Going to the Next Level at “Alex”

Apr 1, 2015

ThyssenKrupp Aufzüge modernizes elevators at Berlin TV Tower.

(photo courtesy of ThyssenKrupp)

The Berlin TV Tower, which started operation on October 3, 1969, is part of Germany’s history and one of the capital city’s landmarks. Located in the center of Berlin on Alexanderplatz public square, known colloquially as “Alex,” the unique structure rises above the skyline like a space rocket, offering from within its sphere fantastic 360° views of the entire city and its many attractions from a panoramic viewing platform at 203 m and a revolving café at 207 m.

Within the tower’s shaft are two public passenger elevators and one service elevator. The original elevators, installed in 1967 by Swedish company ASEA-Graham (now, KONE Hissar AB), were replaced by KONE in 1996. ThyssenKrupp Aufzüge handled the most recent modernization, which commenced on February 10, 2014, and was finished in early March 2014.

The stylish, refurbished units help bring comfort and prestige to a structure that, since the government built it over a four-year period in the 1960s, has become a symbol of a reunified Germany and of Berlin. It has even served as the opening shot for movies set in the city. With several different German architects having a hand in its design, the tower is modeled on the first artificial earth satellite, Sputnik. It commenced test broadcasts in October 1969 and was inaugurated four years later.

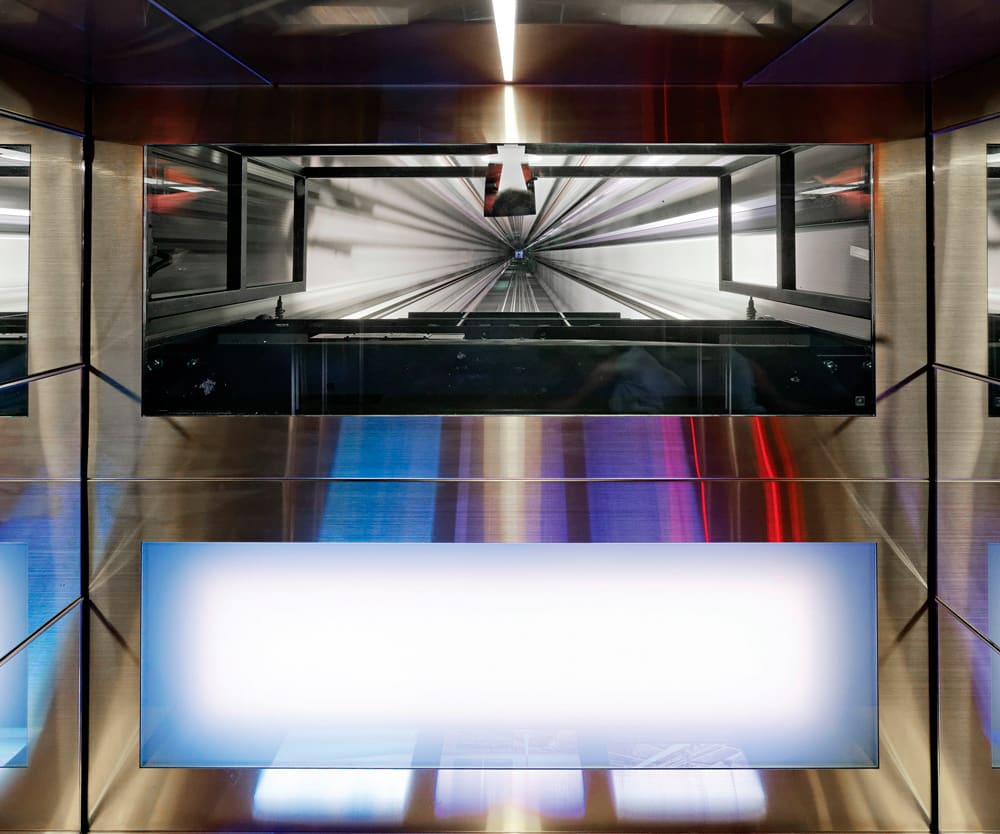

Thanks to the modernization, its two passenger elevators now feature glass ceilings that provide impressive views and energy-recovery systems that result in lower operational costs for the system. They are expected to move an estimated 1.2 million visitors each year.

Each of the two visitor elevators has a capacity of 1200 kg, a rise of 226.28 m and 24 stops. Traveling at up to 6 mps, the units carry visitors to the viewing platform in just 35 s.

The ThyssenKrupp Aufzüge team upgraded the elevators with new control systems, converters, drive units, ropes and two completely new cabs without interrupting service. The cabs feature stainless-steel interiors with glass-covered, energy-efficient LED-backlit rear walls. Transparent cab roofs, made of safety glass that allows passengers to look up into the shaft, are a highlight. Wall panels covered with brushed stainless steel represent another special feature of the cabins. The cabs’ ceilings have an identical look, adding to a sense of symmetry.

Embedded in the rear walls, illuminated glass silhouettes of the tower capture passengers’ attention. Roberto Wirgailis, branch manager, ThyssenKrupp Aufzüge in Berlin, observed:

“The new elevators in the Berlin TV Tower were custom built. The control, drive and monitoring systems were designed to be integrated into the existing environment. To make the view through the glass roof even more impressive, the cab roof was redesigned and manufactured especially for the TV Tower.”

The elevators are equipped with an energy-recovery system. When they descend, the system generates electricity. Rising energy costs and growing public environmental awareness have brought about a global rethink when it comes to planning, building and modernization, ThyssenKrupp Aufzüge observes, and elevator systems such as the one for the tower are indicative of that. Energy-efficient equipment installed includes a TCM/MCI controller with a CPI 310 transformer and DAB 530 machine. Wirgailis stated: “The perfect interaction of all elevator components, combined with maximum efficiency and energy recovery, underline ThyssenKrupp’s sustainable engineering expertise.”

Among the challenges of this particular modernization was connecting the new elevators to the tower’s building systems to create communications interfaces, ThyssenKrupp Aufzüge states. Using specially designed hardware and software programmed specifically for the tower, the staff – elevator attendants, telecom technicians, security guards, etc. – continue to operate the elevators the same way they always have without needing additional training.

ThyssenKrupp Aufzüge was hired by main contractor DFMG Deutsche Funkturm GmbH, and worked with C2a Architectes and technical planners Weigelt GmbH. Subcontractors included Schäefer GmbH, which provided the special displays like height indication in the cabs, and Wittur, which supplied complete mechanisms for the cab doors.

Get more of Elevator World. Sign up for our free e-newsletter.