Your author shares insights from his research on possible reasons for passenger deaths in elevator accidents, available safety provisions, their effectiveness and potential for further development.

My ultimate aim to achieve zero deaths in elevator accidents prompted me to study every accident report and analyze it to understand accidents’ root causes. My hope is this research will help the elevator industry and government authorities take the required corrective measures.

Elevator accidents and passenger deaths are major concerns for elevator manufacturers, service providers and government agencies. The number of elevator installations in India is increasing year after year. Thanks to changes in government policies and regular improvement in safety systems and procedures, users enjoy safer travel. According to available data, in 2010 India’s need for elevators was nearly 30,000 units per year. This increased to 85,000 units in 2022. By 2022, the total number of installed elevators in the country surpassed 7 million units. The regular increase in the number of elevator installations demands a proportionate increase in safety-monitoring systems by controlling authorities. My study includes possible solutions/suggestions to help control and reduce the number of accidents and passenger deaths.

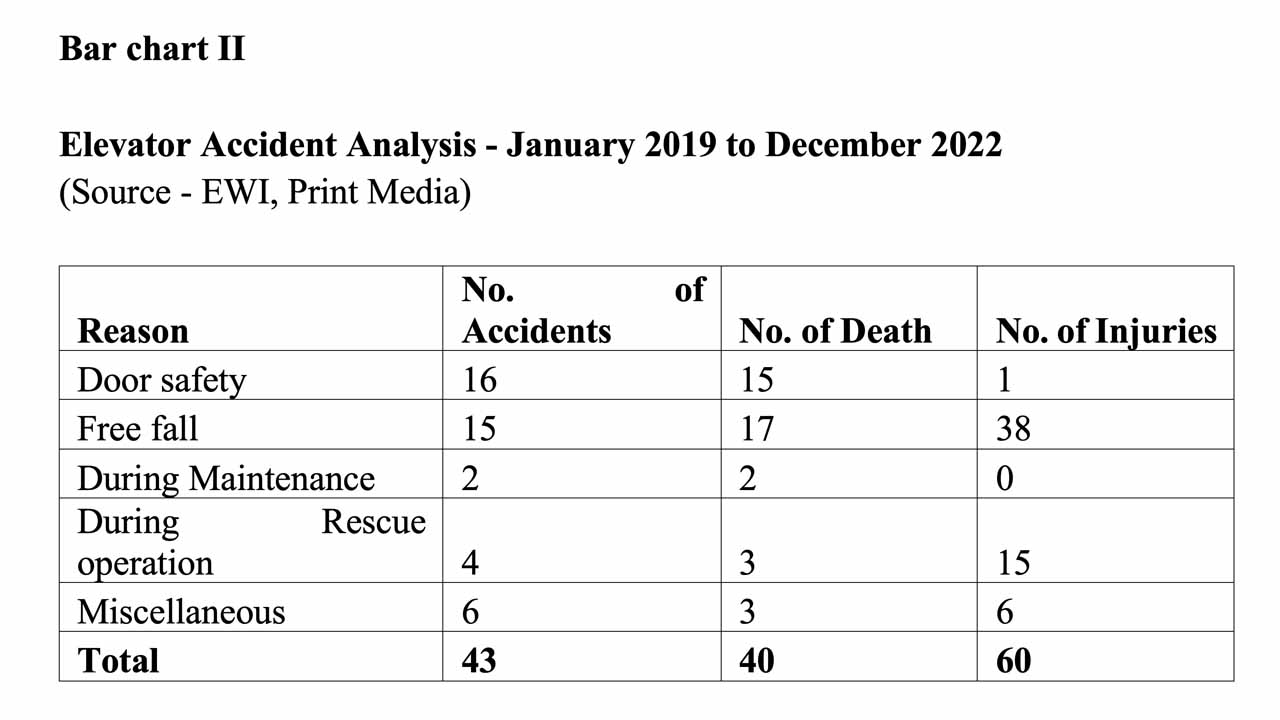

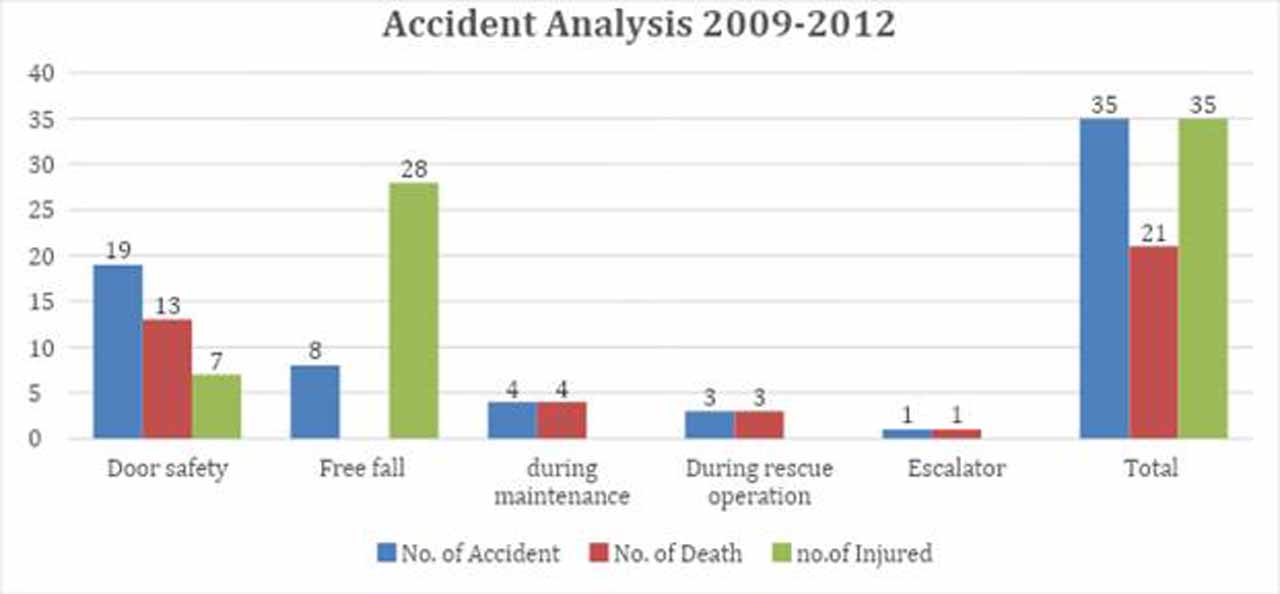

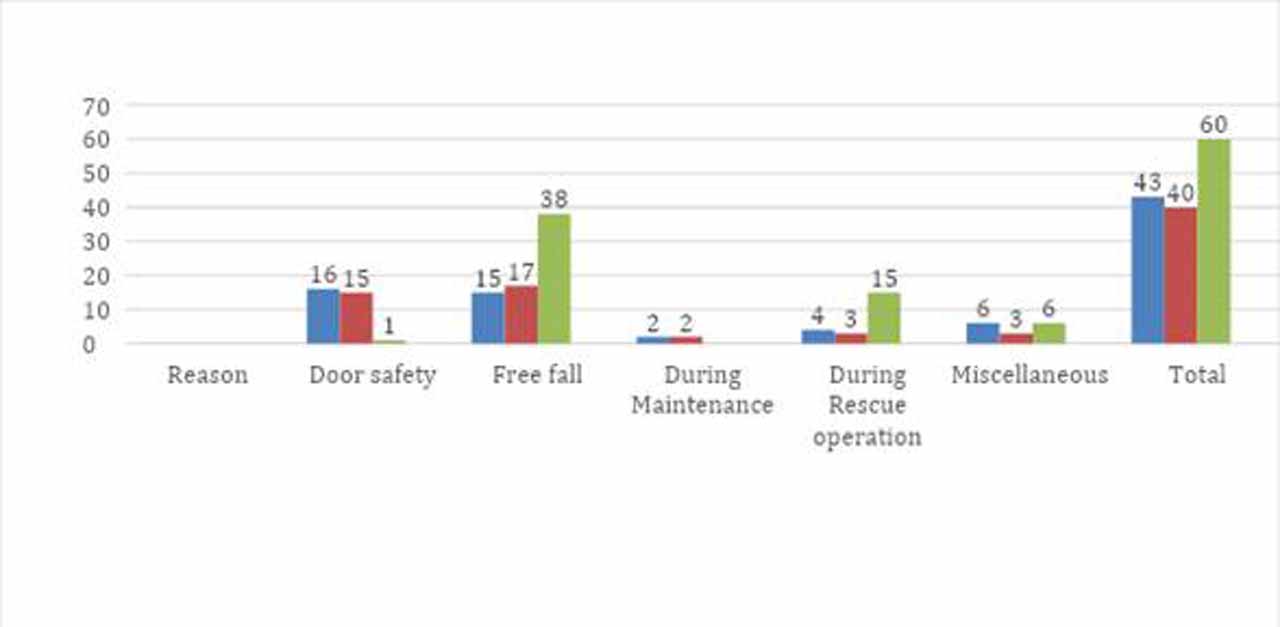

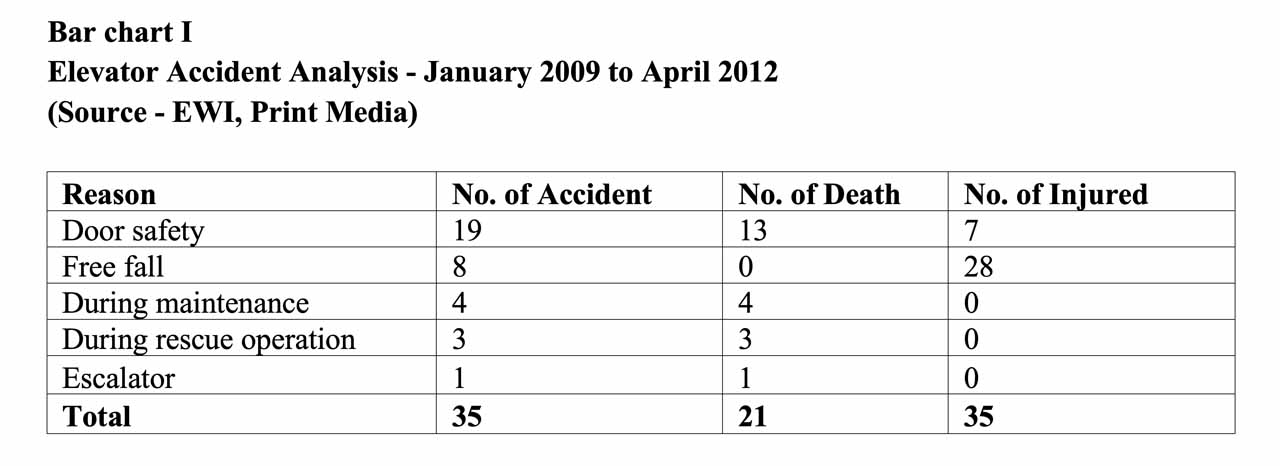

To study the reasons behind elevator accidents, I collected accident data from January 2019 to December 2022. I already had accident data from January 2009 to December 2012, which helped me understand the issue in depth. The old records represent accident details before a number of changes and corrective safety measures taken by The Lift Inspectorate and Indian Standards (IS) specifications for elevators. I have compiled all available data together to make the study easier to understand.

The study is divided into the five most common categories, which are:

- Door system failure

- Free fall

- Rescue operations

- Maintenance work

- Miscellaneous

The sole purpose of all these exercises is to:

- Understand the root cause of the failure that ultimately leads to fatal accidents.

- Study the effect of changes in elevator safety rules and safety requirements introduced by the IS and government authorities.

- Study the effect of corrective action suggested at the user level.

- Study the effect of corrective measures taken by the elevator industry.

The elevator industry and government authorities are constantly working to improve the comfort and safety of users. Many changes and improvements have taken place in the elevator industry, keeping safety, comfort and performance in mind.

Before going into accident details, let us first look at the changes/safety improvement measures introduced in the past decade. These changes are listed here for your immediate reference:

- Audio/visual overload system. Overloading of elevators resulted in many failures. Passengers become trapped due to stopping of elevators, trying to call for outside help for their rescue or trying to release themselves. During rescue operations, no proper procedures are followed, which leads to sometimes fatal accidents. Considering this problem, an audio/visual overload system is made mandatory. In case of overloading, this system provides an audio warning signal and activates the overload relay, which, in turn, cuts off the safety circuit.

- Automatic rescue device (ARD). Power failure is a common occurrence in many cities. The entrapment of passengers and subsequent rescue operations often lead to fatalities. To overcome this, the government has made the ARD (an alternate power supply) compulsory for all elevators, including old installations. This helps the elevator travel to the nearest floor in the event of power failure. In this way, accidents arising from entrapment and rescue operations can be avoided.

- Replacing collapsible doors with imperforate gates. Many accidents have been reported related to the use of collapsible elevator doors. Passengers (particularly children) could insert their hands between the door channels, leading to accidents. Imperforated doors have helped reduce door accidents.

- Lift license validity of 20 years (Maharashtra Lift Act 2017). Elevators have many moving parts that are under constant load/tension. These parts need timely maintenance and replacement whenever compromised. Most societies face financial issues and are forced to compromise on repair/maintenance expenses, leading to serious accidents. This rule is expected to reduce the number of serious accidents.

- Making lift inspection compulsory every year (Maharashtra Lift Act 2017). This is to ensure elevators are maintained properly and all safety components are in proper working order. Regular inspection by an authorized person will help in consistently maintaining safety features.

- Introduction of third-party insurance for lift users. (Maharashtra Lift Act 2017). This rule was introduced to safeguard housing societies and building owners from financial liability arising from fatalities. The effect of this change is visible in the accident chart. The number of fatal accidents is increasing in absolute terms, but, if we compare it with the increase in elevator population, it confirms the percentage increase in accidents is much less than the percentage increase in elevator population. This difference or decrease in accidents in terms of the percentage of the elevator population can be taken as a positive sign that corrective measures taken through lift rules and IS recommendations are working.

Let us study accident details prior to and after the changes in lift rules.

Let us study the accidents’ root causes one by one, with possible solutions.

Door system failure. The number of accidents/deaths is higher in door-accident cases versus other failure reasons. Door accidents account for 37% of total accidents. This has gone up from the decade-old data, which was reported as 20%. Let us go into further detail about the failure causes.

The regular increase in the number of elevator installations demands a proportionate increase in safety-monitoring systems by controlling authorities.

Door lock shortening or contact failure is the most common cause of accidents. There are proper and enough systems for door locks. It has mechanical — as well as electrical — locking. Moving an elevator with the door open is unacceptable. In such cases, the service provider can be subject to the “attempt to murder” clause. But, there is another way of looking at it. When we enter an elevator, do we check before stepping ahead that the elevator cabin is there in front of us, near the floor level? The number of accidents shows passengers try to enter the lift cabin without confirming whether or not the cabin is there in front of them. There was an accident in Bandra where a school principal walked into the lift busy reading the newspaper and fell into the lift well, as there was no lift cabin on that floor. His slight alertness could have saved his life.

In a similar accident, a passenger opened the lift door and entered, but there was no lift cabin. The cabin came down from the upper floor and crashed into the passenger inside the lift well. A possible solution would be to add one more audio/visual warning on the floors that would activate whenever someone tried to enter an elevator if there is no elevator on that floor. This could be achieved by providing a sensor on the top, near the entrance, as well as one inside the shaft, to sense the cabin’s presence. Whenever anyone comes near the door, the sensor on the floor will be activated. If the elevator cabin is not on that floor, another sensor will activate an alarm. Let the design engineers study this issue and work out some effective, feasible solutions. This is a new topic for research.

Can this be taken as a technical failure? In the first place, yes, but if we go into a root-cause analysis, we come to the conclusion that this is purely a result of human error. The door lock, contact or mechanism has its own designed life. We need to follow a system of performing checks and cross-checks at prescribed intervals. This preventive system plays a great role in minimizing similar accidents.

Free fall. Free fall is a vague reason for a failure or accident. There can be many reasons for an elevator to come down suddenly, without any control. Data analysis shows the number of free-fall accidents is around 35% in recent years, which is much higher than the decade-old figure of 22%. Possible reasons could be:

- A worn-out pulley groove

- Reduction in rope diameter over time

- Brake failure

- Broken rope, including governor rope

- Drive feedback circuit failure

Out of these, the first two reasons — a worn-out pulley groove and a reduction in rope diameter — are very common for such failure. Replacement of pulley or rope is generally avoided/neglected unless some authority, auditor or the service provider emphasizes the issue. All these reasons can be well controlled by timely maintenance and adjustment by trained personnel. This is well within the control of service providers.

Reports appearing in the media are, most of the time, unclear and fail to help industry experts understand the exact cause of a failure/accident.

In addition to controlling the impact of sudden falls of the elevator cabin, spring buffers are provided in the elevator pit. The cabin comes down and rests on buffers with some spring effect. During this period, passengers can get hurt due to sudden jumps felt in the cabin. This jumping effect can be further reduced if hydraulic buffers are used in place of spring buffers. Hydraulic buffers will facilitate gradual stopping of the cabin, and problems arising from jumping effects can be easily avoided. Oil buffers are used in elevators having a speed of 2.5 m/s or greater.

Rescue operation. In case of any failure, the elevator gets stopped. This results in passenger entrapments and is very common. But, what is important here is not the entrapped-passenger situation but, most importantly, how they are being rescued. Most rescue operations are undertaken by untrained or less-informed persons. This can result in accidents or major losses. The best way to control such accidents is to keep some occupants/security staff/society committee members as volunteers who are given required rescue training by the service provider. The number of accidents during rescue operations is approximately 9%, which is more or less the same as the old records. In terms of the percentage of installation, this can be taken as a good sign.

Maintenance work. Accidents that happen during maintenance work resulting in injury or death of service technicians are the result of:

- Lack of technician training

- A careless approach taken by the technicians

- An excessive workload

- Use of improper tools

- Taking shortcuts

This is purely in the service provider’s domain. However, considerable improvement in the number of accidents taking place during maintenance work has occurred. If we go into further detail of the accidents, we will notice a few similarities:

- In most cases, the elevators were under a maintenance contract with a small, unorganized service contractor.

- Most accidents were reported from the Slum Rehabilitation Authority (SRA), housing board or tenant buildings. The Chief Electrical Inspector sent a request letter to the CEO of SRA projects stating there is an urgent need for stringent safety standards regarding the design and construction of elevators/lifts in SRA buildings.

In percentage terms, present accidents are at around 5%, versus earlier records of 11%.

Miscellaneous. This accident category includes accidents due to rope breakage, brake failure, control failure or any other part failure that leads to passenger death or injury. Such accidents can be easily avoided by taking service activities seriously and repairing or replacing parts before a major failure or accident occurs. Rope breakage cannot happen in one day. Rope may start showing strand breakage that ultimately leads to complete rope breakage over time. Service technicians cannot overlook such issues. They need to be more careful and vigilant. These accidents are at around 14% of the total accidents reported presently.

From the above statistics, one can easily conclude that the number of accidents and passenger deaths — in absolute terms — is increasing even after many improvements in elevator systems and procedures. This makes us rethink our elevator safety systems, training, rules and procedures, checks and cross-checks.

Reports appearing in the media are, most of the time, unclear and fail to help industry experts understand the exact cause of a failure/accident. If each accident is explained in detail and studied in depth, it can be of great help to industry experts in pinpointing the cause of failure. This will also help the authorities in redefining our systems and procedures, in turn minimizing accidents and losses.

A few more accidents have perhaps not been reported by the media. But, we have to go with the data available through authentic sources. Accident records force us to find suitable answers/solutions to the questions raised here, which are dealt with in detail in the concluding section of this report.

Conclusion

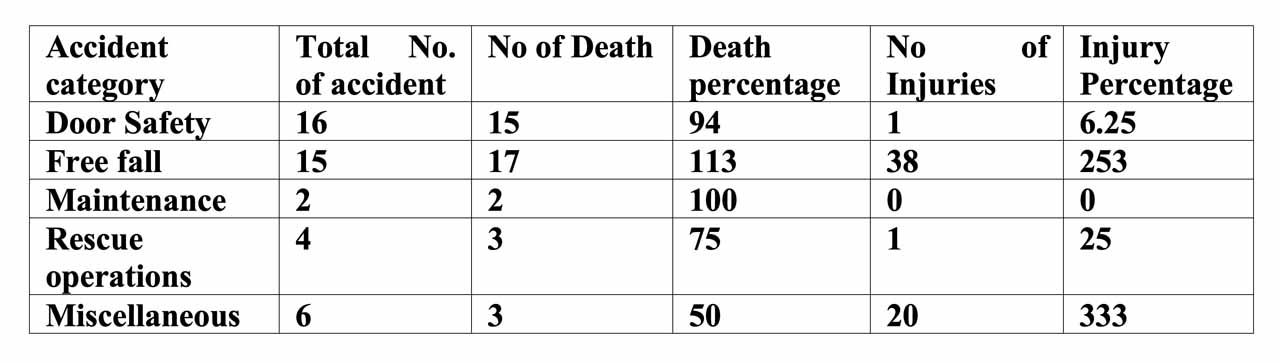

Let us analyze the number of deaths and injuries and their percentage in each accident category. This comparison is prepared to understand the percentage of death and injuries in each accident category separately, and not in terms of overall elevator population.

From this chart, we can easily conclude the death percentage is higher in cases involving door safety, free fall and maintenance. Conversely, the death percentage during rescue operations and miscellaneous categories — accidents due to negligence or human error — is relatively low. We need to focus more on accidents due to door safety, free fall and maintenance issues. Possible solutions or actions are explained here for the benefit of the industry and government authorities.

Awareness Among Users

It is apparent that, in most cases, deaths or serious injuries are due to a lack of awareness regarding elevator safety and rescue procedures. For instance, entrapped passengers panic, and the person present outside who has no knowledge of proper rescue procedures tries to help them. We need to educate users that, if they are inside the elevator and not trying to come out until the elevator is brought to the nearest floor level, they are safe. This procedure takes only 5-10 min. Only how much time it takes for the service technician to reach the site is not certain. This depends on the technician’s location, mode of travel and local traffic conditions. The people outside the elevator should update entrapped passengers about the action taken and provide moral support until the technician reaches the site.

Rescue Training

This analysis confirms we still need to create awareness among users and increase the frequency of safety and rescue training for security and service staff. We need to recruit volunteers in societies and provide them with the required training. The licensing authority can work out a suitable module in which volunteers are provided short-duration practice training and are awarded a certificate upon completion. Licensing authorities could consider authorizing service providers to assume the responsibilities of training and issuing certificates to the society office bearers and security staff.

Introduction of Nationwide Uniform Lift Rules and Their Monitoring

All Indian states should have elevator inspection departments. At present, only 11 Indian states/union territories require lift licenses. These include Maharashtra, Gujarat, Jharkhand, Tamil Nadu, Karnataka, Kerala, West Bengal, Assam, Himachal Pradesh, Haryana and Delhi. Other states have yet to introduce a structured procedure for obtaining an operating license, monitoring elevator activities and providing guidelines for users, as well as suppliers.

The data reveals that deaths due to elevator accidents are mainly reported from elevators (regardless of manufacturer) maintained by freelancers/the unorganized sector. This suggests we work toward an effective and feasible method for providing training, creating awareness and introducing checks for the unorganized sector. Introducing safety audits by qualified/certified auditors can play a great role in improving the safety and reliability of elevator systems.

Introducing Additional Safety Measures

Most elevator accidents are reported because of free falls and door-open conditions. A few suggestions to minimize these failures and losses are provided here. They include providing:

- Hydraulic buffers for all elevators to reduce accidents/losses due to sudden falls or free falls of elevators.

- A sensor to detect the presence of the elevator cabin and provide a warning in case of the door being open. This can help reduce accidents due to door-open issues.

Addressing Unorganized Sector Issues

Societies need to have money to meet the high service charges of organized players. The organized sector should work out some long-term plan so the elevator remains with them for a longer period, if not for its entire life cycle. Maybe offering a service contract with the initial lift supply order for 10-15 years or a lift life cycle can result in positive change. The expenses toward major repair or modification must be considered under building repair activities and the society must be allowed to utilize the money. Societies must take proper care while selecting the service provider. Particularly in the case of going with the unorganized sector, one must go into the details of the agency, its service setup, competency, financial status and records.

For Government Authorities and Policymakers

From the latest accident records, we can easily point out areas where more action or attention is required. These areas include:

- SRA building lift accidents. Overall, these accounted for seven out of a total of 43 reported, which equates to 16%. SRA building lift accidents resulted in 10 deaths, which out of a total of 40 equates to 25%.

- Unorganized sector. Almost all elevators where accidents/deaths are reported are maintained by small, unorganized service providers, irrespective of the make of the elevator.

- Accidents in states that lack lift rules. Out of 43 accidents, 10 are reported from states where lift rules are not implemented, which equates to approximately 23%. There were 12 deaths out of 40 deaths. This is nearly 30%.

The industry is constantly working to enhance the safety of users and the reliability of equipment. The latest IS 17900, Parts 1 and 2 (with many changes), is in the pipeline and may be available for the benefit of users and the industry at any time.

I am hopeful this analysis will help government policymakers and the elevator industry take required corrective measures to make the system more effective and reliable to reduce overall losses due to elevator accidents, ultimately heading toward “zero death in elevator accidents.”

Get more of Elevator World. Sign up for our free e-newsletter.