In-depth LCA heralds a turnaround for more reliable technology in surprising applications.

High-rise elevators that travel at 15 mps are on the exciting new edge of the elevator industry, but most machines installed every year are much less exciting. The residential market across the globe represents 52.39% of the total market, and, in these applications, most buildings are not higher than 10 floors. More than one-quarter of the elevators installed globally are put in short, mostly residential, buildings.

The European Directive 2002/91/EC of December 16, 2002, on “the energy use performance of buildings” does not indicate any requirement for elevators, escalators and moving walks. This is an indication that elevators were considered a negligible energy consumer in buildings.

The residential market was the domain of the hydraulic elevator in Europe, as well as North America, until the end of the 20th century. It remains so in the U.S. to an extent, but, in Europe, the trend has been different. Over the last decades of the last century, the major companies divested their hydraulic activities to concentrate on traction lifts for their whole range of products. When they still needed a hydraulic elevator (for an industrial heavy application, for example), they would order from a smaller producer.

The idea was that the hydraulic elevator consumed too much electricity during its use phase (pushing its piston up) and was not environmentally friendly. Energy efficiency has been dominant in the building sector, where architects desperately try to come to self sufficiency with all types of energy production. Now, regenerative elevators can even give power back to the system.

While North America still installs many hydraulic elevators in small buildings, especially residential ones with low traffic, European hydraulic installations have dwindled from a dominant position to less than 20%. A group of Italian, Spanish, German and Swedish small and medium-sized enterprises found this unfair. They firmly believed one should look at the total lifecycle (not simply the usage phase) of the machine, but technically advanced data collection and comparisons between traction and hydraulic lifts had not been made. They decided within the European Lift & Lift Components Association (ELCA) to order a deep lifecycle assessment (LCA) of a series of hydraulic and traction lifts to compare their total environmental footprints.

For low-use applications in short buildings (fewer than 10 floors) in categories 1 and 2 (fewer than 50 and 150 trips per day, respectively), and for the first years of use of category 3 (lifts making 300 trips per day), the hydraulic elevator comes ahead. It is better for the environment, despite its surge in energy consumption when functioning.

The reasons are simple: hydraulic elevators contain fewer materials, and, at every stage of the lifecycle, they get better LCA results than traction elevators, except when functioning. This is true even in the standby (the largest part of an elevator’s electricity consumption, by far) and maintenance phases, since hydraulic elevators are simple: their maintenance is easy and cheaper, a nonprofessional can free the passengers in case of a breakdown or untimely stop, etc.

Hydraulic elevators are clearly the ideal solution for short buildings (up to six stops with relatively low traffic) because of their lighter environmental impact.

For an LCA, the experts will look at everything and produce a real picture of the lift’s impact:

- Materials extraction and processing

- Manufacturing (components manufacturing and assembly)

- Transportation and distribution

- Installation

- Use (where energy efficiency is considered)

- Maintenance

- Dismantling and recycling (end-of-life)

The result is astounding and could very well mean a “return of the hydraulic lift” in the years to come throughout Europe. It is not normal that hydraulic lifts only represent a mere 24% of the residential segment of the market, with 73% belonging to geared traction lifts and 3% to gearless traction lifts.

ITA’s final report outlined the following:

- Clearly, the traction elevator has an advantage in energy consumption during the usage phase. This is actually limited to the movements of the elevator car. The largest part of electricity consumption of an elevator is during the standby phase, when it waits for passengers. There, all elevators are equal. They need to have “sleep modes” that “wake them up” when a passenger presses the button. New controllers are much more sophisticated now to reduce standby consumption of both hydraulic and traction elevators:

- Hydraulic elevators have less impact in the initial phases (materials and transportation), always resulting in a product with a better (lower) environmental profile in a “cradle-to-grave” approach, without including the service period.

- Hydraulic elevators also have a better profile for all categories in which the use is not very intense, resulting in a better global option for usage categories 1 and 2 (up to 150 daily trips).

- Traction elevators have a higher impact in the initial phases and a worse profile in the service phases (energy consumption) for usage categories 1 and 2. For more intense usages (categories 3 and higher), the lower energy consumption during service tends to compensate for the initial higher impact, resulting in a better (lower) general environmental profile for installations starting at 300 daily trips and more. Nevertheless, even for this category, hydraulic elevators could even be a better option for special cases in which a lifespan is shorter than 10 years.

The industry should realize now that the environmental debate was wrongly focused on electricity consumption during use. It had come to a point where traction (electrical) elevator manufacturers used energy as a decisive factor to choose a traction, rather than a hydraulic, solution. The market had followed. Today, you find high-end traction elevator applications with three stops in buildings with very low traffic: total nonsense in terms of initial costs, maintenance costs and even energy.

The elevator and escalator industry — like most industrial sectors — managed to drastically reduce its energy consumption by roughly two-thirds over 40 years for all types of equipment by adopting innovative and new drive technologies, and modifying drives, speed regulation, etc. Hydraulic elevator technology has basically remained the same for decades, and consumption — though higher per trip — is usually lower, since hydraulic elevators are used less often in residential or smaller administrative buildings (where most elevators are installed).

In a hydraulic elevator, the piston lifts the whole cabin with the whole charge (X 4) when going up. When coming down, the consumption of energy is zero. The result of the functioning of a hydraulic elevator is, on average, twice the charge. The power installed for a hydraulic elevator is X 1 to X 4, but, usually, the yearly consumption is limited to 1.5 times, since the car often goes up without charge (called from the floors) and counts for zero energy use while coming down.

The sort of hysteria that developed about energy never integrated the fact that the energy “supplement” consumed by a hydraulic elevator over one year was a few kilowatt-hours at the cost of a mere US$120. Compared to the savings in maintenance and other advantages, the hydraulic elevator was still a good option, even in terms of energy consumption. But, the damage was done, and the choice of the largest companies was a steamroller for traction solutions.

It went even further: the respected AMEV (German Ministry of Construction), in its instructions to the civil servants who needed to write a call for tender for a new elevator in a public building, were instructed “not to choose a hydraulic elevator, except if they could specifically justify it.” ELCA and VDMA in Germany had to pinpoint the issue of unfair competition to ensure that the German AMEV take out the five or six negative sentences for hydraulic elevators at different places in their instructions.

For the vast majority of elevator applications (some 65%), most residential elevators (and a good chunk of other buildings) should be hydraulic. The present perception (only based on energy use during transportation) is wrong for most buildings and most elevator applications. This could, and should, mean the comeback of the hydraulic lift in Europe.

Interview With Carlos Peribanez

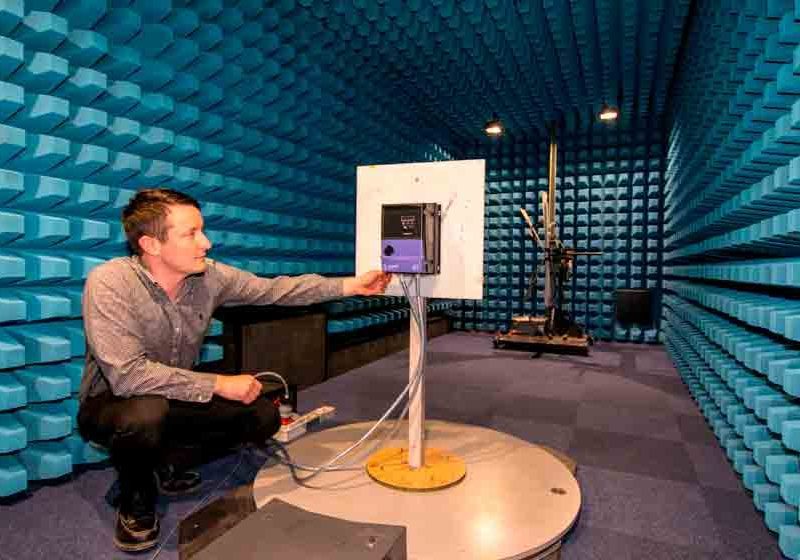

Carlos Peribanez (CP) is an engineer at the ITA laboratory (University of Zaragoza), which collected the data on and tested both traction and hydraulic lifts, for the comparative lifecycle assessments (LCAs) at the request of ELCA. Your author (LR) spoke with Peribanez, who is a signatory of the study.

LR: On which data did you rely to make the LCAs of both types of elevators? Were some data difficult to collect?

CP: We had already produced LCAs for several traction and hydraulic elevators in recent years, mostly for Spanish companies. We used this background and experience as the basis for this work. We also received extensive, complete data from companies in Sweden, Germany, Italy, Spain and Greece for both traction and hydraulic elevators. The Swedish firm Hydroware, for example, had made two official LCAs on one hydraulic and one traction elevator in Germany, so these data were also used as background information.

For maintenance, for example, we had to choose an average distance from the company to the elevator to be maintained and obtained data on frequency of visits and time before considering part replacements, for example.

LR: Is it incorrect for the elevator industry to stress energy consumption during use so much?

CP: All phases in the lifecycle of the elevator have an impact on the environmental performance of the system. The relative importance of each depends on the relative amounts of inputs used — materials and/or energy. Therefore, focusing only on the energy consumption during the use phase could be an oversimplification. This becomes even more important, particularly in case of low-use elevators.

LR: In your eyes, would an LCA for each type of elevator or each actual installed lift be feasible, or is it too expensive for manufacturers and installers?

CP: Data collection requires more resources and, therefore, is the most expensive phase of any LCA, but, once you have them, the calculations are straightforward and well defined in standards and documentation. In any case, general LCAs could be developed for each type and category of elevator as the basis for specific calculations of particular installations where only minor corrections should be considered.

LR: The environmental impact is, of course, different in Poland with its electricity production (produced by coal, with the emissions going with it) than in France (mainly nuclear, so no CO2 emissions). Is the “European average” the best solution?

CP: When you consider electricity as the energy source, of course, you need to consider the way it is produced: does it imply much emission of CO2? The “points” or tonnage involved are different in Poland and France, for example (to take two extremes). To avoid the issue, we took a well-known average, UCTE (for Europe). That is, general results and conclusions can be obtained as average, but, for any specific location, results would be different, depending on the actual electricity production.

LR: It is astonishing to see that even for elevators used 300 times a day and more (category 3), hydraulic elevators fare very well, and it is only after 17 years or so that the traction elevator “catches up” in terms of good environmental practice. Can you comment?

CP: We have made our analysis to come up with average results for a traction elevator in each category (1, 2 and 3) and have done the same to obtain an average hydraulic elevator in each category to find out that hydraulic elevators’ “virtuous” data more than compensated for their higher energy consumption during use, at least for the low-rise buildings.

We have also made an LCA for a hydraulic modernization. It indicates that a hydraulic modernization has a lower (better) impact than a replacement by a completely new elevator. This is even more remarkable in the low-usage cases, where the environmental profile is favorable to hydraulic lifts.

Clearly, this changes perspectives on the best options, depending on height and traffic. But, for the majority of elevators installed, particularly in residential applications, the hydraulic elevator should make a comeback.

For those interested in the techniques used: the calculation methods are CML-IA baseline EU25 and ReCIPe, as it was recommended by the work developed in the Environmental Product Declaration Product Category Rule for Elevators. For climate change, the impact was calculated in kilograms of CO2, and for ReCIPe, in “points.” The LCA software is SimaPro 8.0.3.

Get more of Elevator World. Sign up for our free e-newsletter.