Improving the Efficiency of Hydraulic Elevators

Sep 1, 2011

How Schumacher Elevator Co. utilizes Bucher Hydraulics, Inc. technology to improve hydraulic elevator efficiency.

Denver, Iowa-based Schumacher Elevator Co. has been family owned and operated for 75 years. Marvin Schumacher and his team utilize the latest technology offered by Bucher Hydraulics, Inc. to improve the efficiency of their line of hydraulic elevators. Like other independent contractors, Schumacher has found it difficult to compete on the price for pre-engineered elevator systems. Schumacher has found that offering energy-efficient, high-performance products allows the company to meet its customers’ needs better than its larger competitors. “Many of our customers are excited to hear about the unique product solutions that we offer. Because of the technology offered by Bucher, we are able to differentiate ourselves from the competition,” says Schumacher.

Schumacher has been specifying Bucher valves in power units through architects and consultants. The benefits of reduced energy consumption and a wide temperature range associated with the Bucher electronically controlled valve are of particular interest. With mechanical valves, it is common practice to run the pump motor to heat the oil to 100°F for consistent operation. Control manufacturers require machine-room temperatures to be kept below 90°F. This creates inefficiencies in building-energy consumption. The Bucher electronic control valve does not need to keep oil temperature around 100°F. The Bucher valve operates independent of the oil temperature and load. Temperatures range without any changes of ride performance from 23-150°F. Equipped with the proper technology, Schumacher’s sales force is able to sell the benefits of electronic valve technology, instead of trying to compete on price alone.

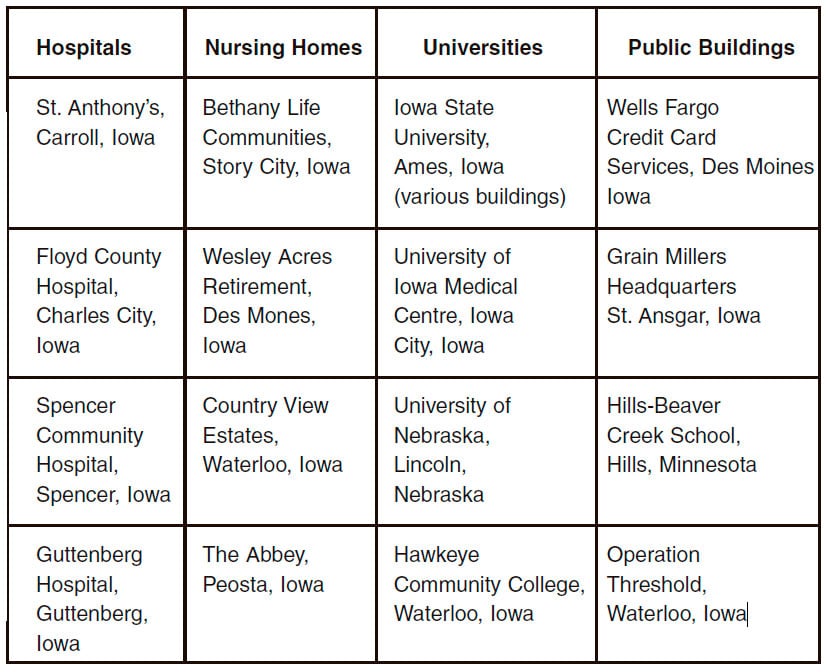

Schumacher has put Bucher valves on a number of installations for its key customers (Table 1). These are selected installations only; over 60 valves are installed to date.

Following in Schumacher’s foot-steps are other independent package builders and their core customers in North America, some of whom have been following hydroelectricity development with a keen interest and using “green” technologies wherever possible.

Aside from using Bucher electronic valves, Schumacher Elevator has also recently used variable-voltage, variable-frequency (VVVF) technology for hydraulic elevators in the U.S. The first VVVF variable-frequency drive hydraulic power unit sold into the U.S. market was purchased by Schumacher just three months ago. The unit was used first for demonstration runs in Schumacher’s in-house test tower, and was presented to NAESA International inspectors visiting Schumacher for training on May 6. Schumacher’s first VVVF unit will be installed at the State of Iowa Department of Transportation Building in Ames, Iowa, in the early fall of this year.

First developed by Bucher Hydraulics 14 years ago, thousands of these VVVF units are in service worldwide on high-load, high-use elevators in hospitals, public buildings, airports, railway stations and shopping malls. The main advantage of this technology is the fact that there is no more heat buildup in the oil. On the down run, the oil is routed straight to the pump, which drives the motor in re-verse; the power generated is routed by the VF inverter to a brake resistor, which can be mounted in the elevator shaft or even outside. Oil stays cool at 100 plus starts per hour. A nice side effect is 60% drive energy savings (versus traditional mechanical valve technology).

Table 1

Get more of Elevator World. Sign up for our free e-newsletter.