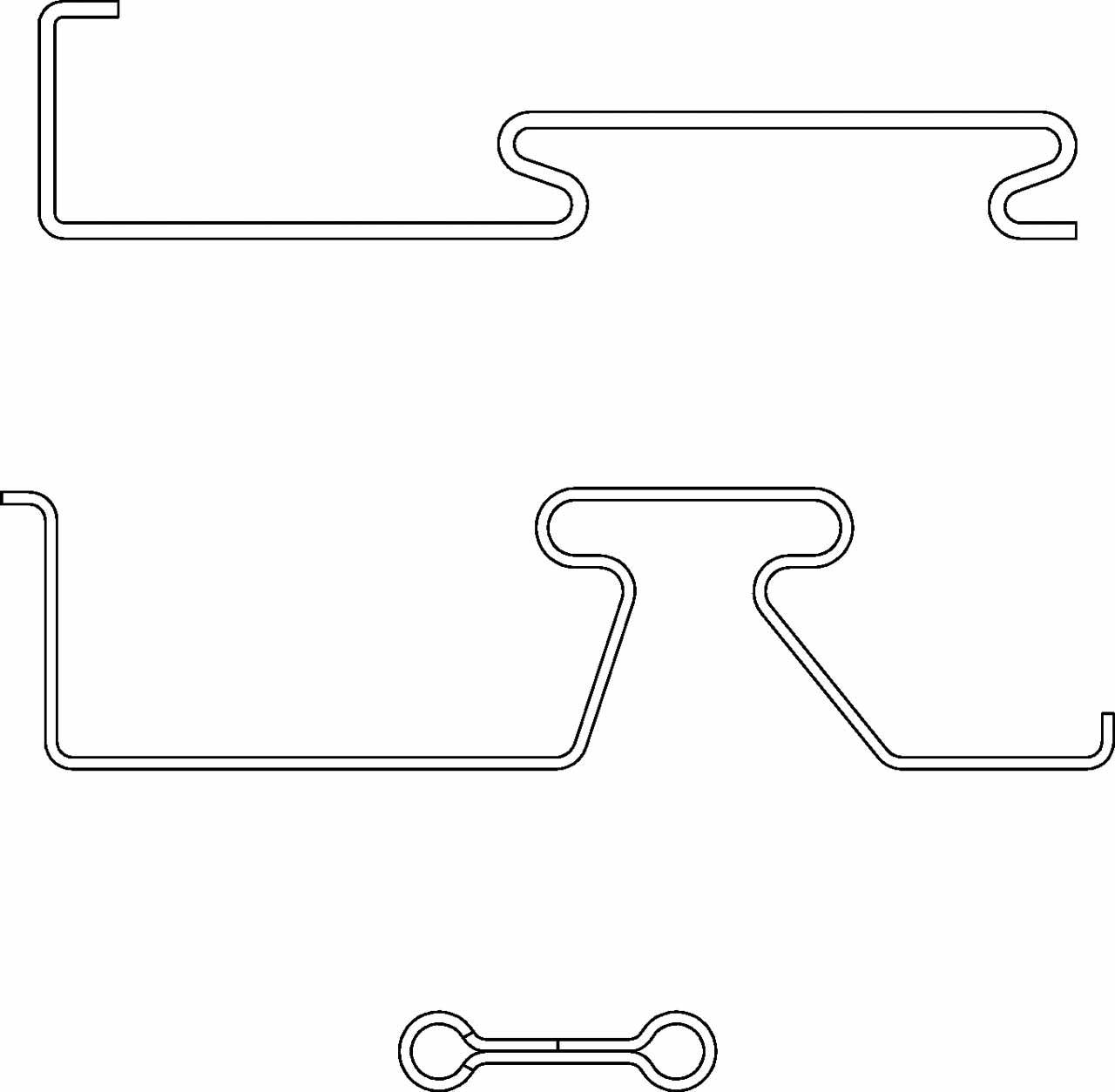

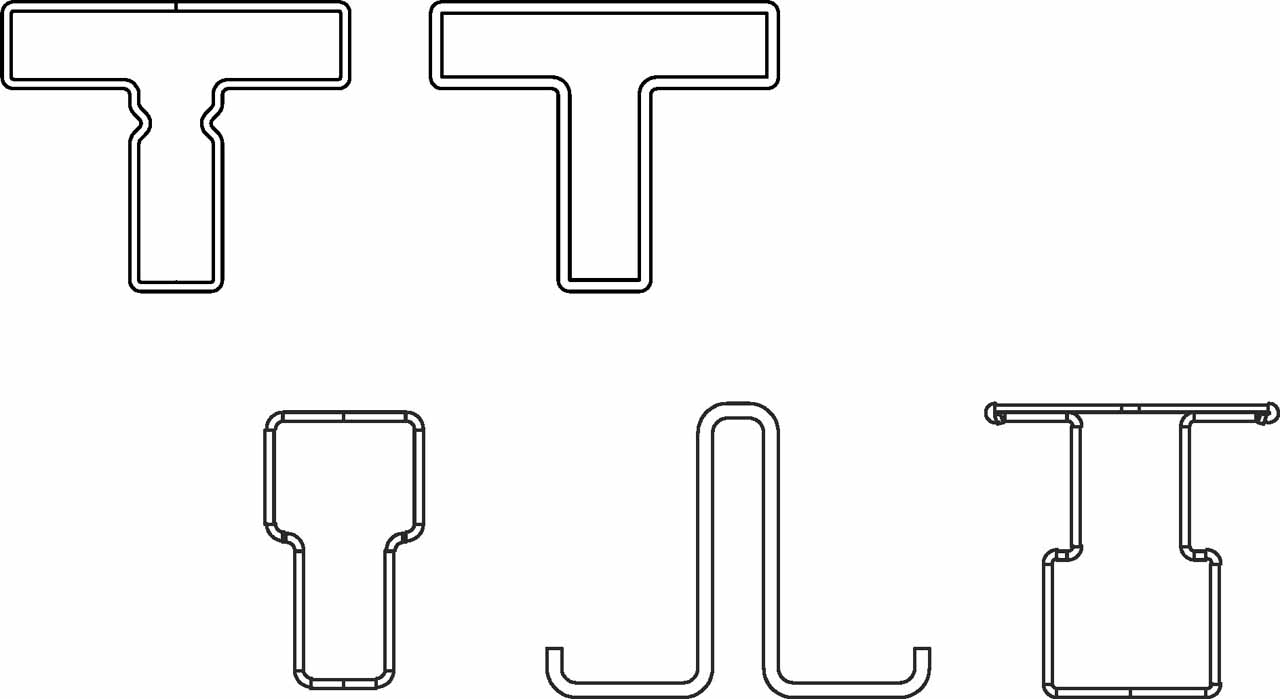

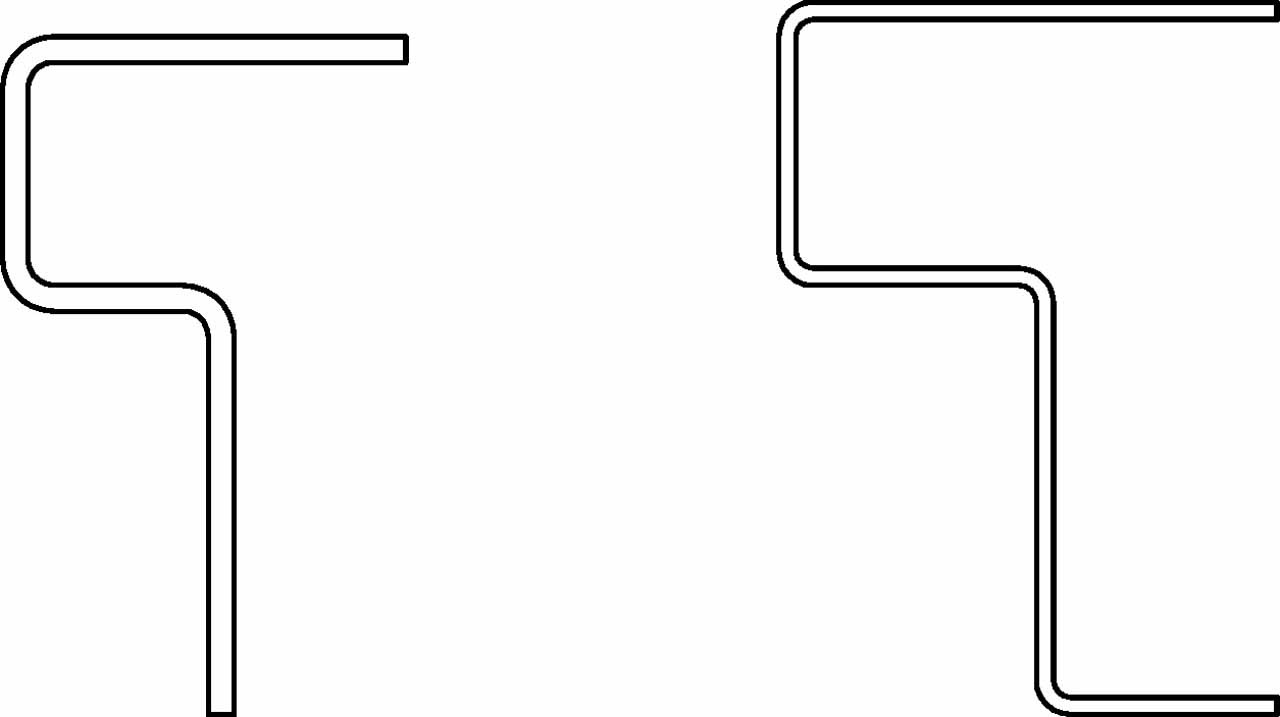

DS: The VT industry in India has experienced significant growth due to several key drivers, including urbanization and infrastructure development, government regulations, safety standards and more. These developments demand high-quality, low-cost equipment that can be delivered and installed quickly. We realized an opportunity in localizing sheet metal parts such as door tracks, hollow guide rails, door stiffeners and many other components. The risk involved in development time, cost of capital expenditure to create required infrastructure and the company reputation in case of failure was very high. But, with a young engineering team, we offered OEMs a risk-free investment that encouraged localization and explored exports of parts and assemblies to their counterparts around the world. Over the past four years, we have supplied parts worth more than Rs 100 crore to OEMs in India.

SSP: To what extent does the progress and development journey of Mother India Forming over the past four decades reflect that of the VT industry and the real estate sector? Has a greater number of high-rise buildings and taller towers that require faster elevators led to more demand for elevators, for instance? What parallels can one draw?

DS: Development of tubular and open profiles with other industrial verticals such as automotive, construction equipment, furniture, textiles and others helped us understand the requirements and expectations of OEMs. This helped us source materials on par with international standards and work toward Lean manufacturing that kept the cost of production at a reasonable level. Some key aspects, such as urbanization, infrastructure development, the real estate boom, high-rise construction, changing building regulations and safety standards and a greater focus on sustainability and energy efficiency create a dynamic environment that fosters innovation, technological advancements and improved VT system efficiency. Mother India is prepared and aware of them!

SSP: In your opinion, which factors will impact development at Mother India Forming and the VT industry going forward? Which products from your portfolio will be in demand and why?

DS: Shopping malls, airports, metro trains, hotels, apartments and high rises already have VT as part of their basic infrastructure. Factors that can impact the VT industry and Mother India Forming would be government housing projects, walkways over high-traffic roads, modernization of railway platforms and interconnected bridges and multi-storied bus terminals. We have the capacity to meet these demands and develop cost-effective sheet metal parts, as well. We will also be developing products that are currently being imported by VT manufacturers other than OEMs, which cater to up to 50% of the market demand.

SSP: As a supplier to leading VT OEM brands, what demand patterns in product categories have you witnessed from them at Mother India Forming, and what trends do you envisage going forward?

DS: The demand pattern is consistently increasing year-over-year. Even month-on-month, demand has been consistent, and we believe that it can be exponentially high if the government considers VT in public infrastructure projects.

SSP: Going forward, you envisage Mother India Forming manufacturing import-replacement products and parts for the VT industry. How will this impact the growth of the company and the VT industry as a whole?

DS: The focus on manufacturing import-replacement products and parts for the VT industry can have several positive impacts. We believe growth of the domestic manufacturing sector, reasonably priced alternatives to imported components, reduction in supply chain vulnerabilities and the “Make in India” initiative are some of the factors that will impact Mother India Forming and the VT industry. Overall, by manufacturing import-replacement products and parts, Mother India Forming can have a positive impact on the growth of the company and contribute to the resilience and competitiveness of the VT industry in India.

About Mother India Forming

Vision: Best practices and work ethic to support the transformation of the nation

Mission: To continue leading invention, innovation, development and supply in the challenging localized sheet metal component market

How we give shape to ideas: Profile Concept > Roll Forming Simulation > 3D Prototyping > Actual Profile > Bending Simulation > Final Product

About Dhirendra Sankhla

Dhirendra Sankhla is a third-generation entrepreneur with two decades of experience in the technological and commercial aspects of the roll forming business. He has been at the forefront when it comes to the development of complex roll-formed profiles and components for the elevator industry and other sectors like automotive, construction equipment, form works and the textile industries. As the COO of Mother India Forming, he oversees the daily operations and strategic planning of the company. He works closely with a young team of engineers to ensure the company meets its goals and objectives, while maintaining a culture of innovation and excellence.

Get more of Elevator World. Sign up for our free e-newsletter.