Hoists, Teagles and Safety in the Early 20th Century, Conclusion

Dec 1, 2011

The final installment of our look at the role of teagles and hoists in early elevators

This month’s article is the third and last in a series on W. Sydney Smith’s Report on the Construction, Arrangement, and Fencing of Hoists and Teagles of 1904. It addresses the safety devices covered in the report and includes a brief examination of the reported causes of hoist accidents. Before beginning his discussion on specific safety devices, Smith stated what was, by 1904, a familiar premise:

“All hoists in which persons are allowed to travel should be provided with [an] efficient safety gear to prevent the cage from falling in case the load in the cage is so great as to overcome the frictional resistance between the suspending ropes and the overhead grooved driving pulleys, or in case of breakage of the suspending ropes, chains or cables. It is also very desirable that the safety gear should be designed to come into action should the cage travel beyond the normal speed.”

The fact that he felt compelled to state such an obvious (and normative) goal serves as a reminder that, in spite of significant efforts to improve safety throughout the second half of the 19th century, it was still possible to find lifts that lacked rudimentary or effective safeties.

Smith discussed and illustrated eight safeties associated with specific designers and manufacturers:

- Broadbent’s Safety Wedge

- Morgan’s Safety Catch

- Barker’s Safety Gear

- Archibald Smith & Stevens’ Safety Gear

- A. & P. Steven’s Safety Gear

- Etchell’s Automatic Hoist Governor

- Maybrick & Ashworth’s Hoist Governor

- Hollins-Amendt Locking Gear

Broadbent’s Safety Wedge, patented in 1865 by Jubal C. Broadbent of Rochdale, U.K., was the oldest system described by Smith. Unfortunately, very little is known about Broadbent. In 1866, his invention was the subject of a brief presentation at a monthly meeting of the North of England Institute of Mining Engineers. (He was also elected to membership that same year). His safety device was designed for hoists that employed four guide rails (one at each corner) — an arrangement typically found in mine hoists. It employed wedges with serrated faces held away from the guides by the tension of the hoisting rope. If the rope broke or became slack, spring mechanisms acted to drive the wedges into the guides. Smith observed that this system “often failed” unless the rope broke “immediately above the cage,” something that he claimed “rarely” happened.

The Morgan Safety Catch had a somewhat similar origin to Broadbent’s device in that its inventor, John Morgan, was a coal miner. Patented in 1899, Morgan’s safety employed two steel cables that flanked the cage and extended from the top to the bottom of the shaft. The system operated in a similar fashion to Broadbent’s; however, in this instance, the safety gripped the cables instead of the guide rails.

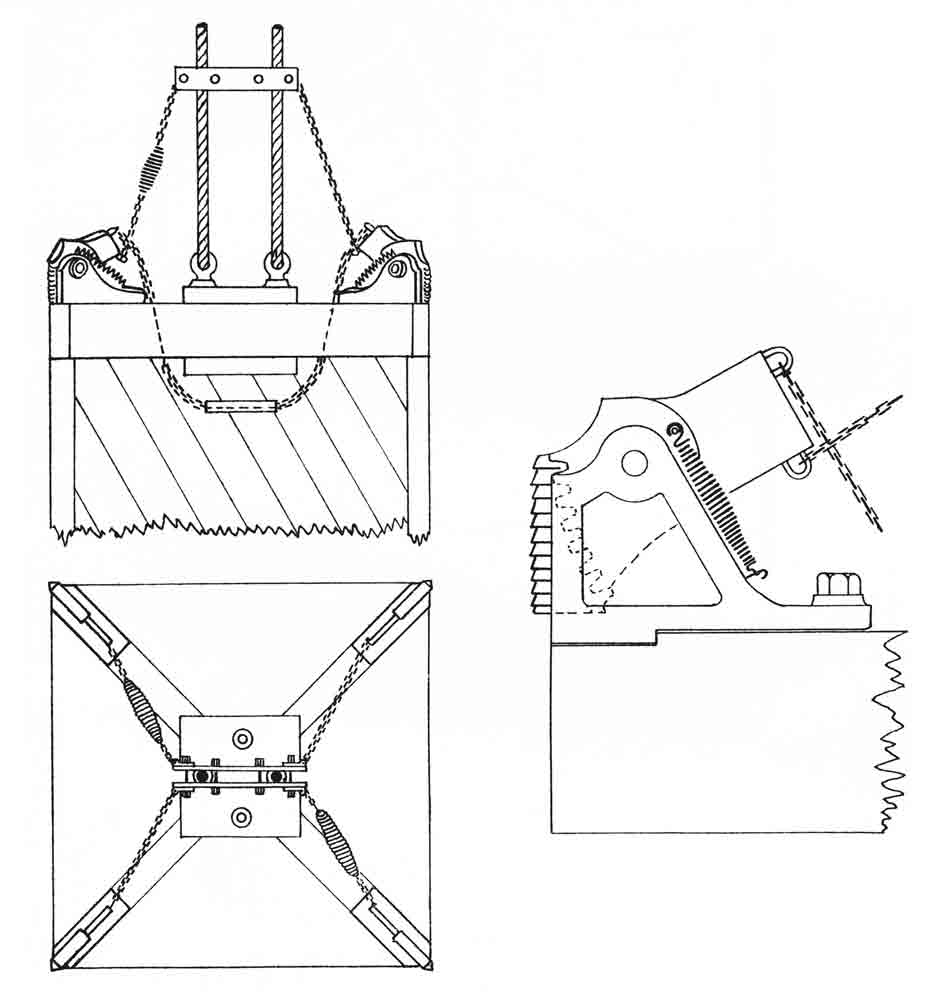

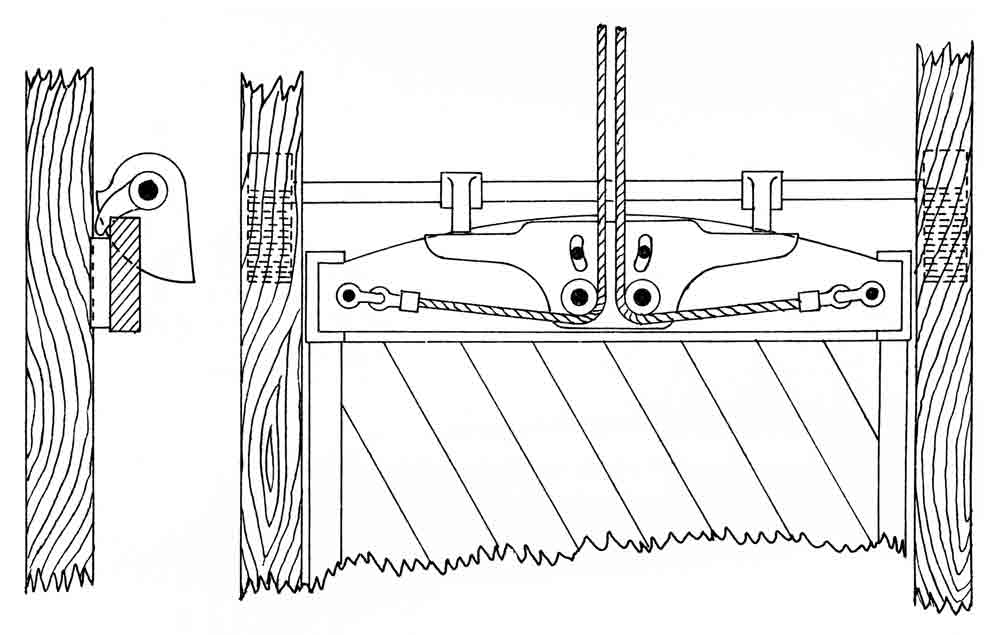

The remaining systems examined by Smith were variations on Broadbent’s scheme in which serrated wedges or levers engaged wooden guide rails. Barker’s Safety Gear, designed and manufactured by John Barker & Sons, Ltd., of Oldham, U.K., was located beneath the cage. Archibald Smith & Stevens of Battersea, U.K., manufactured a safety gear that was located atop the cage and required the use of two hoisting cables. If either cable broke or became slack, the safety would engage. The safety gear designed by A. & P. Steven of Glasgow, U.K., operated in a similar fashion. Each of these devices, in contrast to Broadbent’s and Morgan’s, originated in a company known for its involvement in the vertical-transportation industry. John Barker & Sons manufactured hoists and cranes. (The company’s Automatic Locking Gate system was also examined by Smith; see part two of this article in ELEVATOR WORLD, November 2011.) Archibald Smith & Stevens, which became Smith, Major & Stevens in 1909, was an acknowledged industry leader. Alexander and Peter Steven had begun their careers in Glasgow as hydraulic engineers; in 1865, they joined the Provanside Engine Works, and in the 1870s, began designing and building hoists.

Smith also illustrated and described several generic safeties employed on “passenger hoists.” He noted that most passenger cages were “supported by four steel wire cables” that were typically “anchored near the bottom of the cage, a pair on each side.” Each of the systems described was a variation of a standard safety type mounted beneath the cage that engaged the guide rails through a mechanism comprised of bell crank levers, springs and cams with serrated edges. In addition to these safety devices, Smith described three “safety gears actuated by centrifugal governors.”

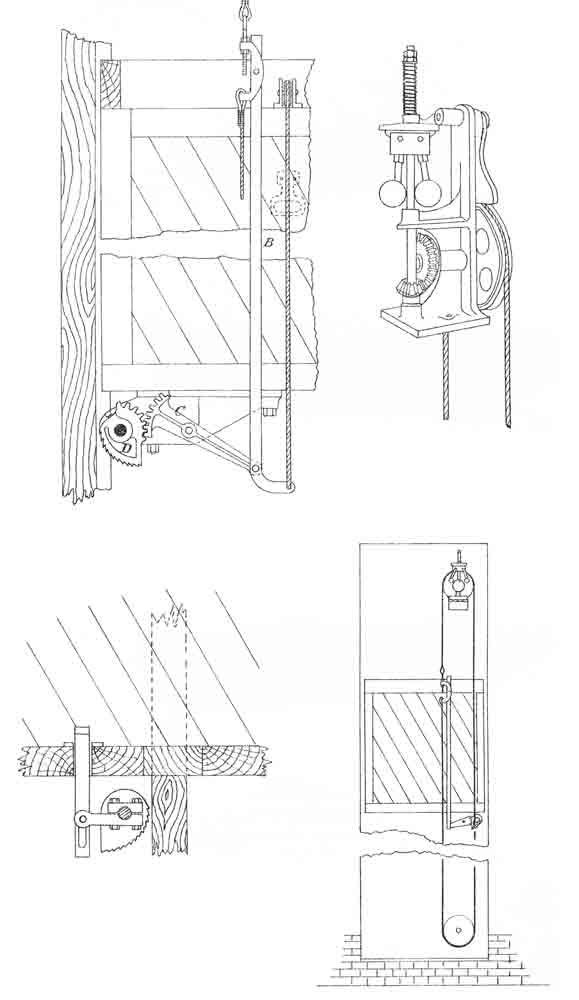

Interestingly, although the first system discussed was “the well known Otis type,” Smith did not provide drawings of this system. Instead, he gave pride-of-place to two British systems: Etchells’ Automatic Hoist Governor and Maybrick & Ashworth’s Hoist Governor. The former was designed by John C. Etchells and described as “similar in principle to the Otis governor.” In addition to an automatically operating system, this safety could also be installed such that it could be activated either by a “hand pull” inside the cage or by a “simple push projecting through the floor of the cage.” The “push” was the top of a lever that projected into the cage; the operator would presumably press down and hold to activate the safety. Etchells would later partner with C.H. Congdon and Francis Muir to found Etchells, Congdon & Muir; thus, this invention also originated with an individual well known for his involvement with the vertical-transportation industry.

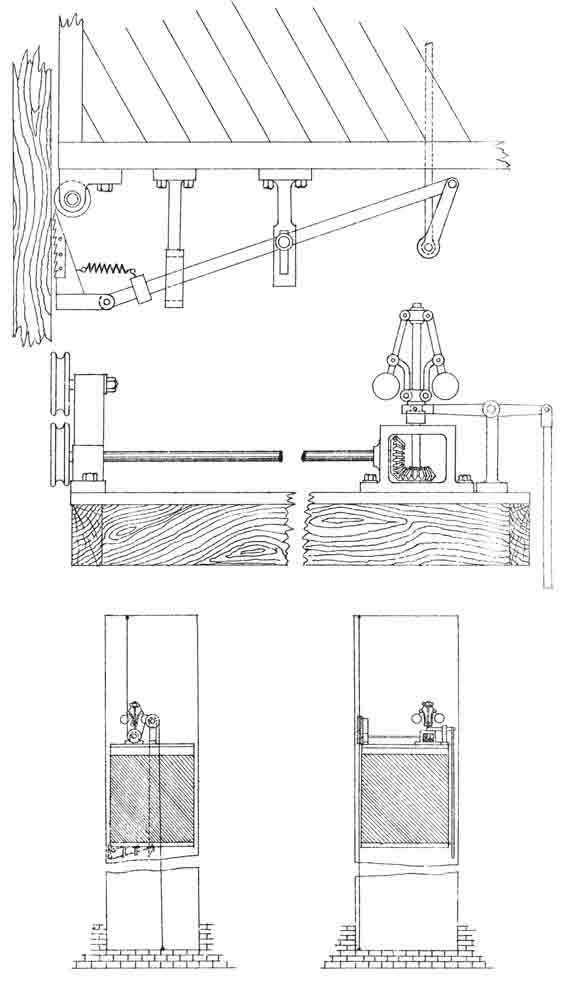

Interestingly, the safety governor system to which Smith devoted the most attention was Maybrick & Ashworth’s Hoist Governor, which had been designed and patented by a firm that was, apparently, only tangentially related to the vertical-transportation industry. The safety had been designed in 1893 and patented in the U.S. and U.K. in 1894 by Thomas Maybrick and William J. Ashworth. In their British patent, the former listed his occupation as a “hydraulic packer,” and the latter described himself as an engineer. The only reference to their firm found thus far is a brief article on their safety published in a June 1896 issue of the Marine Engineer, described as “a monthly journal of marine engineering, ship building, steam navigation & electrical engineering.” Maybrick & Ashworth’s Hoist Governor was located on top of the cage and attached to a cable or “driving rope” fastened at the top and bottom of the shaft. The cable activated the governor, which in turn activated a gripper if the cage exceeded a predetermined speed. Smith noted that while this system was “simple in construction and instantaneous in action,” the “driving rope through long continued use may become weak and break. . . if a sudden strain is thrown upon it.”

Smith concluded his safety examination with a discussion of “locking grips for hand ropes or chains.” He made the following observation about their importance:

“It often happens that, unknown to the person in charge of the hoist, the cage is set in motion by other persons from other floors, with the result that the former, expecting to find the cage still in the position in which he left it, falls down the hoist well. It should be remembered. . . that goods such as heavy cases, skips, and hampers are often placed in the cage by persons walking backwards pulling the goods in after them.”

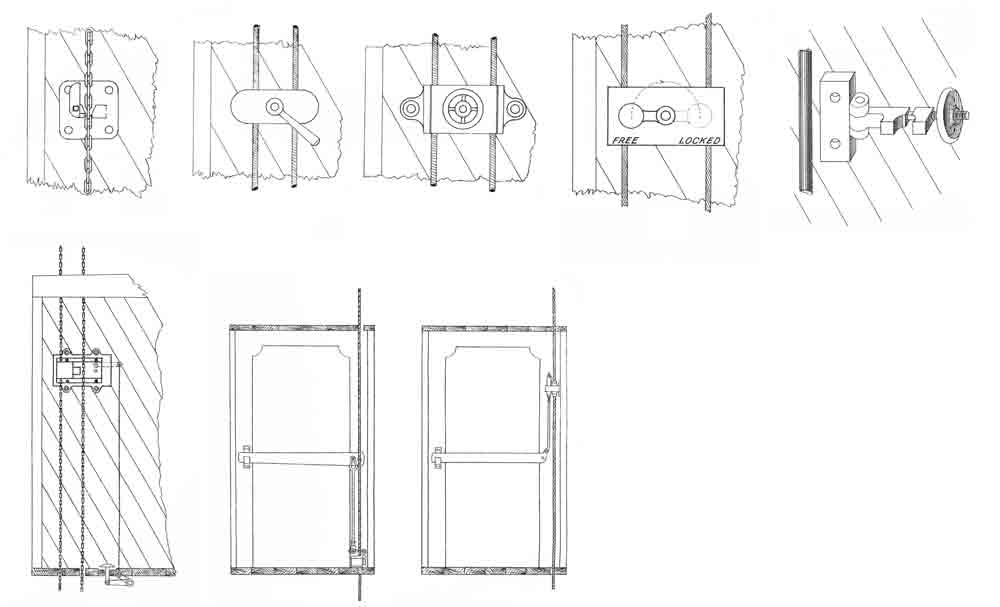

This practical description of how hoists were used in industrial settings, where noise often made it impossible to hear the hoist motor, illustrates how easily accidents could happen. Smith described and illustrated a variety of locking grips, including a simple chain catch, various screw grips, a spring-and-cam system, a foot-lever system, and grips linked to bars that closed the shaft door. The only identified system he discussed was the Hollins-Amendt Locking Gear. In this system, the hoist attendant locked and unlocked the starting rope and cage door in sequence so that it was impossible to open the door until the starting rope was secured. The system was available in both an electrical and mechanical version:

“In the electrical device, the door locks and the gripper are all under electrical control, the current being furnished by a battery of Leclanché cells. Before any of the doors can be opened, the hoist attendant is obliged to put the gripper into action by means of a rope pull, lever, or treadle inside the cage. As soon as this is done, the lock of the hoist door is free to be thrown back; the act of the door opening automatically prevents the gripper from being unlocked, and it is impossible to release the starting rope until the door is again closed and locked.”

“Leclanché cell” refers to a battery developed by Georges Leclanché (1839-1882) in 1866 primarily used for telegraph and bell signaling systems where only intermittent current was needed. Its use was probably recommended by Frederick T. Hollins, who was a telegraph engineer with Great Eastern Railroad Co. The mechanical version employed two identical locks operated by a single key; the key in the rope gripper could not be removed until it was locked, after which it could be used to unlock the car. Smith noted that this system had been “designed so as to suit all kinds of hoists and hoist doors” and that it could be installed “without difficulty by any ordinary carpenter.” Henry C.T. Amendt, Hollins’ partner, was the manager of the Hotels and Refreshment Department of Great Eastern Railroad, as well as manager of the Great Eastern Hotel in London. This intriguing pair received two patents for their invention (1900 and 1902, respectively), and their safety was manufactured and marketed by R. Waygood and Co.

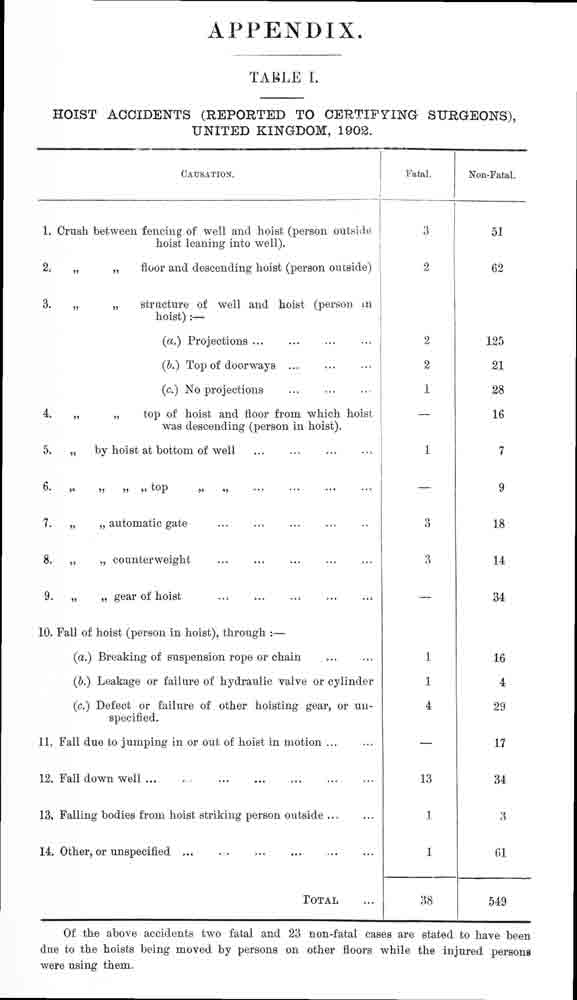

Smith ended his report with a summary of the causes of hoist accidents; most of it reiterated points made in the context of his discussion of door and safety systems. He observed that the majority of accidents were due to the “indiscriminant use of hoists” by untrained personnel. Smith suggested that, “wherever possible, a hoist attendant should be employed,” and that attendants should be of a “mature age.” He also provided two tables for 1902 that gave detailed breakdowns of the various types of accidents and where they occurred. During that year, 587 accidents were “reported to certifying surgeons in the U.K.” Of these, 38 resulted in fatalities. Interestingly, only six deaths and 49 injuries were attributed to mechanical failures; the majority of accidents were due to human error and/or the absence of appropriate safeties.

Archibald Smith & Stevens’ Safety Gear

Etchell’s Automatic Hoist Governor

Maybrick & Ashworth’s Hoist Governor

(top, l-r) Chain Grip, Lever Handle Screw Grip, Wheel Handle Screw Grip #1, Cam/Spring Grip, Wheel Handle Screw Grip #2, (bottom, l-r) Grip Activated by a Foot Lever, Door/Bar System #1 and Door/Bar System #2

Table 1 of the Report on the Construction, Arrangement, and Fencing of Hoists and Teagles Appendix

Get more of Elevator World. Sign up for our free e-newsletter.