High and Mighty

Feb 1, 2022

Otis project gives 30 Hudson Yards guests insightful tower to behold.

A new, supertall skyscraper, 30 Hudson Yards, has joined the Manhattan skyline, and Otis provided its vertical-transportation (VT) system, including 63 elevators and nine escalators.

Standing 1,270 ft tall with 101 floors, 30 Hudson Yards is 20 ft higher than NYC’s venerable historic tower, the Empire State Building. Several years ago, Otis had modernized that iconic building’s elevator system, topped off by a one-of-a-kind, custom-built, Gen2™ glass elevator and hoistway that ascends to the 102nd-floor observatory. Similarly, for 30 Hudson Yards, Otis provided two dramatic double-deck elevators that transport passengers in less than a minute to the building’s more-than-1,100-ft-tall cantilevered, open-air observation deck known as “Edge.”

The building is a glass trapezoid that anchors Hudson Yards, a 28-acre neighborhood on Manhattan’s West Side that’s been described as the largest private real estate development in U.S. history and NYC’s largest new development since Rockefeller Center. This LEED Gold, Class-A tower features a triple-height lobby, column-free floor plans and floor-to-ceiling glass to ensure unimpeded, river-to-river panoramic views. The structure is topped with an angled triangle above the projecting observation deck and includes several unique wall types, similar to those on the recently completed and adjacent 10 Hudson Yards. Designed as a pair, the two towers tilt in opposing directions – one facing the city and the other toward the Hudson River.

The “Edge” observation deck extends 80 ft outward on the south of the building, and visitors can lean into the 9-ft-high clear glass barricade slanted 6.6° to check out the street and rooftops below. It also features a 225-ft2 glass triangle in the floor that offers guests a view down to the street, more than 1,100 ft below.

Leading commercial tenants in the building include Warner Media, Facebook, KKR, Wells Fargo Securities and Related Cos.

Transportation System Details

Otis supplied the VT system of 72 elevators and escalators for NYC’s newest landmark building. This includes 56 SkyRise® elevators: 50 passenger units equipped with the Otis CompassPlus® dispatching system, two SkyRise double-deck elevators that bring visitors to “Edge” and four service elevators. Otis also provided six hydraulic elevators supplied by MEI Elevator and featuring Otis controllers and fixtures; one gearless traction freight elevator supplied by MEI Elevator and featuring an Otis machine, drive, controller and fixtures; and nine sleek, energy-efficient NCE™ escalators.

The SkyRise elevator is Otis’ most advanced high-rise elevator to date, combining cutting-edge science and precision engineering. Each SkyRise elevator installation integrates industry-leading technologies to ensure the safe, reliable operation of the entire system. SkyRise’s features include a noise-blocking Q-frame cab and aerodynamic shroud, designed using computational fluid dynamics and wind-tunnel testing to ensure a smooth, quiet ride, and safety brakes made from the same heat-resistant materials used for jet-engine nozzles. Each SkyRise unit also includes Otis’ energy efficient SkyMotion® machine and ReGen™ drive that captures energy that would otherwise be lost as heat. Instead, it is fed back into the building’s power grid as electricity.

Otis’ CompassPlus intelligent dispatching system makes moving people within the building easy and efficient, offering clear wayfinding, customizable screens and personalized operation. Building tenants also can use the Otis eCall™ Pro smartphone app, which presents a unique and personalized customer experience to any tenant in the building. The eCall Pro app is integrated into the Hudson Yards tenant app and offers a personal elevator button and seamless mode of transportation throughout 30 Hudson Yards. Beacons placed near elevator lobbies can sense passengers approaching and place their elevator calls automatically, or passengers can access the eCall app through the Hudson Yards building app and thus log their destination manually. Either way, the elevator is ready when passengers arrive, eliminating time waiting in lobbies or on elevator landings.

SkyRise’s features include a noise-blocking Q-frame cab and aerodynamic shroud, designed using computational fluid dynamics and wind-tunnel testing to ensure a smooth, quiet ride, and safety brakes made from the same heat-resistant materials used for jet-engine nozzles.

A 24-Elevator Machine Room

The building is designed to give tenant groups a sense of their own building, with three separate entrances, three main elevator lobbies and three separate sky lobbies on floor 35. The hoistways assigned to each tenant have hall doors and fixtures only on that tenant’s floors, maximizing usable space for other tenants.

The 24-elevator machine room holds the machines that deliver passengers to the sky lobbies and is among the largest Otis has ever built. Hoisting the machines around the existing building structure and into place in the machine room presented a challenge during the construction phase. “There were eight holes in the roof above the machine room for us to drop three machines into each,” said Michael Kaufman, project executive, Manhattan New Equipment and Otis’ 30 Hudson Yards project manager. “Once they were in, we maneuvered each machine into its respective location.”

Customized Communications Systems

The two double-deck elevators stack one cab on top of another, with each featuring its own hoistway and machine. They are powered by two massive, 100-T machines — among the last 100-T machines Otis made and the only ones Otis installed in the U.S. Passengers traveling to “Edge” on the 100th floor and to the restaurant and event space on the 101st floor first ride escalators to the fourth and fifth floors, where they are guided into the elevators by building greeters.

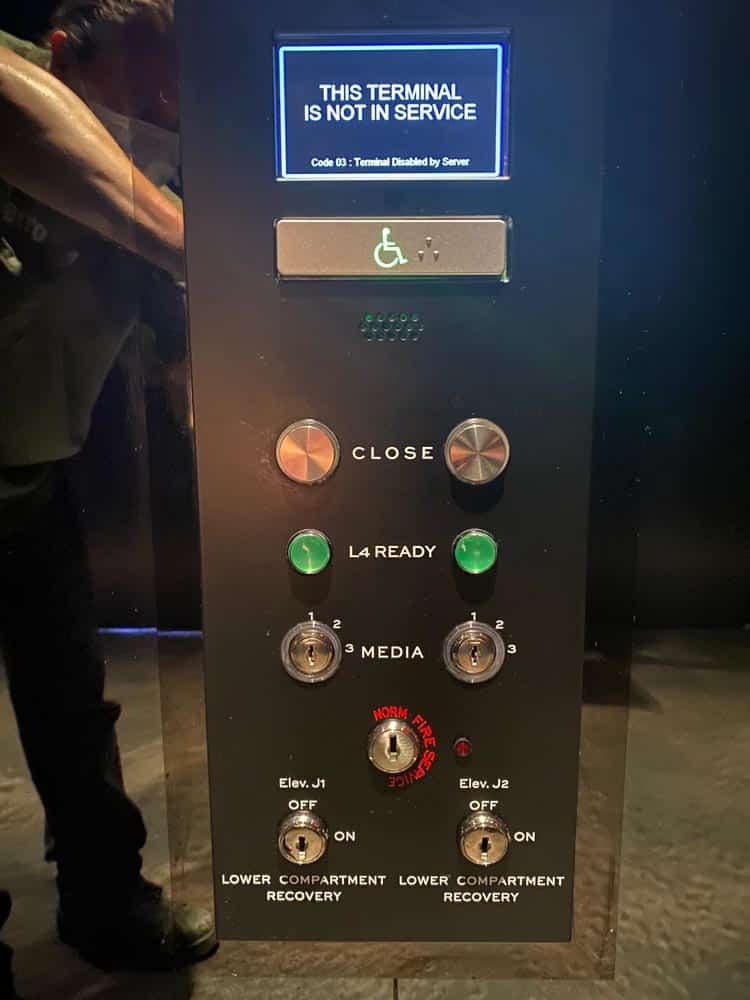

A custom hall fixture system developed at the Otis Service Center in Connecticut allows greeters on the fourth and fifth floors to communicate with one another. When passengers on one floor are safely loaded into the elevator car, the greeter can activate a light on the other floor so other greeters know to finish loading to reduce wait time for a smoother passenger experience.

Once inside the elevator, it takes only 52 s to ascend to the observation deck. As they climb, passengers watch an animation that begins with an architect’s sketch of the skyline and gradually becomes filled in and rendered as the elevator cab rises. A separate video plays on the descent, showing nearby sites the High Line and Vessel.

The video communication system designed specially by Otis engineers allows building staff to easily select and change which videos passengers watch during the trip. It can be programmed to show different videos in each car during ascent and descent, giving, for example, the option for customized greeting and farewell videos for guests attending a function at the event space. The double-deck elevators’ cabs and fixtures were customized to accommodate the video displays, and Otis engineers developed a unique system to capture heat from the video monitors and remove it from the cabs.

The nine NCE™ escalators at 30 Hudson Yards are a versatile solution for commercial buildings, shopping malls, hotels, casinos, airports and hospitals. The NCE model provides sustainability benefits, including a sleep mode that slows the escalator when not in use and an automatic lubrication system that maintains proper lubrication of all vital components while using up to 98% less oil than conventional systems. Otis ReGen™ drives and long-lasting LED lighting allow for a variety of lighting options while considerably reducing the amount of electricity consumed.

Installing a complex elevator and escalator system featuring more than 70 units is a challenge in any city, let alone NYC, with its heavy street traffic patterns and little space at ground level to deliver, store and stage the vast amount of material necessary for such a multifaceted job.

“Determining what material needed to be delivered when to ensure a seamless and orderly installation as the building rose, coordinating those deliveries and having the material in the right building locations took tremendous focus by a dedicated team,” Kaufman said. “Some 30-plus teams were installing equipment day and night, five- to six-days a week, for 24 months. Over that time, to ensure we stayed on schedule, we received approximately 1,700 total deliveries, of which approximately 1,000 were tractor-trailers.”

Project Details

Project Locations: 500 West 33rd Street, NYC

Building Owner/Developer: The Related Cos. LP & Oxford Properties Group, Inc.

Architect: Kohn Pedersen Fox Associates

Structural Engineers: Thornton Tomasetti

Construction Manager: Tishman Construction

Elevator/Escalator Services Provider: Otis Elevator Co.

Elevator Consultant: Jenkins & Huntington

Cabs & Entrances: Gunderlin Ltd.

Get more of Elevator World. Sign up for our free e-newsletter.