Importance of Maintenance on Escalators / Moving Walkways

Mar 2, 2023

by Battal Murat Öztürk

Summary

The importance of maintenance for passenger, maintainer and system health is increasing in escalators/moving walkways, the number of which are increasing day by day and are no longer a luxury but a necessity. It is frequently reported in the media that negligence in these matters leads to life-threatening risks and accidents. In order to minimize this situation, maintenance companies, users and building supervisors need to be aware and question the situation.

Introduction

In high traffic buildings, underpasses, overpasses and short distances where elevators cannot handle the traffic, escalators/moving walkways have become a necessity rather than a luxury. Some shopping centers have even developed a sales strategy using escalators. How safe are these devices that operate 24/7?

It is known that there is no registration process for escalators/moving walkways in our country. Accordingly, unless there is a major accident or problem, there is no control or expert survey service by any accredited organization.

The entire responsibility for ensuring the safe and healthy operation of these devices, which we use every day and are a part of our lives, lies with the personnel working in the organizations providing installation or maintenance services.

How well can these companies or the personnel they employ do this job? In this paper, how maintenance should be done, which components should be checked in which periods and the accidents that may occur after negligence will be expressed.

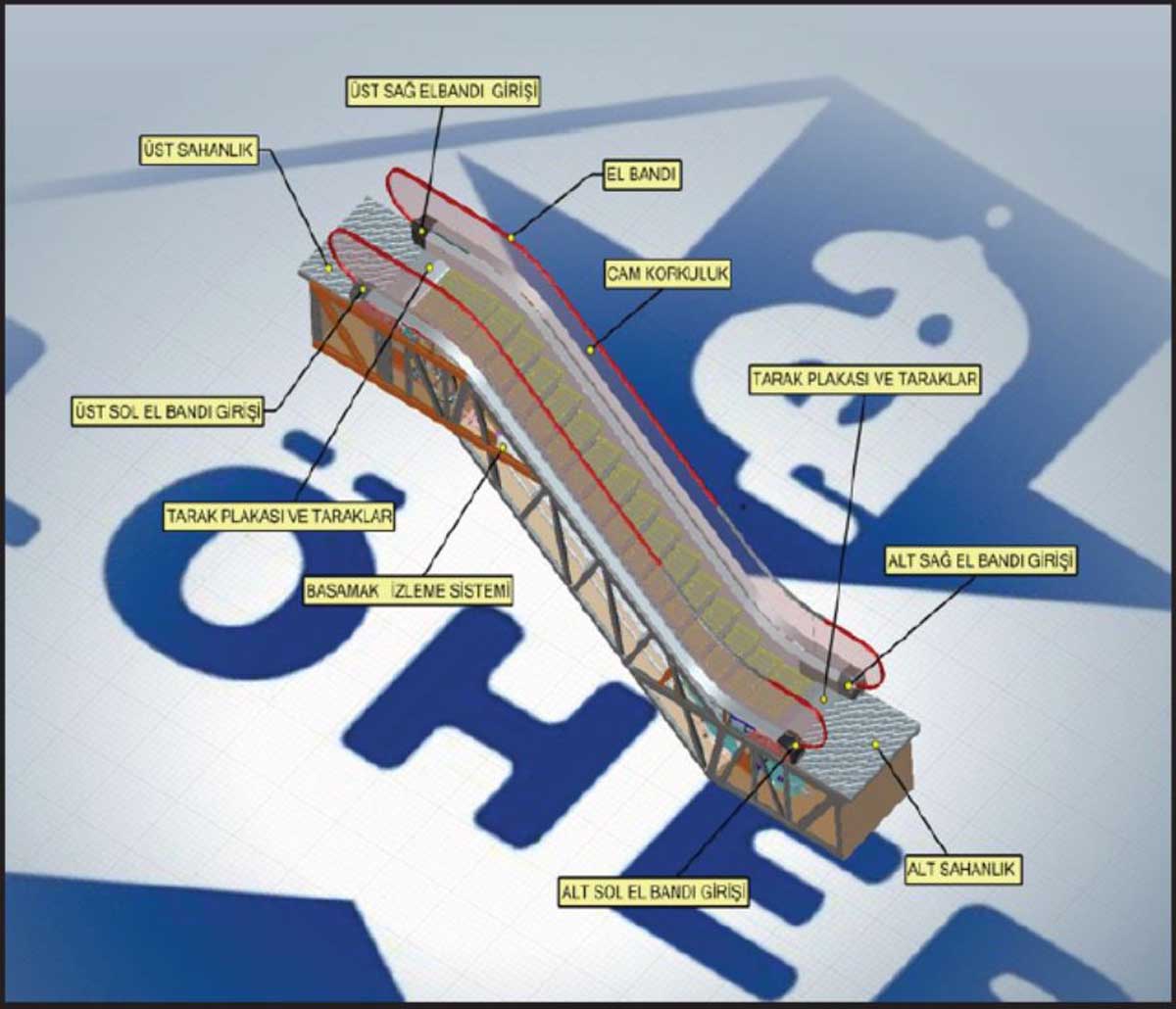

Maintenance on Escalators/Moving Walkways

1- Maintenance Periods And Responsibilities On Escalators/Moving Walkways

a. Maintenance Periods

Escalator/Moving belt maintenance periods, which are not defined in any regulations, are carried out entirely on the recommendation/forcing of the maintenance company and the periods requested by the customer. In places with heavy traffic (shopping malls, overpasses, railway stations, metro stations, etc.), maintenance must be done once a month. For escalators that operate on seasonal periods, maintenance must be carried out before commissioning, monthly during operation and at the end of the season.

b. Responsibilities of the Building Supervisor in Maintenance

- To ensure that the escalator/moving walk installed is approved for use and to verify that it complies with the current standard.

- Following the use approval process, to have regular maintenance performed by a company holding a TSE Service Competence Certificate. To ensure that deficiencies observed in maintenance are eliminated.

- To ensure that it is checked by an inspection organization at least once a year.

c. Responsibilities of the Maintenance Company

- To perform the maintenance of the escalator/moving walkway.

- To report deficiencies observed in maintenance and give a copy of it to the building supervisor.

- To ensure that deficiencies observed during the maintenance are addressed.

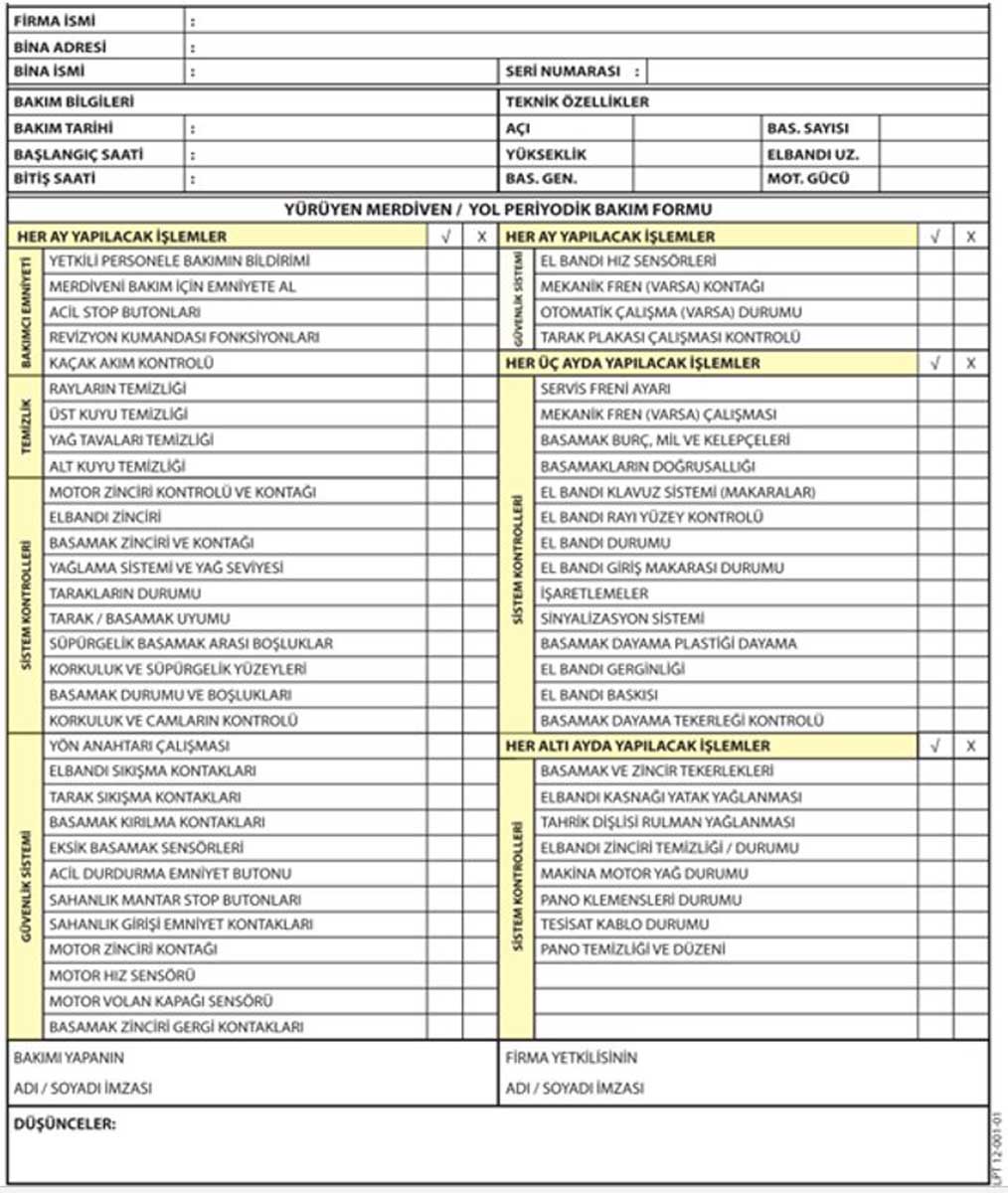

2- Maintenance Form

3- Safety In Maintenance

- Informing the authorized personnel of the building and facility that maintenance will be performed.

- Surrounding the escalator/moving walkway to be maintained with a safety barrier.

- Checking the functioning of the upper and lower emergency stop buttons before starting maintenance.

- Checking the operation of the revision controller functions

- Creating a safety area around the escalator/moving walkway.

4- Components to be Checked Every Month

Cleaning

- Cleaning of step rails and checking the condition of the rails.

- Cleaning of upper and lower station elevator shafts.

- Cleaning of the oil pans along the entire escalator and draining the waste oil.

System check

- Engine chain elongation check.

- Handrail elongation check.

- Step chain elongation check.

- Operation check of the automatic lubrication system and oil level check.

- Oil check of the step rest plastic.

- Comb plate function check.

- Checking the harmonious operation of combs and steps.

- Checking the gaps between skirting boards and steps.

- Checking the railing, glass and skirting surfaces.

- Checking the operating distance between comb plate and steps.

Safety circuits check

- Function check of the direction switches.

- Function check of the handrail jam contacts.

- Function check of the comb plate jam contacts.

- Function check of step break contacts.

- Missing step sensor/contact function check.

- Emergency stop button function check.

- Checking the permanently positioned emergency stop contacts in the upper and lower station shafts.

- Function check of the contacts on the upper and lower station safety covers.

- Function check of the engine chain elongated/disconnected contact.

- Overspeed measuring sensor/contact function check.

- Engine flywheel cover sensor/contact function check.

- Function check of step chain tensioner contacts.

- Function check of the handrail speed measuring sensor/contact.

- Mechanical auxiliary brake contact function control. (H=6000 mm above)

- Auto start system sensor/contact function control. (If available)

5- Components To Be Checked Every Three Months

- Engine service brake adjustment.

- Step bushing, shaft and clamp check.

- Steps linear operation check.

- Handrail guide rollers/system check

- Handrail track surface check.

- Handrail inlet roller check.

- Markings presence and condition check.

- Direction signalization system check.

- Step rest plastic check.

- El bandı gerginliğinin kontrolü.

- Handrail print system check.

- Step stop rollers check.

6- Components To Be Checked Every Six Months

- Steps and step chain rollers check.

- Handrail pulley shaft bearing oil condition check.

- Drive gear shaft bearing oil condition check.

- Cleaning and checking the condition of the handrail chain.

- Machine motor gearbox oil level check.

- Electrical installation and control panel condition check.

Consequences Of Incomplete Maintenance

The increasing use of escalators/ moving walkways in recent years has led to incorrect or incomplete maintenance and accidents. Some oversights and their consequences are listed below.

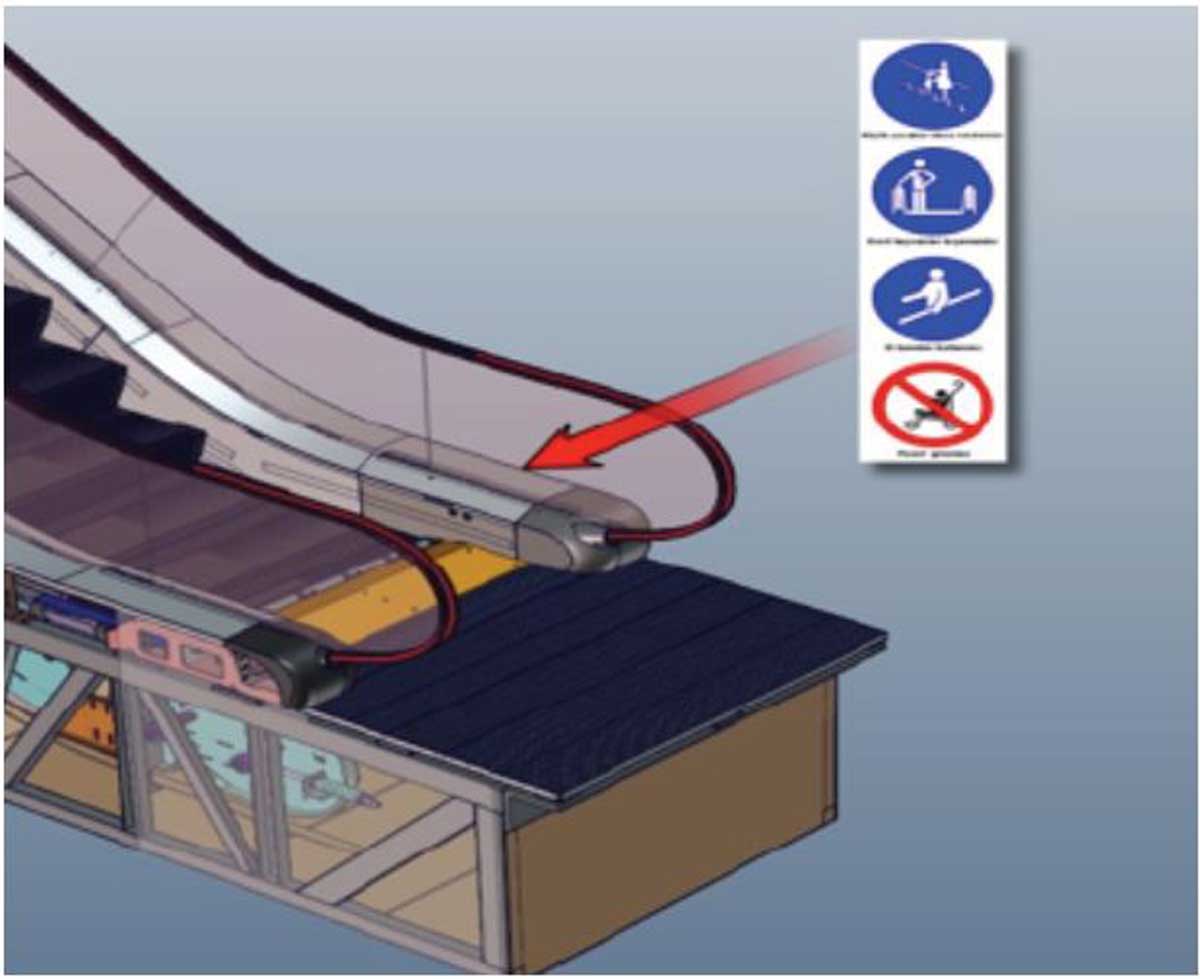

1. Information Labels

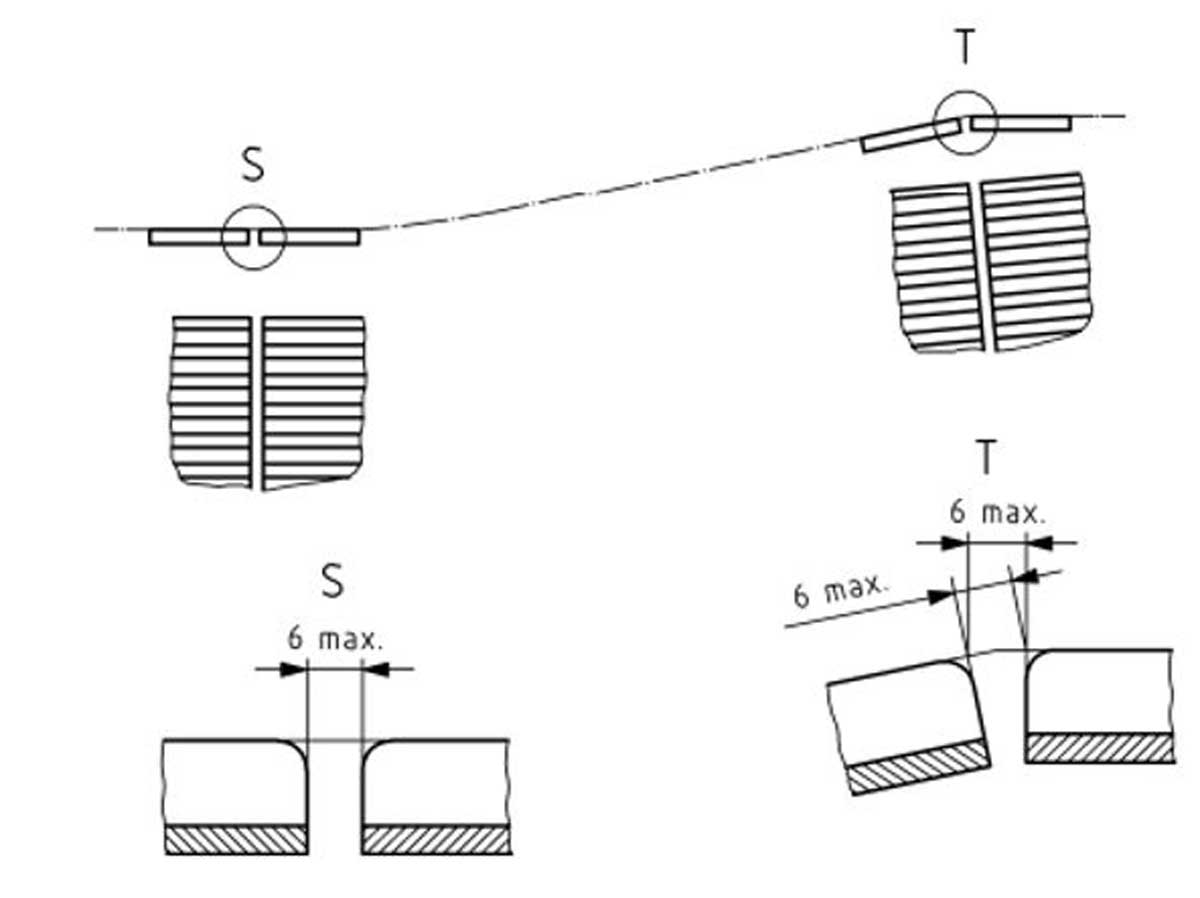

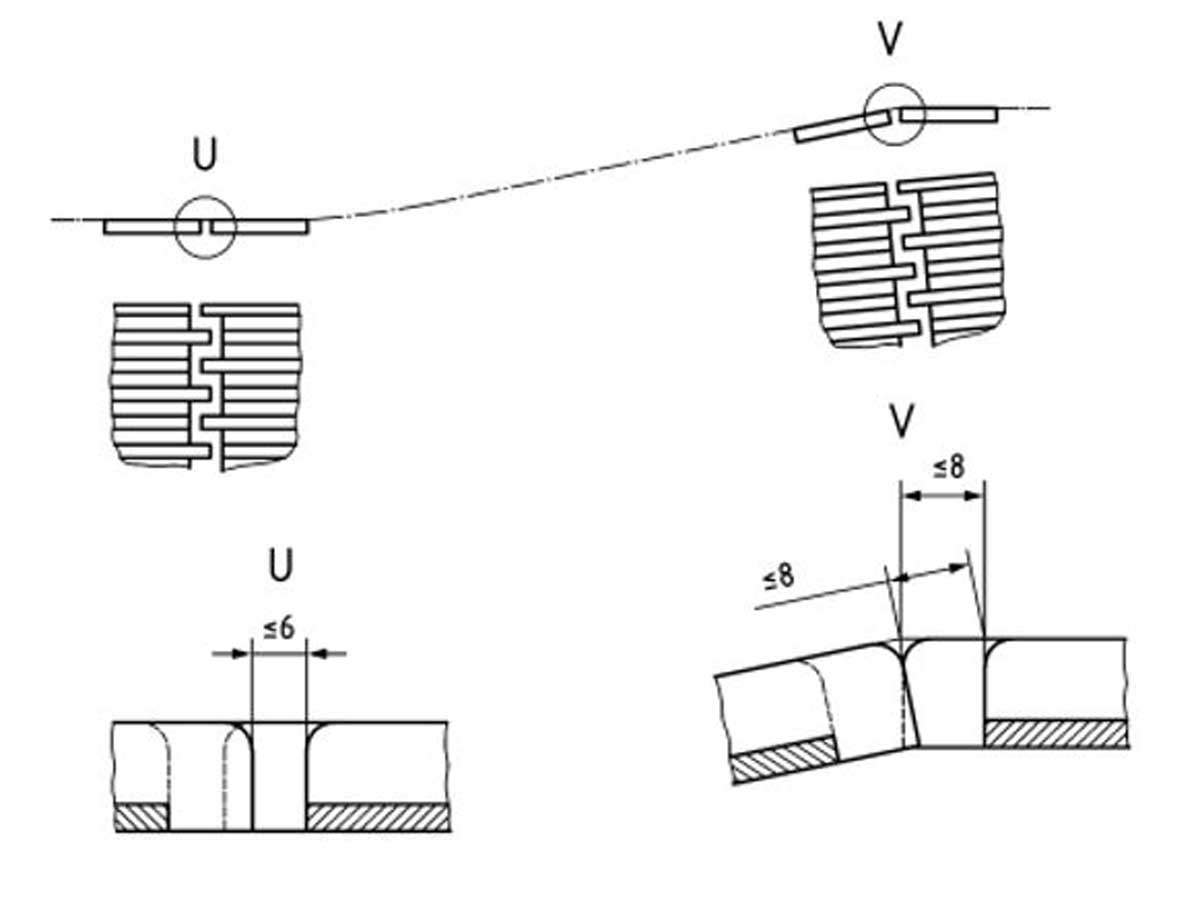

A few of the labels required for the health of the user, passenger and system are shown below.

It informs users on ¬how to move on the escalator¬ in the upper and lower entrance and exit areas. The authorized personnel for the escalator are responsible¬ for affixing these labels.

The following types of accidents can occur as a result of the lack of these information labels.

2. Signalization Marks

Signal lights indicate the direction of the escalator/moving walkway. A red light on the upper and lower landings warns the user not to take the escalator in the wrong direction. Signal lights can be placed in different positions on the escalator.

If these signalization marks are missing or not working, falls and consequent injuries can occur.

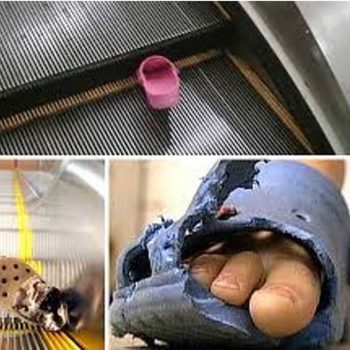

3. Missing Step Monitoring System

In case the escalator is put into service without replacing the step removed during maintenance, there should be a control mechanism in place to stop the system before the missing step leaves the comb plates.

This system is very important for both the maintenance personnel and the users.

The accident that may occur if this system is missing or not working is shown below.

4. Moving Comb Plate and Combs Check

If the comb parts connected to the comb plate are damaged or missing, there is a risk of injury and therefore the escalator must not be used.

This safety device is activated, for example, if something gets caught between the comb plate and the step chain. In this case, the comb plate presses a button horizontally, which stops¬ the escalator

If the comb plate safety system is not present or is inoperative, the following accidents can occur.

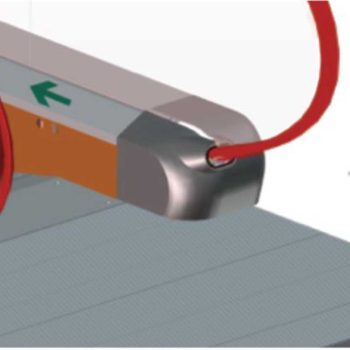

5. Handrail Jamming System Check

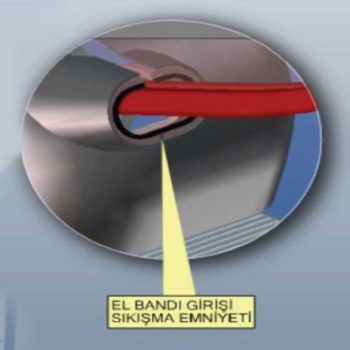

Handrail inlets are security systems with plastic body and moving mechanical system. Thanks to the movable brush, the safety switch on the inside of the brush ensures that the escalator¬ stops when the handrail gets jammed.

Accidents that may occur if the handrail jamming system is not present or is inoperative are shown below.

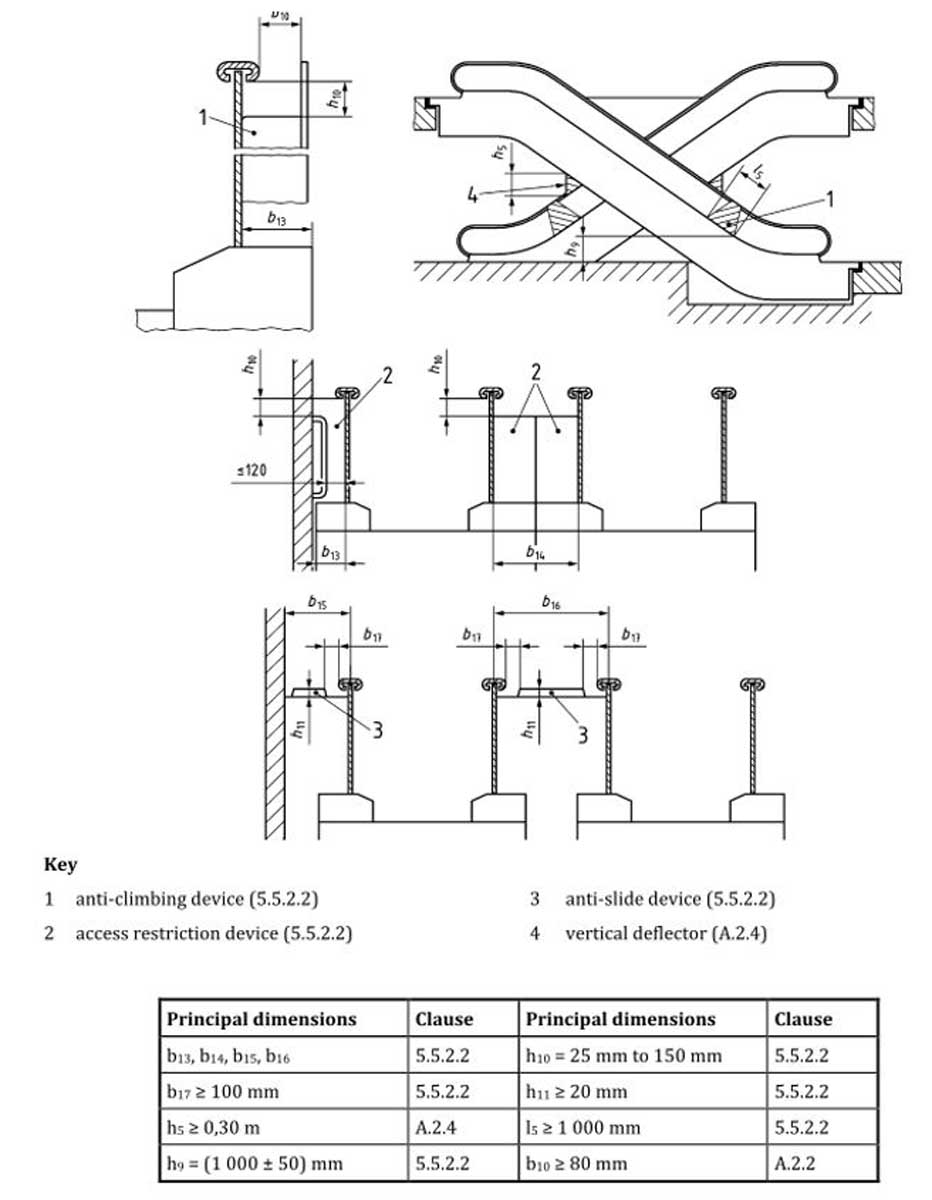

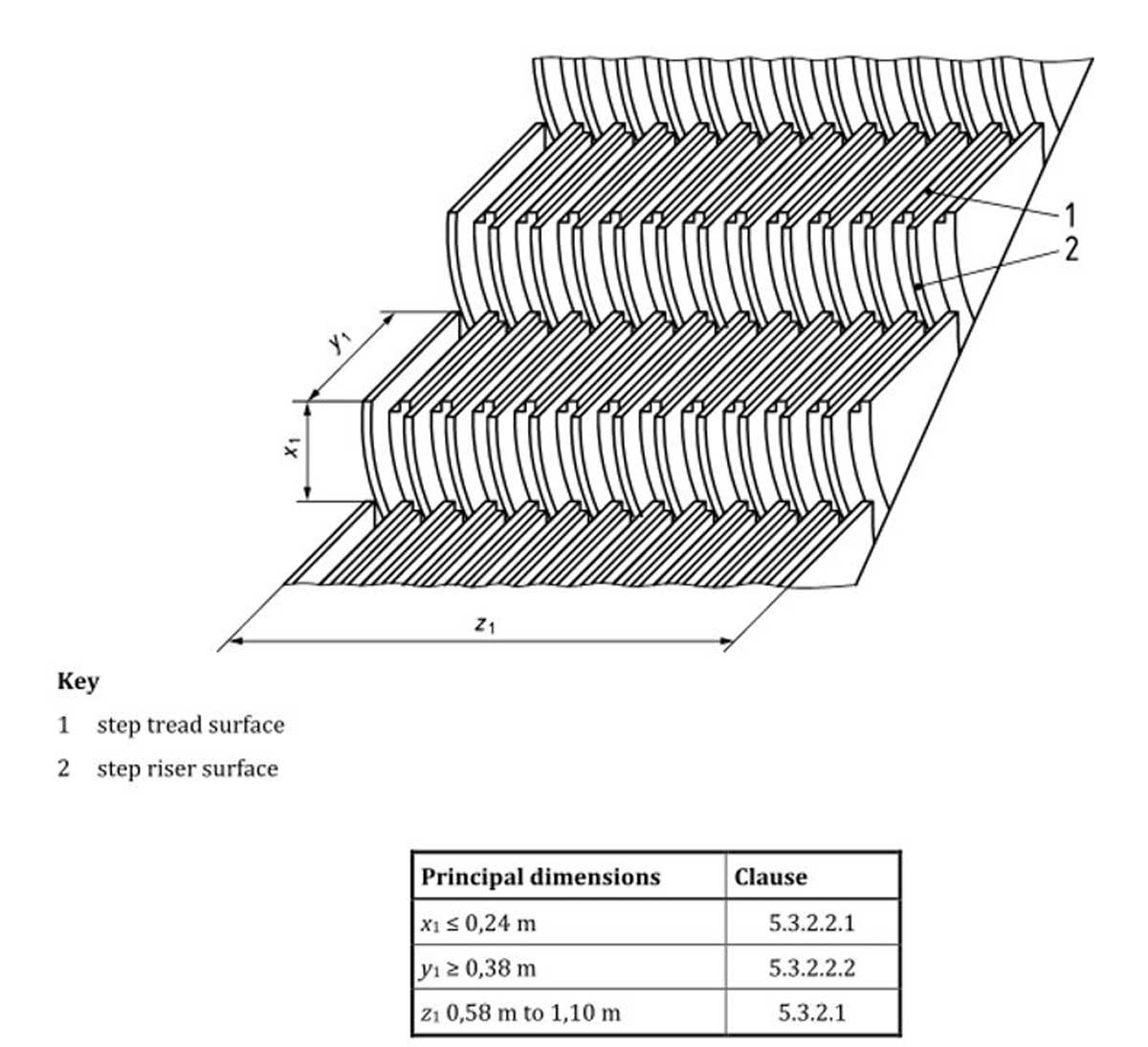

6. Gaps Check

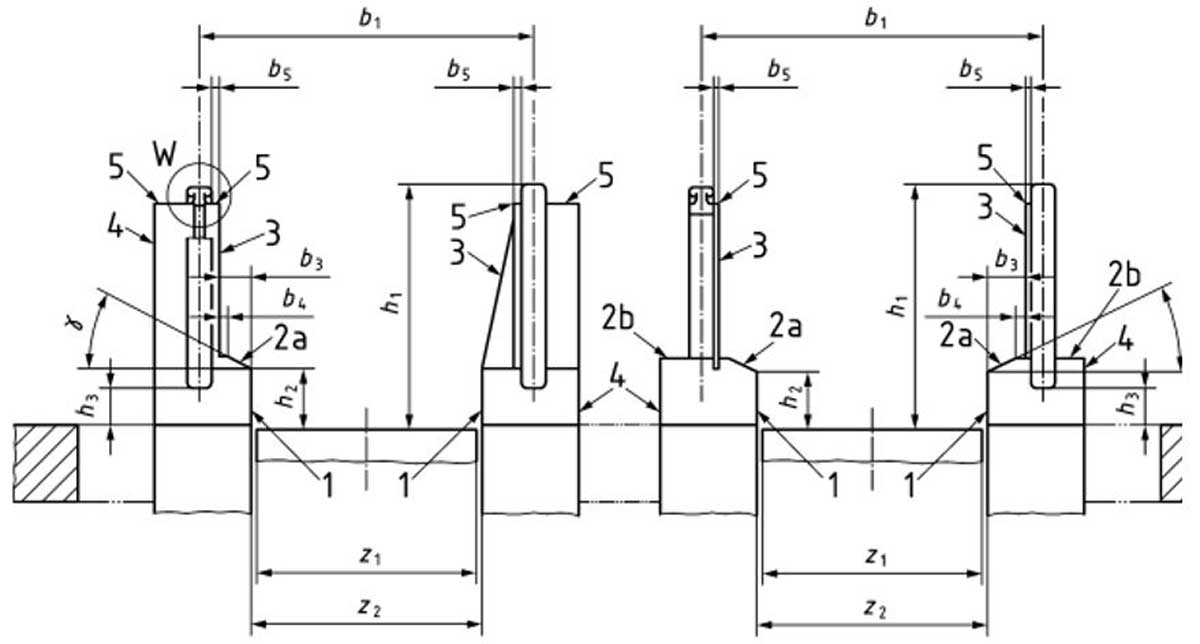

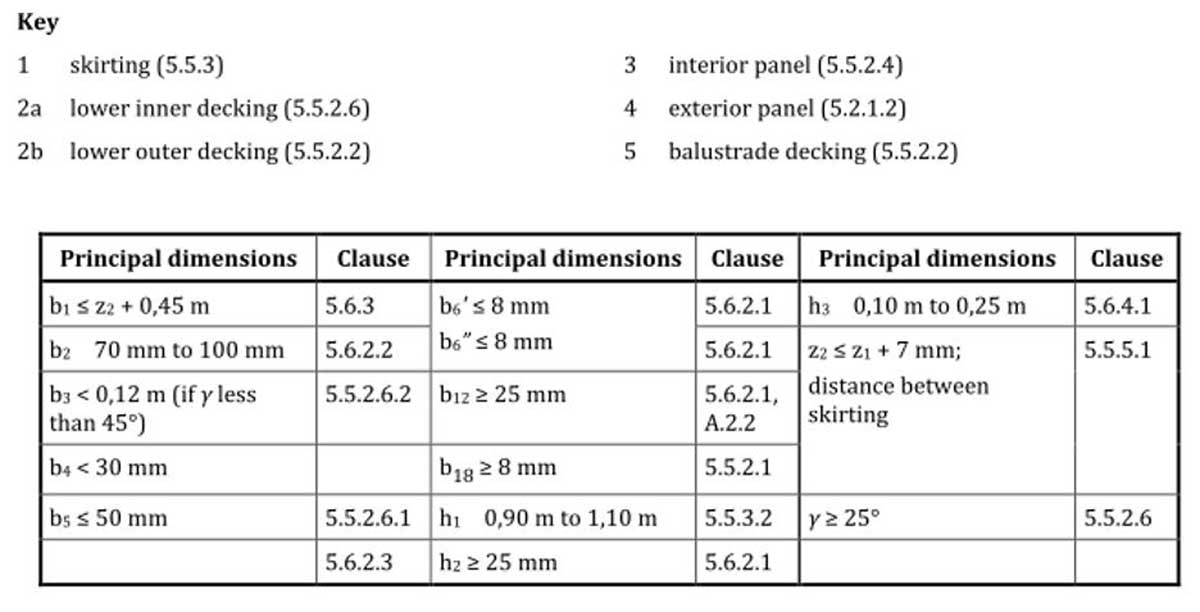

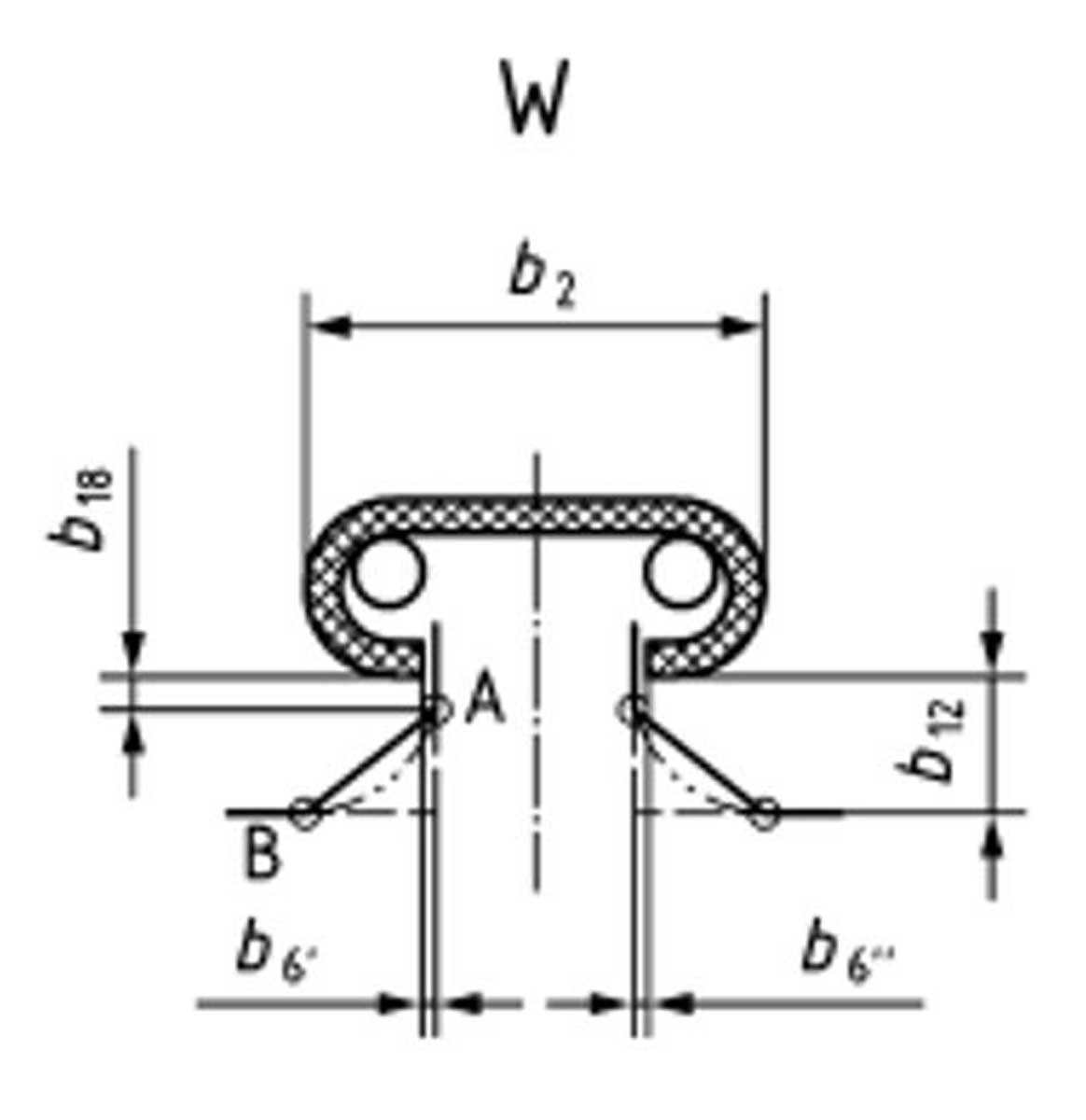

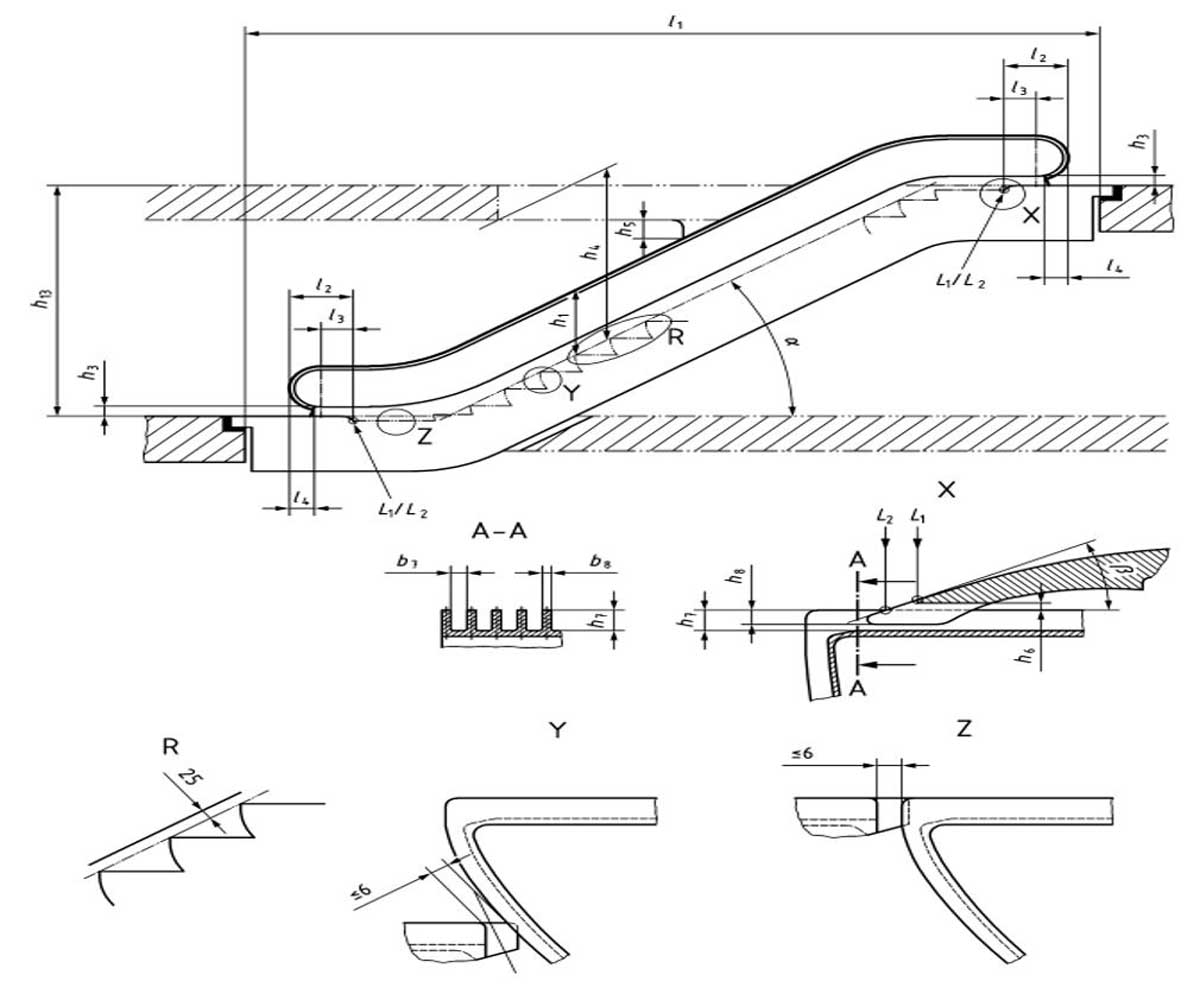

The gaps allowed by the EN 115-1 standard should be checked. If there is a change, they should be adjusted to acceptable levels.

Some of the accidents that may occur if these openings are exceeded are as follows.

Raising User Awareness

Are there no accidents on escalators and moving walkways that are regularly maintained and deficiencies are eliminated? Fifty percent of accidents are caused by the system, and 50% are caused by user error. For this reason, the awareness of users needs to be raised.

The points that users should pay attention to are as follows.

- Escalators should only be operated by people trained on it.

- Wheelchairs, strollers or people riding roller skates are not considered safe as they cannot hold on tightly while traveling on the escalator

- Carrying loads can damage the escalator and make it unsafe to transport¬ people.

- Under no circumstances may loads be carried on escalators or steps.

- There are a wide range of safety devices with electrical hazards on escalators. They are intended to ensure the safety of the people using it and to prevent damage to property. Safety¬ device switches must not be removed or tampered with.

- The escalator must not be used if there is damage to the electrical or mechanical system. This applies in particular to faults in the display or safety devices. Therefore, it is important to check the escalator at least once a day before operating the device and make sure that the steps, combs, handrails, balustrades, covers, indicators, external safety devices are not defective or missing. If a damage occurs during operation, you must immediately stop the escalator, take the necessary¬ precautions to prevent it from being operated again and close it for use.

- All circuit elements of the electrical-electronic system can cause electric shock. This system should only be intervened by authorized persons;

- Do not hang over the handrail.

- Do not wait on the entrance landings.

- Complete your journey by holding onto the handrails throughout the entire journey.

- Do not sit on steps. Do not leave your belongings on it.

- Hold your children by the hand and do not let go until they leave the escalator/ moving walkway.

Reference

[1] TS EN 13015 + A1 Elevator and Escalator / Belt – Maintenance Instructions _ June 2009

[2] 2006/42/EC Machinery Safety Directive _ R.G. No. 27158 dated 03.03.2009

[3] TS EN 115-1 Safety for escalators and moving walks – Part 1: Construction and assembly _ December 2013

[4] TS EN 115-2 Safety for escalators and moving walks – Part 2: Rules for improving the safety of existing escalators and moving walkways _ December 2013

Get more of Elevator World. Sign up for our free e-newsletter.