Over the approximate century since Frederick “Fred” Hymans developed the theory of rope traction in 1920, there have been a few minor challenges to a couple of the assumptions posited by Hymans — specifically, the hoist rope maintaining its cylindrical shape and the radial compressibility of the rope cross-section as wires cross each other and as the rope profile seats itself in the rigid groove. The relative hardness of the wires and sheave groove must be considered. In an era when instrumentation technology was primitive by contemporary standards (and decades before the emergence of computers), it can be argued that Hymans made reasonable assumptions to set up the mathematical model and develop a meaningful solution. It can also be argued that his theory and practice of rope traction has withstood the test of time, especially since numerous test programs over the century have shown the theory and practice was made to a reasonable degree of engineering accuracy. As stated in Part One of this article (ELEVATOR WORLD, February 2017), Hymans’ theory has become the gold standard for rope traction over the last century.

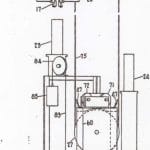

Over the many decades of ASME A17 Mechanical Design Committee discussions, countless references to Hymans have been made in relation to his expertise in mechanics of motions, rope traction, analysis and design of safeties, machines, structures and buffers, just to name a few. Notably, Hymans presented a technical paper at the annual meeting of the American Society of Mechanical Engineers (ASME) in December 1926, in New York City (NYC). This paper,[1] shown in Figure 1, is a cornerstone technical treatise about the emergency mechanical stops of high-speed elevators. In it, Hymans introduced the “Equivalent Dynamic System,” which he used throughout his years at Otis. It’s a variation on Newton’s Second Law of Motion but offers a convenient analytical methodology. Prior to his retirement, Hymans authored an in-depth analysis of centrifugal governors,[2] which readers might find informative.

Hymans is a legend within the worldwide elevator (lift) industry. Can any other information be found to highlight the human dimensions of the man? Beyond their technical writings, patents and publications, the technical giants of yesteryear left little footprint other than the folklore tales of their accomplishments, which were handed down to successive generations of engineers.

Hymans was a contemporary of several notable engineers of his time. These included David L. Lindquist, John N. Anderson, George W. Crabbe, George Lautrup and Clifford Norton. Swedish-born David L. Lindquist, Otis chief engineer (Figure 2), is credited with masterminding Otis’ technological progress through the first half of the 20th century.[3] He was a “founding father” at the A17 committees, participating in the development of the 1921 and several subsequent editions of the A17 code. Following an outstanding career of 43 years at Otis, Lindquist retired in 1944 at the age of 70. [3]

During Lindquist’s era of technological leadership as chief engineer of Otis, several other technical giants reported to him, including Anderson, Crabbe, Lautrup, Hymans and Norton. The one thing they, with the exception of Lindquist, had in common was their collective retirement from the Otis Engineering Division at the end of 1947.

Reference is made to an archival Otis Bulletin article[4] from December 1947 (Figures 3 and 4). The article profiled Anderson, Crabbe, Lautrup, Hymans and Norton as “The Men Who Made the Modern Elevator.” These five gentlemen were the technical giants within the Otis Engineering Division, located at 260 11th Avenue, NYC.

At the time of Hymans’ retirement, he was 72 years young! An interesting footnote is in order. In 1947, Otis’ mandatory retirement age for its employees was 65 years, the traditional age used throughout the U.S. business community during the 1940s. But, the senior and highly valuable engineers of that era, like Hymans, and possibly some or all of the others shown, were classified as consultants and, therefore, not impeded from continuing to contribute their expertise to Otis beyond the normal, age-65 retirement. These pictures and accompanying narratives have been excerpted from the Otis Bulletin, December 1947.[4]

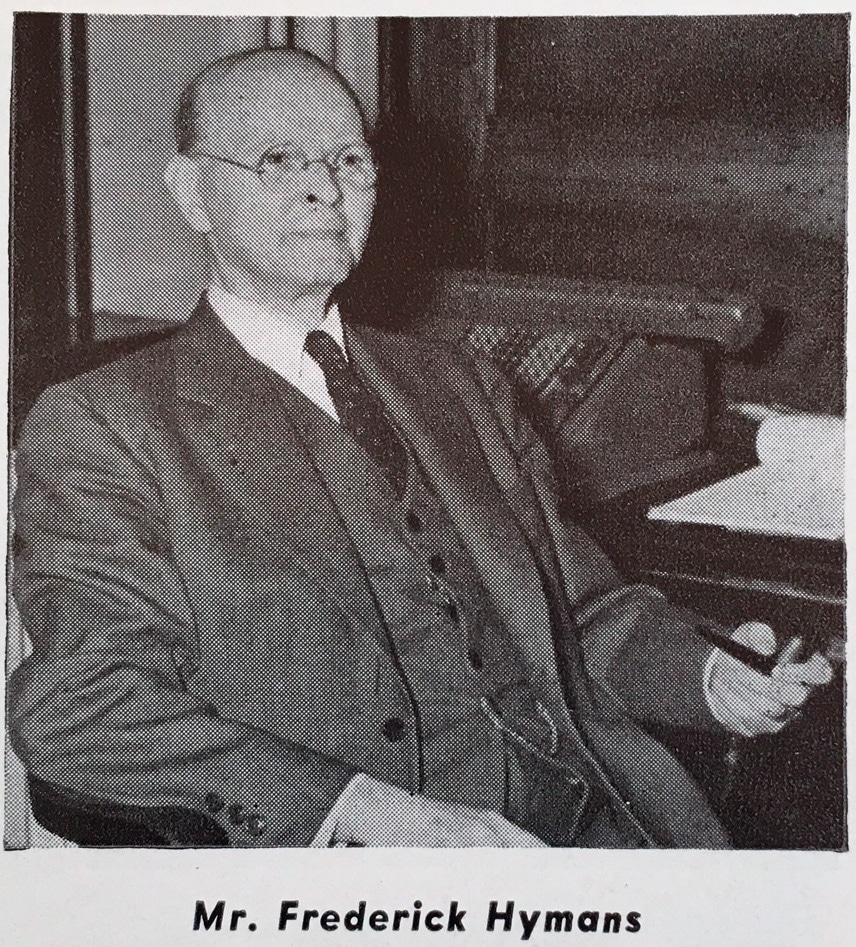

Hymans is seen in a rare photo in his Otis office in Figure 7. We now know that he was a pipe smoker and enjoyed a highly coveted window view from his desk. Interestingly, the calculator just behind him is a Friden electromechanical calculator, the same as your author used between 1960 and 1967, when they were finally trashed, having reached the end of their useful and repairable lives.

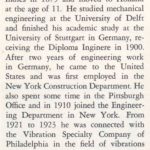

After receiving his engineering degree from the University of Stuttgart in 1900, Hymans was involved in the design of steam engines, cranes and structural steel in Germany. After emigrating to the U.S., he started his career with Otis in 1902. With the exception of 2-1/2 years when he left Otis to work as a research engineer at Vibration Specialty Co. in Philadelphia,[1] Hymans spent his entire professional career at Otis from 1902 through 1947. Early in his Otis career, he was assigned to the Otis New York Construction Department. He worked in the Otis Engineering Division continuously from 1910 through 1947. Throughout, he focused on the design and rigorous theoretical analyses of geared and gearless machines, structures, safeties, governors, buffers, mechanics (motions), hydraulics for deck-edge elevators for aircraft carriers and other special designs in which Otis was involved. He had several patents, notably those summarized in Table 1. The Otis Bulletin profile of Hymans’ life is seen in Figure 8.

On one of their early trips back to the U.S., Hymans, age 30, and his wife, listed as Lydia, age 22, sailed on the SS Zeeland from Antwerp, Belgium, on November 4, 1905, arriving in NYC on November 14, 1905.[5] Fred’s citizenship was Dutch; his occupation was listed as “Mechanical Engineer.” Lydia was listed as a housewife, born in Germany, having German citizenship. Their New York destination was their home on Clove Road, West New Brighton, Staten Island, New York. Fred first arrived in the U.S. in 1902. The data entries were recorded on a sheet reserved for saloon- or first-class passengers.[5] This 1905 trip was Lydia’s first trip to the U.S.

The beginning of the 1900s ushered in a new era for high-rise, high-speed elevators. Up to that point, roped hydraulics using reeving ratios as high as 12:1 dominated the high-rise market but were superseded by electric gearless traction elevator systems introduced in 1903. A new generation of skyscrapers was built in NYC in the early 1900s. These include the 612-ft.-tall Singer Building, 1906 – 1908; the 700-ft.-tall Metropolitan Tower, 1910; and the 792-ft.-tall Woolworth Building, called the “Cathedral of Commerce,” 1912. The highest elevator speeds in the Woolworth Building were 600 fpm and 700 fpm.[9] Hymans played a significant role in the development of the new high-speed elevator systems in connection with their gearless traction machines, governors, safeties and buffers.

In the 1930 U.S. Census,[6] taken on April 4, 1930, Frederick F. Hymans (the first known appearance of his middle initial) and Anna Lydia Hymans resided at 317 Hawthorne Avenue, City of Yonkers, Westchester County, New York. He was listed as a mechanical engineer working at the Otis factory. The census form noted that he first emigrated to the U.S., in 1902, with this being the case for Lydia in 1905. Otis’ main factory was the one in Yonkers. Engineering activities under the purview of the New York Engineering Office were performed in the New York Executive Offices, 260 11th Avenue, NYC, and in the Yonkers factory offices on Wells Avenue. Otis also had its test tower in the Yonkers factory. It was not uncommon for engineers to work in both locations back in the 1930s right up until the Engineering Division was relocated to Mahwah, New Jersey, in 1974.

Several months after the 1930 census was taken, the Hymans sailed from Antwerp, Belgium, on the SS Lapland on September 19, 1930, arriving in NYC on September 28, 1930.[7] According to the ship’s records, Fred was naturalized in the Supreme Court, Yonkers, in May 1925. Lydia was naturalized at the same location in July 1928. At the time of the ship’s voyage,[7] the couple resided at 317 Hawthorne Avenue, Yonkers, later relocating to Larchmont, New York.

In the 1940 U.S. Census,[8] the Hymans resided in an area of financial means at 93 Stuyvesant Avenue in Larchmont. Fred was listed as a mechanical engineer in the elevator industry. His neighbors were all professional people, having such employment as broker, boat captain, sales manager, executive, teacher, treasurer, etc. Since there were no other residents at the Hymans’ address, it must be concluded that they lived in a private one-family home.

Hymans authored numerous publications throughout his professional life. His books include Der Neuzeitliche Aufzug mit Treibscheibenantrieb[Part One, 20] and Electric Elevators, Books I & II.[Part One, 10 & 11] He is credited with authoring additional publications on stress analysis and vibrations. During his Otis career, Hymans taught several engineering courses in stress analysis, mechanics and vibrations in the evening postgraduate school of the Polytechnic Institute of Brooklyn, New York, known as “Brooklyn Poly.” Several Otis engineers took many of Hymans’ courses at Brooklyn Poly. Your author took numerous postgraduate- and doctoral-level engineering courses at Brooklyn Poly in the 1960s. Indeed, the Otis engineers who took Hymans’ courses sat at the foot of the master!

One of Hymans’ protégés was Joseph “Joe” Mastroberte, who worked under Hymans’ tutelage for 19 years between 1926 and 1945. Mastroberte would later describe Hymans as an outstanding mentor, albeit a bit frugal in giving merit raises! Other associates at Otis described Hymans as “a person always willing to help a young engineer; those at Otis knew him as ‘The Man.’”[Part One, 11]

Mastroberte recounted that during the period when the Empire State Building was being designed in the late 1920s, Hymans was heavily involved in the design of all the mechanical systems. When the building was being erected in early 1931, Lindquist and Hymans made several presentations to the NYC Buildings Department urging the approval of higher-speed elevators for it. In that era, elevator speeds in the new generation of NYC skyscrapers were limited to 700 fpm, since this was deemed to be the maximum speed a human elevator operator (attendant) could safely control,[9] i.e., stopping the elevator at a destination floor without overshooting the landing and having to relevel. In fact, this 700-fpm limit was specified in the Building Code of New York City, 1911, Part XVII, effective September 1, 1911, Section 20, in the Borough of Manhattan. This section[10] remained in effect until the early 1930s, when the automation of speed controls influenced NYC to raise the speed limits to 1,000 fpm[3 & 9]. This 1911 requirement stated:

“20. The speed of all elevators must not exceed five hundred feet per minute, except that express elevators may run seven hundred feet per minute for that portion of the shaft in which no intermediate stops are made.”

The NYC Building Code, 1911,[10] Section 12, limited express elevators to 700 fpm and required car safeties to stop a 700-fpm nominal (rated) speed car in a distance not greater than 8 ft. The text of the requirement stated:

“12. Safety Gear. All elevators, except direct plunger elevators and freight elevators having a rise of 15 ft. or less, shall have a governor or speed regulator properly connected to the safety devices on the car, in such a manner that the car will be brought to rest with an easy and gradual stop, or in a distance not greater than 8 ft. for a speed of 700 ft. per minute except that on elevators having a speed of 100 ft. per minute or less safeties of the instantaneous type may be used.”

As a result of the numerous Otis presentations by Lindquist and Hymans to the NYC Buildings Department and other NYC officials, NYC increased the limits on car speeds in the NYC Building Code, thus allowing the Empire State Building elevators to be run at their higher design speeds. While not a member of any of the A17 committees, Hymans assisted his boss, Lindquist, in giving technical presentations to assist the committee members in appreciating the technical detail. Offline from the committee meetings, Dickinson of the U.S. National Bureau of Standards frequently collaborated with Hymans in the 1930s and 1940s on numerous mathematical analyses relating to oil buffer performance, safety design and testing.

During the 1930s and 1940s, the major elevator companies contracted with the U.S. National Bureau of Standards (NBS) for buffer and safety testing. Dickinson was the primary person doing the work, most of which was subsidized by the major elevator manufacturers, for the bureau. Early A17 minutes and code editions noted that Dickinson was the secretary of the A17 Sectional Committee, participating in the formulation of the A17 codes, starting with the 1921 code up through the 1960 code. He not only served as the secretary, then secretary emeritus, but was also a major contributor to the technical work. Up until the 1970s, the NBS was one of three co-secretariats for the A17 Standards Committee. Dickinson was a contemporary of Hymans, and both respected each other’s scholarly work. Dickinson performed many freefall buffer and safety tests at the NBS; many were supervised by him at the test towers of the companies. He collaborated extensively with Hymans during the years leading up to Hymans’ retirement.

In the section of the publication[11] “History Is Made Up of Recollections,” George Reppert, Otis electrical engineer, and later code engineer for the National Elevator Industry, Inc., acknowledged Lindquist and Hymans:

“I recall when I joined Otis’s construction manager’s office in 1909, there were no elevator codes. The manufacturers policed themselves and did a good job of it. Of course, there were only a few companies. Otis was the big one, and A.B. See was active at that time. Haughton was also in the picture. They were all very much aware of what the others were doing, and there was a real effort to maintain high standards according to sound engineering practices. The Otis chief engineer, Dave Lindquist, and [its] chief mechanical engineer, Hyman[s], had a good deal to do with this and with promoting the first codes. . . .”

Mastroberte recounted many folklore tales about Hymans. Legend has it that a young engineer who started in Otis Engineering after World War II asked, “What does Mr. Hymans do?” The answer from a senior engineer was, “Whatever he wants to!” Another asked, “Who does he report to?” The answer from another experienced sage: “The Almighty!” Such were the anecdotal stories about this legendary engineer.

During his career with Otis, Hymans was a research engineer, then chief mechanical engineer and, finally, consulting mechanical engineer in his later years. Upon Hymans’ retirement, Mastroberte was appointed the Supervisor of Machines & Structures Engineering; he was later appointed department head, Machines, Structures & Safeties Engineering. Mastroberte was the chairman of the A17 Mechanical Design Committee for several years, starting in mid 1961 until his retirement in 1967. Joe Mastroberte mentored your author from 1960 to 1967, a stroke of good fortune, indeed!

Hymans gave much of his collection of technical manuscripts to Mastroberte, either as originals or blueprint copies, such as those seen in Figures 7, 14, 16, 17 and 18 in Part One of this series. He memorialized many of Hymans’ technical papers as Otis Theory & Practice Books, subsequently used by the Otis mechanical and structural engineers in their work.

After a long illness, Hymans passed away on March 23, 1959, at the age of 84 at his home in Larchmont. His obituary in The New York Times[12] published the following day noted his 45 years as a mechanical engineer at Otis and nine years as an adjunct professor at the Brooklyn Poly (1931-1940), and that he wrote several books on stress analysis. He was survived by his wife, Lydia, two brothers and three sisters.

There are undoubtedly several untapped sources for further research into Hymans’ life. Hopefully, the author has inspired further research. Hymans deserves the tribute!

- Figure 1: Hymans’ 1926 ASME paper

- Figure 2: David L. Lindquist, Otis chief engineer, 1912-1944

- Figure 3: First volume in a series of bound Otis bulletins

- Figure 4: Cover of the December 1947 Otis Bulletin

- Figure 5: “The Men Who Made the Modern Elevator”: (l-r) John N. Anderson, George W. Crabbe, George Lautrup, Fred Hymans and Clifford Norton. Vests and pocketwatch chains were the order of the day![4]

- Figure 6: “Profiles of Talent”[4]

- Figure 7[4]

- Figure 8: Hymans’ career history[4]

- Figure 8: Hymans’ career history[4]

- Figure 9: Flexible Guide Clamp Safety

- Figure 10: Mono-Mass Safety for Tied-Down Compensation

References

[1] Hymans, F. “The Emergency Stops of the Gearless Traction Elevator at the Terminal Landings,” ASME, New York (December 6, 1926).

[2] Hymans, F. “Centrifugal Governor in Elevator Service,” Semi-Annual Meeting of the ASME, Chicago, IL (June 16-19, 1947).

[3] Goodwin, J.P. OTIS, Giving Rise to the Modern City, Ivan R. Dee, publisher, p. 127, 128 & 132.

[4] Otis Elevator Co. Otis Bulletin, December 1947.

[5] New York Passenger Lists, 1820-1957. “List or Manifest of Alien Passengers for The U.S. Immigration Officer at Port of Arrival,” roll T715, microfilm roll: roll 0641; line: 9, “Departing Antwerp, Nov. 4, 1905, SS Zeeland.”

[6] U.S. 15th Census, City of Yonkers, Westchester County, NY, Supervisor’s District No. 20, Enumeration District No. 60-5, Sheet 61A (April 4, 1930).

[7] New York Passenger Lists, 1820-1957. “List of United States Citizens (For The Immigration Authorities),” roll T715, roll 4836, line: 13, p. 154, “Departing Antwerp, Sept. 19, 1930, SS Lapland.”

[8] U.S. Census, Supervisor’s District No. 25, Enumeration District No. 60-109, Sheet 61A, 1940.

[9] Landau, S.B. & Condit, C.W. Rise of the New York Skyscraper: 1865-1913,” p. 386 (1996).

[10] Cullmer, H.R. Elevator Shaft Construction, or Practical Suggestions for the Installation of Electric Elevators in Buildings (1912).

[11] ELEVATOR WORLD. “In Search of the Past,” September 1963, p. 35.

[12] The New York Times, Obituary Section, March 24, 1959.

Get more of Elevator World. Sign up for our free e-newsletter.