Hydraulic Elevators in Europe and the U.S.

Jun 1, 2021

In this History article, we learn that VT technology was an international story from the very beginning.

The history of vertical-transportation (VT) technology has, from the very beginning, been an international story. Throughout the 19th century, engineers, inventors and manufacturers in Europe and the U.S. were aware of each other’s activities through articles published in technical journals, the patent record and travel. However, while it was not unusual for one country’s technical press to report on an event that occurred outside their borders, comparative international studies were rare. One of the first such studies was published in 1883. Die Hebezeuge (Hoists), by German engineer Adolf Ernst (1845-1907), contained a broad examination of cranes, industrial lifts, freight hoists and passenger elevators in Germany, France, England and the U.S. This examination addressed a wide range of elevator technologies, including hydraulic systems, and constitutes an intriguing lens through which to view the past.

Ernst’s interest in this topic developed early in his career. Following graduation from high school in 1863, rather than pursue his interest in mechanical engineering at university, he entered the workforce and took a position with the Weber Maschinenfabrik in Berlin. After a year and a half of work, he decided to continue his education at a local trade school, the Berlin Gewerbeinstitut, which provided training for manufacturing specialists. His education was interrupted in 1866 by military service during the Austro-Prussian War. In 1868, he joined the E. Becker Maschinenfabrik in Berlin. Eduard Becker (1832-1913) had also been employed at the Weber Maschinenfabrik. He left in 1866 to establish his own company, which quickly established itself as a leading manufacturer of freight elevators and industrial lifts. This was Ernst’s formal introduction to the world of VT. However, while this experience made a significant impact on the young engineer, he left after only one year to travel to England, where he planned to work and improve his language skills. While there, he worked for two companies associated with the railroad industry.

In 1870, the death of his mother forced his return to Germany. There, he joined the Maschinenfabrik von L. Schwartzkopff in Berlin, which specialized in building locomotives. However, the outbreak of the Franco-Prussian War in mid-1870 recalled him to military service. Ernst was wounded twice during the war, with his second injury resulting in a lifelong health condition that required constant care. During his lengthy initial convalescence, he returned to school, once again pursuing studies at the Berlin Gewerbeinstitut. While there, he encountered Professor Hermann Wiebe, who encouraged him to pursue a study of elevators, which led to Ernst writing a critical analysis of hoist development from 1855 to 1875. He completed his studies in 1876 and took a position on the faculty of the Halberstadt Gewerbeschule as a teacher of mechanical engineering. After he had settled into his new position, he began work on Die Hebezeuge. His hope (and goal) was to use the book as a means of furthering his career. In fact, the book’s success was such that in 1884 he was offered a position at the Technische Hochschule (Technical College) in Stuttgart.

Die Hebezeuge is an intriguing book. While it was best known by its abbreviated title, the full title, Theory and Criticism of Hoist Construction (Die Hebezeuge Theorie und Kritik Ausgeführter Konstruktionen), speaks to his analytical methodology. His approach was also practical. In the book’s forward, he thanked only two people by name: Hermann Wiebe and his “teacher in practice, Mr. E. Becker in Berlin.”[1] This practice-based approach was evident in the book’s subtitle: A Handbook for Engineers and Architects, and Self-Study Guide for Students, and in the numerous mathematical formulas that were provided to explain the logic behind the mechanical operation of elevator systems and components. Ernst’s approach was also academic. His use of footnotes demonstrated the scholarly nature of his investigation and allowed readers to pursue additional information. Lastly, the book was richly illustrated. The main text featured 306 illustrations, and the accompanying atlas included 46 foldout pages filled with approximately 400 drawings.

The content on hydraulic elevators was divided into two sections: direct-acting and indirect-acting systems (the former relied on a plunger to move the car, while the latter employed ropes). Ernst introduced this topic with the observation that direct systems were typically safer than indirect systems. Direct-acting systems were also described as the primary choice for passenger elevators, with freight elevators only using direct-acting systems when the lifting heights were moderate or the loads were significant. This observation was decidedly Eurocentric in that it ignored the extensive presence of American steam-powered passenger elevators and William E. Hale’s indirect-acting passenger system.

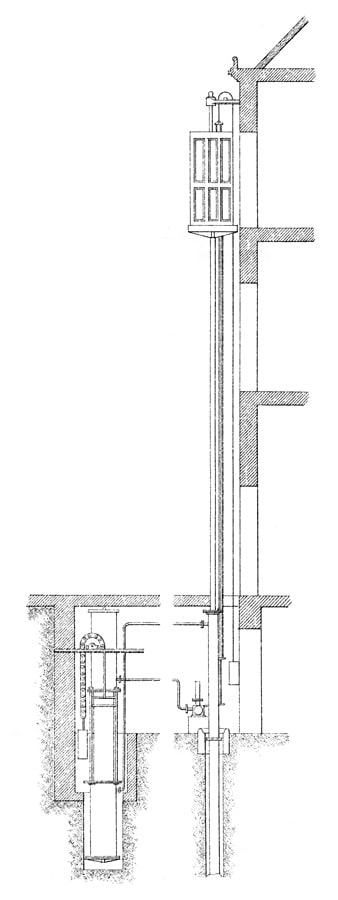

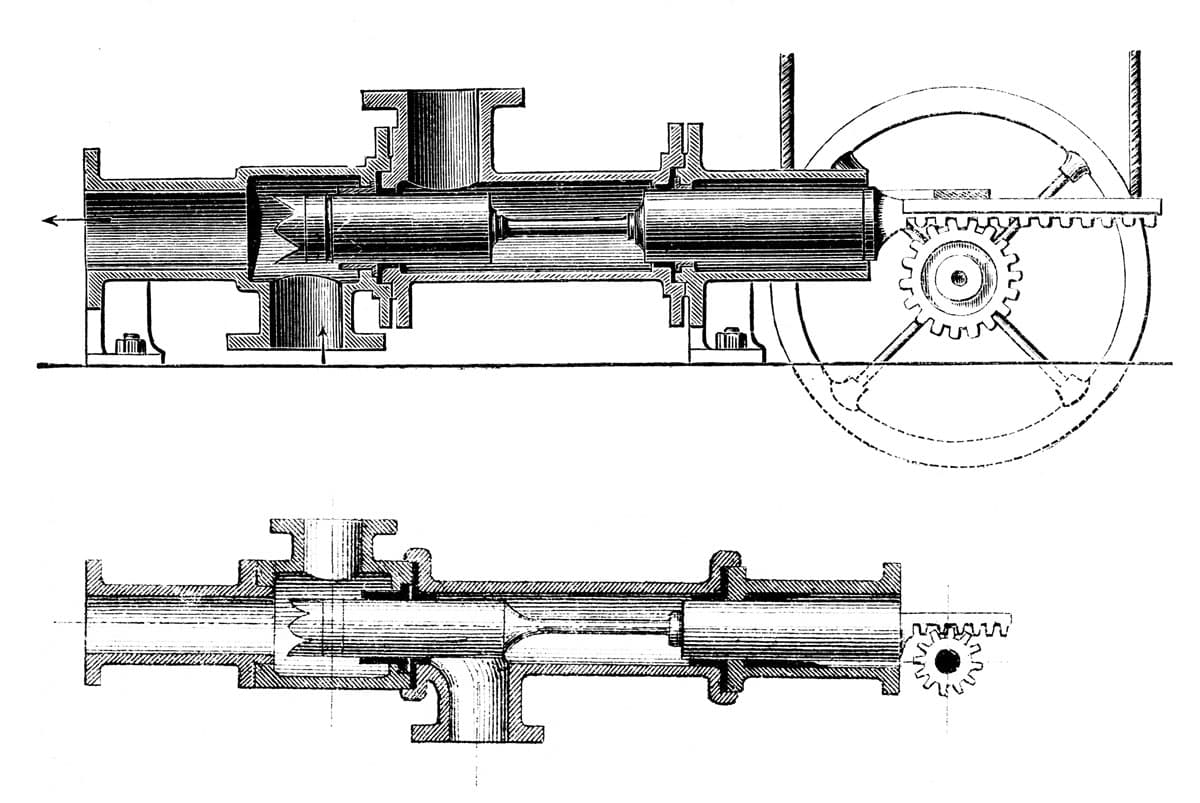

His discussion of direct-acting systems began with a brief overview of the pioneering work of French engineer Félix Léon Edoux (1827-1910). Ernst acknowledged that “simple, direct-acting passenger elevators only became known to wider circles on the continent through the elevator installed by Edoux for the Paris World Exhibition of 1867.”[1] While this event resulted in this type of elevator often being described as employing the Système Edoux, Ernst also noted that directing-acting elevators had been in use in large English hotels prior to 1867. His example of an elevator employing the Système Edoux was, perhaps surprisingly, not French, but German: he described a passenger elevator designed in 1880 by Emil Blum, director of the Anhaltischen Maschinenbau Aktien Gesellschaft in Berlin. The car was attached to a direct plunger whose movement was controlled by a shipper rope attached to an operating valve at the base of the shaft (Figure 1).

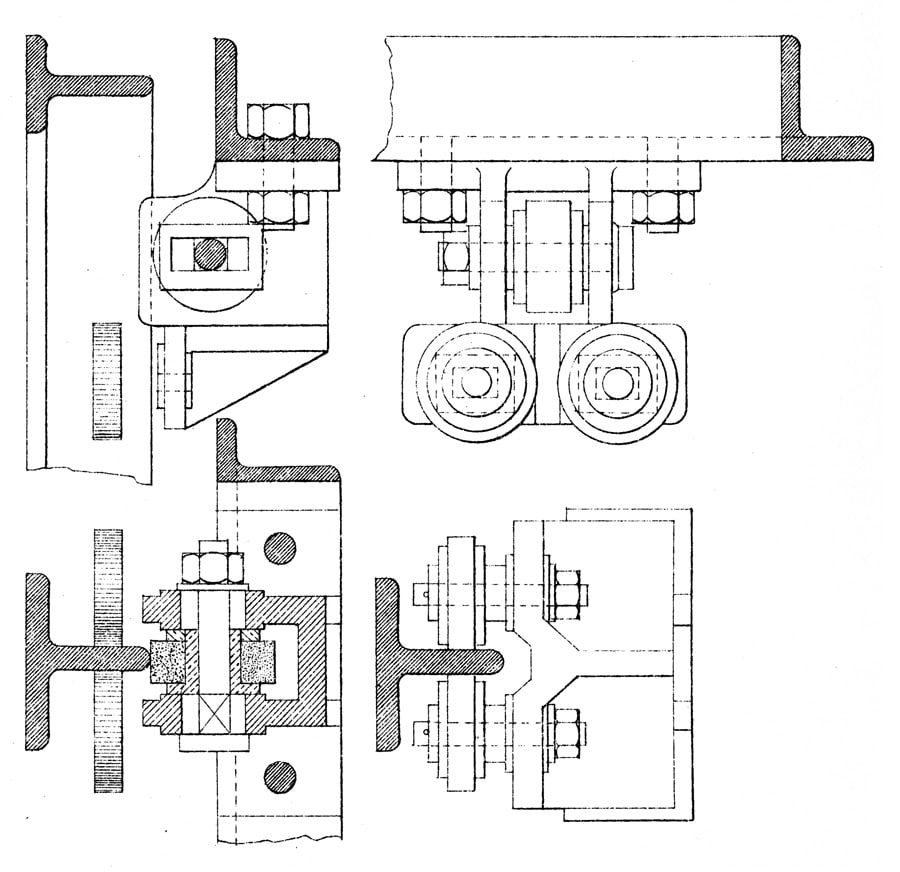

Ernst referred to the operating valve as a “balanced piston controller,” and he stated that the design originated with the American firm of Lane and Bodley.[1] A probable source for Blum’s awareness of the Lane and Bodley valve was Austrian engineer Alois Riedler’s extensive report on elevators exhibited at the United States Centennial Exhibition (Ernst also cited this report in his footnotes).[2] A comparison of the two valves reveals a clear similarity in design (Figure 2). Blum’s design also employed cast iron counterweights to compensate for the “dead weight of the plunger” (Figure 3).[1] Two counterweights were attached to the car by chains, the weight of which Blum included (as they passed back and forth over the sheaves) into the formula that determined the counterweight size. An aspect of the system only briefly mentioned in the text, but which was the subject of four drawings, was the guide rails and car roller guides. The T-shaped metal guide rails were attached to wooden posts embedded in the shaft’s masonry walls, and the roller guides embraced both sides of the rails (Figure 4).

Ernst recognized that a critical design aspect of direct-acting systems that employed counterweights was ensuring a strong connection between the plunger and the car. He referenced an 1878 accident to a hydraulic elevator in the Grand Hotel in Paris where the car became detached from the piston, was carried upward by the counterweights, crashed into the top of the shaft and then fell to the bottom, killing all onboard. While he stated that these elevators, when well designed, were safe, he noted that a direct-acting system invented by French engineers Emile Heurtebise and Ferdinando Tommasi eliminated this problem because it did not rely on a counterweight. Their design utilized a compensating cylinder to balance the weight of the car and plunger. Ernst also commented on the rapid adoption of this system throughout France: the elevator was patented in 1879, and by 1881 there were “thirty in Paris, seven in Nice, and several in Monte Carlo, Cannes, Lyon, Luchon, Angers, Barcelona, etc.”[1] Interestingly, he did not discuss an actual installation. His description and the accompanying illustrations addressed the machine in a general manner (Figure 5).

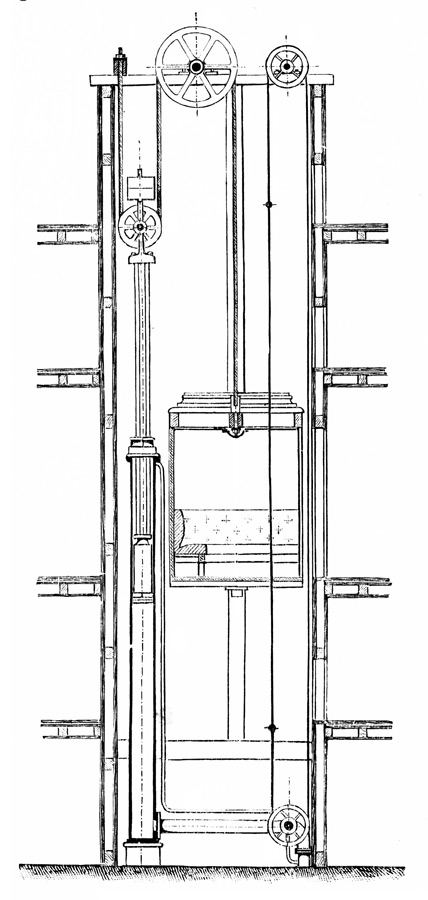

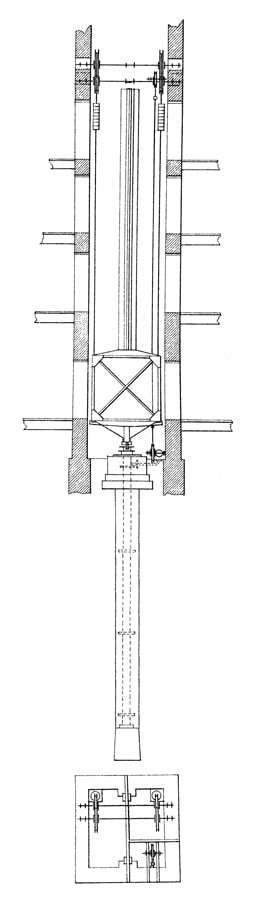

His discussion of indirect-acting hydraulic elevators began with a blunt warning. These machines was only viable options if the user (or designer) were willing to “dispense” with “the safety offered by the direct support of the car by the plunger.”[1] The primary advantages of indirect-acting systems included lower cost (no boring or in-ground installation) and design flexibility because the hydraulic cylinder could “be set up in any desired position.”[1] The critical design decisions concerned the number of sheaves and the nature of the roping system. Ernst first described and illustrated one of the earliest and simplest indirect-acting machines, designed by Austrian engineer Anton Freissler (1838-1916) for use and display at the 1873 Vienna World Exposition. The system employed a slender hydraulic cylinder located immediately adjacent to the shaft. The plunger was connected to a hoisting rope that passed over a single sheave. The car was also equipped with a safety catch in case the rope failed (Figure 6).

William E. Hale’s roped hydraulic elevator was discussed as an American alternative to, and as an improved version of, Freissler’s design (Figure 7). The primary advantages were the enclosed hydraulic cylinder and the presence of a counterweight located at the top of the plunger. These features compensated for the weight of the car and helped to prevent the loss of power as the car ascended and descended. Interestingly, because he apparently relied primarily on Riedler’s report for information on American designs, Ernst was not aware that by 1880 Hale’s elevator was marketed (and best known) as Otis’ Standard Hydraulic Elevator.

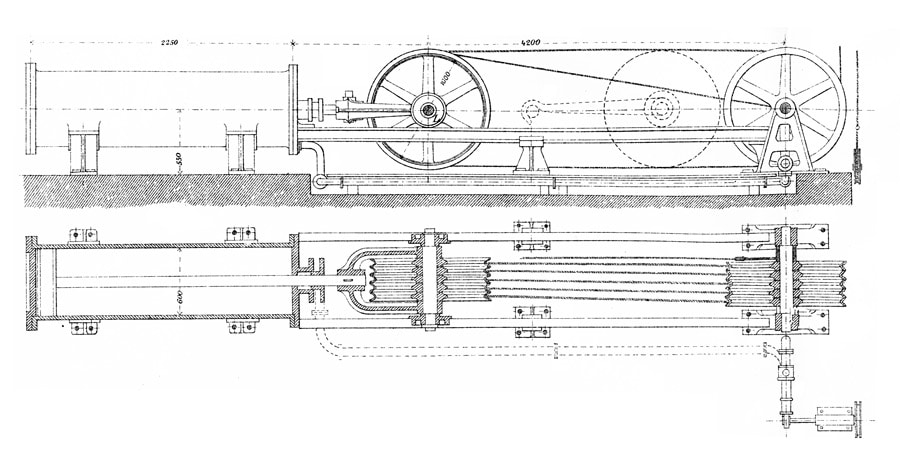

Ernst continued his discussion of indirect-acting systems with a brief examination of an elevator designed by F. Witte in 1874 for the Reichspost building in Berlin. The elevator employed a short vertical hydraulic cylinder and two sets of sheaves (Figure 8). He concluded his discussion of indirect-acting systems with a comparative presentation of two horizontal machines. Ernst first discussed Lane & Bodley’s horizontal hydraulic elevator engine. Once again, his primary source was Riedler, who had described and illustrated a machine that featured a detachable set of sheaves that could be employed when extra lifting power was needed (Figure 9). Ernst claimed that this idea had been developed by two English engineers, Bryan Johnson and Edward B. Ellington, in their design of a vertical hydraulic freight hoist.[3] Ernst praised the “American exploitation of the English patent,” and claimed that the Lane & Bodley design was “to be preferred insofar as the rollers switched off by the multiplication of the stroke are completely still and do not uselessly increase the rope resistance” as occurred in the English design.

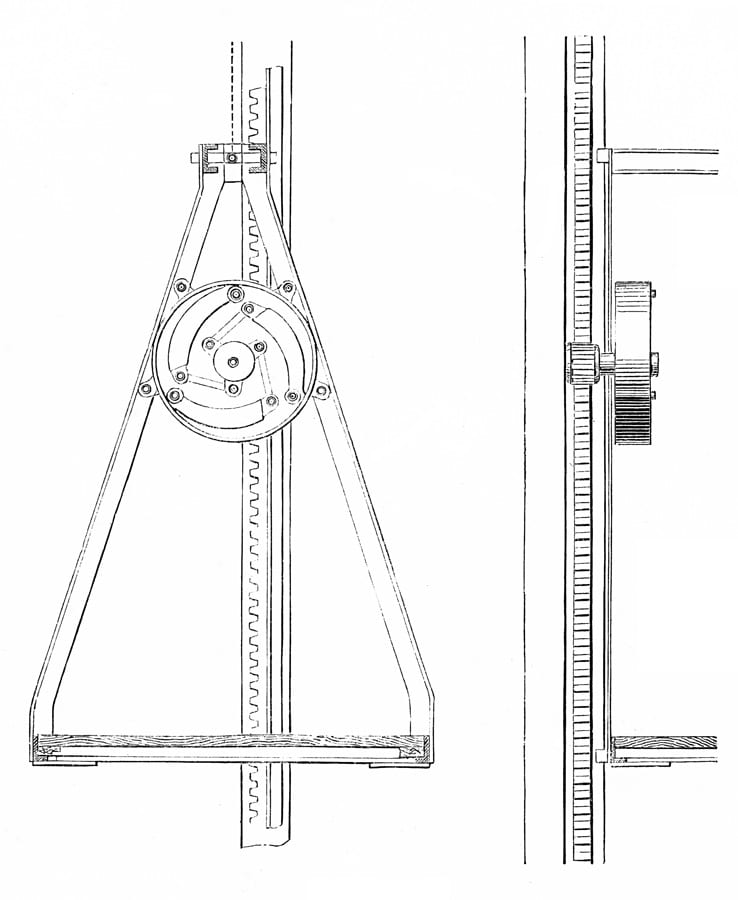

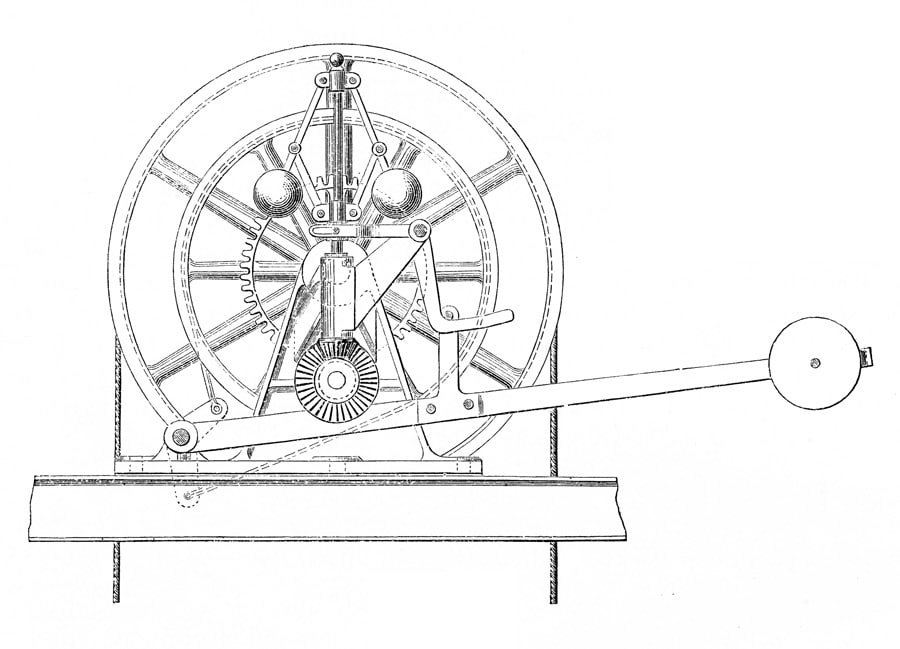

The second example of a horizontal indirect-acting machine was a German elevator that Ernst claimed was based on Lane & Bodley’s design. The machine had been designed by Blum and built by the Anhaltischen Maschinenbau Aktien Gesellschaft to serve as a luggage lift in the Berlin railway hotel. Ernst also reported that this system employed a version of the “safety drum with centrifugal regulator introduced by Otis Brothers in New York for use on steam elevators.”[1] The ropes connected to the hydraulic engine drove the motion of the safety drum, which carried two hoisting ropes. Unfortunately, Ernst did not illustrate the full system; however, he did provide a drawing of Blum’s version of the Otis safety drum (Figure 10). Ernst also offered an appraisal of this safety, noting that while the system “prevents the normal lowering speed from being exceeded … It goes without saying that the cumbersome Otis centrifugal brake device can be replaced with advantage by the newer, improved and simplified centrifugal brake regulators” designed by Bernhard Stauffer and Eduard Becker.[1, 4] Both German designs relied on centrifugal motion to propel brake shoes against the inner surface of a circular housing. The Becker safety was attached to the hoisting platform, and its rotational speed was governed by a pinion gear that meshed with a vertical rack that extended the height of the shaft (Figure 11).

Ernst’s comparative and critical analysis of hydraulic elevators is consistent with the approach he employed throughout Die Hebezeuge. A future project involves an examination of the accuracy of his criticisms and claims concerning the alleged attributes and limitations of various systems. A related endeavor involves an analysis of the numerous formulas found throughout the book. Multinational investigations such as this were unusual, and its existence serves as a reminder of the ability of 19th century engineers to maintain an understanding and awareness of events outside their immediate surroundings. While the speed with which information traveled in the late 1800s was much slower than today, it did travel and was readily available — to those who were willing to look for it.

References

[1] Adolf Ernst, Die Hebezeuge Theorie und Kritik Ausgeführter Konstruktionen, Berlin: Verlag von Julis Springer (1883).

[2] Alois Riedler, Personen- und Lastenaufzüge und Fördermaschinen, Vienna: Commission-Verlag von Faesy & Frick (1877)

[3] Bryan Johnson & Edward B. Ellington, Hydraulic Cranes, Great Britain Patent No. 3,409 (February 15, 1870).

[4] Bernhard Stauffer, Regulator an Aufzügen, German Patent No. 2,798 (February 17, 1878) and Eduard Becker, Neuerungen an Centrifugalbremsen, German Patent No. 7,205 (April 6, 1879).

Get more of Elevator World. Sign up for our free e-newsletter.